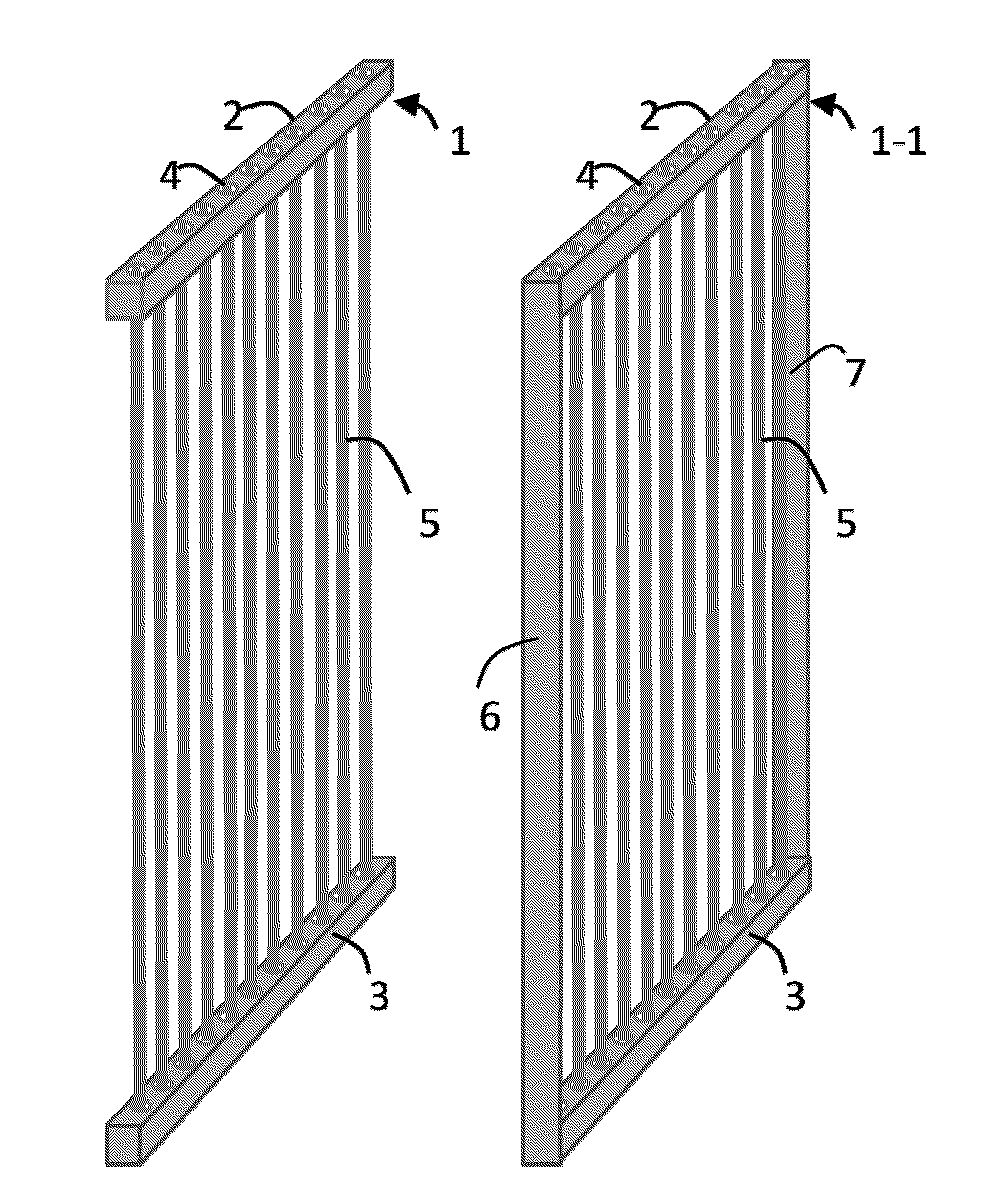

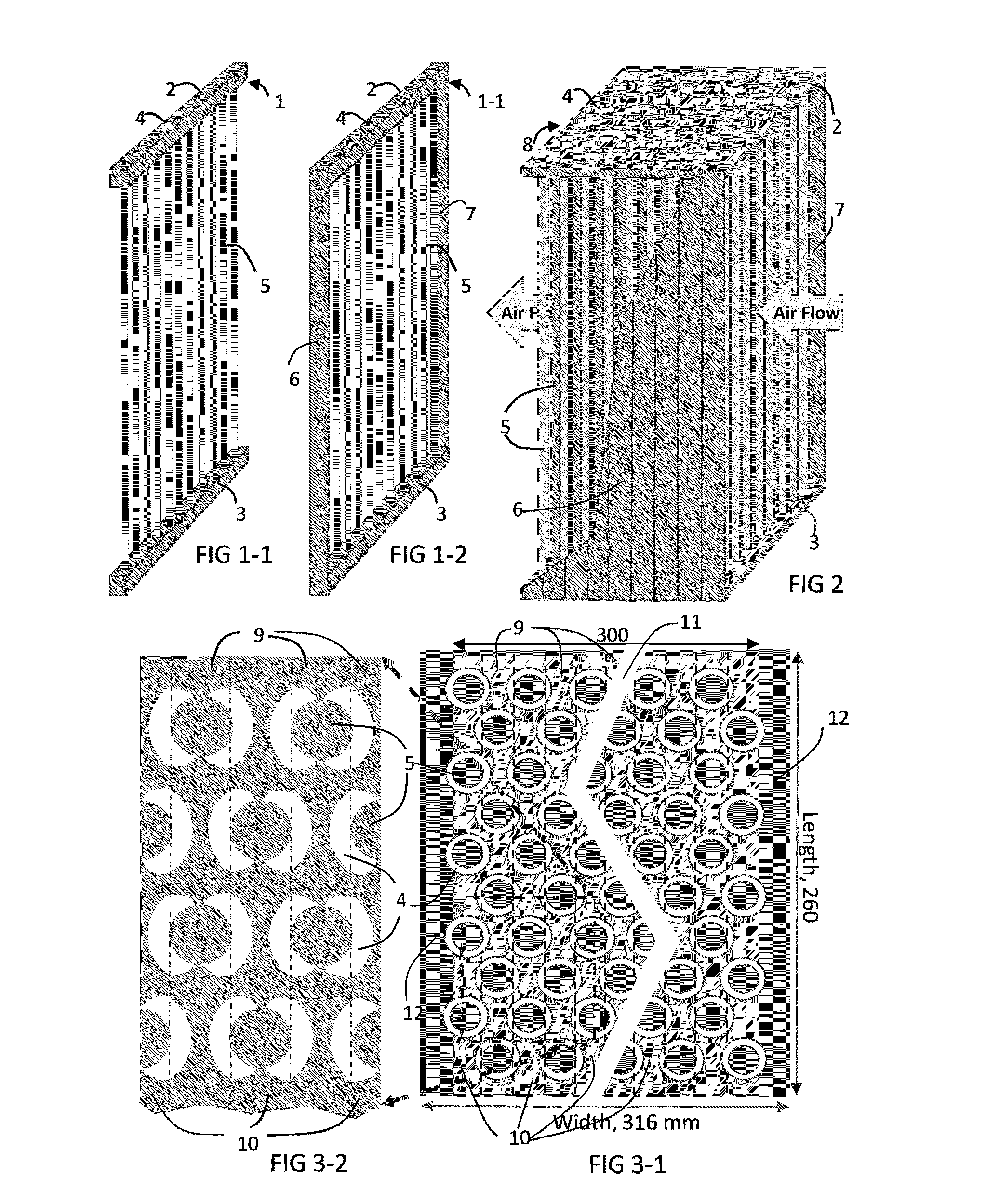

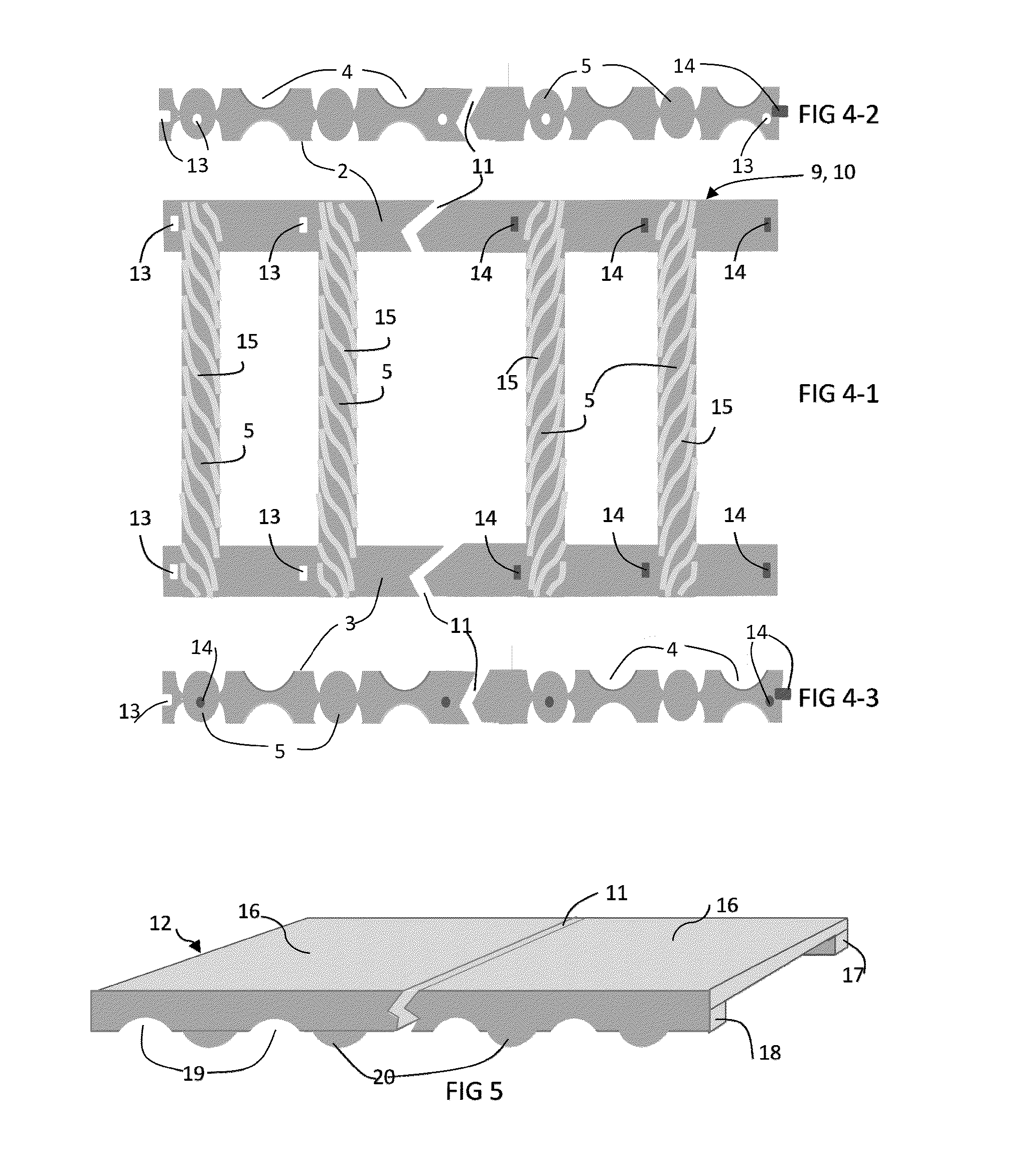

Plastic-Rod-Screen-Fills for Use in Evaporative Water Cooling and Airborne Fumes Removal Apparatuses and Fabrication Thereof

a technology of evaporative water cooling and airborne fume removal, which is applied in the field of filling media of plastic rods, can solve the problems of high manufacturing cost that cannot be eluded, and achieve the effects of more rigid, stronger and more rigid, and stronger and more rigid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071]The string screen fills (SSFs) invented by the present inventor have a disadvantage in manufacturing of the SSFs, since they are fabricated through separated two manufacturing lines of molding fabrication of SSF frame and webbing fabrication of winding strings over the SSF frame. Such manufacturing lines have a problem limiting more reduction of the manufacturing cost of SSFs. To complement such a problem, a one step manufacturing line, described above, of the present invention is invented. One step manufacturing means a manufacturing of SSF frame and string winding over the frame within one manufacturing line at a same time instead of individual fabrication through two different manufacturing lines, In other word, the SSF frame and loading string on the frame are completely accomplished in one step same manufacturing. Therefore, one step manufacturing line can reduce by nearly one half of manufacturing time and cost required in the previous manufacturing process claimed in US...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com