Jet Pump Stabilizer

a stabilizer and jet pump technology, applied in the field of clamps, can solve the problems of low static pressure of the driving flow, unstable pressure fluctuations, abnormal wear of the jet pump assembly, etc., and achieve the effect of restricting coolant leakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

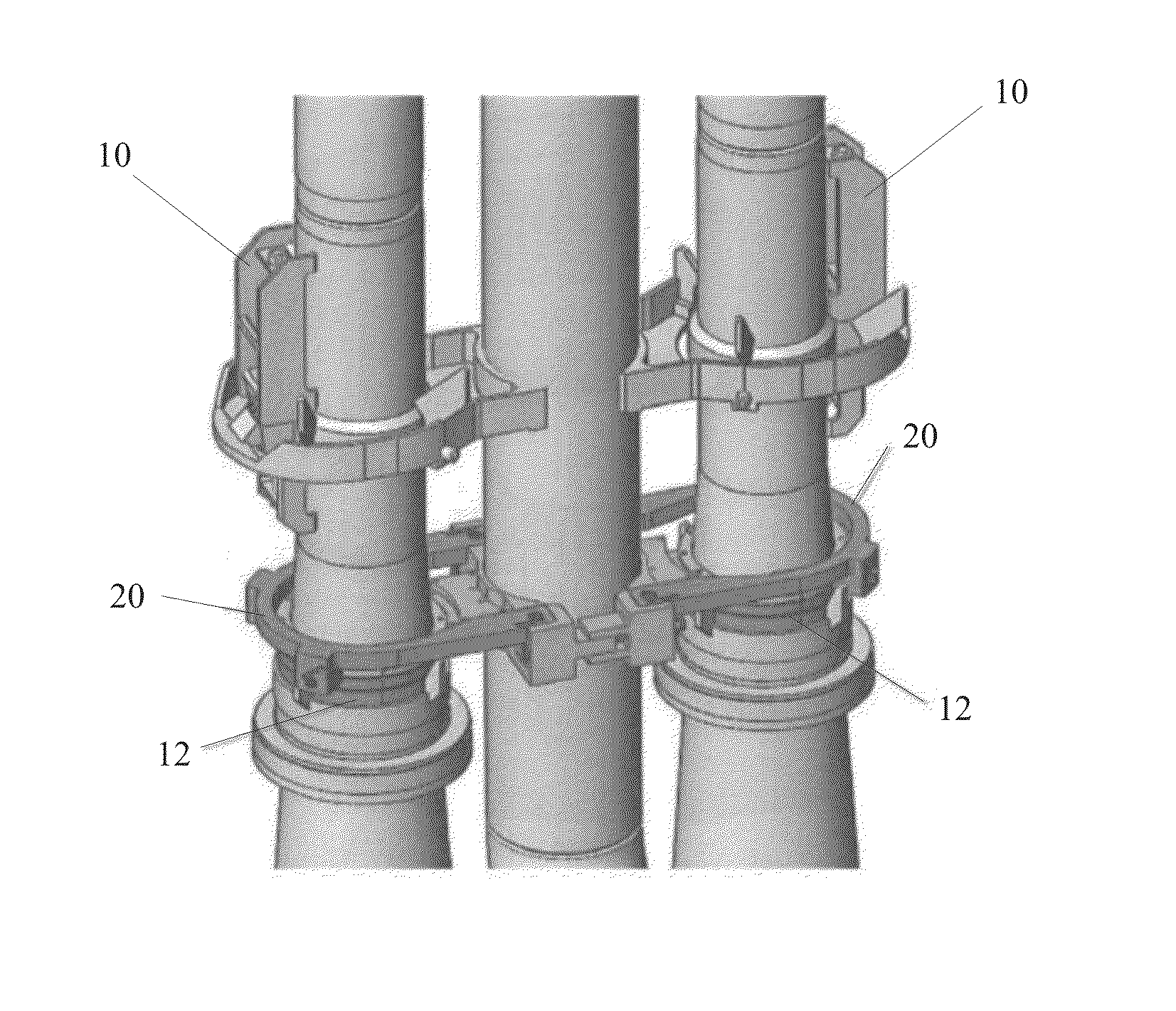

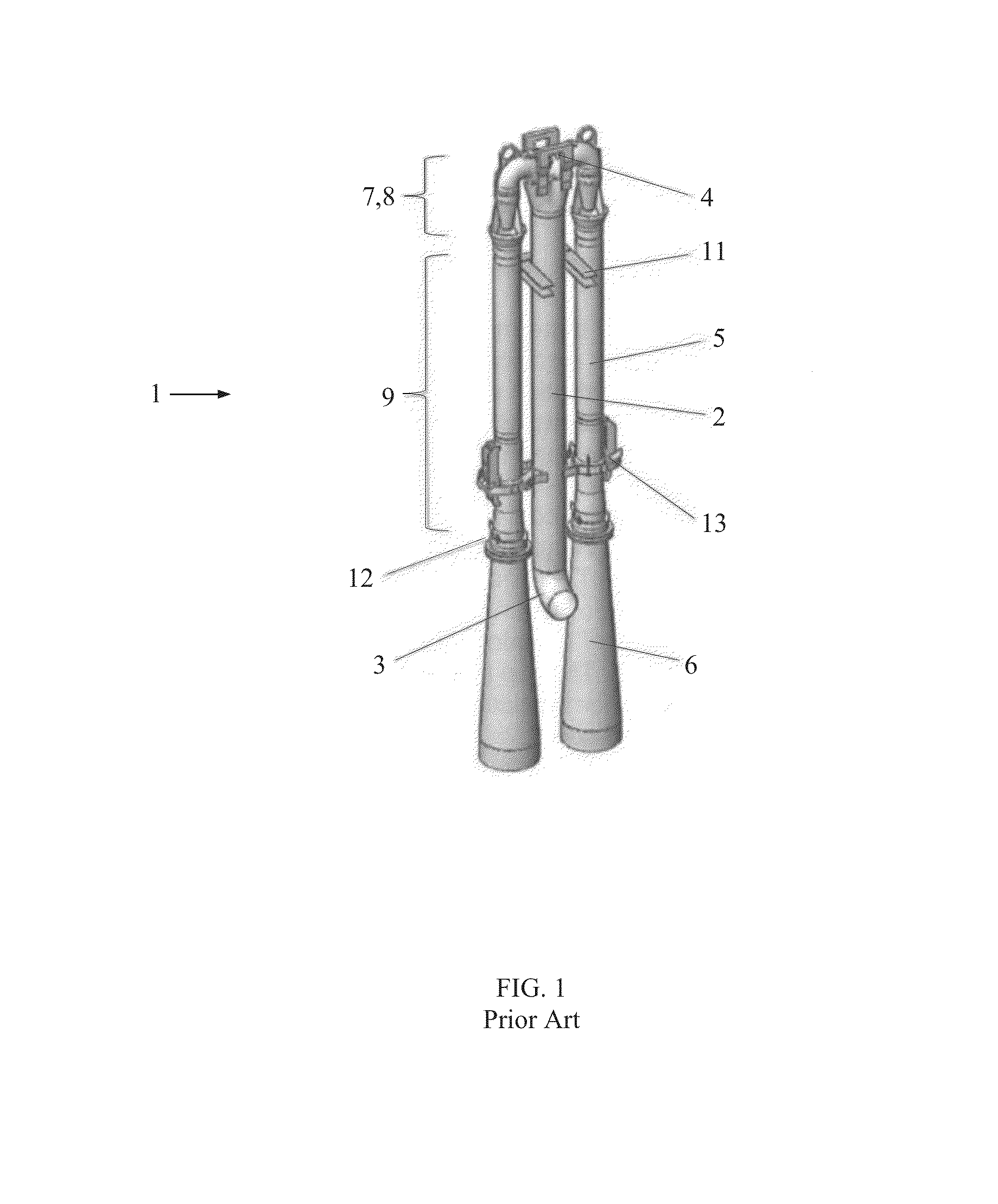

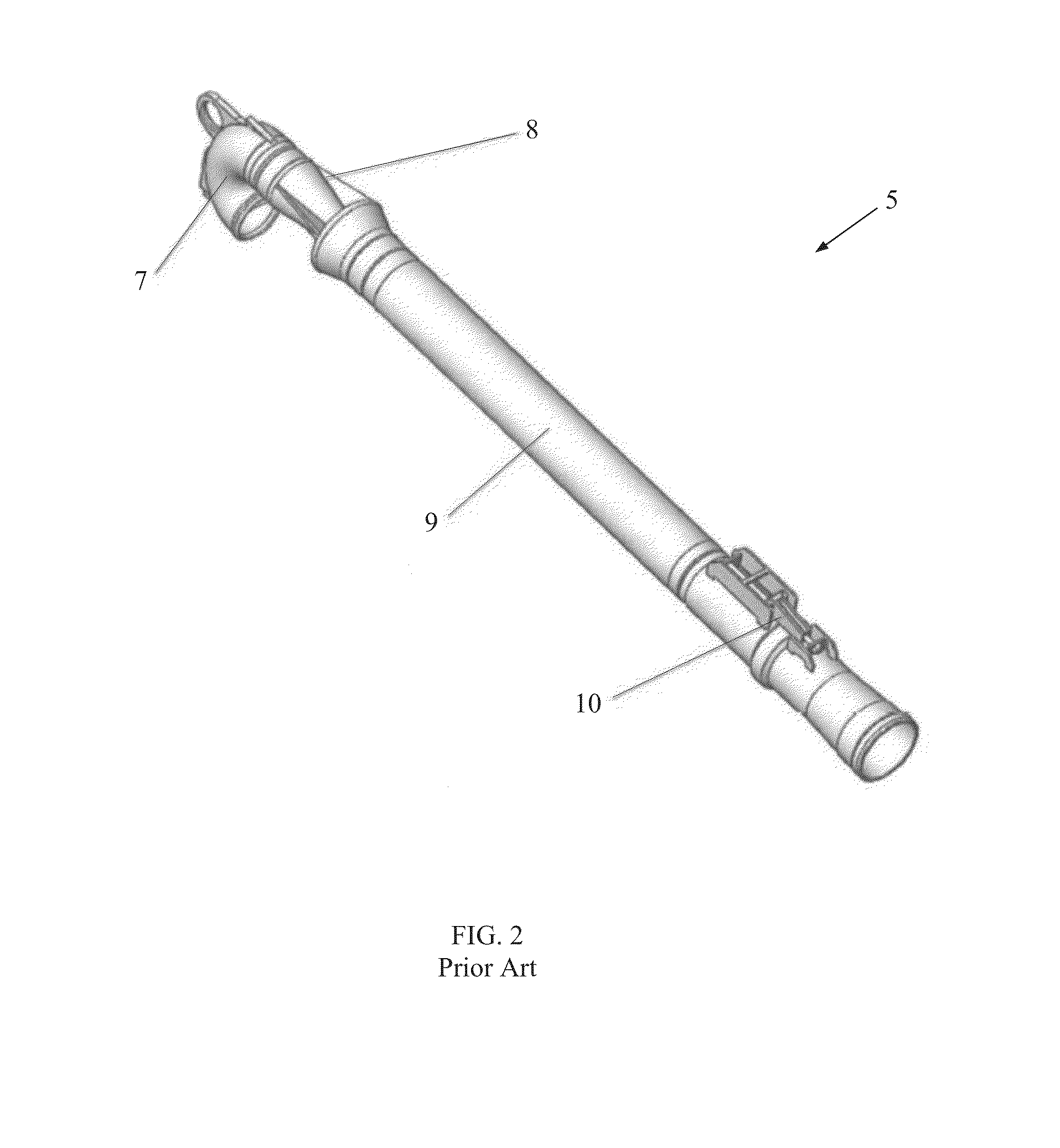

[0029]FIG. 3 shows a slip joint clamp 20 of the present invention, and FIG. 4 shows a slip joint clamp subassembly 30 thereof. The subassembly 30 includes inboard 31 and outboard 32 semicircular clamp segments, which are joined together by a pair of slip joint bolts 40 and bolt keepers 41 to form a circular clamp ring 33. A seal ring 36 includes inboard 34 and outboard 35 semicircular seal segments that are joined to the clamp ring 33 by several guide pins 37. Captive to the guide pins 37 are spring elements 38, which collectively provide a separation force between the stationary clamp ring 33 and the moveable seal ring 36. The seal ring 36 is designed to move axially upward in response to the thermal growth of the diffuser 6 relative to the inlet mixer 5. This upward axial movement is resisted by the compressive action of the spring elements 38.

[0030]The inboard 31 and outboard 32 semi-circular clamp segments are configured with an opposing tongue-and-groove design to ensure proper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com