Trigger mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

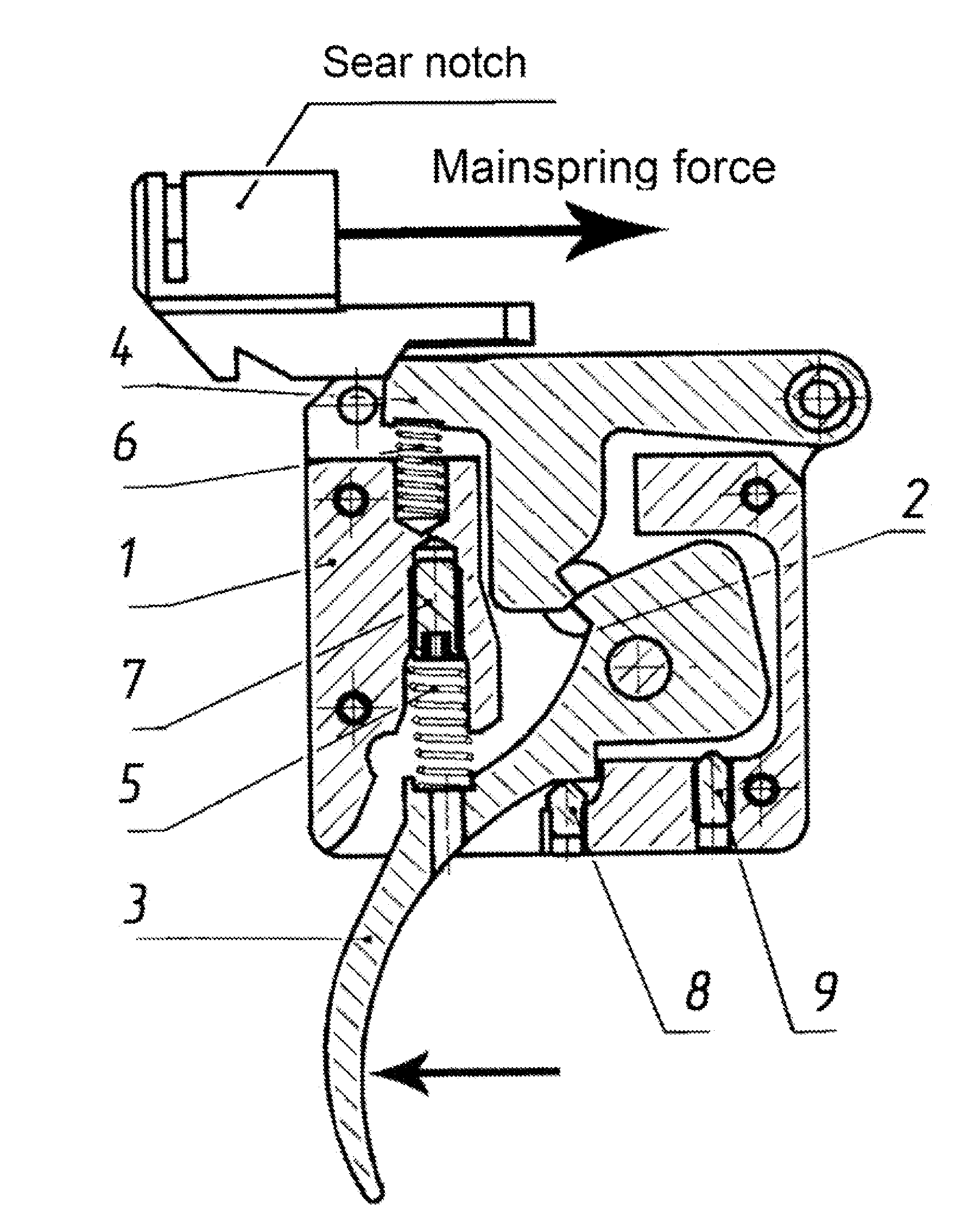

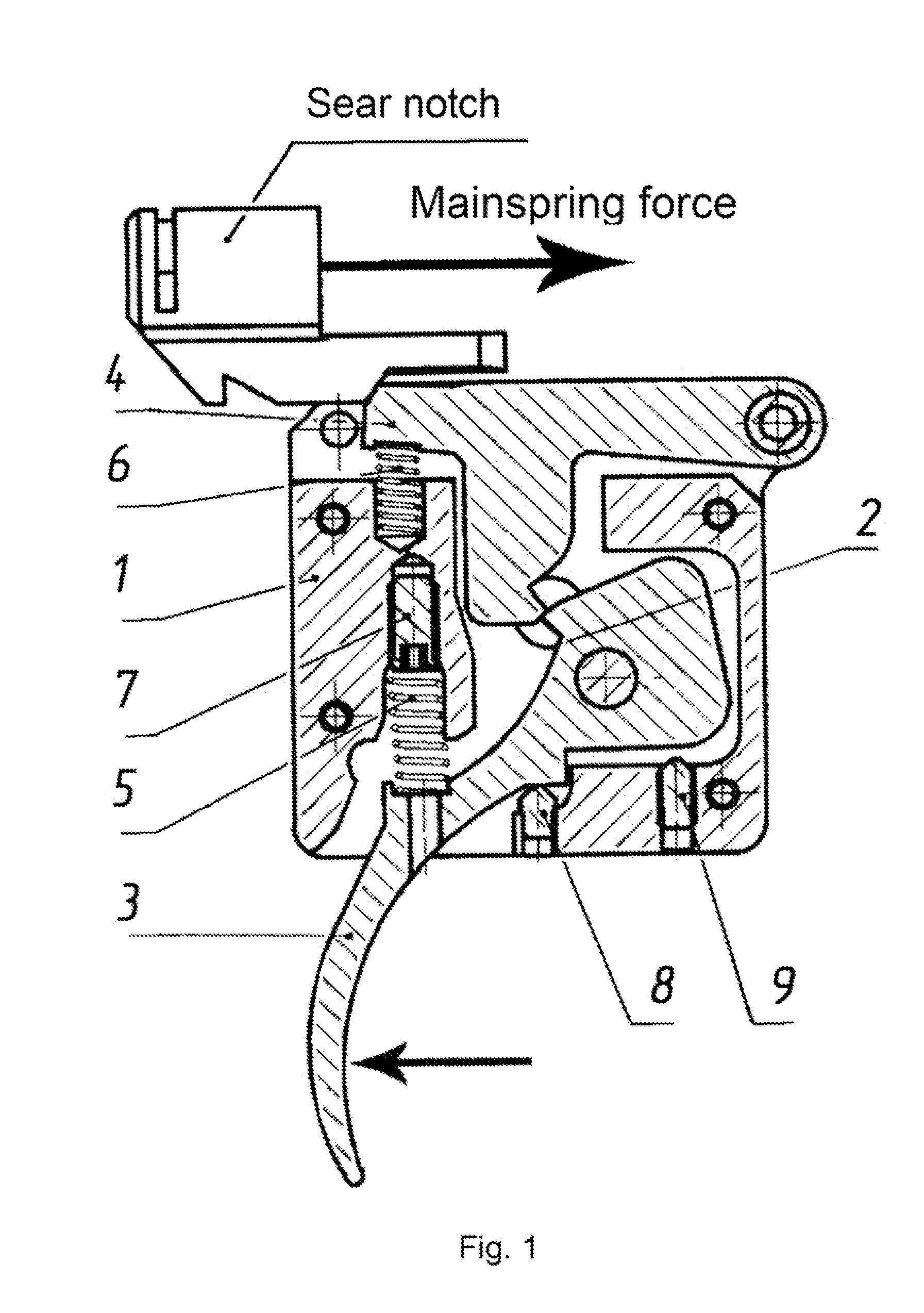

[0017]As shown in FIG. 1, the trigger mechanism in accordance with the preferred embodiment of the invention comprises a body 1 having an aluminum cover (not shown), a technological hole 2, a trigger 3, a sear 4, a triggering spring 5, a sear spring 6, a screw for adjusting triggering 7, a screw for adjusting amount of engagement of the trigger with the sear 8, and a screw for adjusting triggering motion 9.

[0018]Adjustment screws 7, 8, and 9 are mounted in the body base and are oriented vertically at an angle of 90° to the horizontal axis thereof. The sear 4 has a tooth is provided with a tooth which can come into contact with a tooth present on the trigger 3.

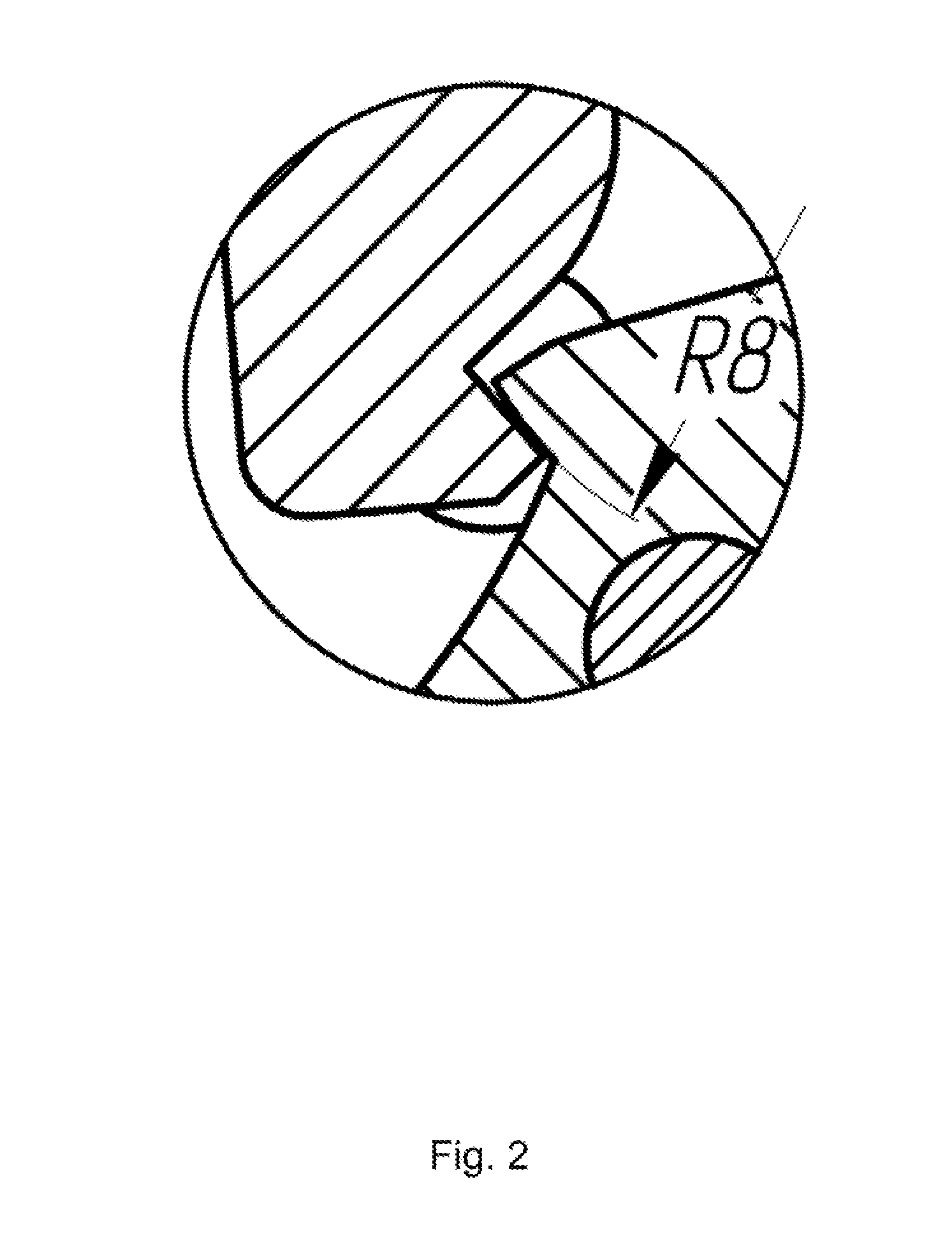

[0019]The trigger tooth surface, which interacts with the sear tooth surface at the time of cocked trigger, is curvilinear, in particular, as shown in FIG. 2, it is a convex arcuated surface of a curvature radius (R) between 5 and 8 mm.

[0020]The amount of engagement is the area of interaction of the teeth surfaces of sear 6 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com