Method for Preparing Positive Electrode Active Material for Lithium Secondary Battery, Positive Electrode Active Material for Lithium Secondary Battery, and Lithium Secondary Battery Including Same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

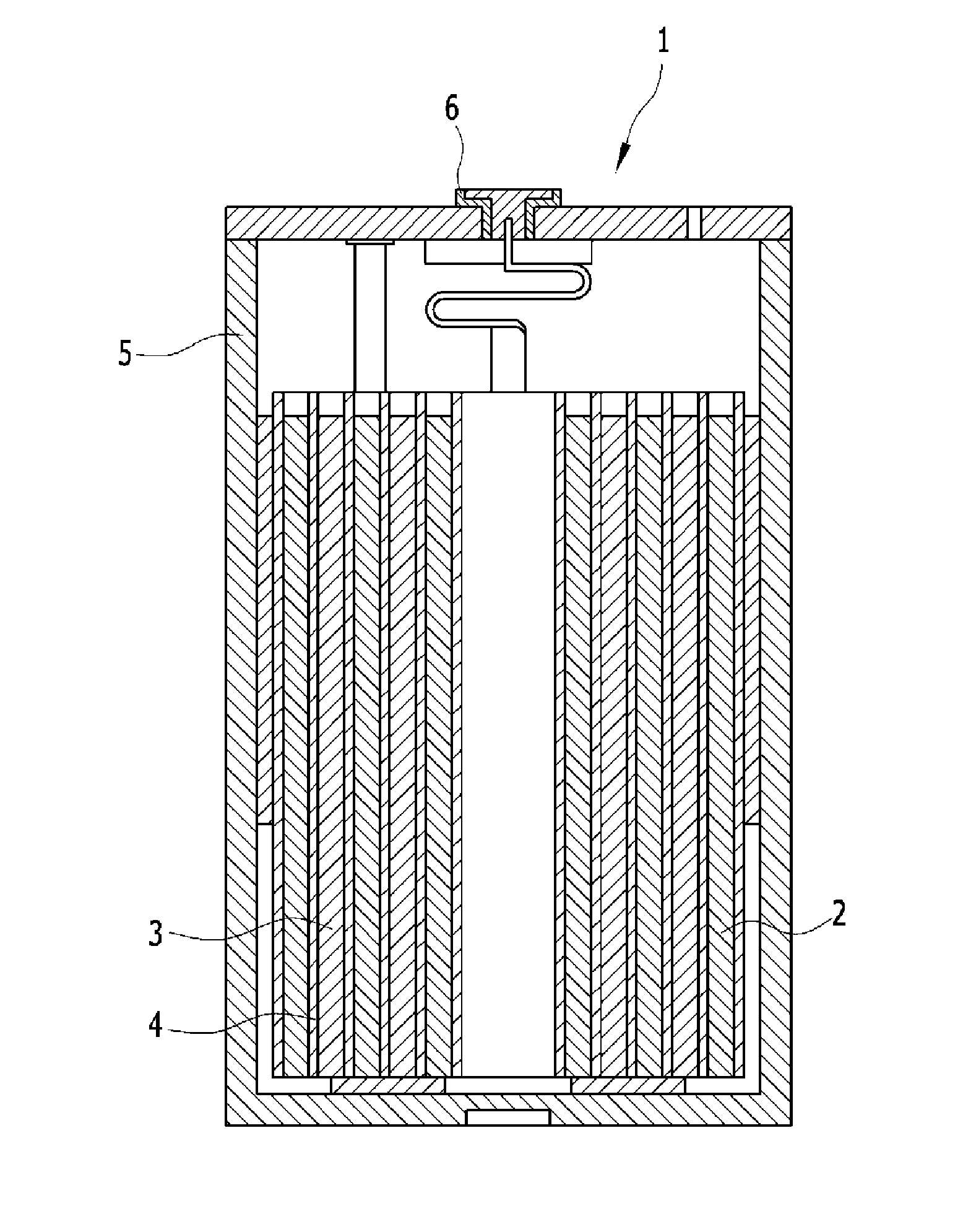

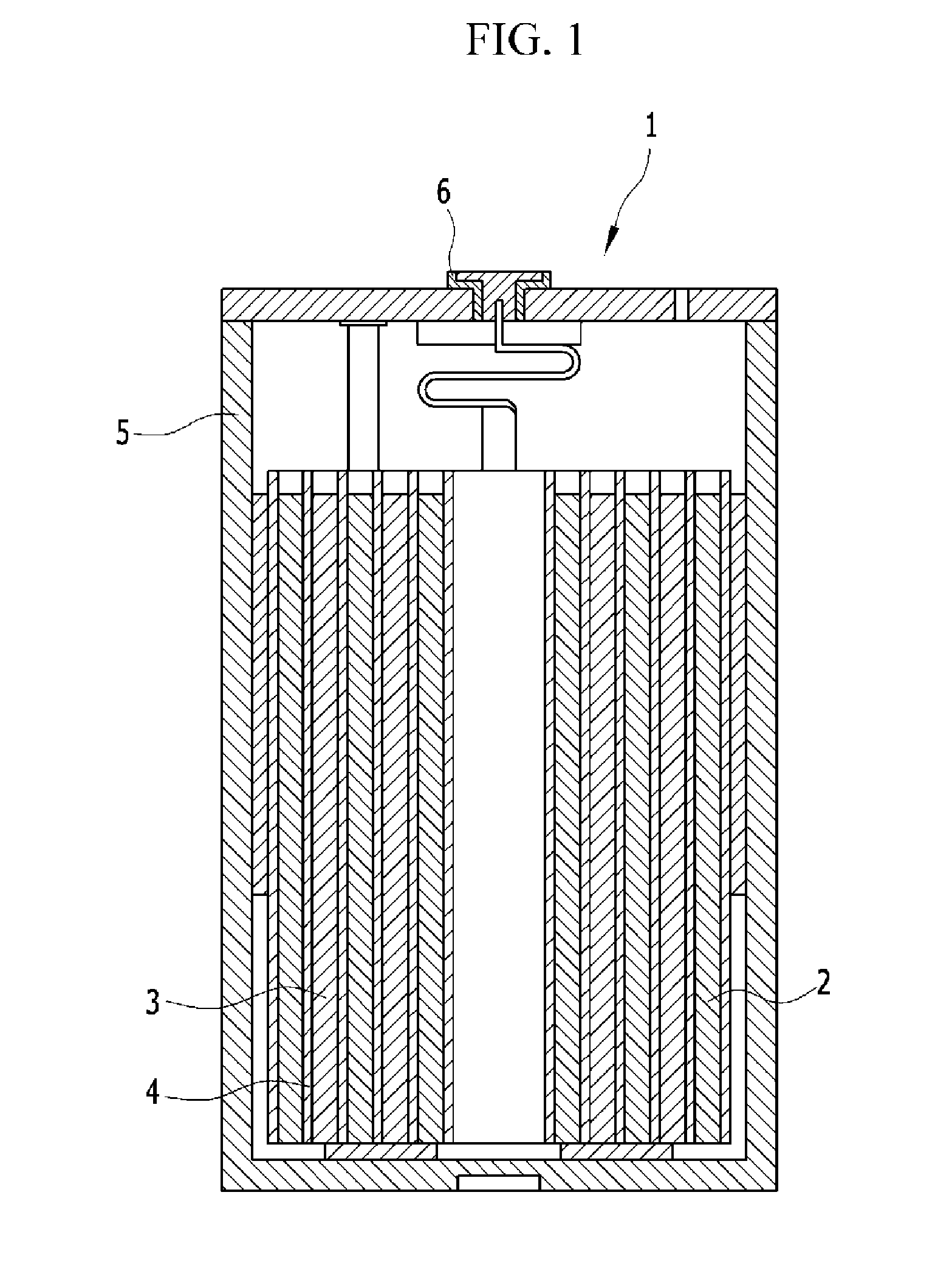

Image

Examples

synthetic example 1

Preparation of Lithium Composite Oxide

[0124]Li2CO3 (Product name: SQM) and Ni0.47Co0.20Mn0.33(OH)2(D50: 5 μm) were mixed at a weight ratio of 1:1.03 (Metal:Li) using a mixer. The obtained mixture was fired for a total of 20 hours while the time rise reaction time was 6 hours in air and the time for a maintenance period was 7 hours at 950° C., thereby preparing a fired material.

[0125]The obtained fired material was slowly cooled and then reduced to powder, thereby obtaining a lithium composite oxide powder for mixing and firing according to an embodiment of the present invention.

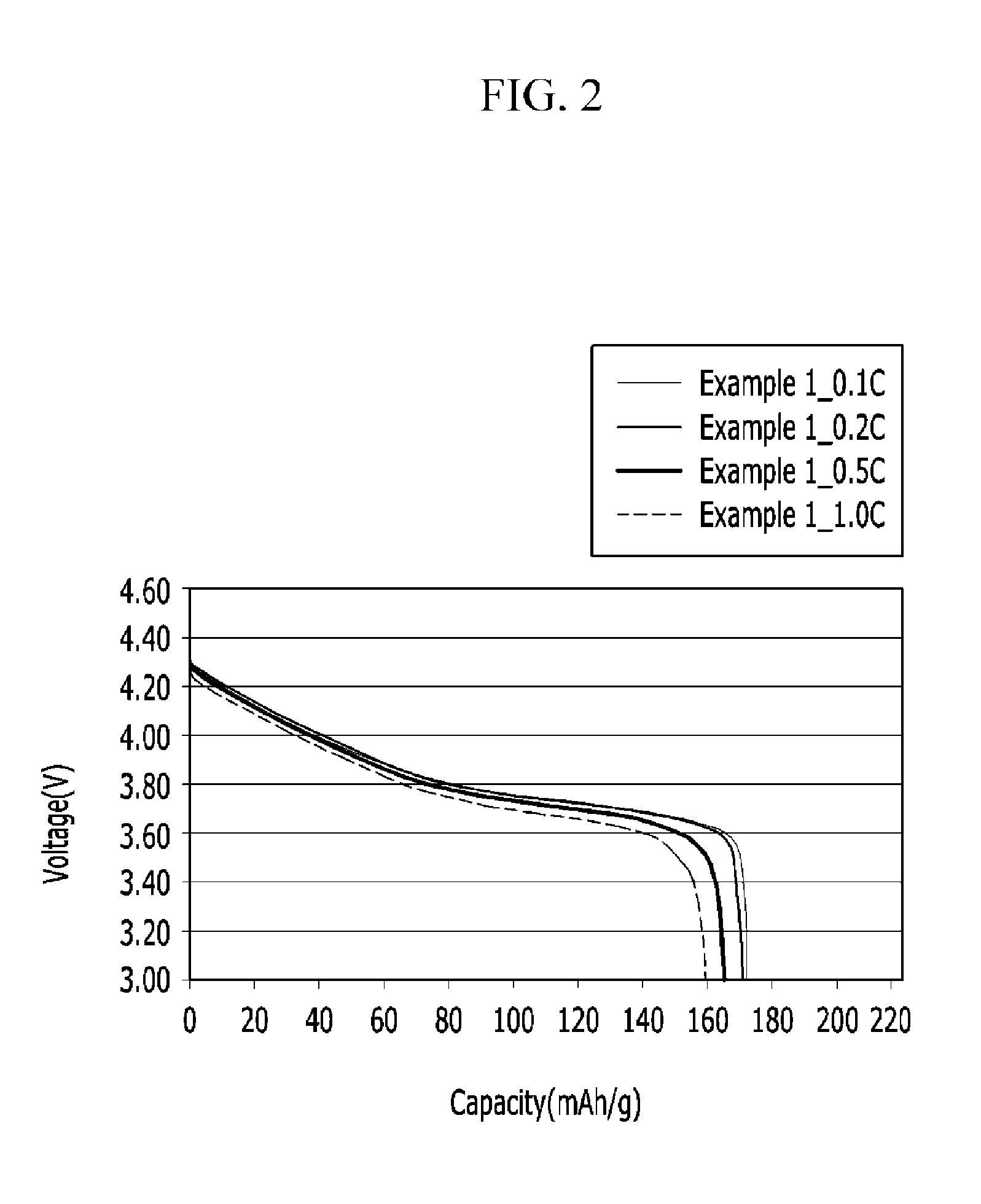

example 1

Preparation of Positive Electrode Active Material Through Mixing and Firing

[0126]Li2CO3 (Product name: SQM) and Ni0.55Co0.20Mn0.25(OH)2 were mixed at a weight ratio of 1:1.03 (Metal:Li) using a mixer.

[0127]After the final firing, LiNi0.47Co0.20Mn0.33O2 was further added thereto such that the weight ratio of LiNi0.55Co0.20Mn0.25O2 and Li0.47Co0.20Mn0.33O2 of Synthetic Example 1 was 90:10.

[0128]The obtained mixture was fired for a total of 20 hours while the time rise reaction time was 6 hours in air and the time for a maintenance period was 7 hours at 940° C., thereby preparing a fired material.

[0129]The obtained fired material was slowly cooled and then reduced to powder, thereby preparing a positive electrode active material.

example 2

Preparation of Positive Electrode Active Material Through Mixing and Firing

[0130]A positive electrode active material was prepared by the same method as in Example 1, except that LiNi0.47CO0.20Mn0.33O2 was added such that the weight ratio of LiNi0.55CO0.20Mn0.25O2 and LiNi0.47CO0.20Mn0.33O2 was 80:20, followed by mixing and firing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Solubility (ppm) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com