Flexible tank for fluid containerisation

a flexible tank and container technology, applied in the direction of containers, packaging, linings/internal coatings, etc., can solve the problems of excessive pressure on exacerbate the risk of permanent distortion or deformation, structural failure, etc., and achieve the effect of bending the end and side walls of the container permanently outwards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]There follows a description of some particular embodiments of the invention, by way of example only with reference to the accompanying diagrammatic and schematic drawings, with some simplification and informality in style for ease of illustration, and in which:

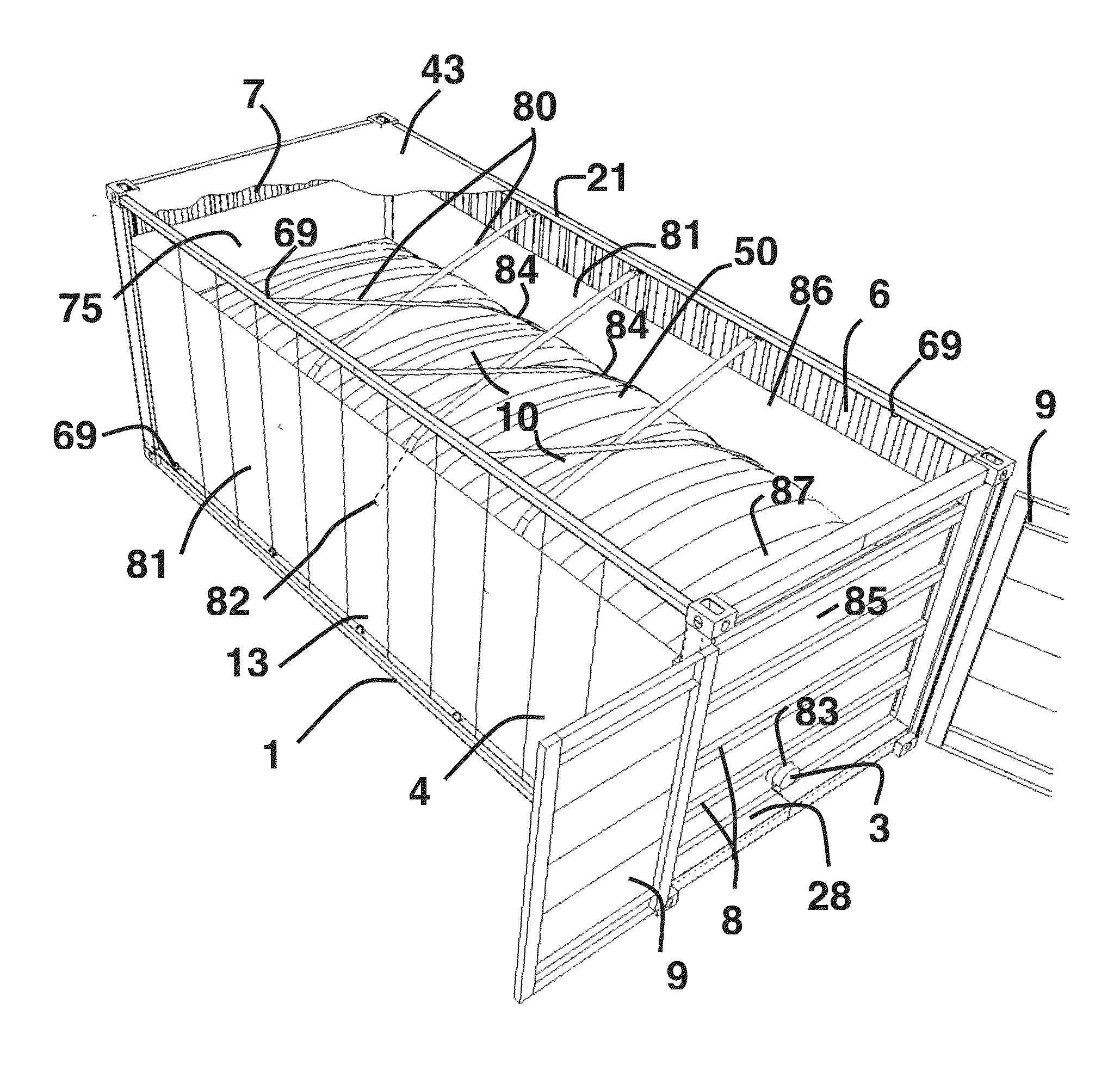

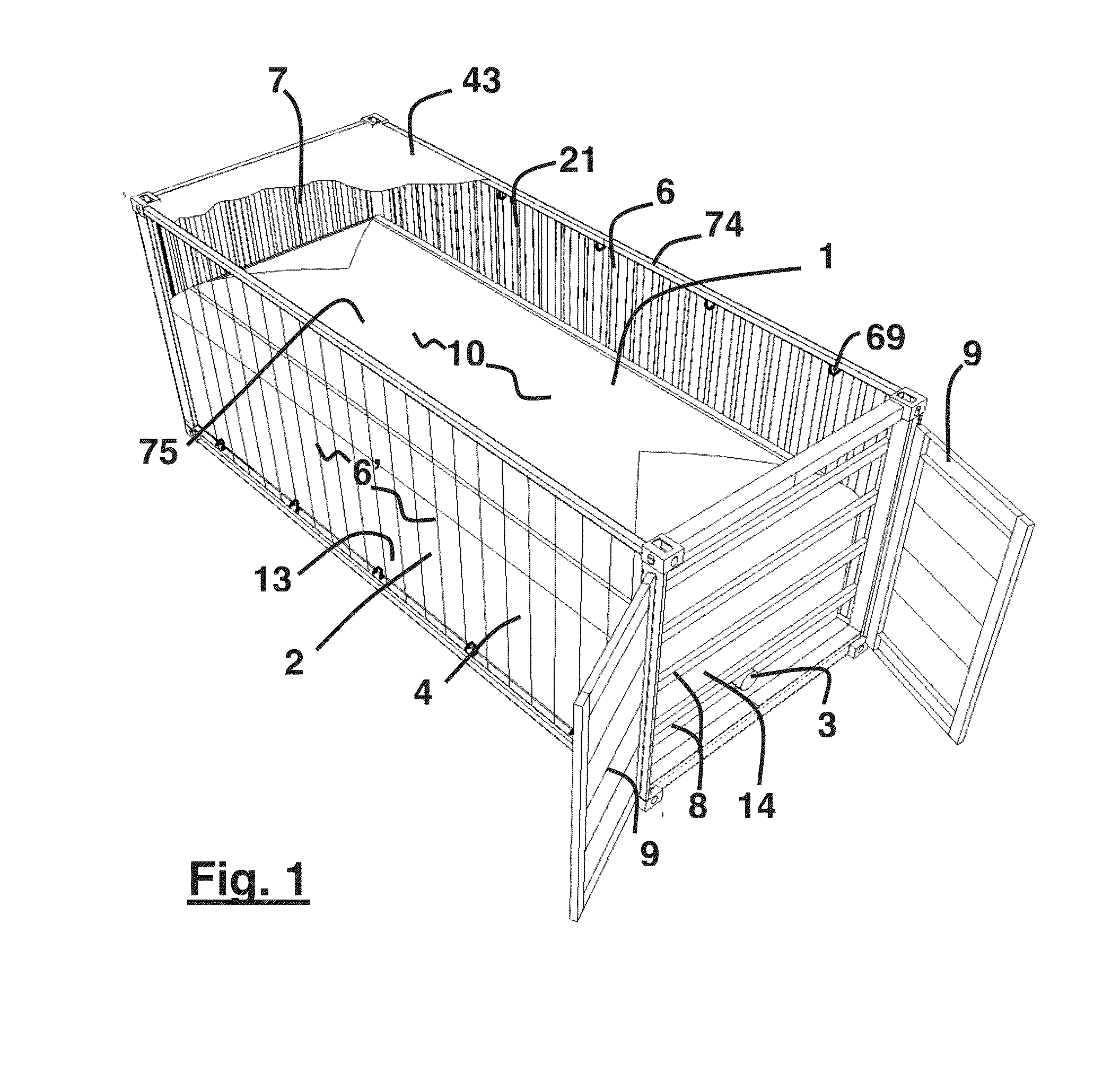

[0036]FIG. 1 shows three-quarter 3D perspective ghosted view of an otherwise standard format container with internal flexible wall tank disposed as an internal liner for liquid storage;

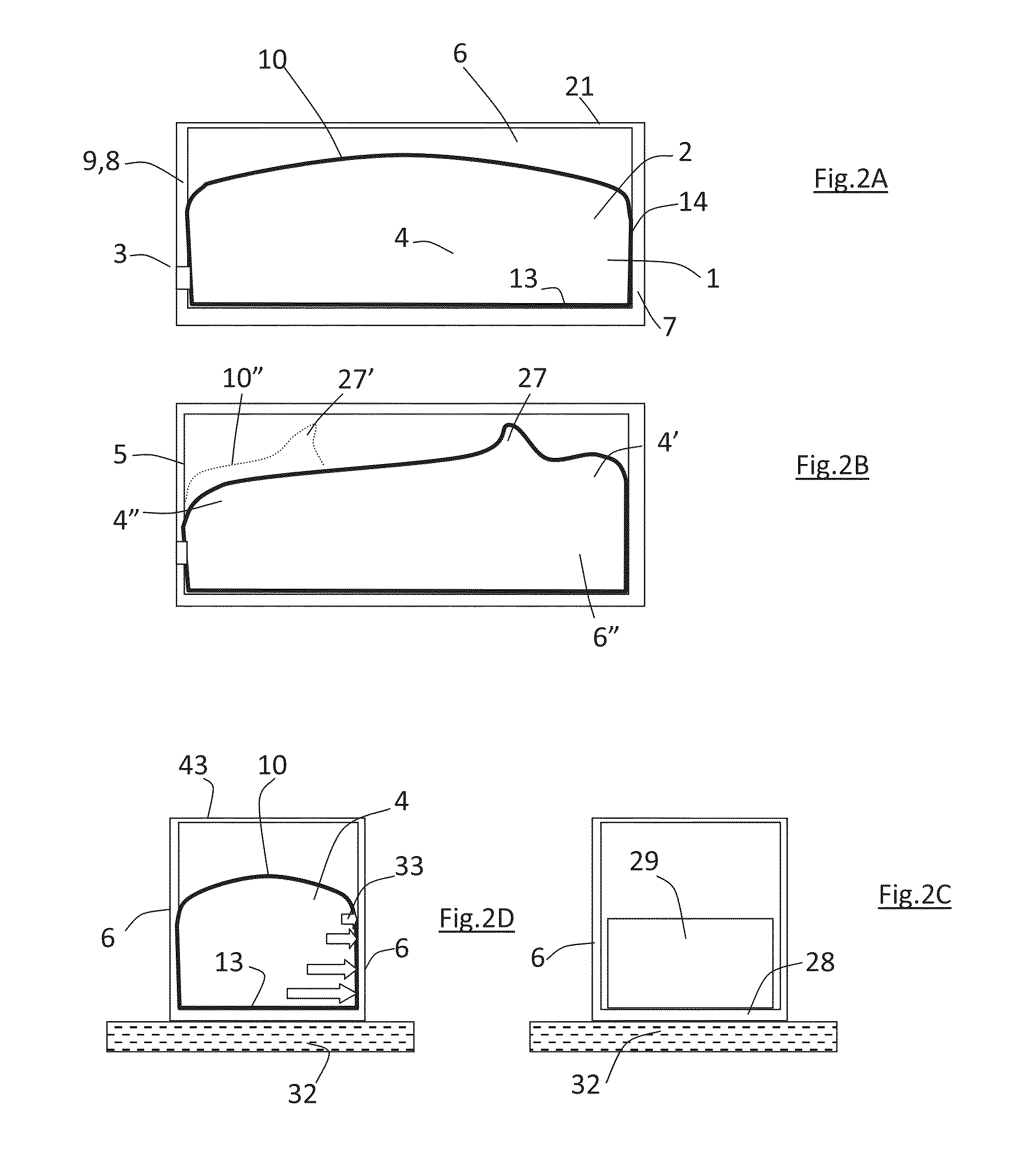

[0037]FIGS. 2A through 2D show variously longitudinal and cross-sections of the tank of FIG. 1 and the behaviour of liquid content in the flexible wall tank bag under shunt and cornering loads;

[0038]More specifically . . . .

[0039]FIG. 2A shows a longitudinal section of a static unloaded (aside from its own passive weight and that of its liquid contents) bag of shallow domed form, sat snug within container longitudinal confines but with a gap overhead between respective bag and container roofs;

[0040]FIG. 2B shows the bag of FIG. 2A under sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com