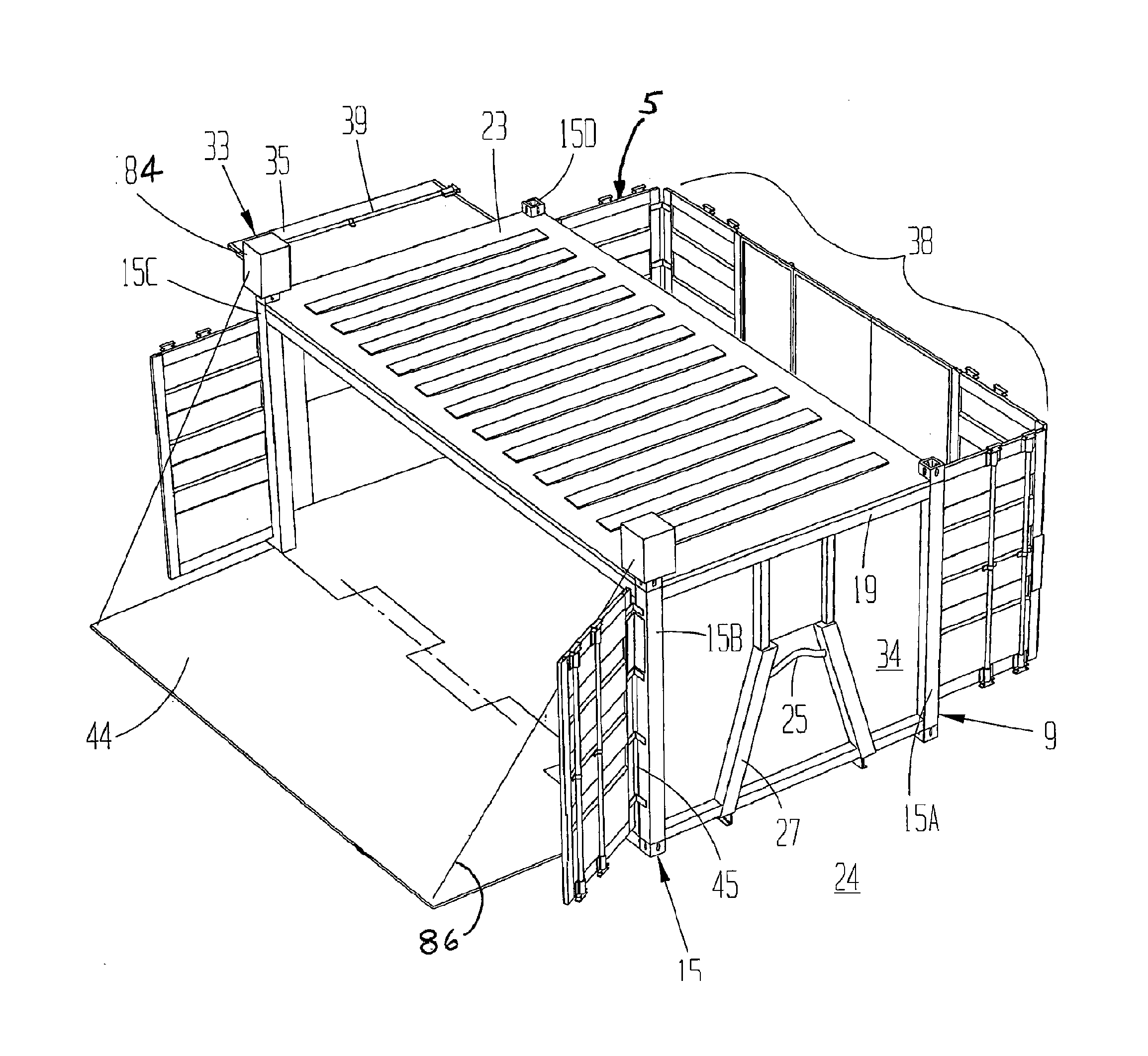

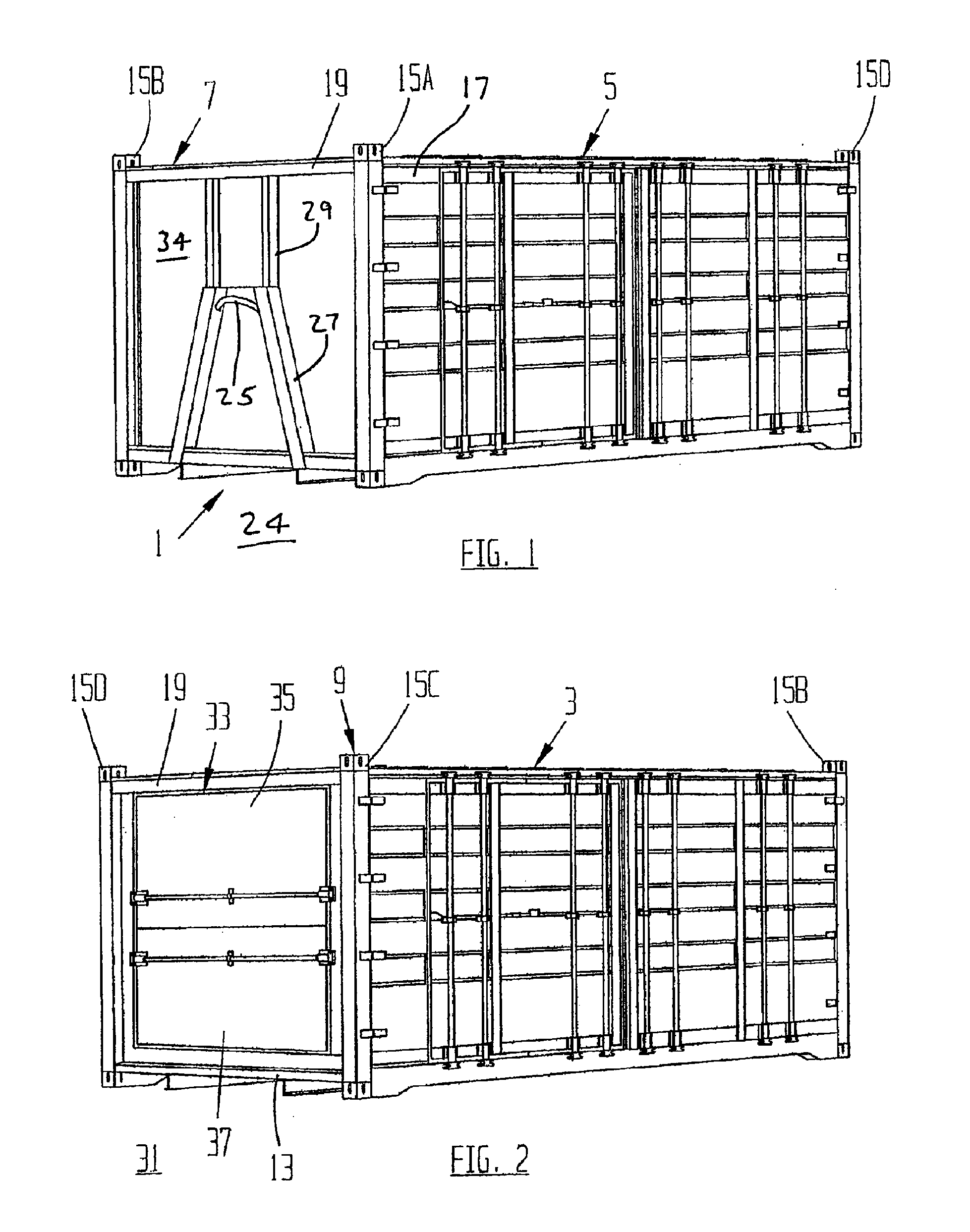

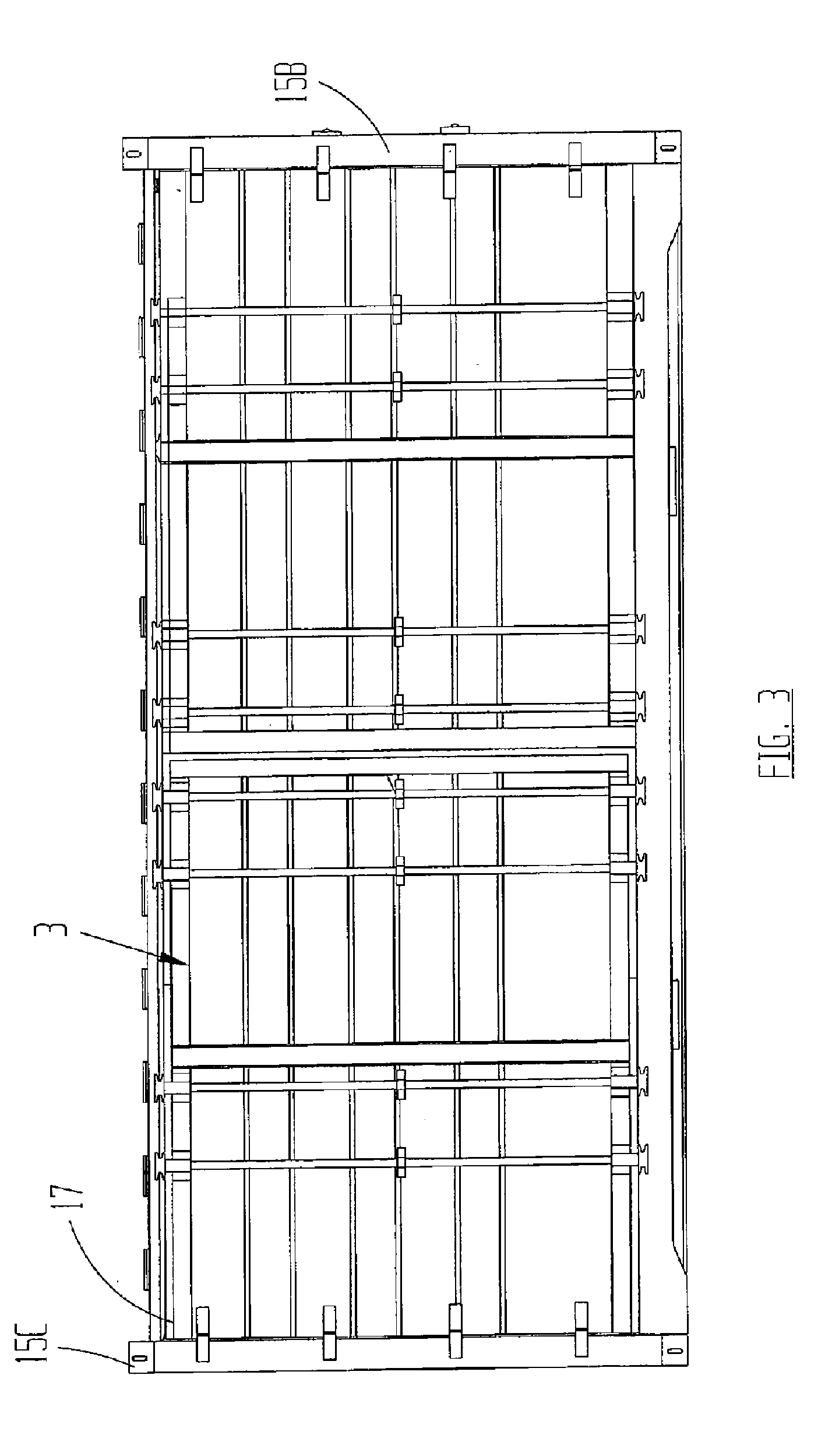

Convertible hard side shelter

a hard side shelter and convertible technology, applied in the field of portable shelters, can solve the problems of not only the size of the shelter, tire failure could jeopardize the success of the truck crew in hostile areas, and the failure of the tire of the military truck, so as to increase the interior space available for personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0067]As described thus far, the convertible hard side shelter 1 is constructed with the bar 25 and channels 30 that enable it to be handled by a conventional pallet loading system. The versatility of the invention is such that both center section ends 24 and 31 may be provided with end doors 33, thereby eliminating the bar 25. FIGS. 12 and 13 show a convertible hard side shelter 1′ according to the invention. The convertible hard side shelter 1′ is constructed with a double end door 95 at both ends 24 and 31. It will be understood, of course, that a double end door 95 may be at only one end 24 or 31, if desired. The double end door is comprised of top and bottom doors 35′ and 37′, respectively, that may be substantially identical to the doors 35 and 37 described previously in connection with FIGS. 1-11. The double end door further comprises a pair of outer doors 97. Each outer door 97 is hinged to an associated corner post 15 for pivoting about a respective vertical axis. Each oute...

third embodiment

[0078]Referring now to FIGS. 23-27, the shelter 1′″ is illustrated in which the shelter 1′″ includes cover panels 300 on each side of the shelter 1′″. The cover panels 300 disposed on either side of the shelter 1′″ each are formed of a number of separate cover sections 301 connected to the center section roof 23. Each section 301 include a rigid exterior wall 302 formed of a suitable material, such as a metal, and preferably a relatively lightweight, but durable metal such as aluminum, that forms the outside surface of the section 301. In the illustrated embodiment, the rigid exterior wall 302 is formed of hurricane corrugated shutter steel or aluminum, having a breaking strength of over 200 lbs per square foot. The exterior wall 302 formed of this material, or any other suitable material, can have strips of insulation 304 positioned within the spaces 306 defined by the material on the interior-facing surface of the wall 302 and extending along the length of the exterior wall 302. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com