Tri-Axis Close Loop Feedback Controlling Module for Electromagnetic Lens Driving Device

a technology of electromagnetic lens and feedback control, which is applied in the direction of dynamo-electric components, instruments, dynamo-electric machines, etc., can solve the problems of slow response and interaction speed of auto-focus modules, delay in focusing operations, and difficult circuit design for conventional technologies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

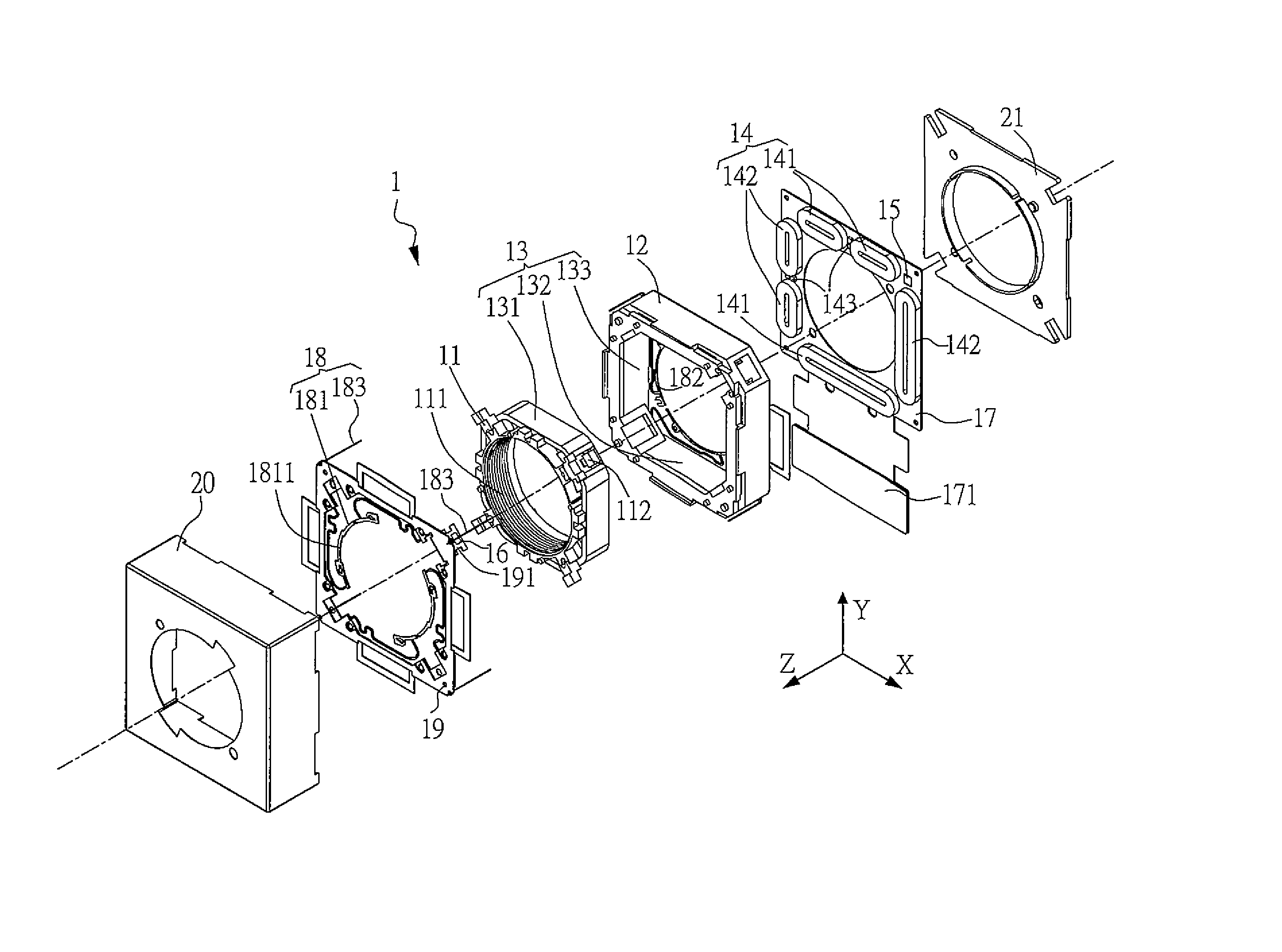

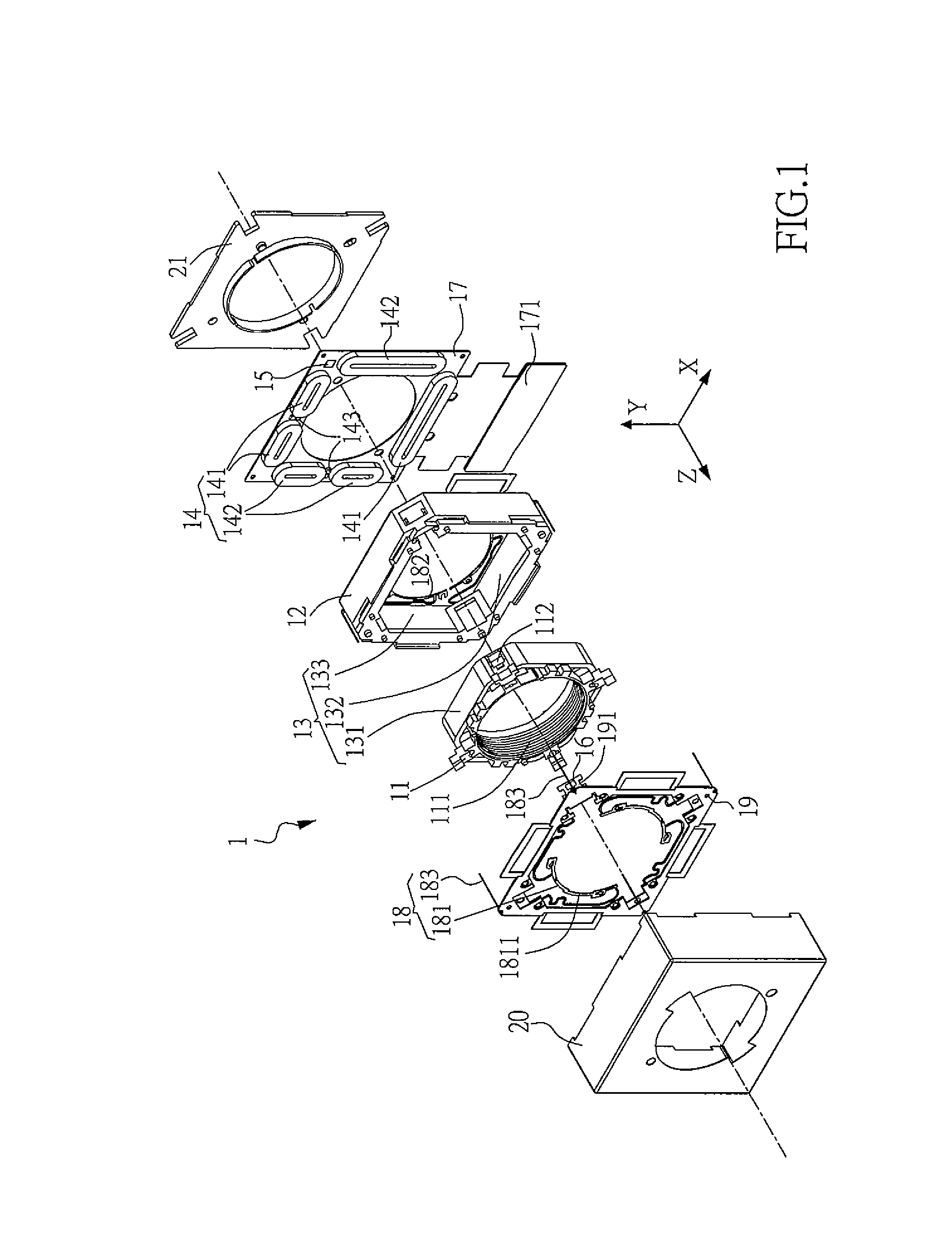

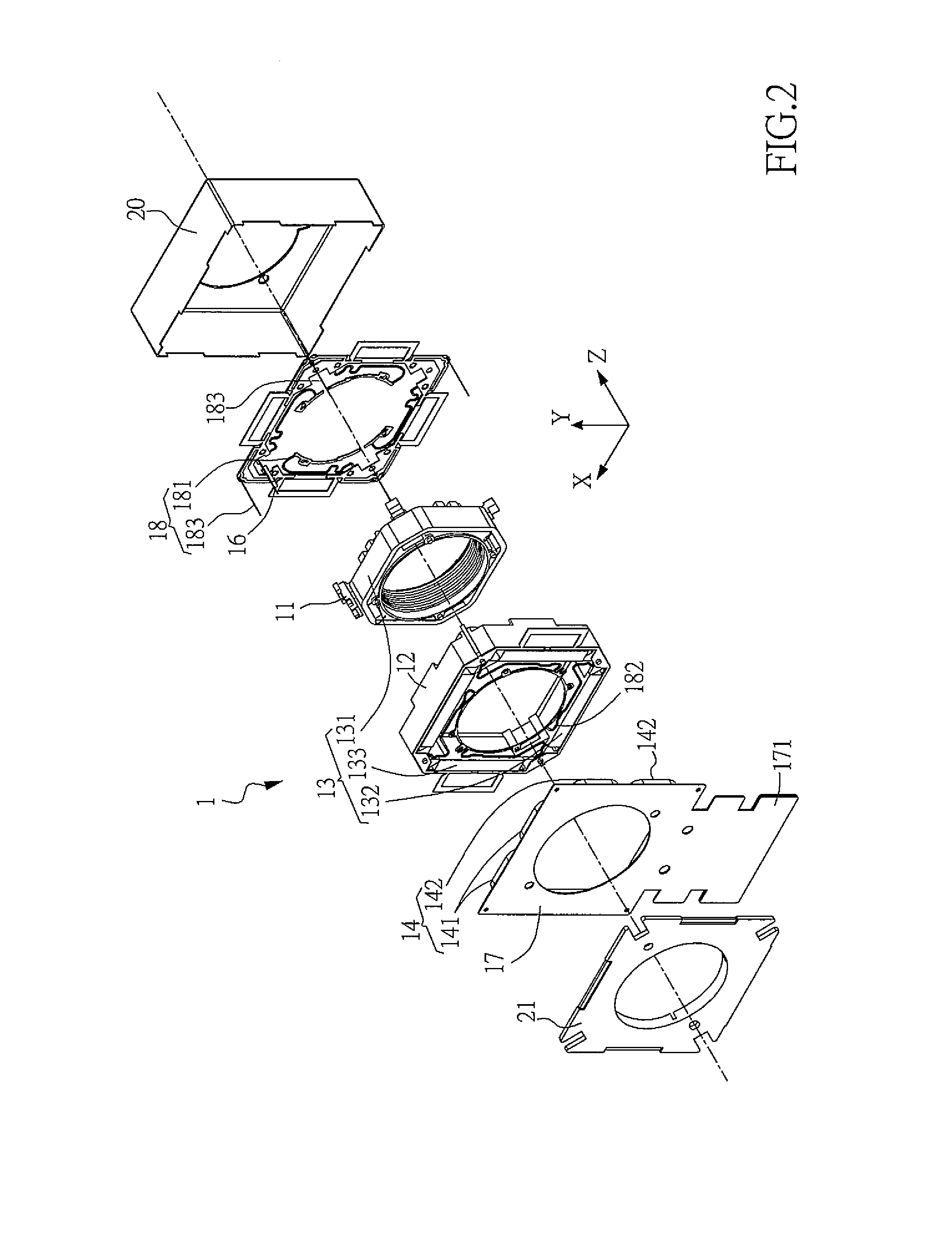

[0055]The tri-axis close-loop feedback controlling module for electromagnetic lens driving device according to the present invention comprises a 6-pins Hall Magnetic Sensing Element (also referred as 6-pin Hall element hereinafter). Two pins of the 6-pin Hall element are coupled to an auto-focus module for providing a current to the auto-focus module in order to drive the auto-focus module to conduct the auto-focusing operations along the Z-axis; while other four pins of the 6-pin Hall element are coupled to a control unit. The control unit can detect the signals generated by an OIS module to obtain the X-Y axial positions of the auto-focus module relative to the OIS module, so as to generate a control signal according to the X-Y axial position of the auto-focus module, and then send the control signal to the 6-pin Hall element. Therefore, the 6-pin Hall element not only can provide its own feedback controlling function according to the Z-axial position of lens, but also can accept ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com