Detailing and polishing pad

a technology for detailing pads and detailing, applied in the direction of manufacturing tools, cleaning machines, carpet cleaners, etc., can solve the problems of pad delamination, foam core deformation, and foam core deformation, so as to prevent the pad from breaking down and delaminating during use, remove fine scratches, swirls and holograms, and reduce the effect of foam cor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

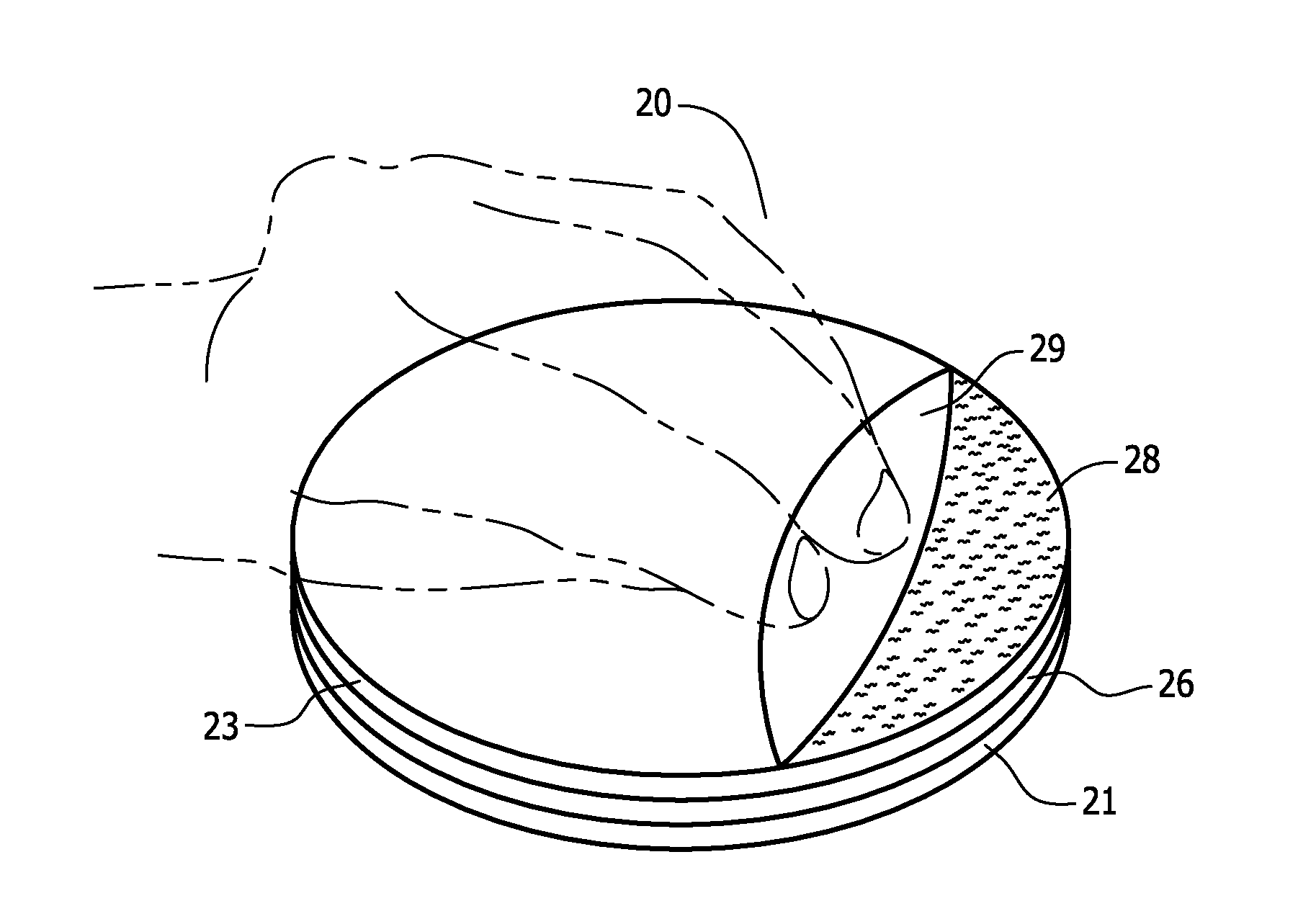

[0028]FIGS. 3A-5 show the present invention polishing pad 20 in a preferred embodiment. These figures depict an improved polishing pad 20 that is adapted to be used on a polishing tool that includes a generally planar support surface for receiving the pad. In one embodiment, polishing pad 20 includes a polishing layer 21 comprising a fabric polishing surface 22. Polishing pad 20 also includes backing layer 23. Backing layer 23 has an inner surface 24 and outer surface 25. Outer surface 25 of backing layer 23 is adapted to mechanically or adhesively attach in removable fashion to the support surface of the polishing tool.

[0029]Present invention polishing pad 20 includes a middle layer 26 made from a non-foam, solid thermoplastic polymer. By non-foam, it is meant that the middle layer is neither an open-cell foam nor a closed-cell foam. Middle layer 26 forms a flexible sheet between polishing layer 21 and backing layer 23. Middle layer 26 is bonded to polishing layer 21 and inner surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com