System And Method For Multiple Layer Coil Winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

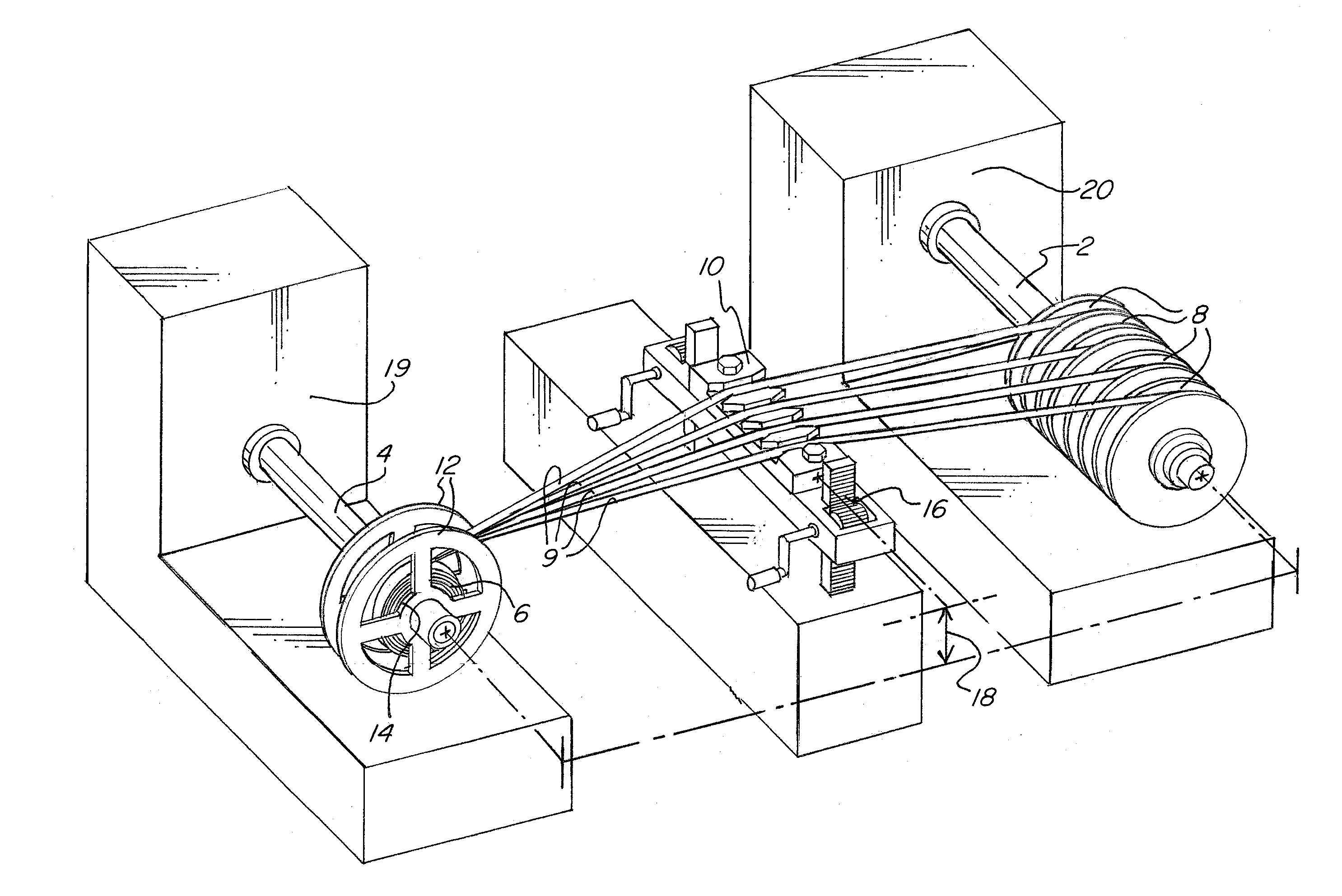

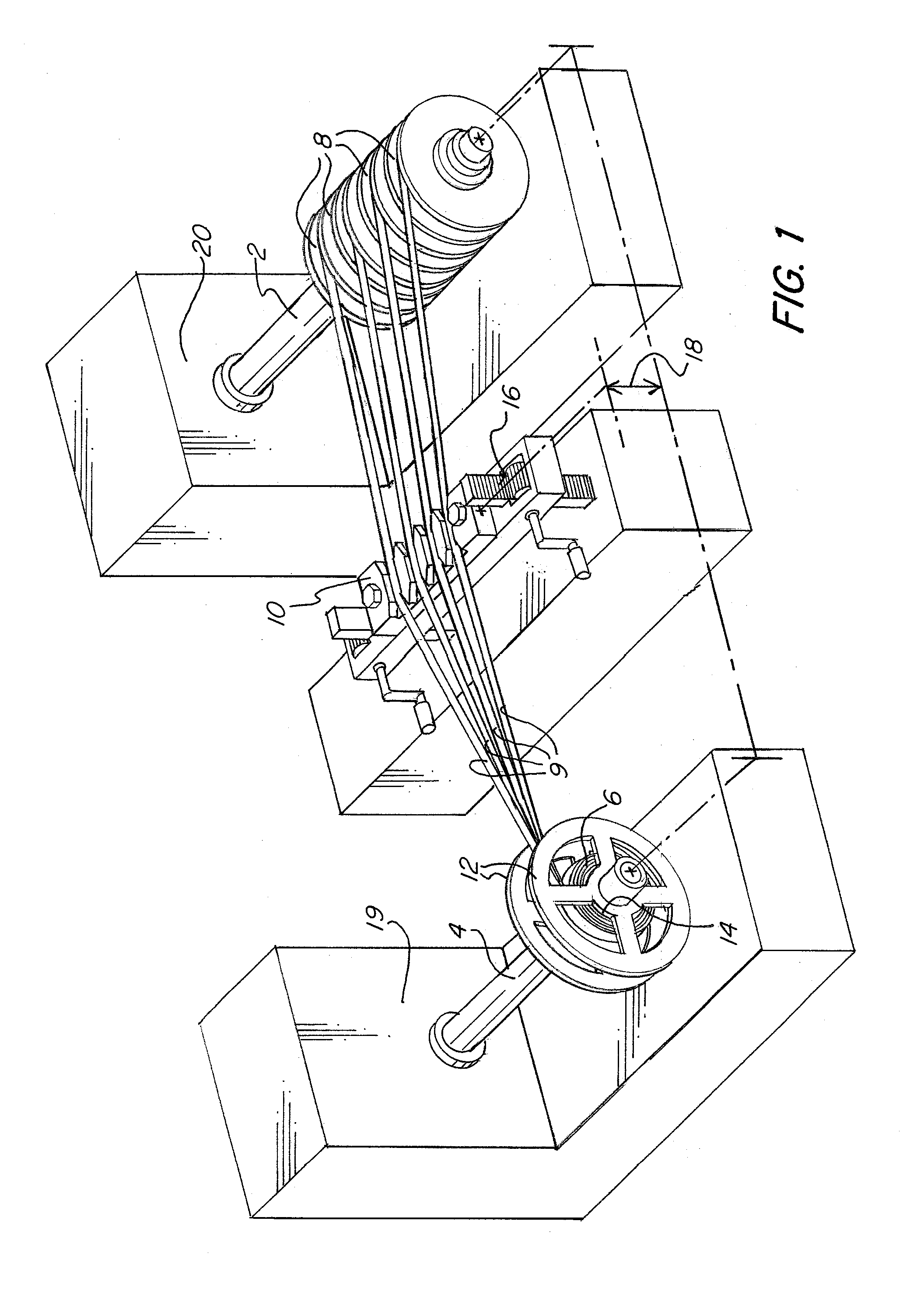

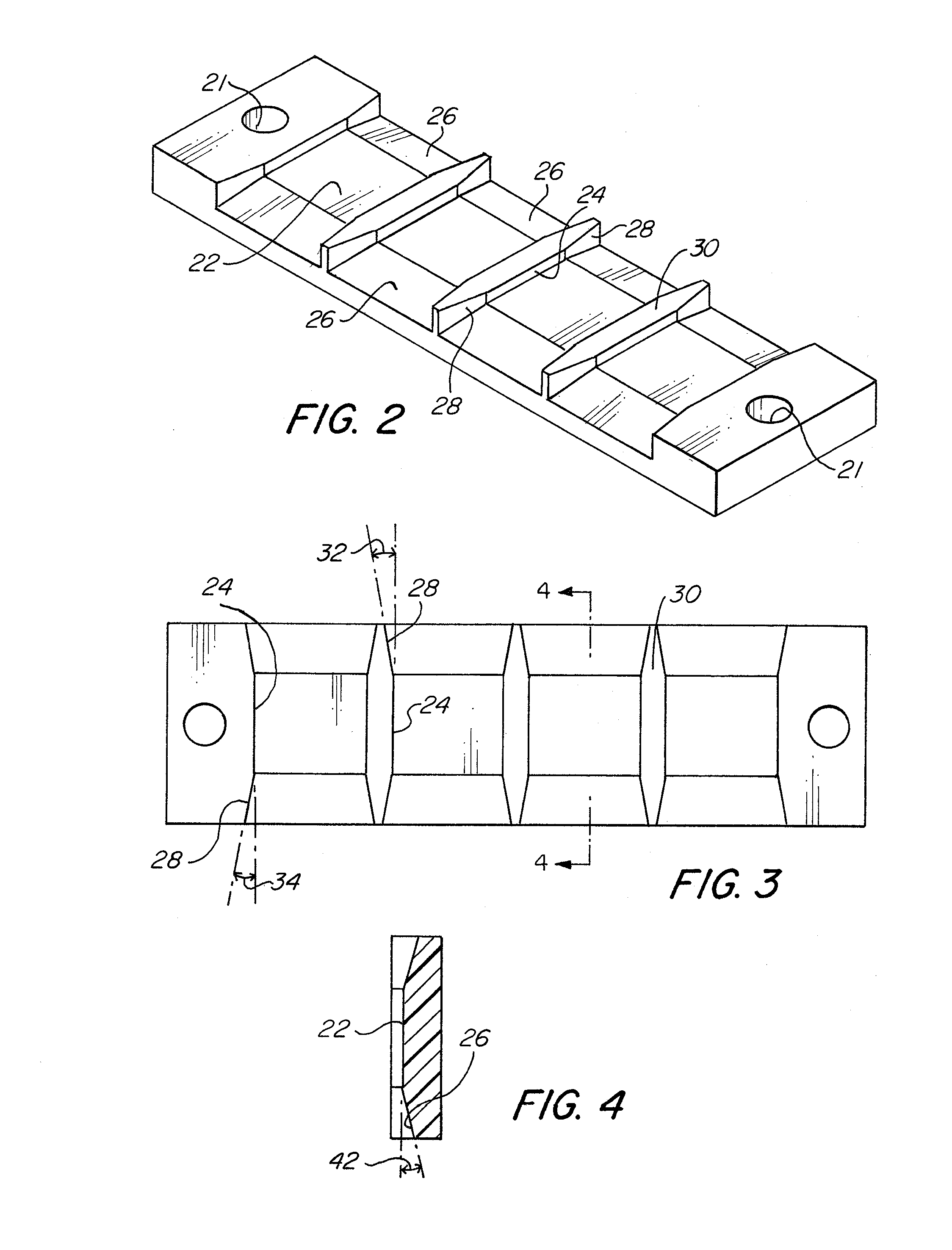

[0034]The invention relates to thin-coiled strips of material. The material may be metallic, plastic or other materials. In a preferred embodiment the invention relates to rolled metal coil. Rolled metal coil usually comes in wide widths. Often, it is desirable to have narrower coils of thinner material. The wide material is often fed through a rolling machine, which reduces the thickness. Then, the wide material is fed through a slitting machine, which cuts the wide roll into multiple narrow strips of material. The apparatus and method described herein winds the plurality of coils into a single coil with a plurality of layers. The existing slitting machine may be retrofitted to wind a multiple layer coil.

[0035]In some instances, it is desirable to have a material of multiple layers in a single coil. For example, four coils of aluminum could have dimensions of 0.005″ thickness and 1.00″ width. These four coils would be rewound onto a single drum, resulting in a final coil that would...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com