System, method, and apparatus for heating

a technology of system and method, applied in the field of system, method and apparatus for heating, can solve the problems of overestimation of the duration of the heating process, process to be completed, and use more energy than necessary, so as to improve the accuracy of the computed warm up time, avoid wasting energy, and minimize the running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

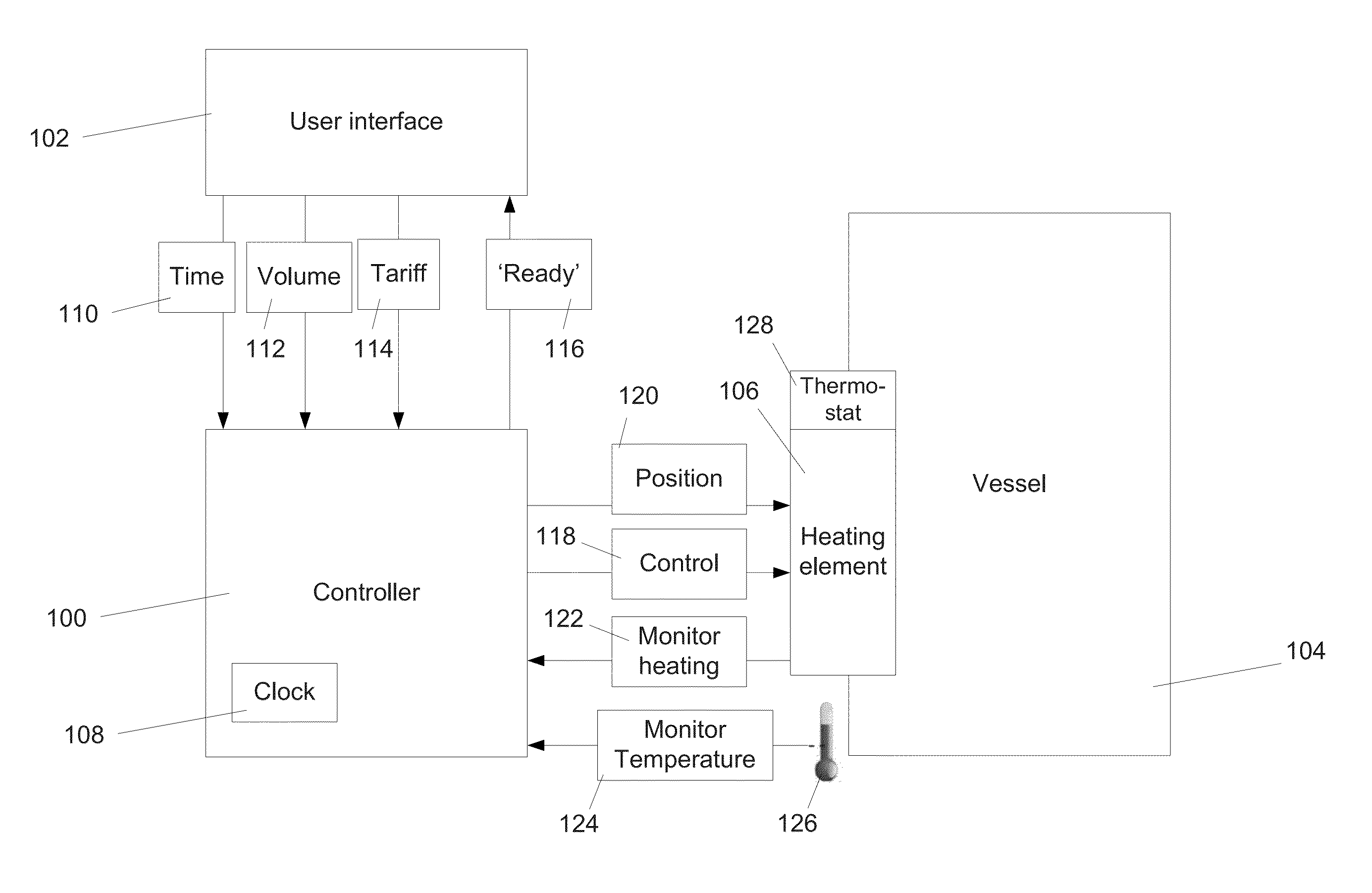

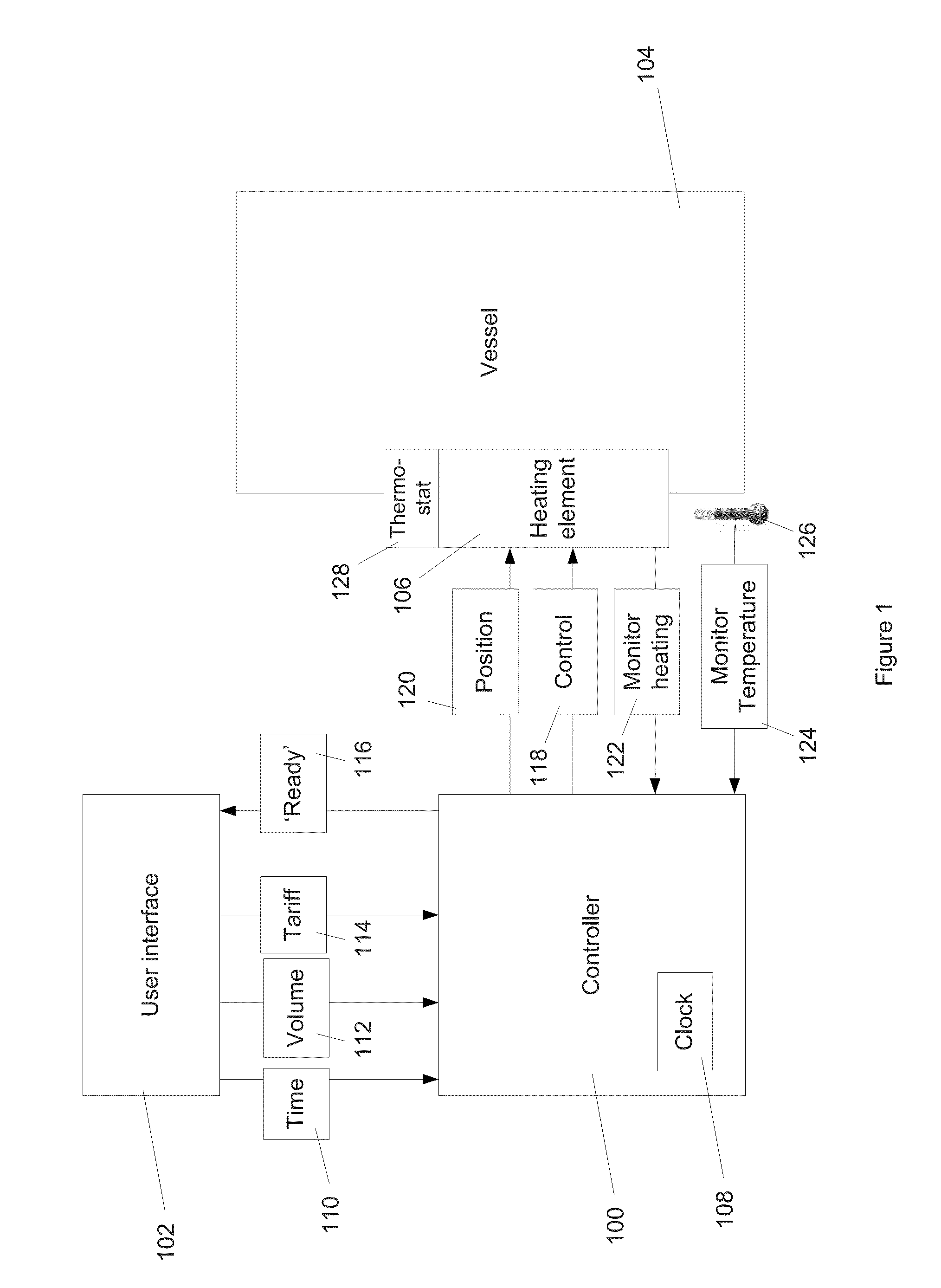

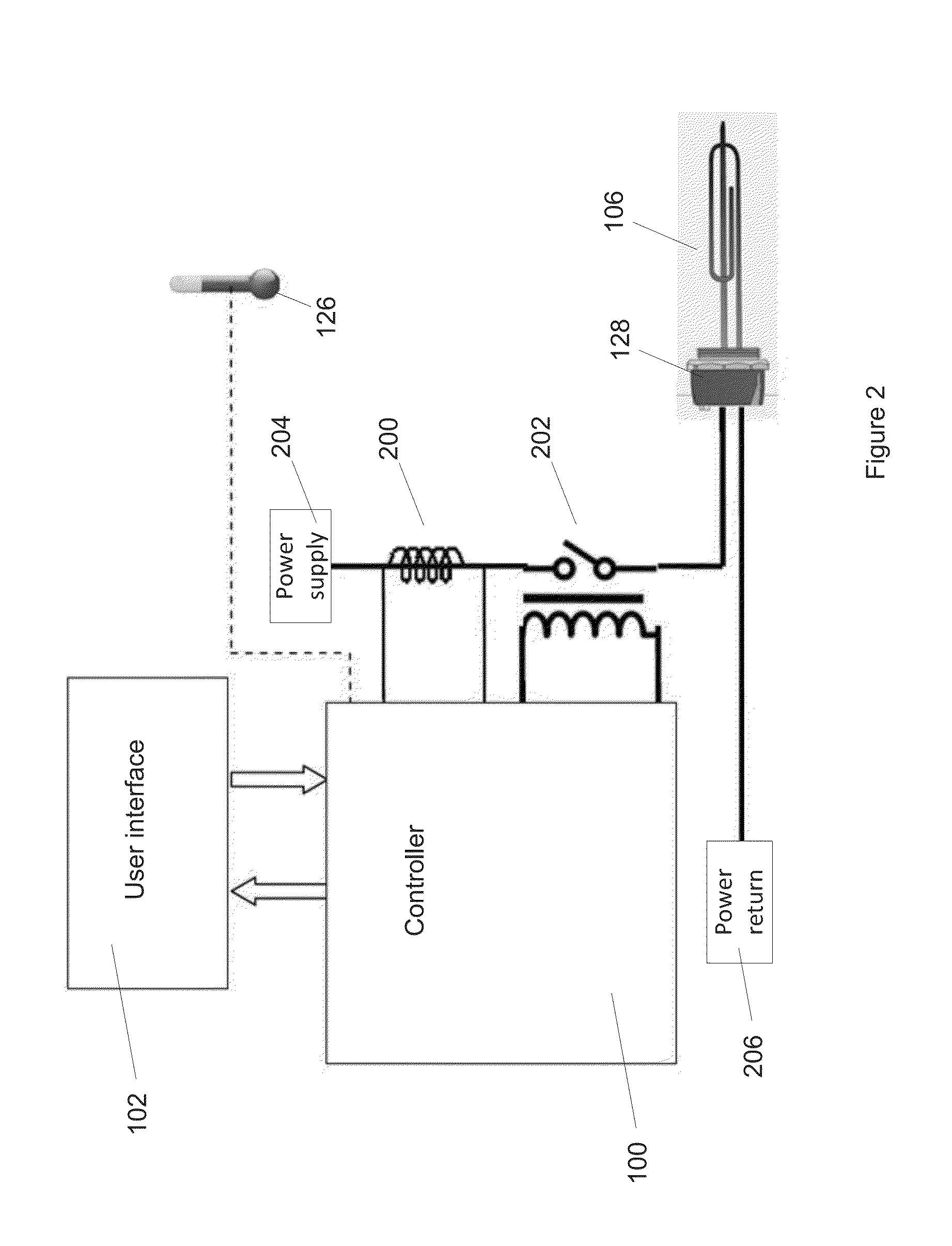

[0227]In reference to FIG. 1, a controller 100 monitors heating 122 of a heating element 106, for example by measuring the current flowing through an immersion element. This allows the controller 100 to detect when a vessel 104, typically containing hot water, has reached the desired temperature. An algorithm embedded within the immersion controller learns the time required for the vessel to reach the desired temperature, for example by inspection of the current waveform. The user of the controller programs, via a user interface 102, the required times 110 at which the vessel's contents are to be at some desired temperature. The user may input further variables, including volume 112 of water desired and information regarding energy tariffs 114. An algorithm embedded in the controller 100 calculates scheduling of the immersion element. This allows the controller 100 to control 118 heating, in particular initiating and terminating heating, for example by control of the power supply to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com