Method and Device for Producing a Composite Sheet-Metal Part with a Metal Edge Region

a metal edge region and composite sheet metal technology, applied in the direction of manufacturing tools, welding/soldering/cutting articles, welding with roller electrodes, etc., can solve the problems of inability to achieve sufficiently good connection between a composite sheet metal part and a metal part with difficulty, and the method is, however, very complicated and can only be automated with difficulty, so as to achieve significant enhancement of automation of the production of composite sheet metal parts with metal edge regions and processing speeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

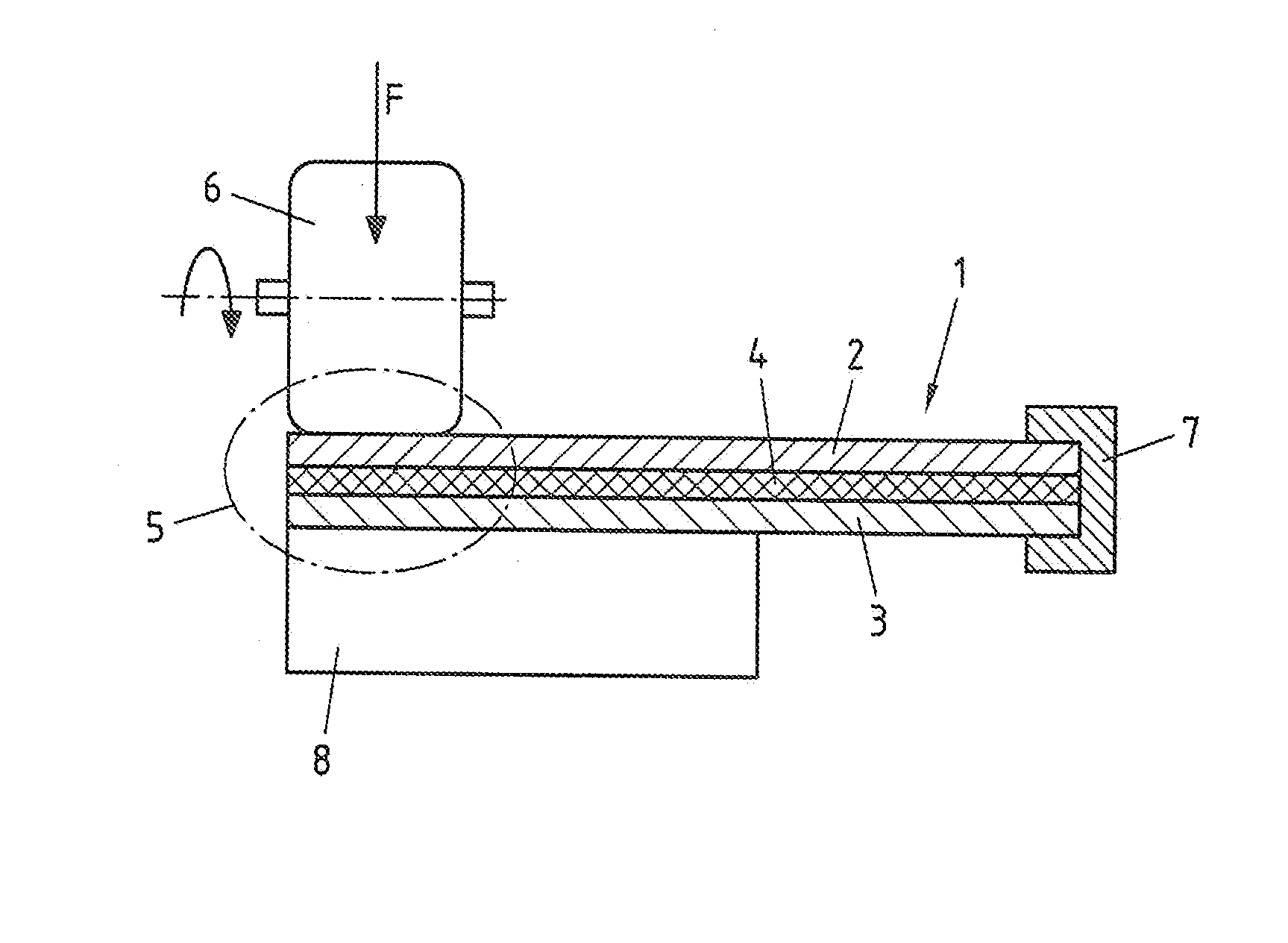

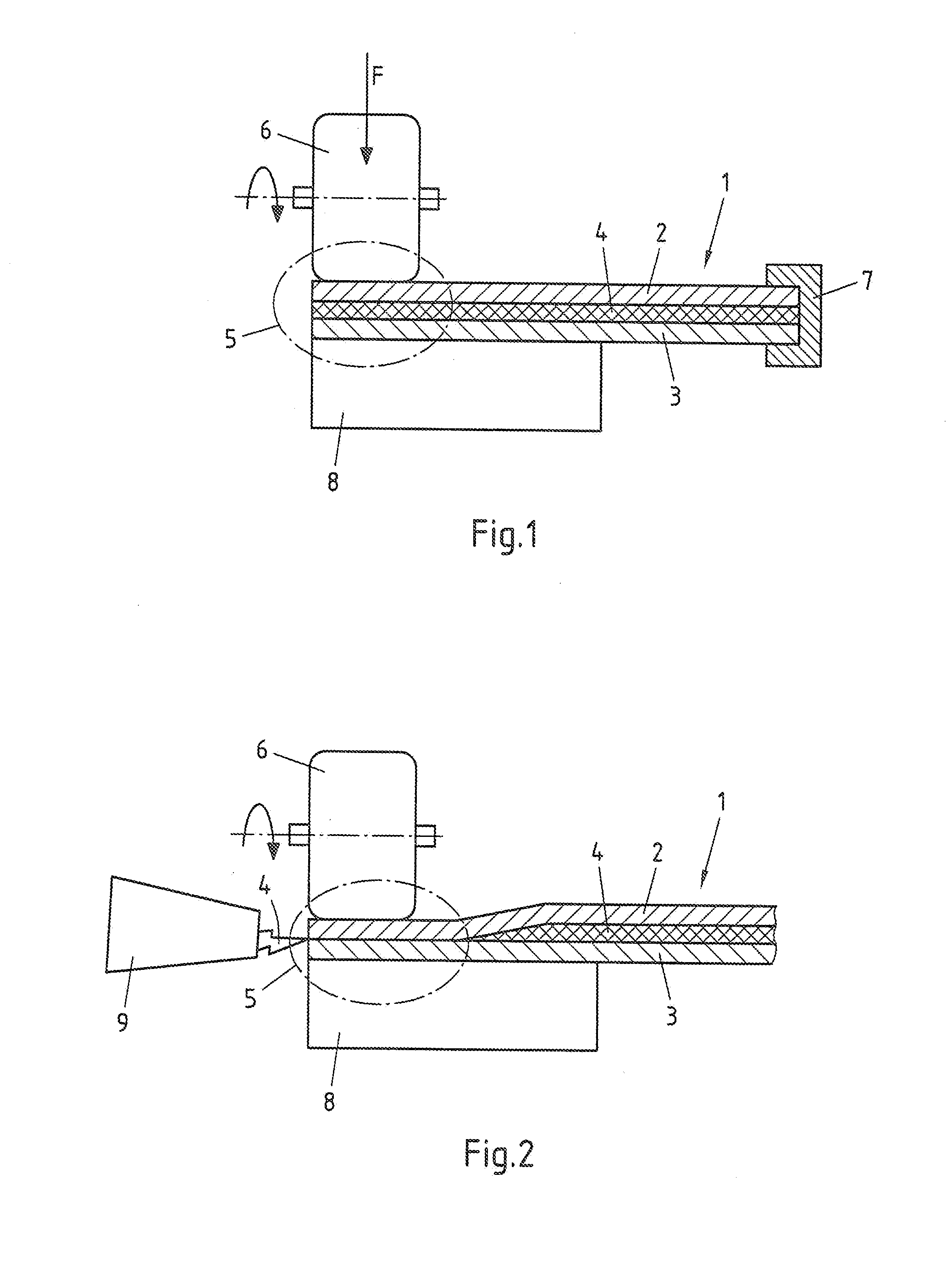

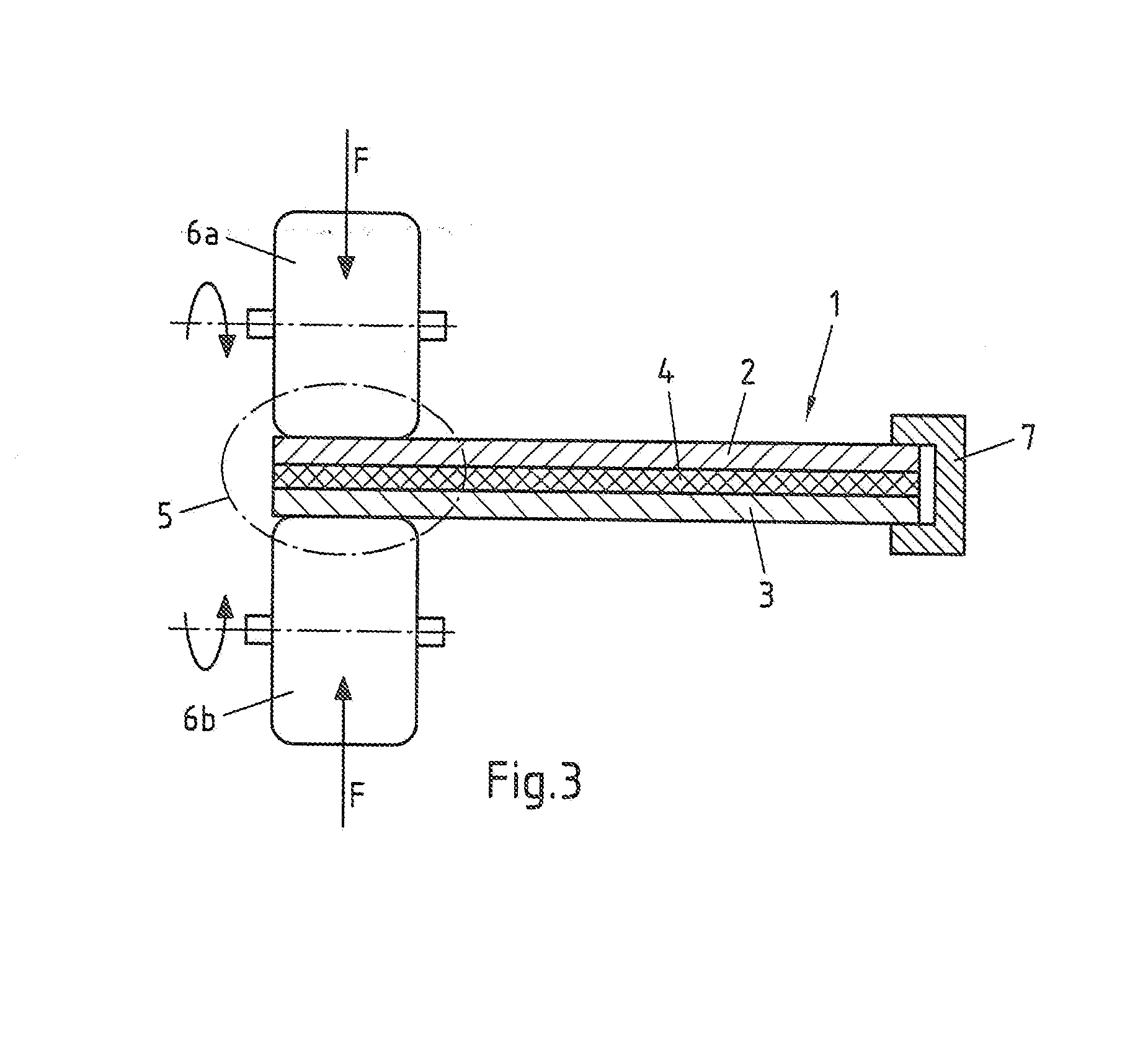

[0041]A first embodiment of the method according to the invention is first of all illustrated in FIG. 1 in which a composite sheet metal part 1 consisting of two outer covering sheets 2, 3 and a plastic layer 4 arranged between the covering sheets 2, 3, is heated in its edge region 5 in such a way that the plastic layer 4 in this edge region 5 softens. The heating of the edge region 5 can take place in various ways and means. In the present exemplary embodiment a current is fed to the composite sheet metal part 1 via the roller 6 and the current conducting clamp 7 and via the dolly bar 8, wherein especially in the contact region of the roller 6, namely in the edge region 5, a powerful heating of the upper and optionally of the lower covering sheet 2, 3 takes place so that the plastic layer 4 provided in the edge region 5 appreciably softens. As a result of the force transmitted to the roller 6 in the direction of the composite sheet metal part 1 the upper covering sheet 2 in the edg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| wall thickness | aaaaa | aaaaa |

| wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com