Method for adjusting height position of polishing head and method for polishing workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0057]A workpiece was polished in accordance with a method for adjusting a height position of a polishing head and a method for polishing a workpiece of the present invention, and then the flatness thereof was evaluated.

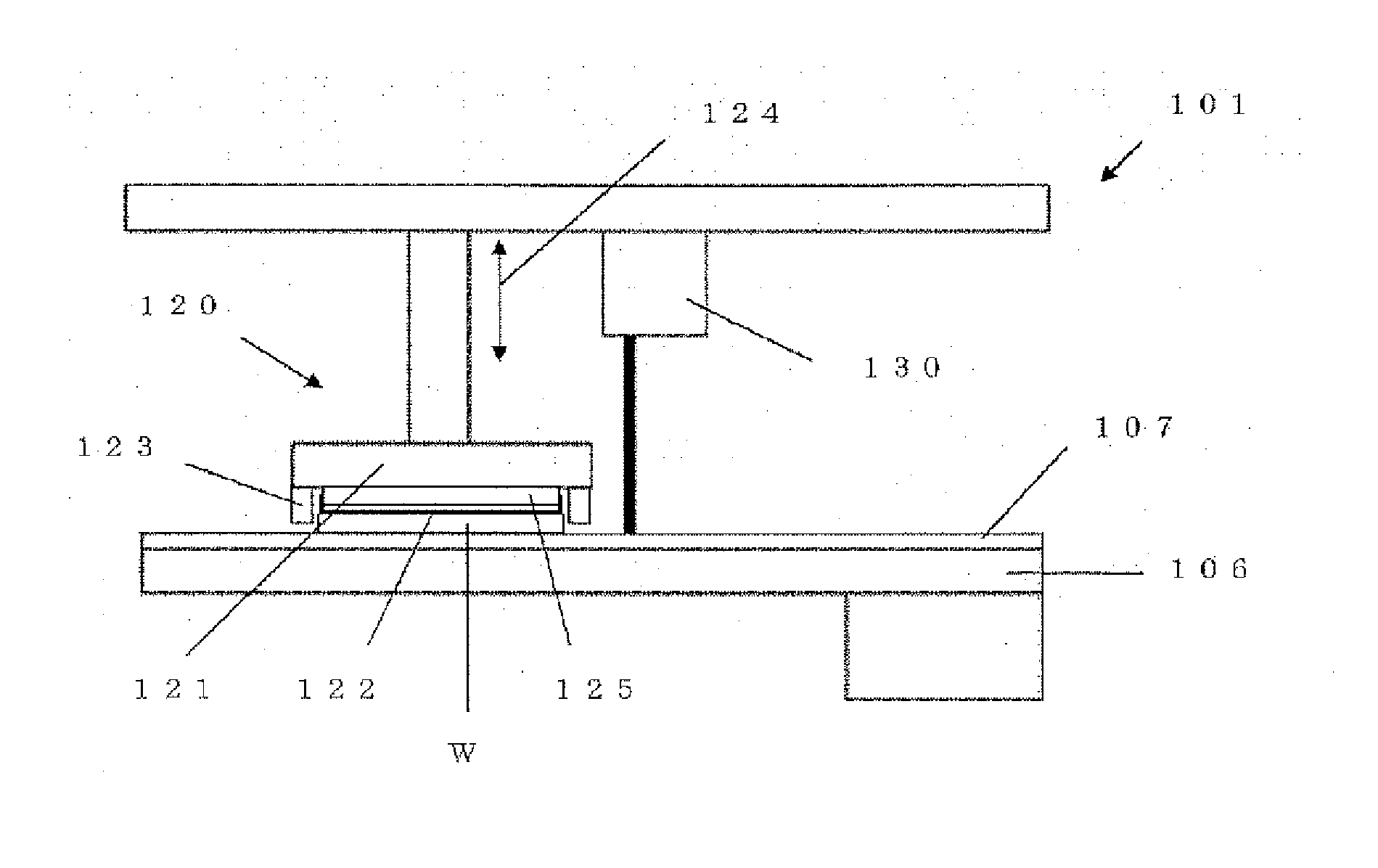

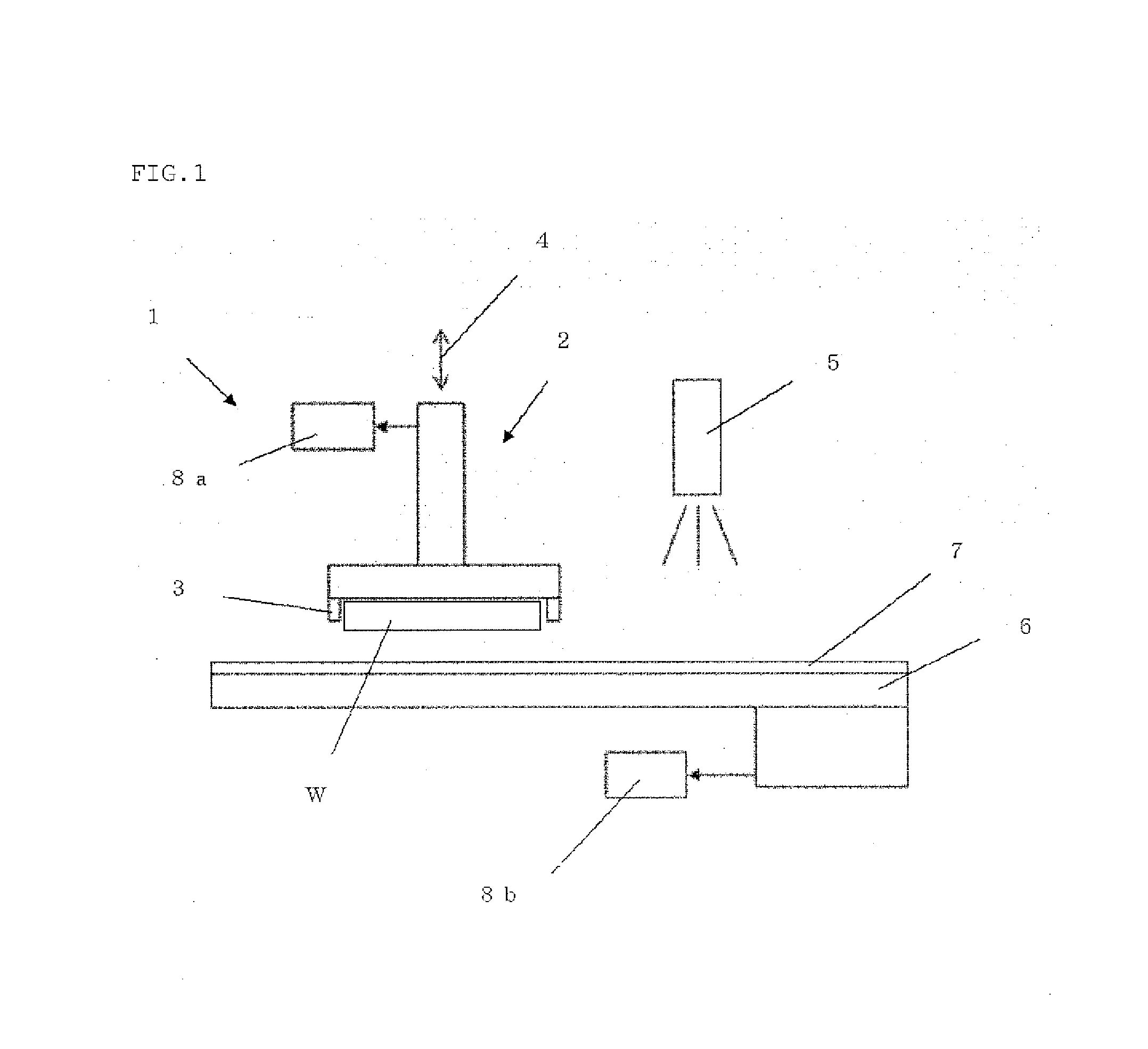

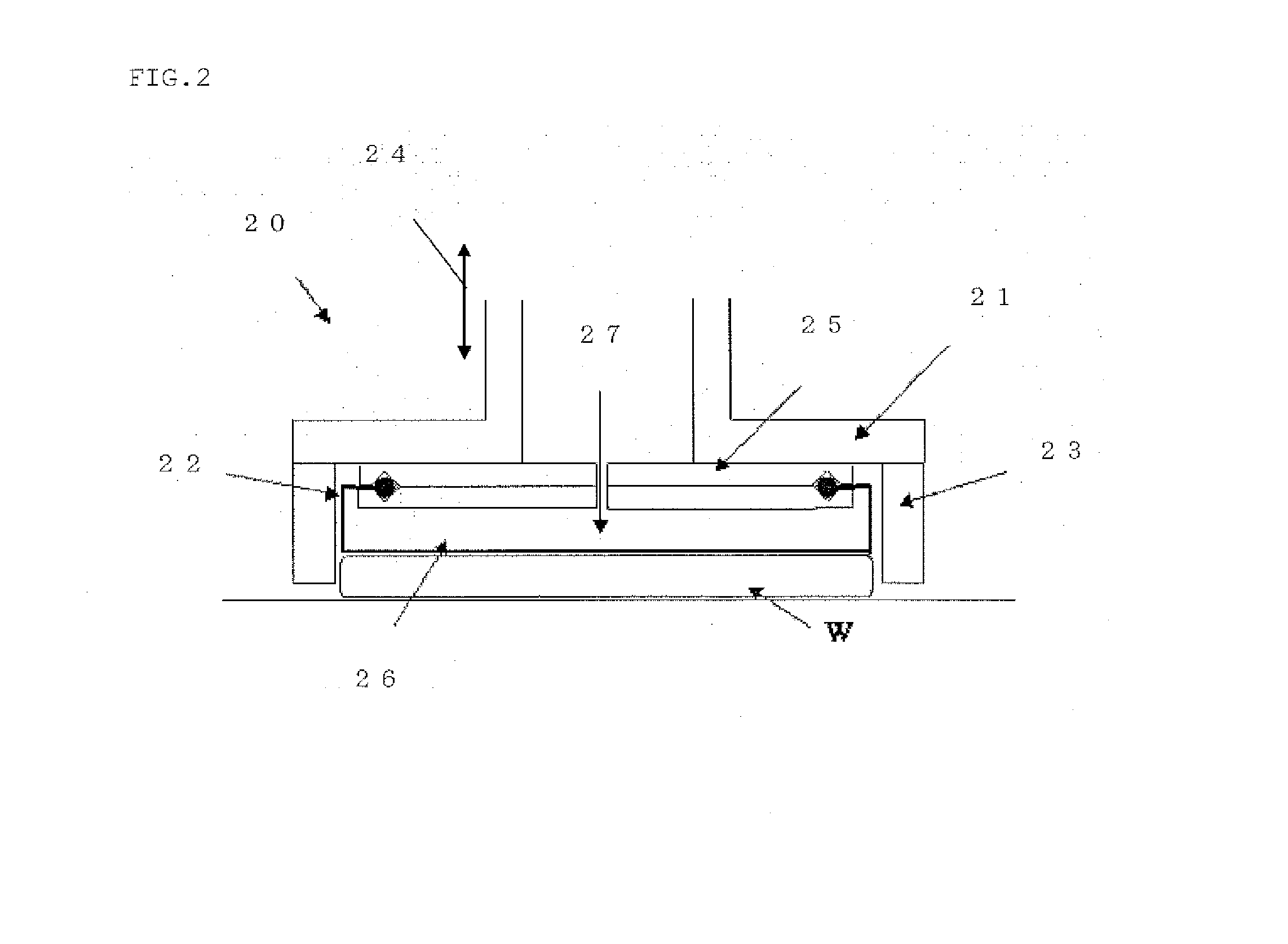

[0058]A polishing apparatus as illustrated in FIG. 1 having a polishing head by the rubber-chuck method as illustrated in FIG. 2 was used to polish 100 silicon wafers each having a diameter of 300 mm. The maximum value, the minimum value, and the average value of the flatness, and variation in the flatness of each polished wafer were then evaluated. The flatness was evaluated by global backside ideal range (GBIR) within a region except for the outer circumferential part of 2 mm using Wafersight made by KLA Co. Ltd.

[0059]First, the height position of the polishing head was adjusted such that the distance between the guide ring of the polishing head and the surface of the polishing pad became 190 mm, in accordance with the method for adjusting a height position of a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com