Multi chamber filled construction panel

a construction panel and multi-chamber technology, applied in the direction of building components, doors/windows, heat-insulating coating, etc., can solve the problems of mechanical or aesthetic function of the panel, and the latter solution is not usable for translucent panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

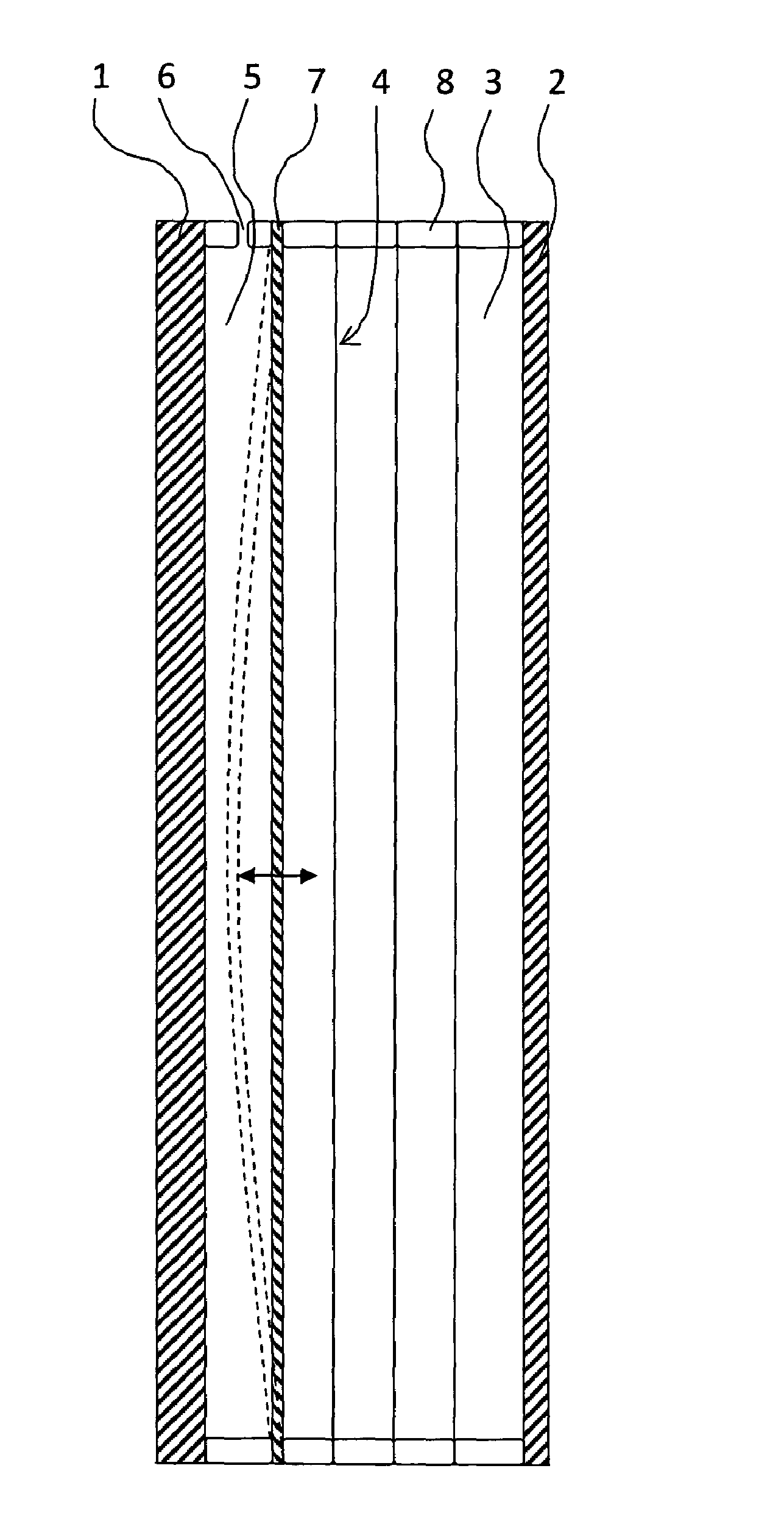

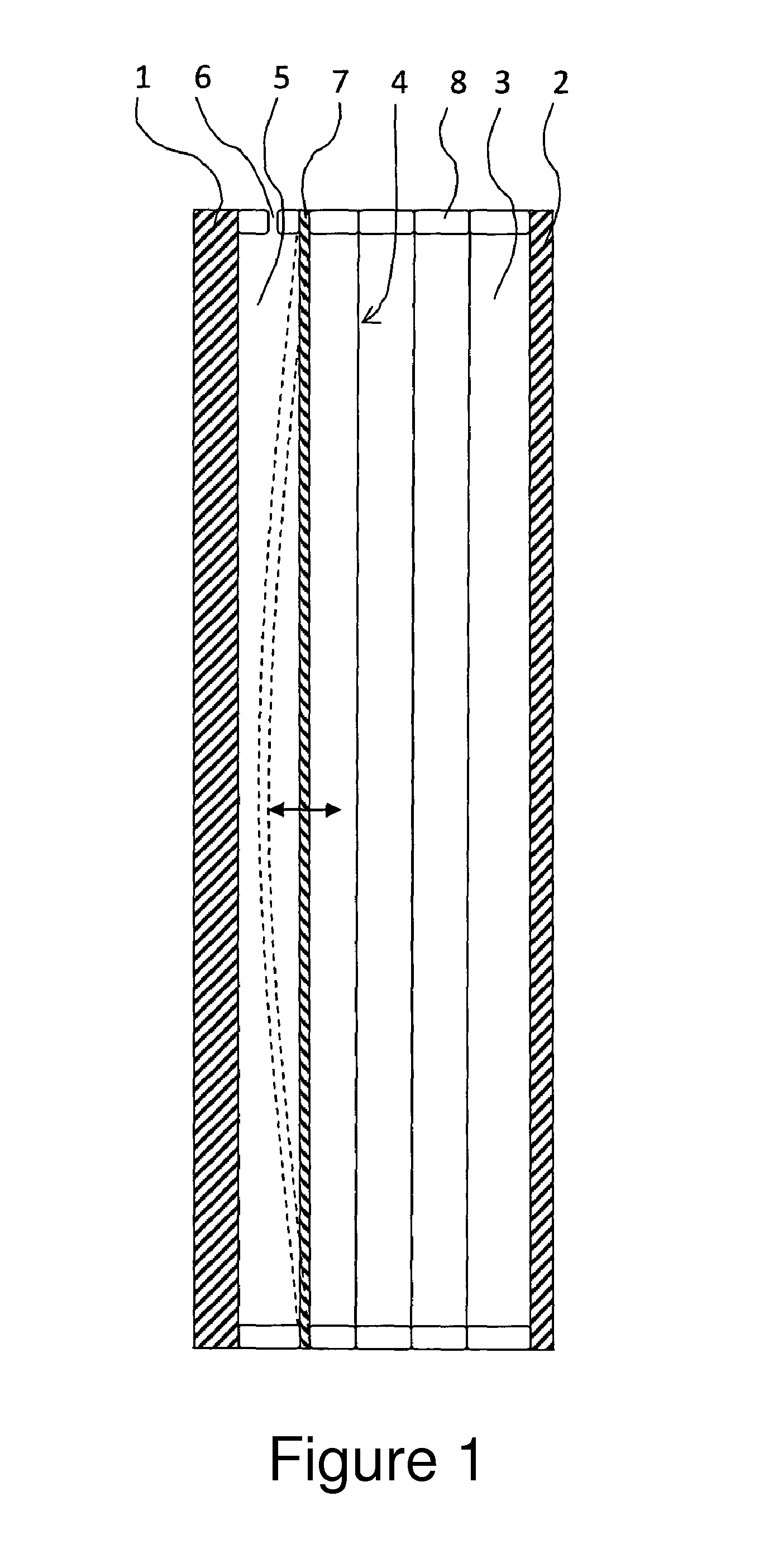

[0009]The multi-chamber gas-filled building panel solves the above referenced technical problem by construction of building panel comprising essentially of planar parallel inner (1) and outer (2) plates (FIG. 1), typically manufactured from tempered float glass.

[0010]FIG. 1 is a cutaway view of one embodiment of the present invention, showing inner plate (1), outer plate (2), insulation gas filled chamber (3), polymer foil (4), air-filled chamber (5), opening (6), divider (7), and spacer (8).

[0011]The plates preferably of glass (1) and (2) are usually approximately 6 to 8 mm thick monolithic or thicker, while the glass is either etched glass or composite etched or fully transparent glass. For purposes of this application the composite glass refers to laminated safety glass, fire proof and / or insulation glass (IGU) or some other solution known in state of the art achieving same or similar purpose. Between the plates preferably of glass (1) and (2) there is at least one gas tight cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com