Automatic roller shade

a roller shade and automatic technology, applied in the field of roller shades, can solve the problems of inconvenience in use, small children's safety threats, and exposed pull cords and lifting cords of window shades, and achieve the effect of reducing the power consumption and manufacturing cost of automatic roller shades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The present invention will now be described with a preferred embodiment thereof and with reference to the accompanying drawings.

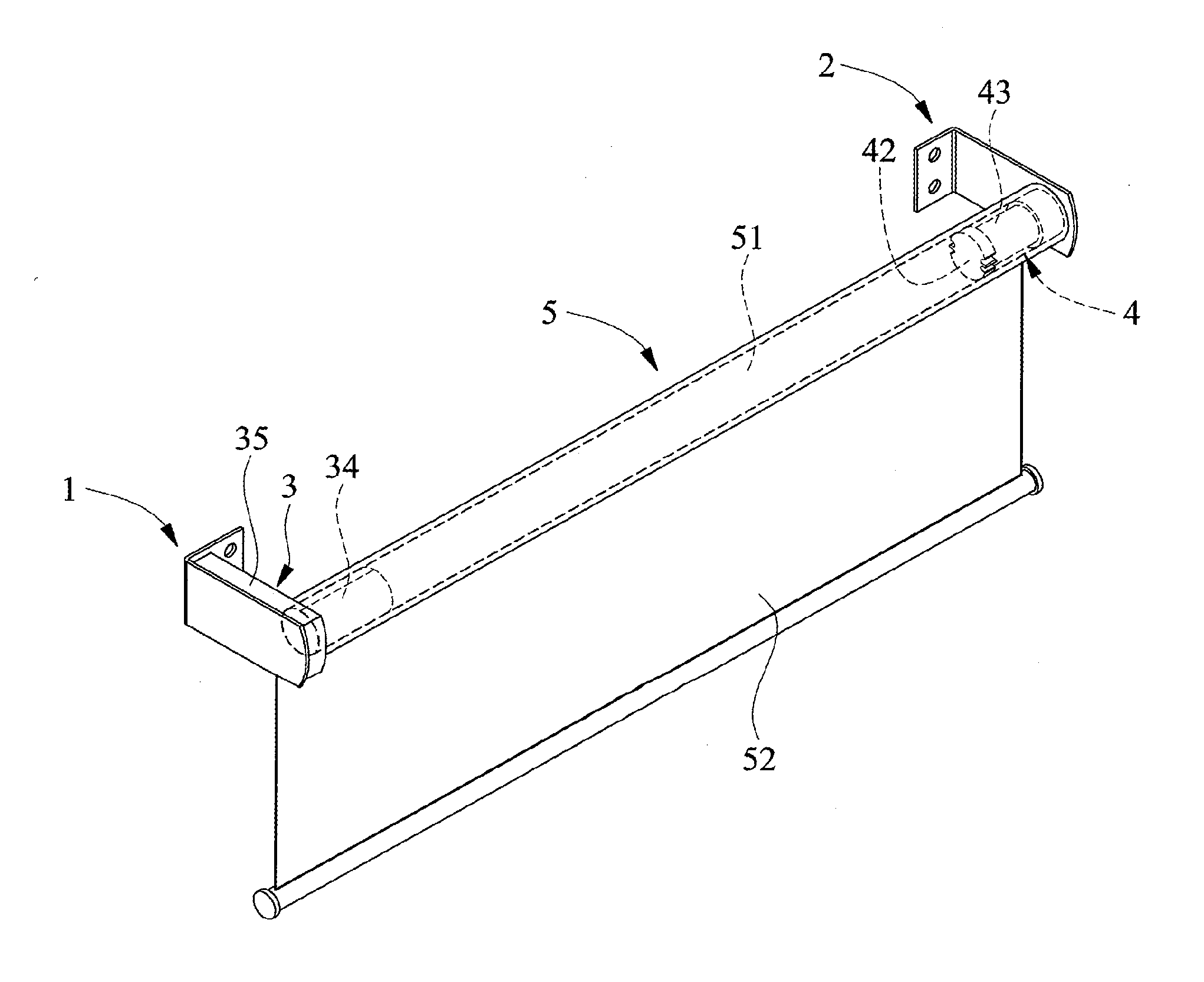

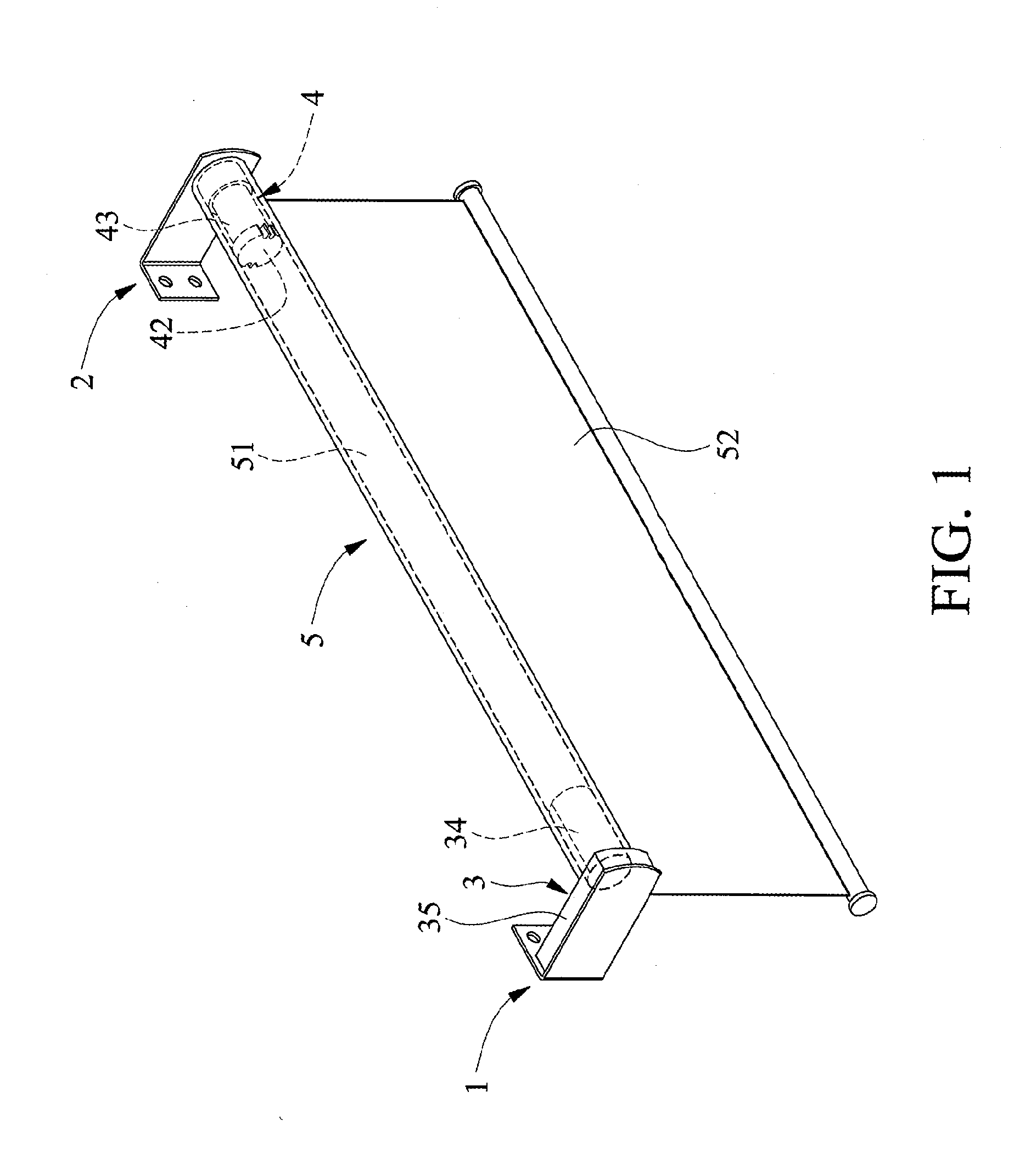

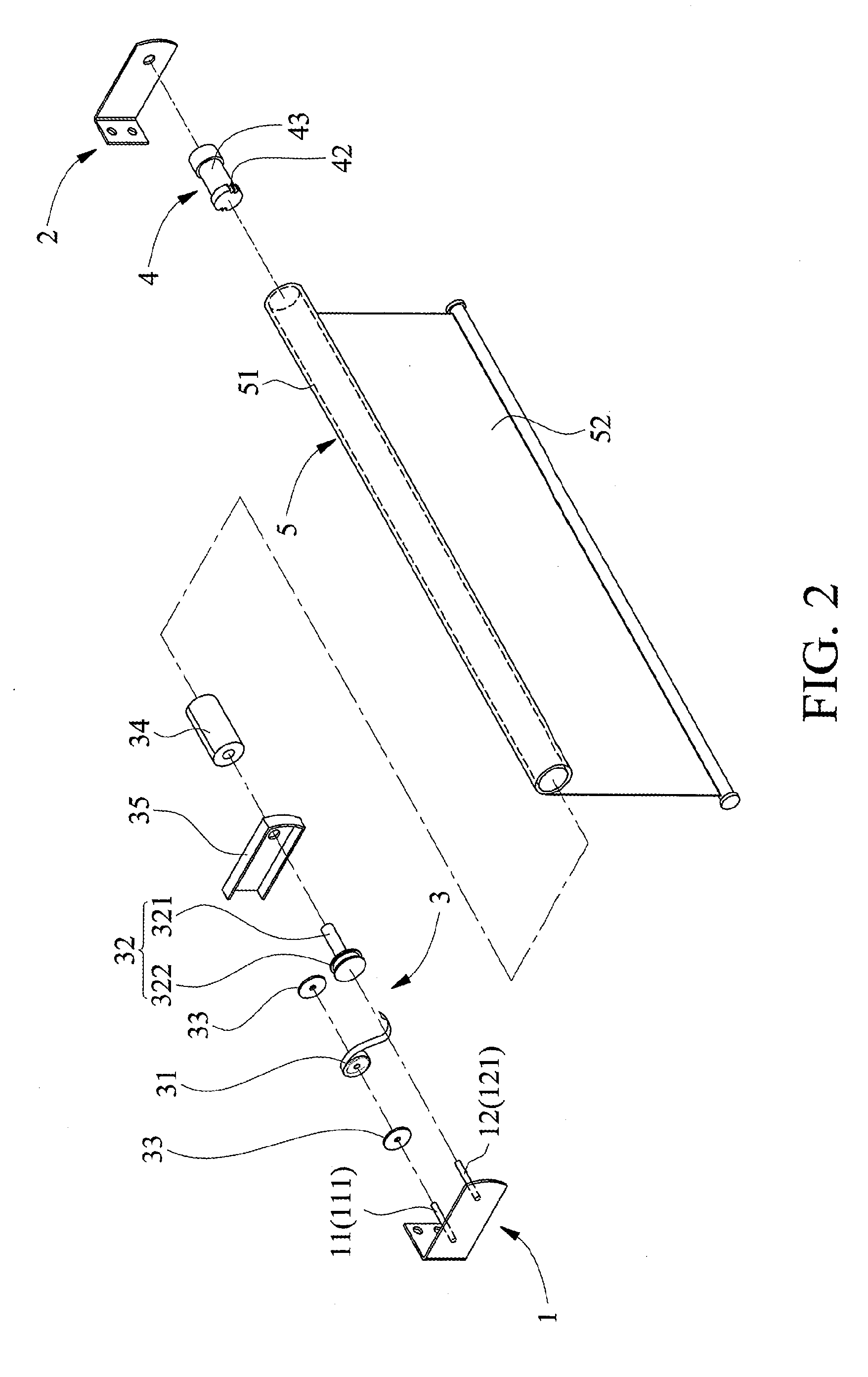

[0023]Please refer to FIGS. 1 and 2 that are assembled and exploded perspective views, respectively, of an automatic roller shade according to a preferred embodiment of the present invention. As shown, the automatic roller shade in the illustrated preferred embodiment includes a first mounting bracket 1, a second mounting bracket 2, a stop mechanism 3, a driving mechanism 4, and a shade body 5.

[0024]As can be seen in FIG. 2, the first mounting bracket 1 is a member to be fixedly mounted on a wall and is provided with a first supporting section 11 and a second supporting section 12 located adjacent to and spaced from the first supporting section 11. The first supporting section 11 has a first shaft 111 connected thereto, and the second supporting section 12 has a second shaft 121 connected thereto.

[0025]As also can be seen in FIG. 2, the second mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com