Pad conditioning process control using laser conditioning

a technology of laser conditioning and process control, applied in the direction of abrasive surface conditioning devices, lapping machines, manufacturing tools, etc., can solve the problems of uneven roughness across the polishing surface, less ability of the pad to properly and efficiently remove material from the substrate, and non-planar feature side of the substrate,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

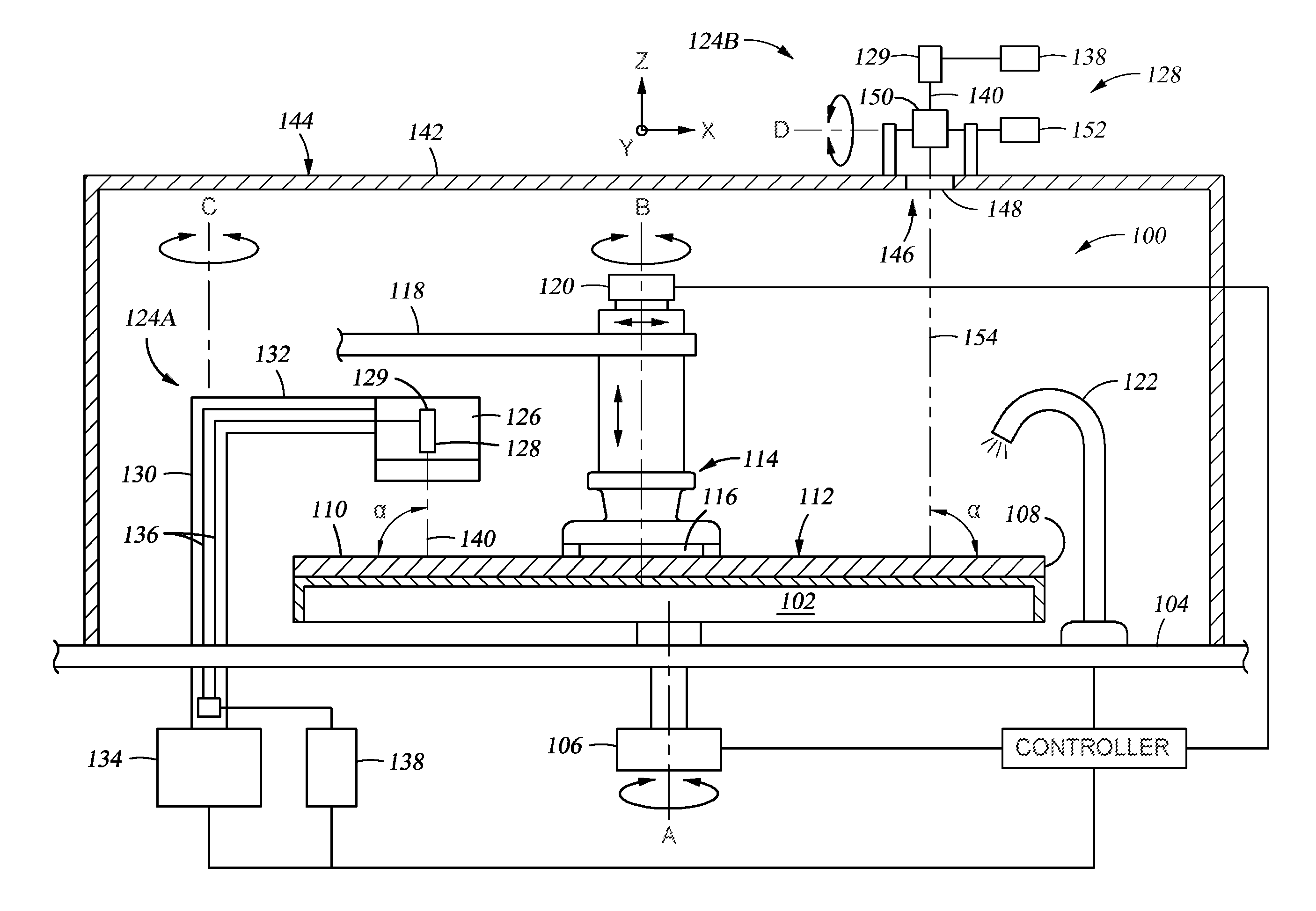

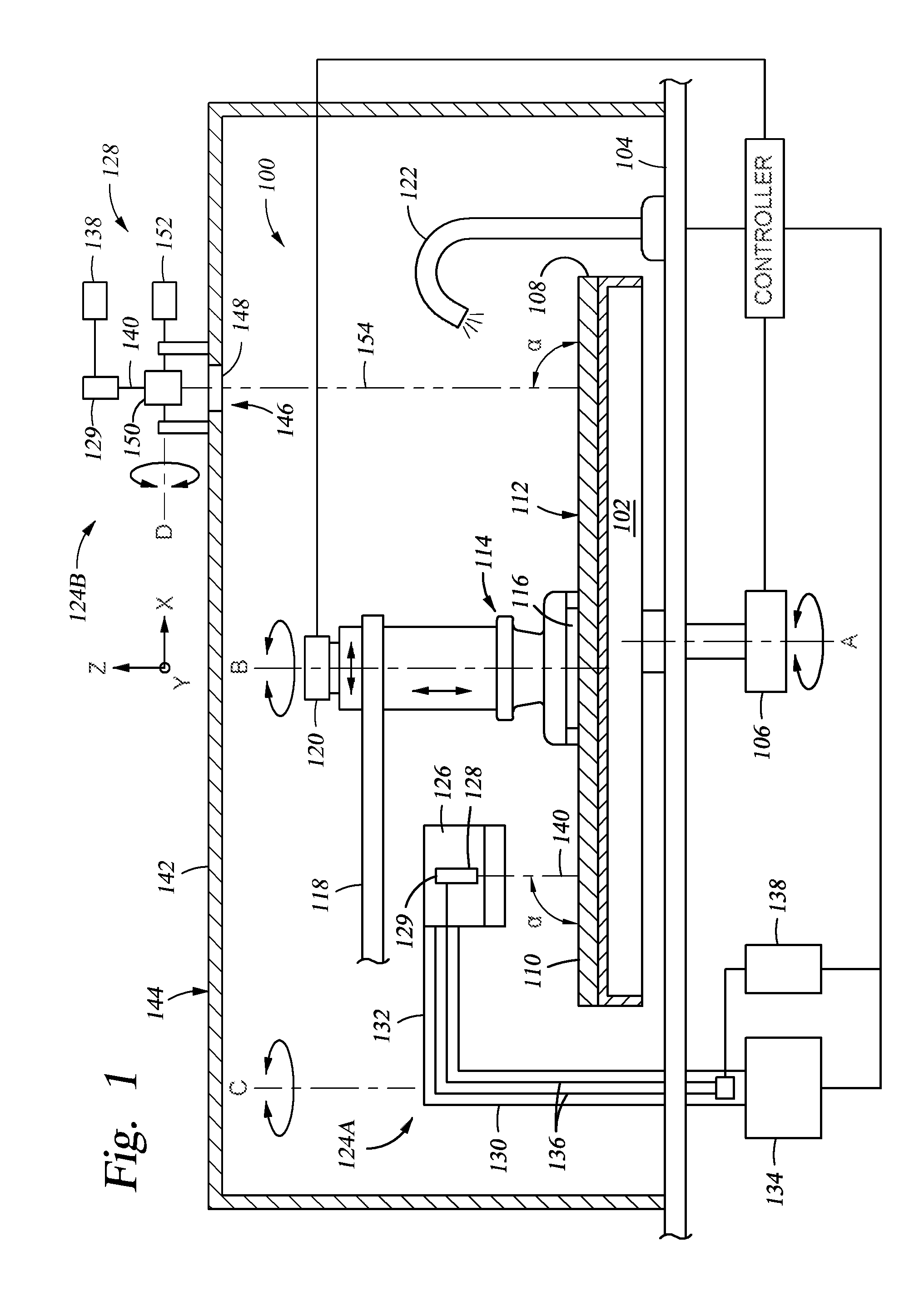

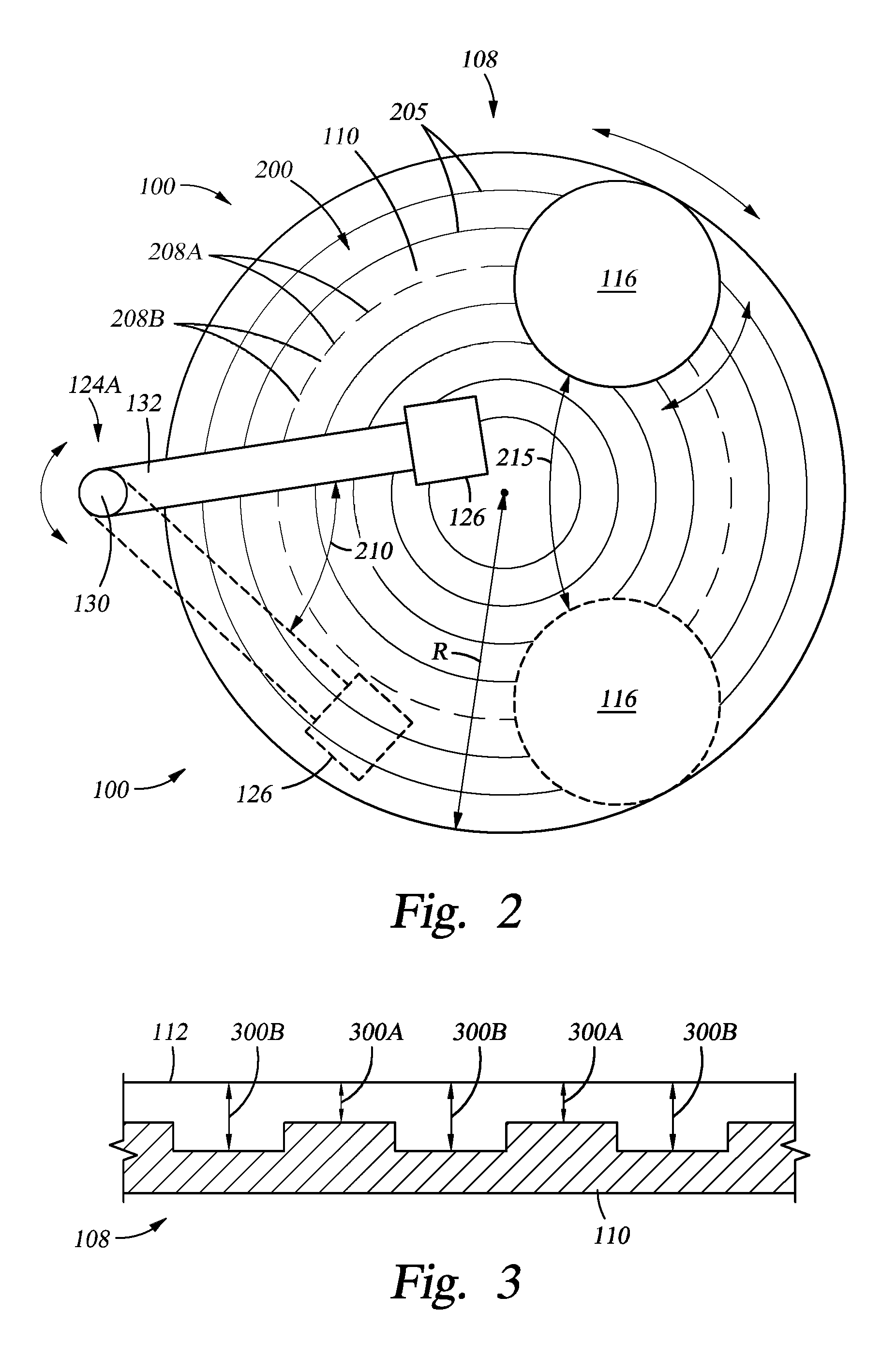

[0024]FIG. 1 is a partial sectional view of one embodiment of a processing station 100 that is configured to perform a polishing process, such as a chemical mechanical polishing (CMP) process or an electrochemical mechanical polishing (ECMP) process. The processing station 100 may be a stand-alone unit or part of a larger processing system. Examples of a larger processing system that the processing station 100 may be utilized with include REFLEXION®, REFLEXION® GT, REFLEXION® LK, REFLEXION® LK ECMP™, MIRRA MESA® polishing systems available from Applied Materials, Inc., located in Santa Clara, Calif., although other polishing systems may be utilized, including those from other manufacturers. Other polishing modules, including those that use other types of processing pads, belts, indexable web-type pads, or a combination thereof, and those that move a substrate relative to a polishing surface in a rotational, linear or other planar motion may also be adapted to benefit from embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com