Heater and heating method for wet extraction tank

a technology of wet extraction and heating method, which is applied in the direction of lighting and heating apparatus, separation processes, applications, etc., can solve the problems of poor insulation and insecurity, serious affecting the quality of separation products, and poor extraction, so as to achieve safe and stable, low energy consumption, and clean and friendly environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

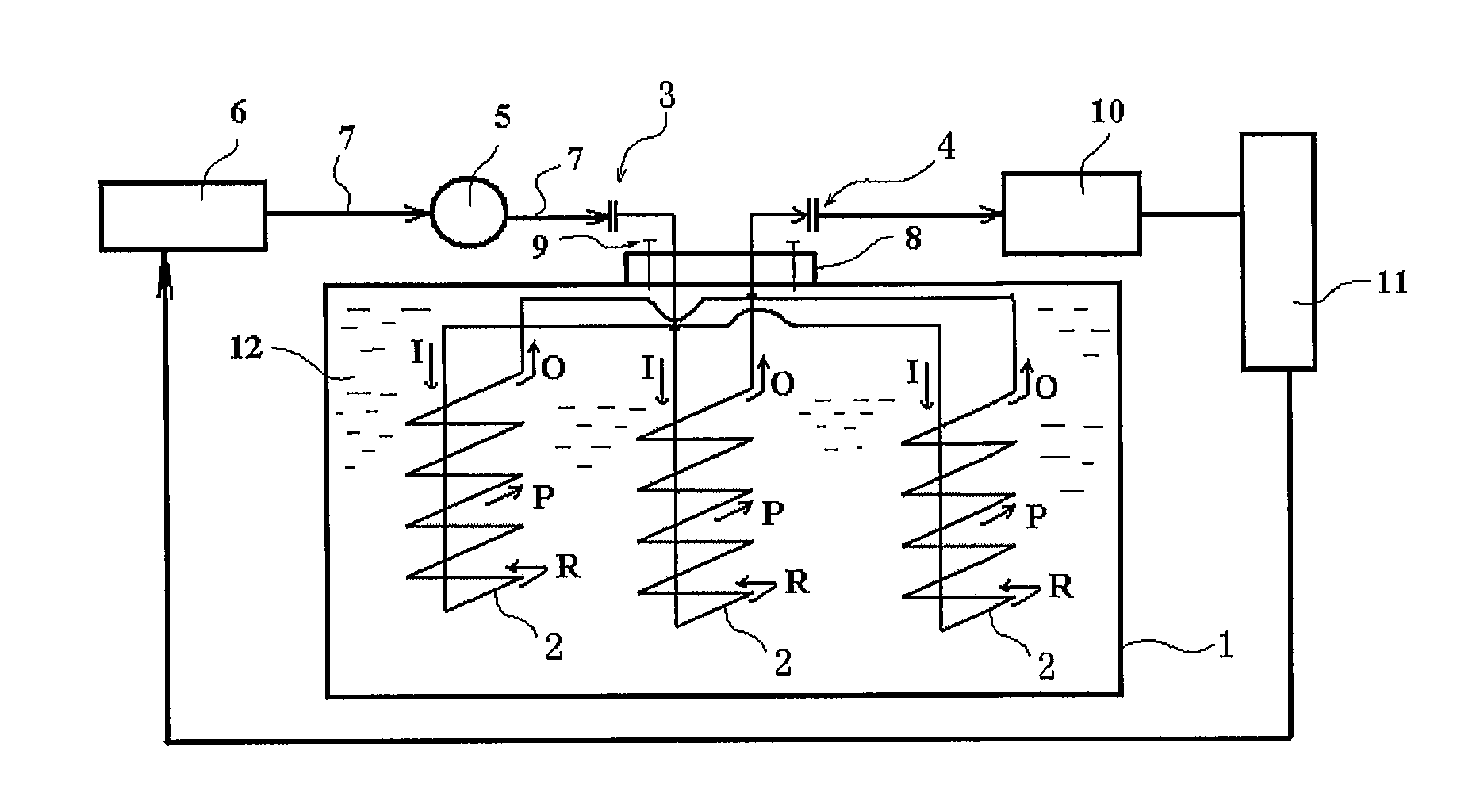

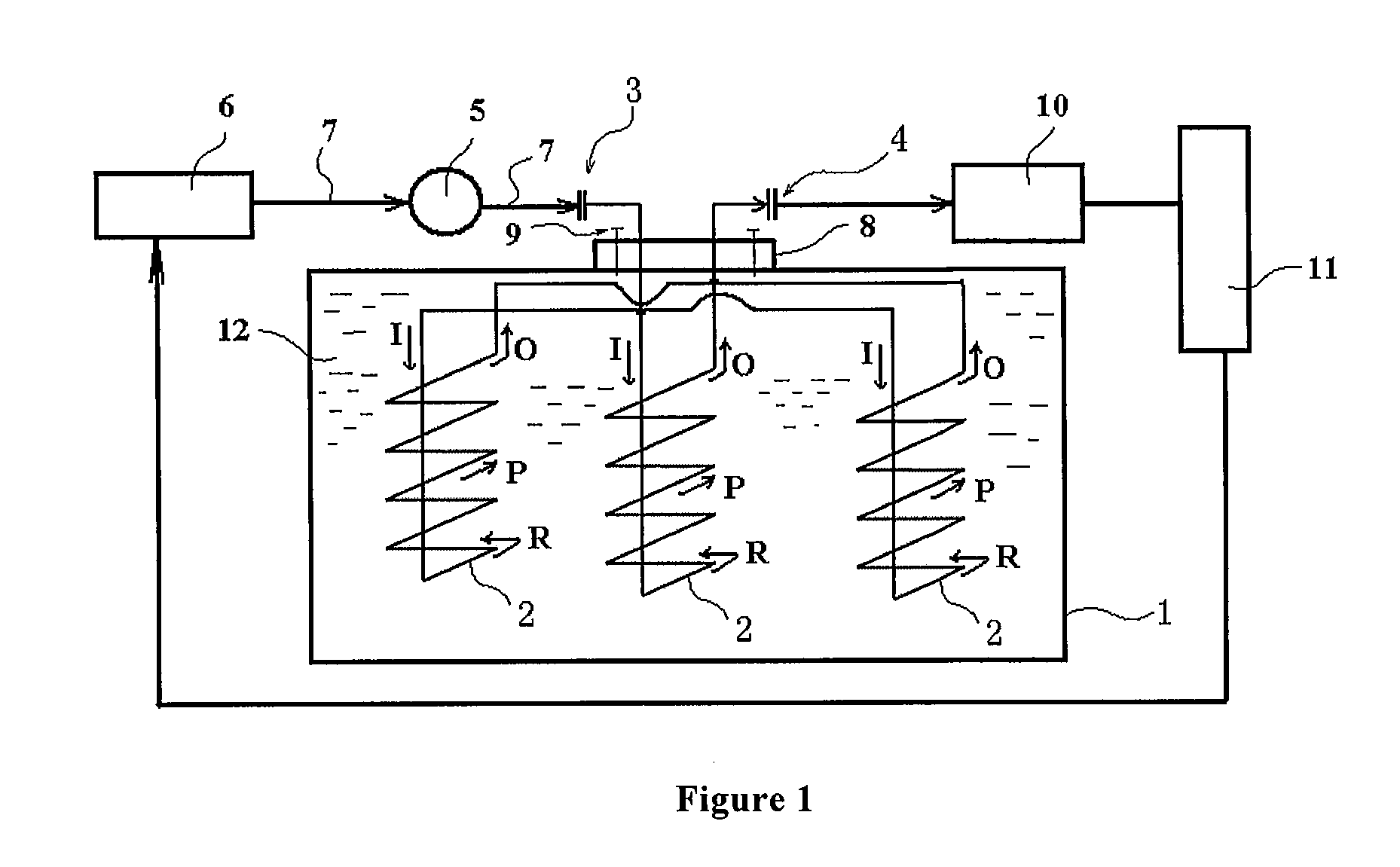

[0018]As shown in FIG. 1, the heater for extraction tank according to the present invention comprises a heating tube 2; said heating tube 2 is a spiral glass tube (or called a spirally coiled glass tube, or serpentine glass tube, or cobra like glass tube), the two ends of the heating tube 2 are provided with a gas inlet 3 and a gas outlet 4, respectively, the gas inlet 3 is connected to a vapor supplying apparatus 6 via a vapor pipe 7, and a pressure regulating valve 5 is provided on the vapor pipe 7 for regulating the pressure of the vapor entering into the heating tube 2; the hot vapor enters into the heating tube 2 from the gas inlet 3 at one end, and later leaves from the gas outlet 4 at the other end as a liquid.

[0019]In another embodiment, it is a hot water or micro-vapor that leaves from the gas outlet 4 at the other end, and the hot water or micro-vapor is contained in an apparatus 10 capable of containing hot water or micro-vapor. In another embodiment, the apparatus 10 cap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com