Patents

Literature

35results about How to "Environmental friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

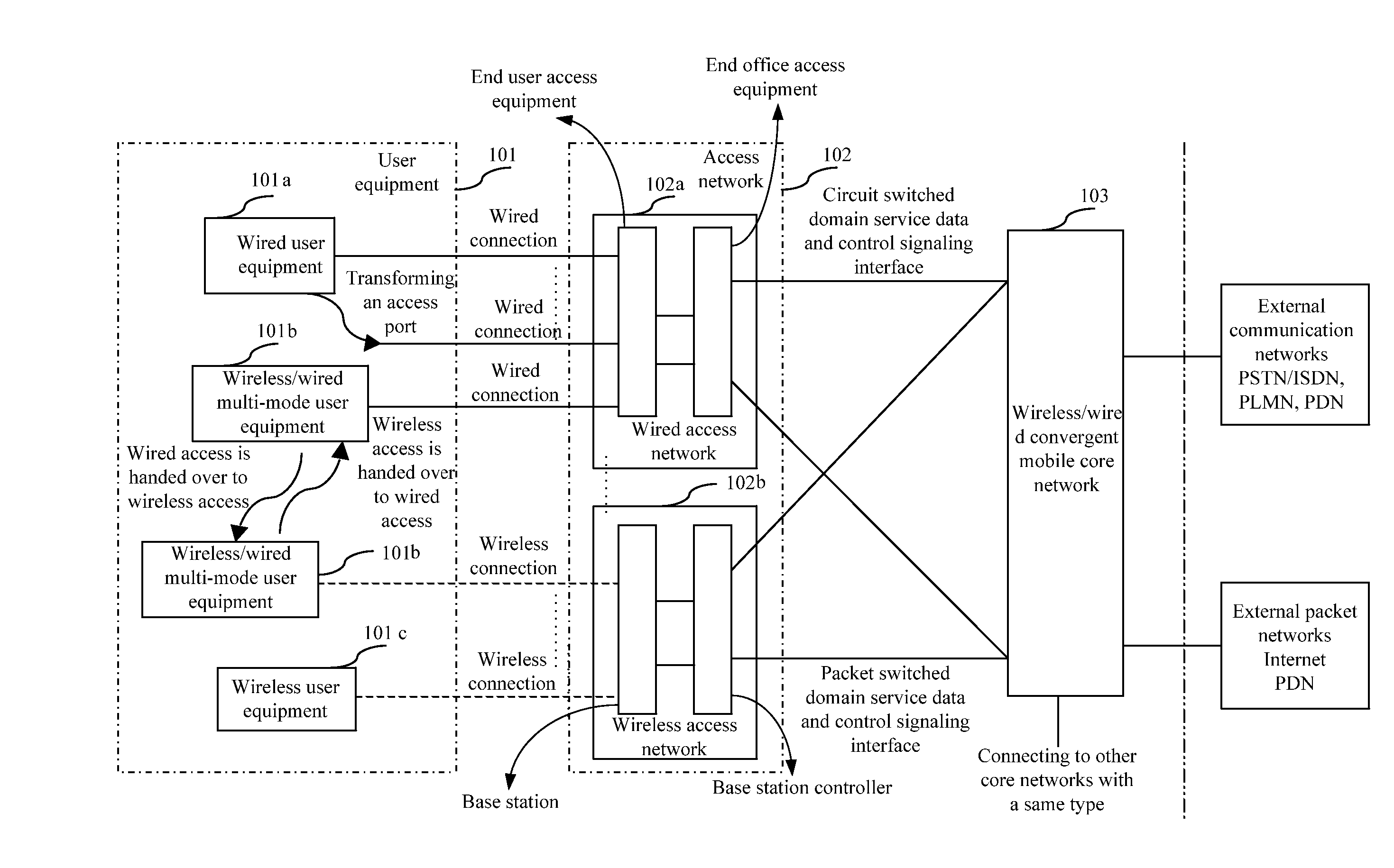

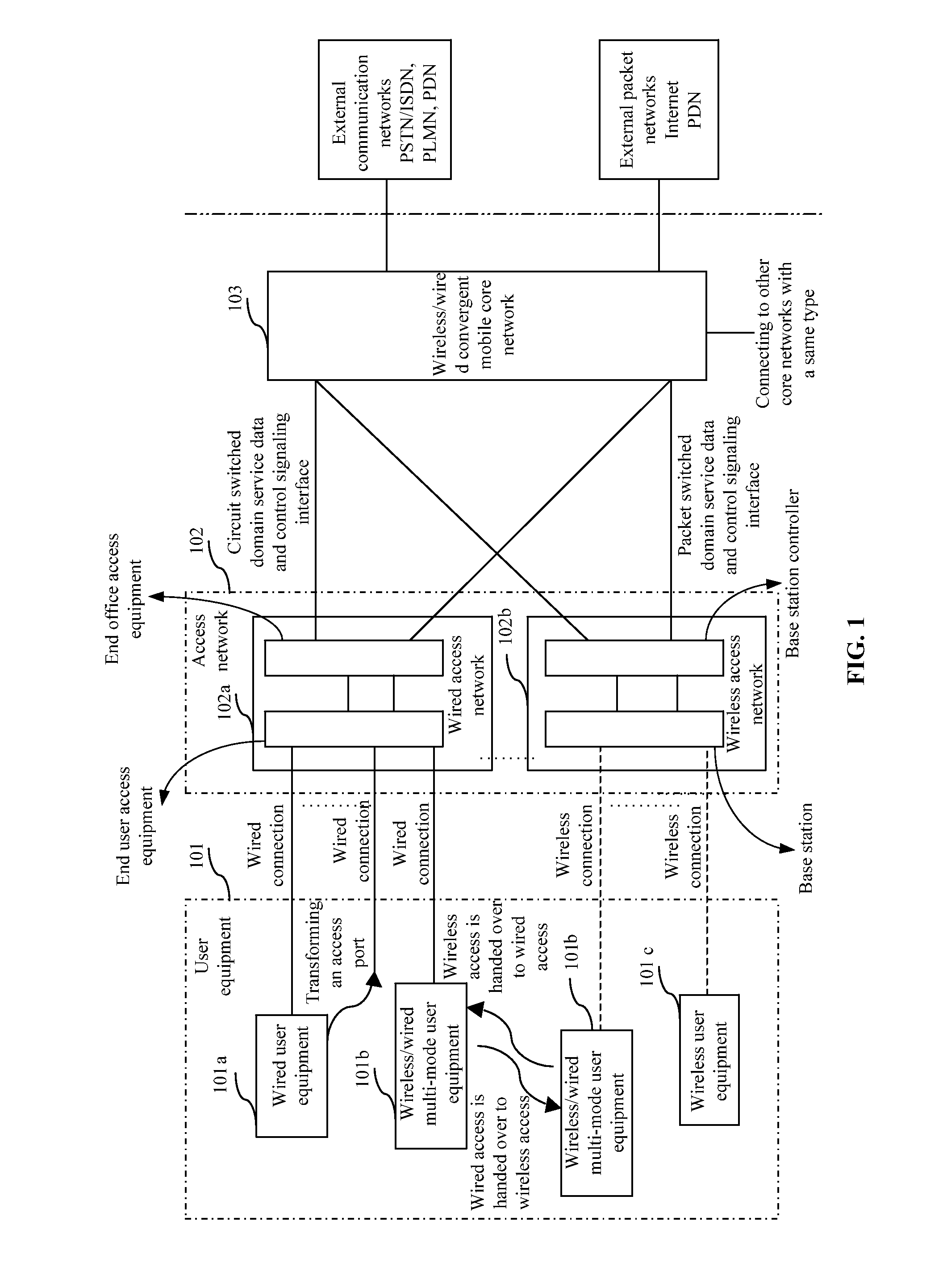

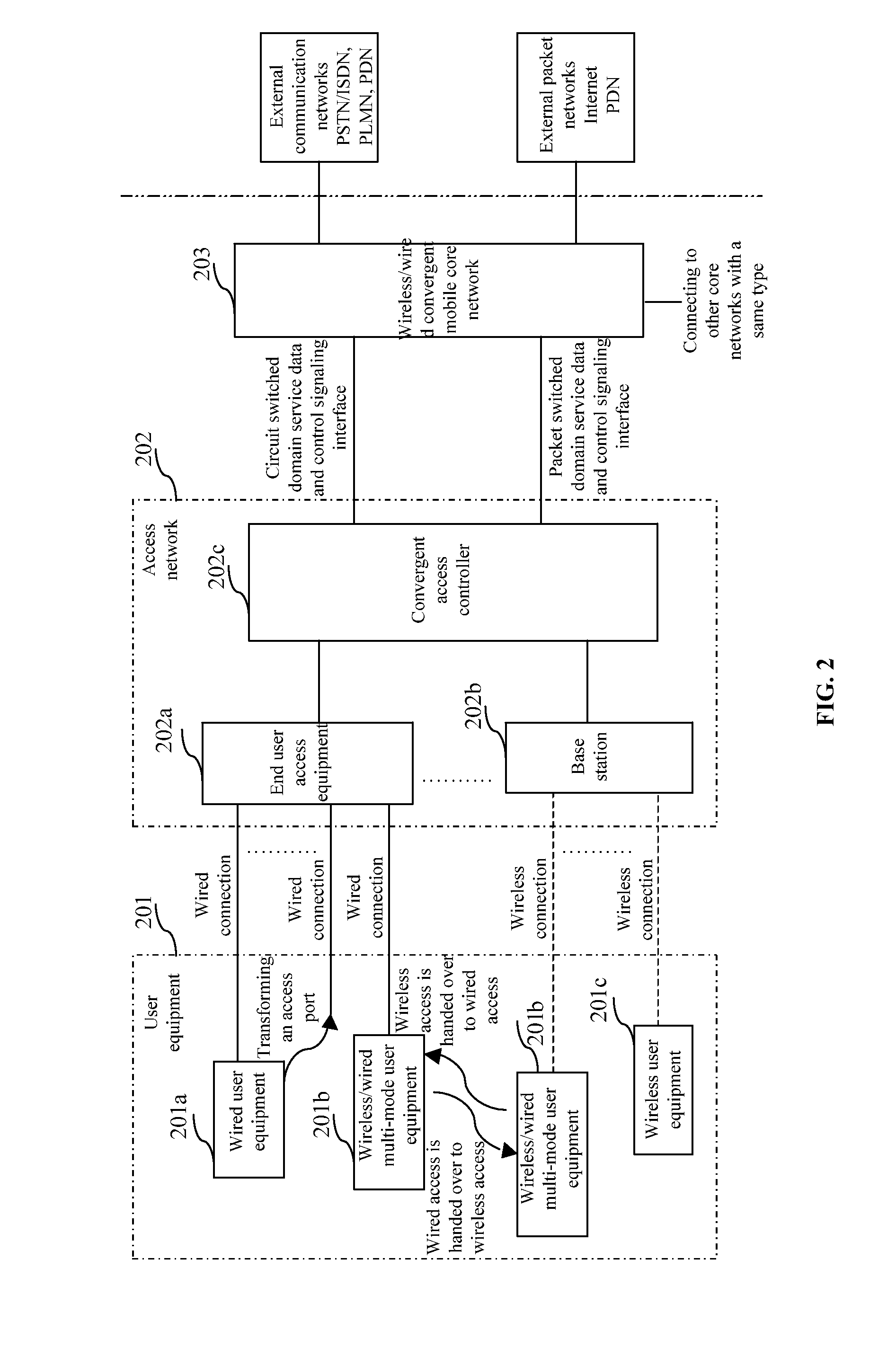

Communication Network System Converging Wireless Mobile Network and Wired Discontinuous Mobile Network and Method Thereof

InactiveUS20080070619A1Abundant bandwidth resourceFriendly communication environmentSubstation equipmentRadio transmissionAccess networkWireless mesh network

A communication network system that converges a wireless mobile network and a wired discontinuous mobile network and the method thereof is provided herein, with the communication network system and method applicable to the wireless and wired communication technology fields. The convergent communication network includes a user equipment, an access network and a wireless / wired convergent mobile core network. The invention provides a convergence of a wireless mobile communication technology and a wired discontinuous mobile communication technology, and the convergence of wireless mobile communication and wired discontinuous mobile communication in terms of the system functions and structure of a core network, an access network, a user equipment, and a full network. The invention combines the respective advantages of wireless mobile communication and wired communication, overcomes the deficiencies thereof, and solves various problems with conventional wireless mobile communication and wired communication, such as separated networks, complex interconnection and interoperability, the waste and non-sharing of communication resources, and high cost.

Owner:YU JUN

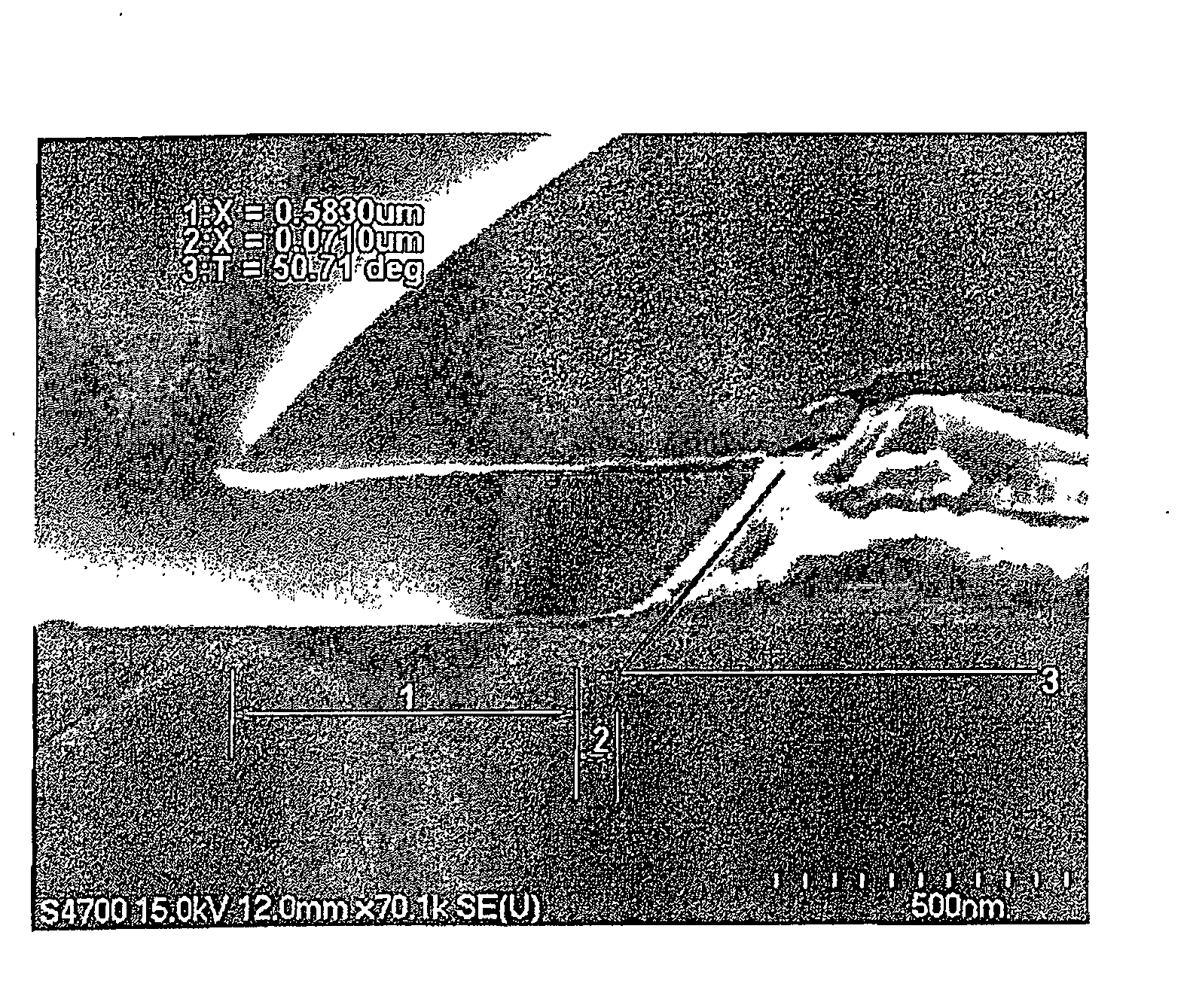

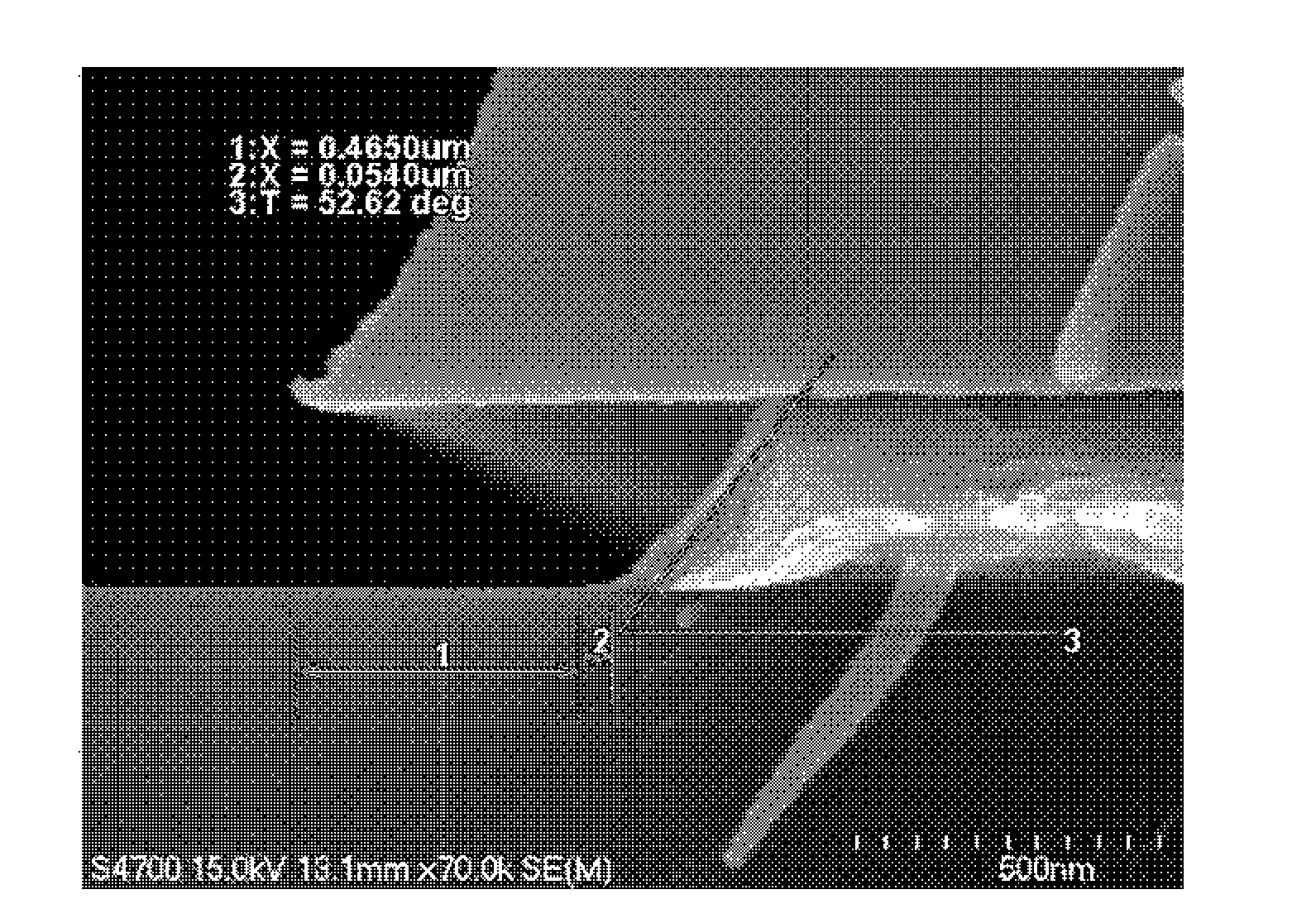

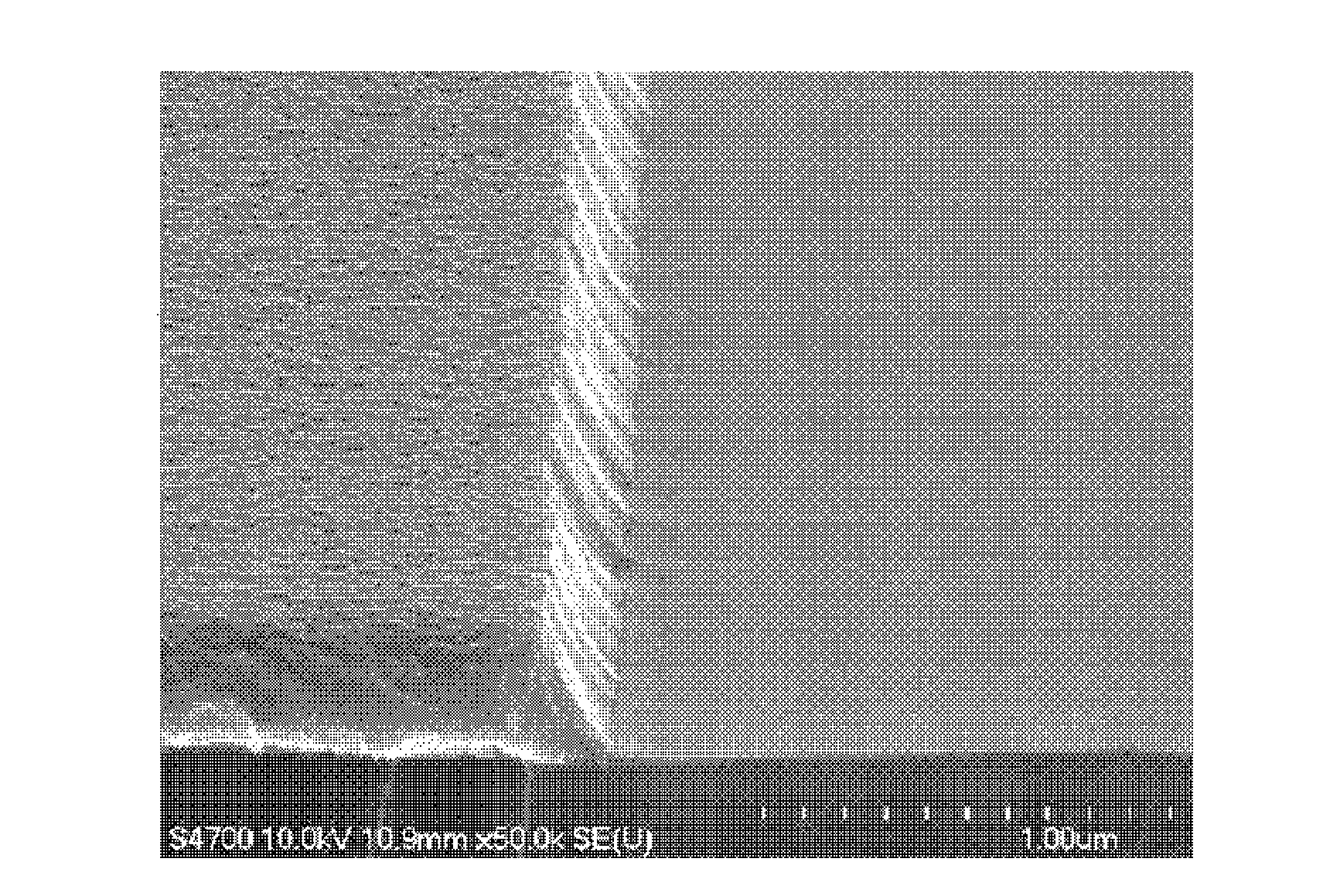

Method for preparing array substrate for liquid crystal display device

ActiveCN103052907AEnvironmental friendlyPrevent poor wiringSolid-state devicesNon-linear opticsCrystallographyOrganic acid

The present invention relates to preparation method for an array substrate for the use in a liquid crystal display device, using an etchant composition comprising: a) 5-25 wt% of hydrogen peroxide (H2O2); b) 0.1-5 wt% of an organic acid; c) 0.1-5 wt% of a phosphate compound; d) 0.1-5 wt% of a water-soluble cyclic amine compound; e) 0.1-5 wt% of a water-soluble compound having a nitrogen atom and a carboxyl group in a molecule; f) 0.01-1.0 wt% of a fluorine-containing compound; g) 0.001-5 wt% of a polyhydric alcohol-based surfactant; and h) the balance of water based on the total weight of the composition.

Owner:DONGWOO FINE CHEM CO LTD

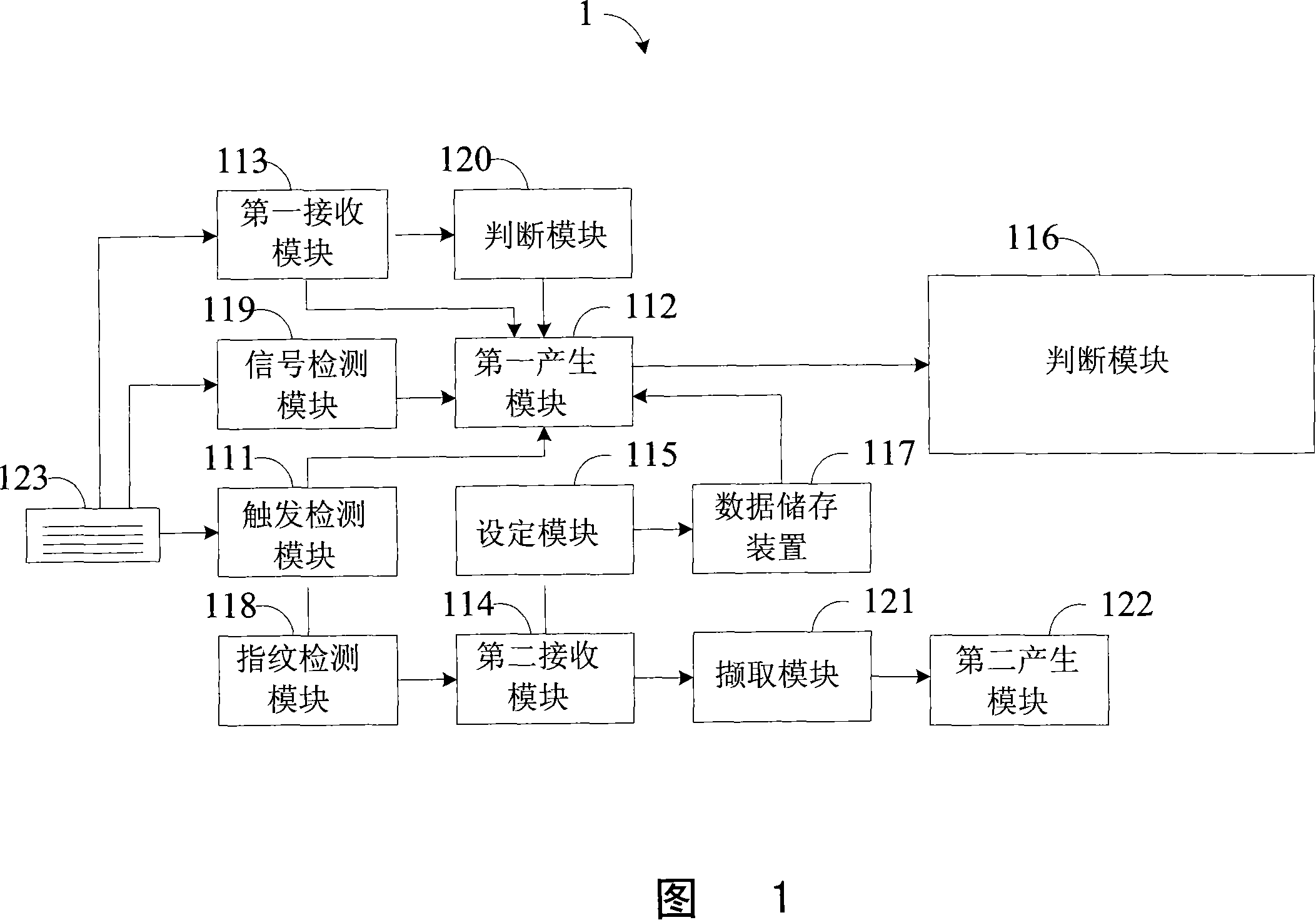

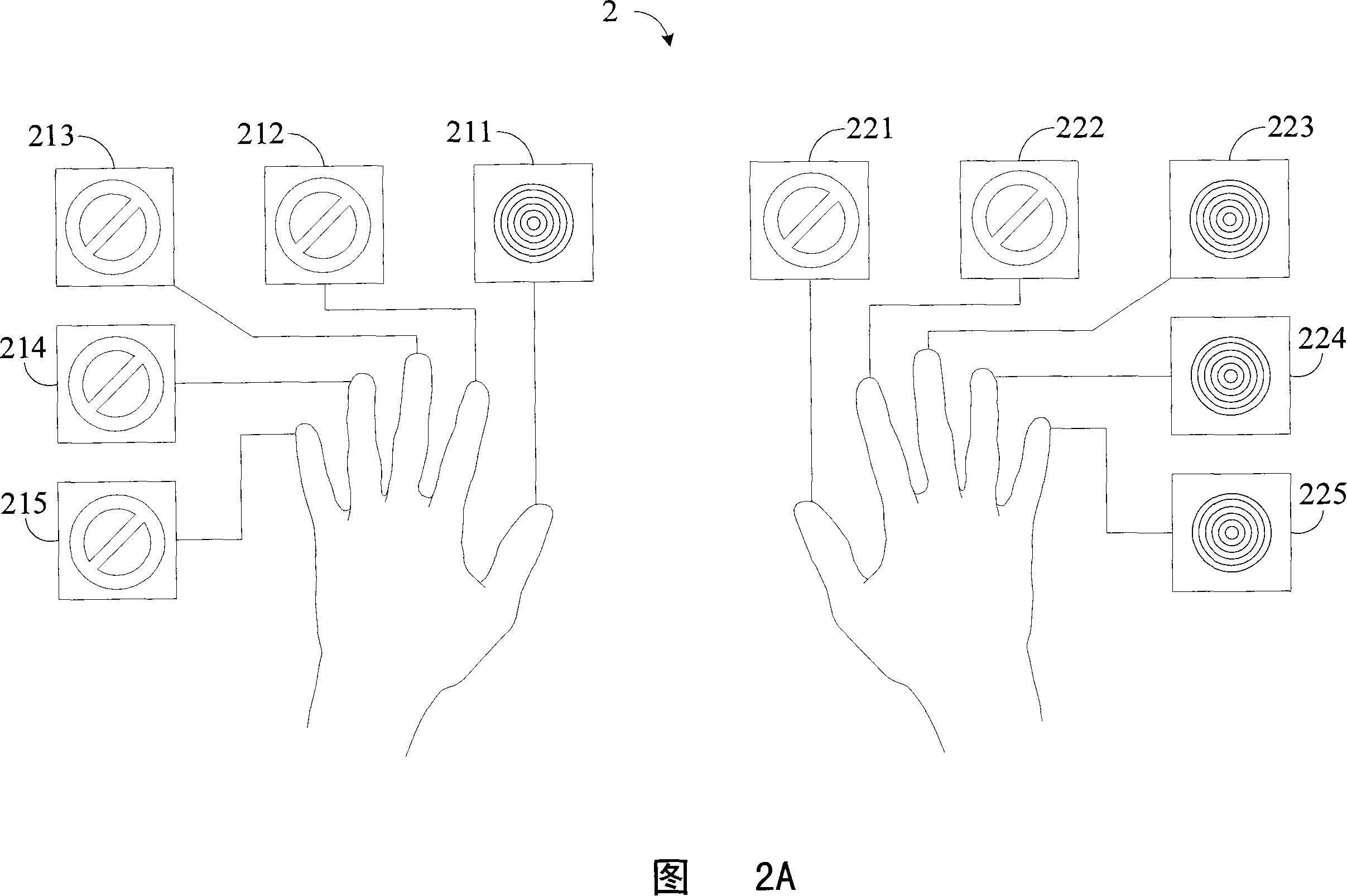

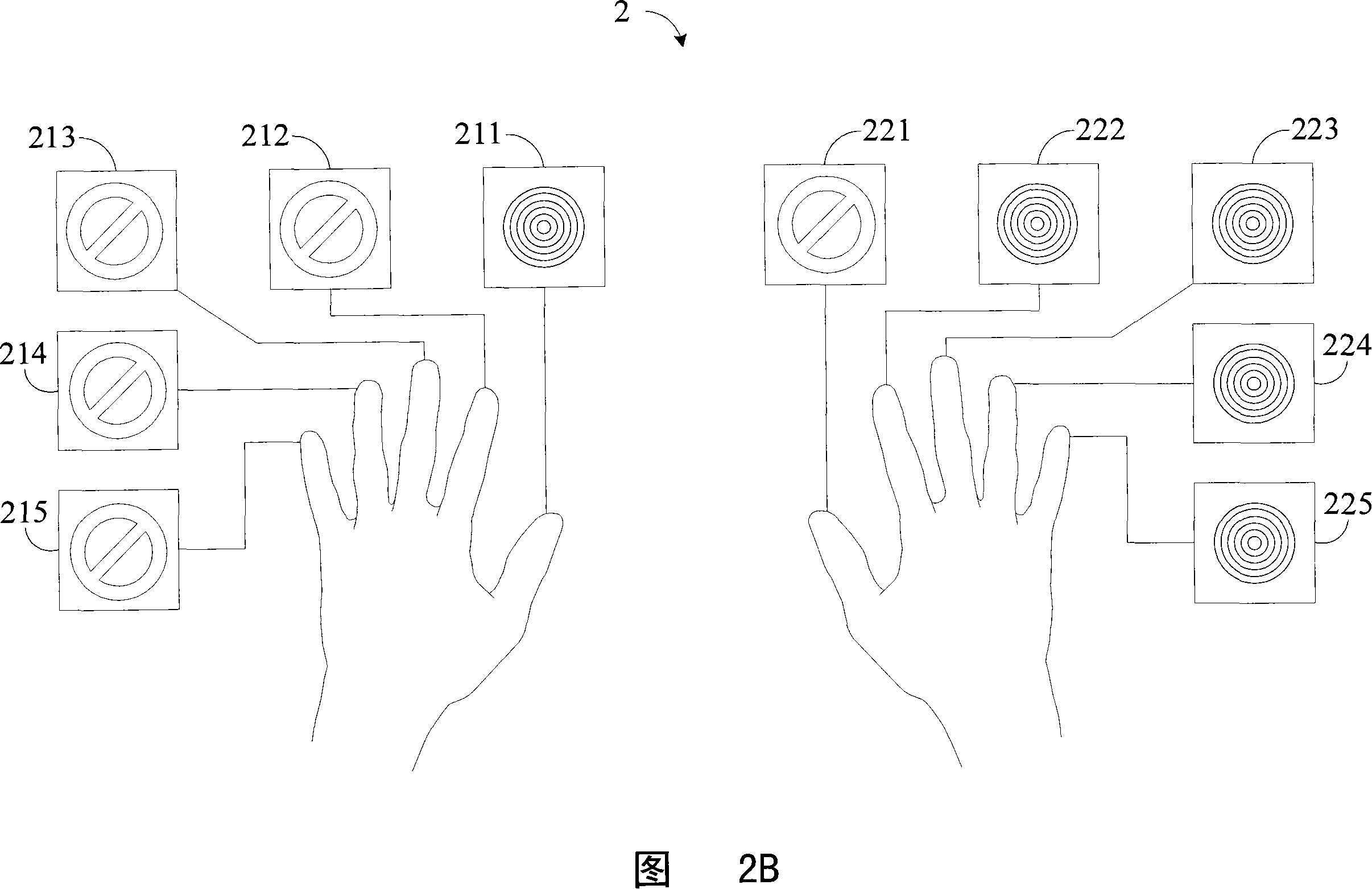

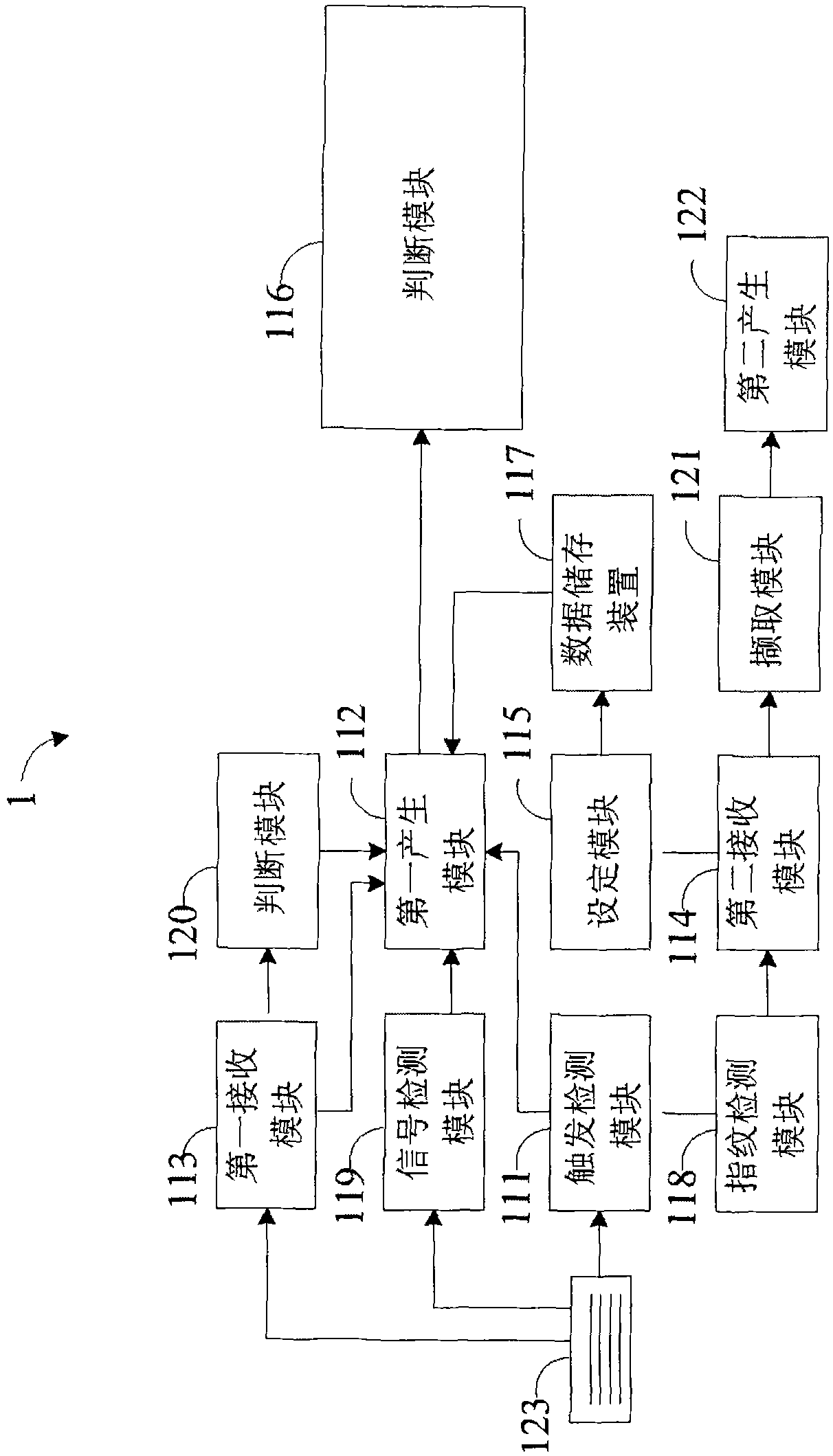

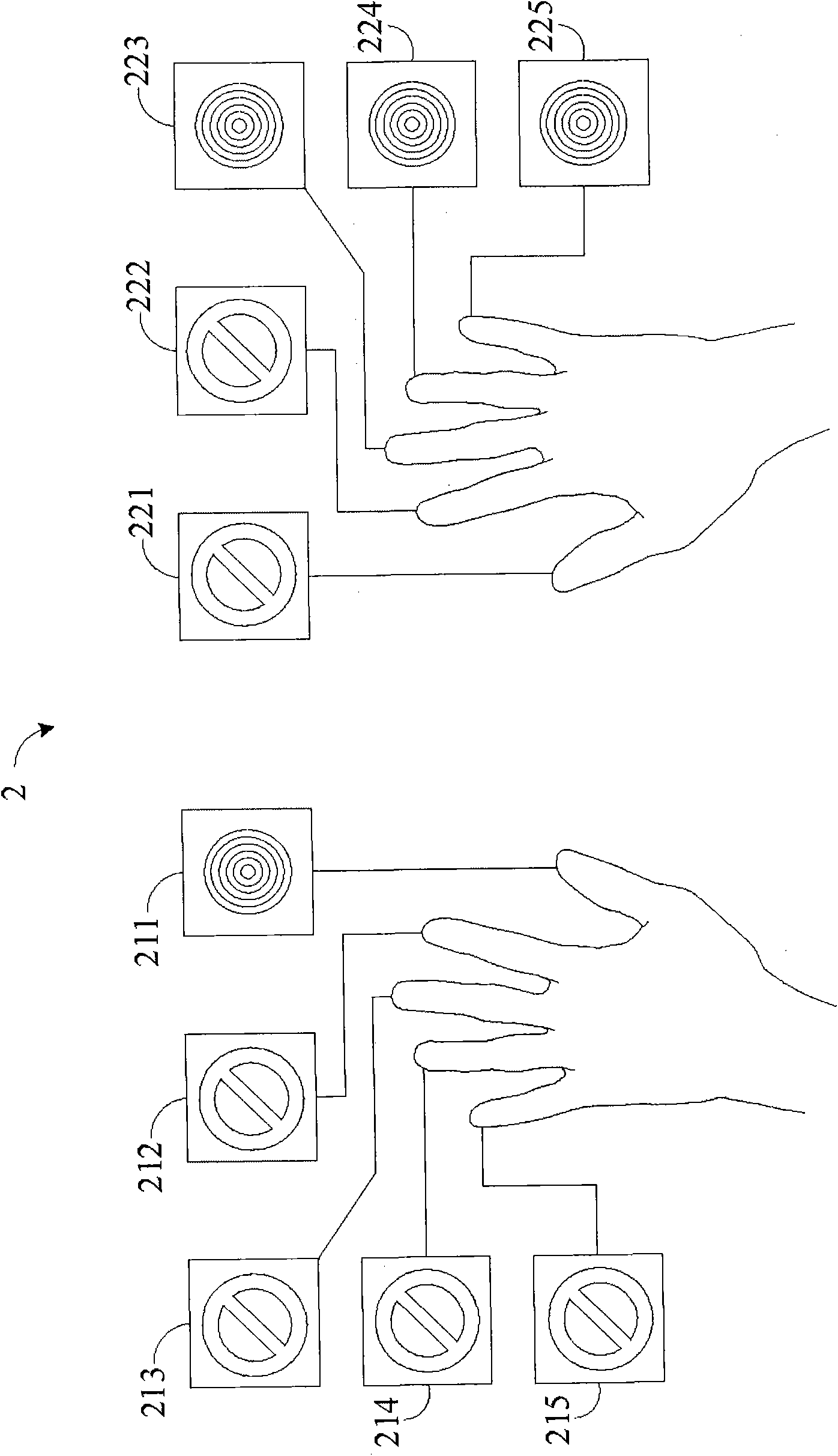

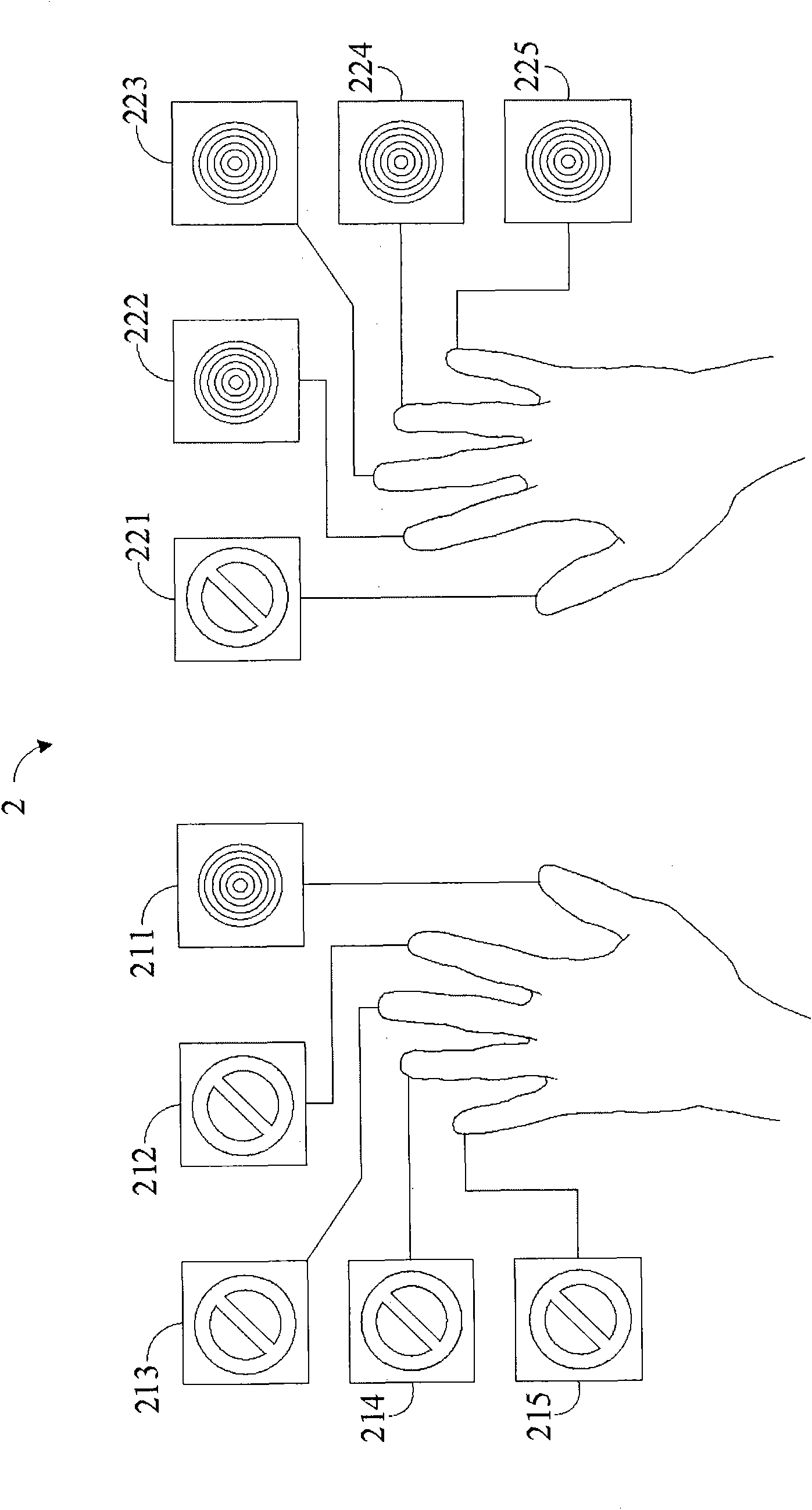

System and method for registering finger print, logging-ins application software and setting its log-ins mode

InactiveCN101140609AEnvironmental friendlyEliminate troubleCharacter and pattern recognitionDigital data authenticationPasswordSoftware engineering

A system and a method of fingerprint registration to define login modes of an application software and login the application software: In the fingerprint registration stage, the system receives a fingerprint signal, and defines the fingerprint signal as corresponding with one of a plurality of relevant finger data. In the application software definition stage, the system tests a login signal; the login signal includes an account number, a password and a command to execute the application software; instruct to display the relevant finger data; receive selected information corresponding with one of the relevant finger data; and define a corresponding relation between the application software, the account number, the password and the relevant finger data. In the login stage, the system receives the fingerprint signal; pick up the application software related to the fingerprint signal, the account number and the password; create a starting signal, and the sarting signal includes commands to utilize the account number and the password to execute the application software.

Owner:京达国际科技股份有限公司 +1

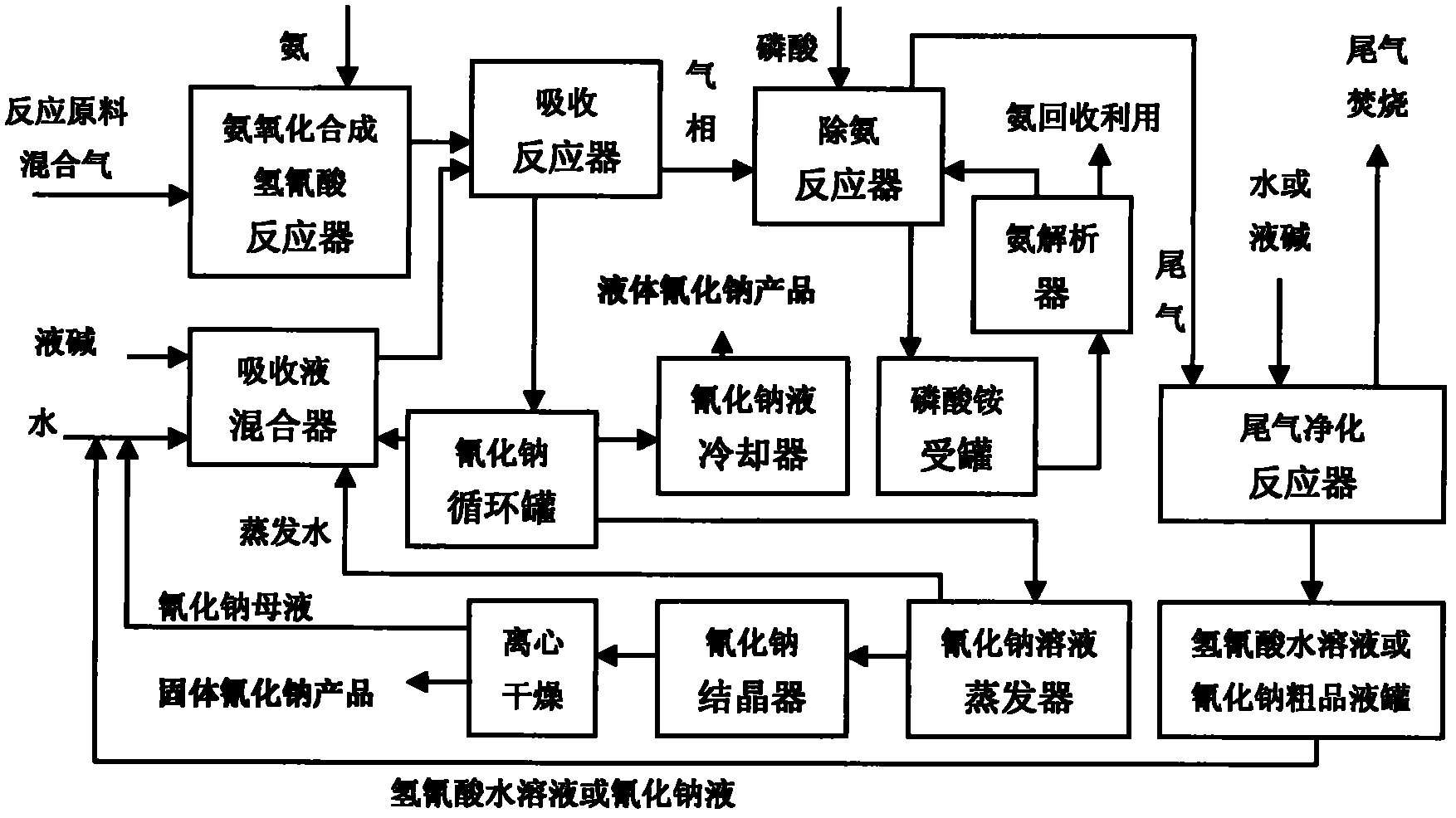

Environment-friendly clean production method for high purity sodium cyanide

InactiveCN103073027ARealize recyclingAchieving a circular economy modelAlkali metal cyanidesPhosphoric acidSodium cyanide

The invention provides an environment-friendly clean production method for high purity sodium cyanide. The production method comprises the following steps that: without removal of ammonia, hydrocyanic acid synthetic gas synthesized through ammoxidation is directly absorbed by and reacts with an aqueous sodium hydroxide solution to obtain a high purity aqueous sodium cyanide solution, and free ammonia remains in tail gas; the aqueous sodium cyanide solution is cooled and blended to obtain a high purity liquid sodium cyanide product, the high purity liquid sodium cyanide product undergoes condensation, crystallization and centrifugation to obtain a high purity solid sodium cyanide product, and mother liquor is indiscriminately used in liquid alkali absorption liquor; phosphoric acid or ammonium biphosphate is employed as a carrier for repeated cyclic indiscriminate application of ammonia so as to recover ammonia in the tail gas; and after recovery of ammonia, the tail gas is purified and absorbed with water or the aqueous sodium hydroxide solution, a small amount of the aqueous hydrocyanic acid solution or a crude aqueous sodium cyanide solution product is obtained while the tail gas is purified, the purified tail gas is burned with a tail gas boiler, and the aqueous hydrocyanic acid solution or the crude aqueous sodium cyanide solution product is indiscriminately used in the liquid alkali absorption liquor.

Owner:龙智

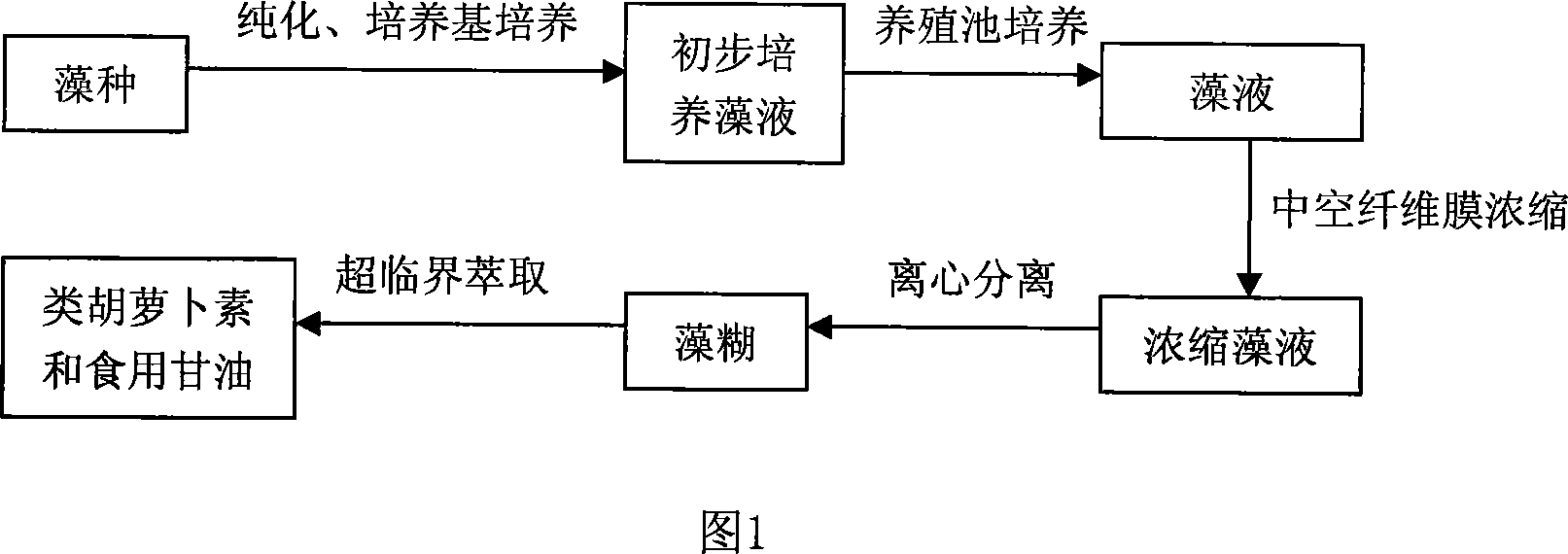

Method of extracting carotenoid and edible glycerol from Dunaliella sallina

InactiveCN101107991AEnvironmental friendlyLess damage to algaeOrganic chemistryChemical recyclingDunaliellaChemistry

A method for extracting carotinoid and edible glycerin from Dunaliella sallina is provided, which comprises the following procedures: optimized nurture of Dunaliella sallina, concentrate the sallina liquid with hollow fiber film method, centrifugal separation, dehydration and drying, extraction of carbon dioxide with super-critical method. The invention adds no chemical reagent in the extraction process, thus ensuring environment-friendly performance, low loss rate of Dunaliella sallina in the extraction process, high recovery rate of carotinoid and edible glycerin, simple process, low cost and suitable for large scale production.

Owner:TSINGHUA UNIV

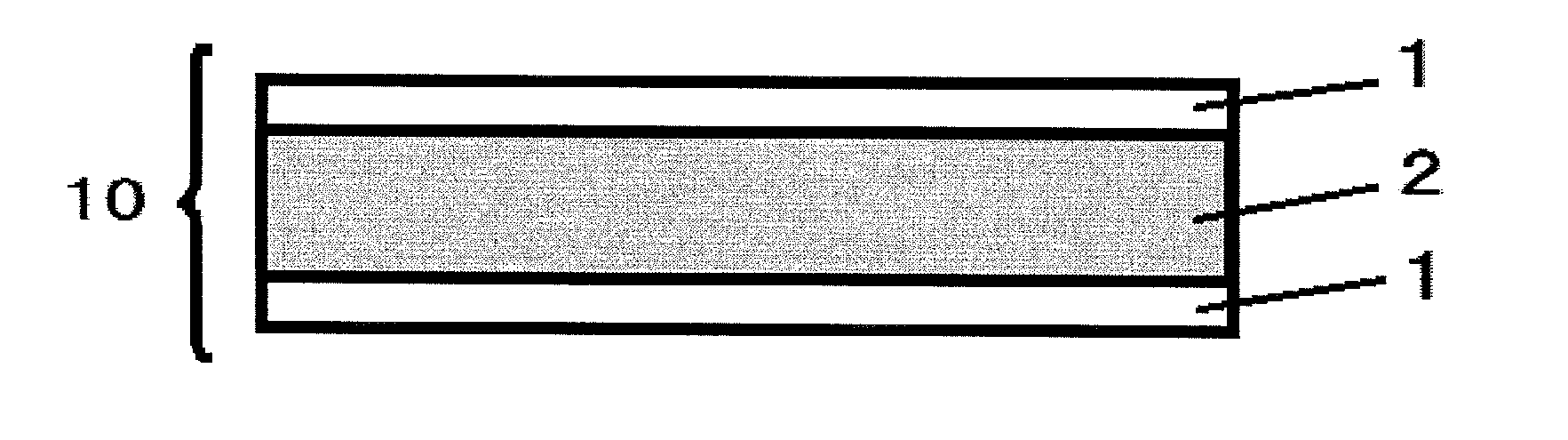

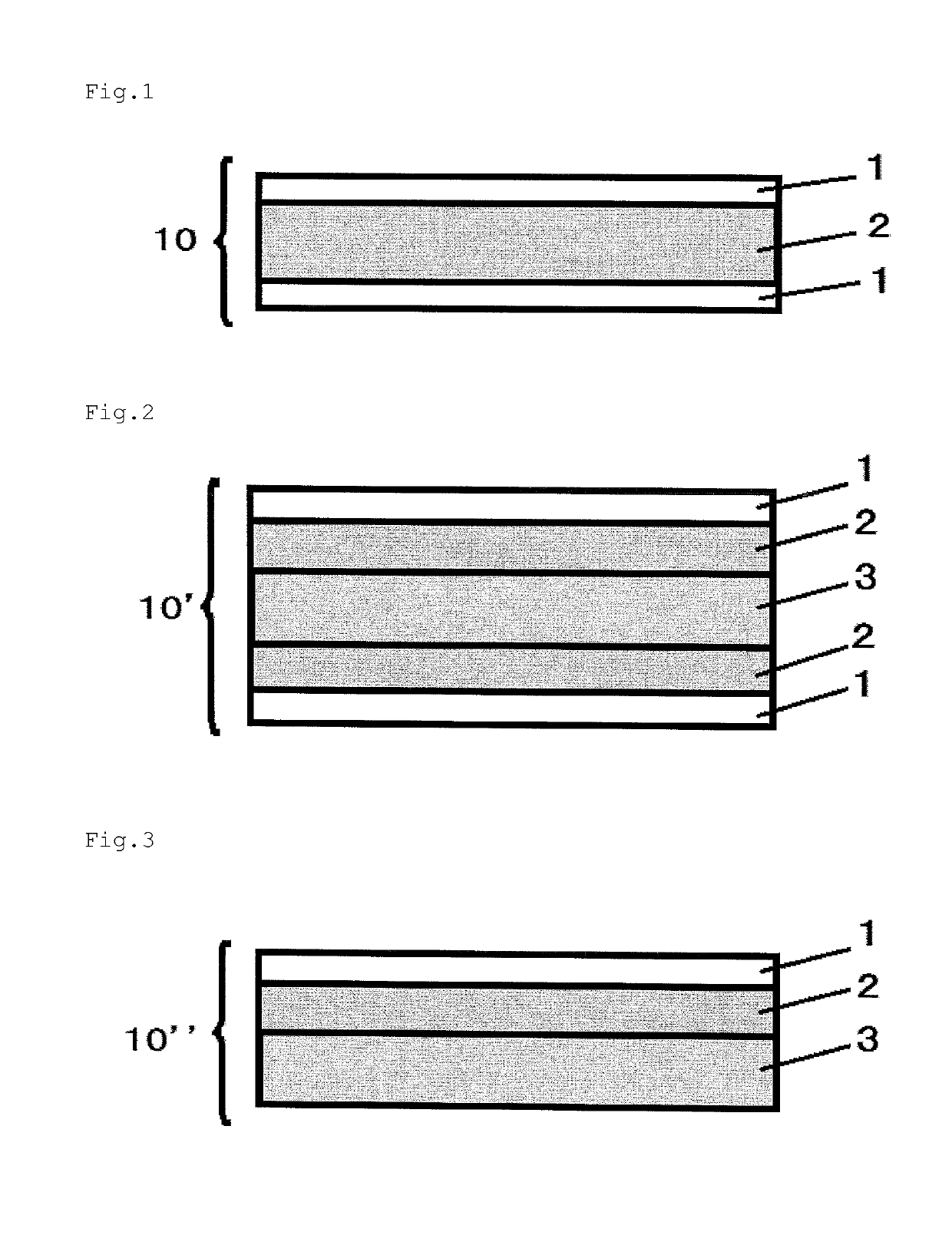

Crosslinked solid type pressure-sensitive adhesive composition, pressure-sensitive adhesive sheet comprising the composition, and pressure-sensitive adhesive sheet for waterproofing/airproofing comprising the sheet

InactiveUS20040258936A1Increase forceEvenly dispersedFilm/foil adhesivesSynthetic resin layered productsQuinoneOrganic solvent

A solid type pressure-sensitive adhesive composition capable of being applied without the necessity of using an organic solvent or water and a pressure-sensitive adhesive sheet, which are excellent in both adhesive force and holding power and, in particular, undergo no decrease in low-temperature adhesive force even when the adhesive layer thickness is small. The crosslinked solid type pressure-sensitive adhesive composition comprising (a) a rubbery polymer, (b) a tackifier, and (c) a crosslinking agent comprising at least one member selected from the group consisting of thiuram vulcanizing agents, quinoid vulcanizing agents, quinone dioxime vulcanizing agents, and maleimide vulcanizing agents.

Owner:NITTO DENKO CORP

System and method for registering fingerprints, setting logging mode of application software and logging application software

InactiveCN101799860AEnvironmental friendlyEliminate troubleCharacter and pattern recognitionDigital data authenticationFingerprintStart signal

The invention relates to a system and a method for registering fingerprints, setting a logging mode of application software and logging the application software. In the stage of fingerprint registering, the system receives a fingerprint signal and sets the fingerprint signal to correspond to one of relevant data of the finger; in the stage of setting the application software, the system detects a logging signal which comprises an account number, a password and an instruction for executing the application software; the relevant data of the finger is indicated and displayed; selective information is received and corresponds to one of the relevant data of the finger; the application software, the account number, the password and the relevant data of the finger are set to correspond to each other; in the stage of logging, the system receives the fingerprint signal; the application, the account number and the password related to the fingerprint signal are captured; and a starting signal is started and comprises the instruction which uses the account number and the password to execute the application software.

Owner:EGIS TECH +1

Solid type pressure-sensitive adhesive composition and pressure-sensitive adhesive sheets using the same

InactiveUS20010006723A1Reduce molecular weightReduce compoundingNatural rubber adhesivesLayered productsCrosslinked polymersLayer thickness

A solid type pressure-sensitive adhesive composition containing a rubbery polymer as the main polymer; and pressure-sensitive adhesive sheets which use the pressure-sensitive adhesive composition, are excellent in adhesive strength and holding power, retain the intact holding power even when allowed to stand at high temperatures or made to have a reduced adhesive layer thickness, and are free from the problem of adhesive protrusion or adhesive remaining. The pressure-sensitive adhesive sheets comprise a substrate and formed thereon a layer comprising a solid type pressure-sensitive adhesive composition obtained by a method comprising adding a tackifier to a rubbery polymer and treating the resultant mixture with an isocyanate crosslinking agent to crosslink the polymer.

Owner:NITTO DENKO CORP

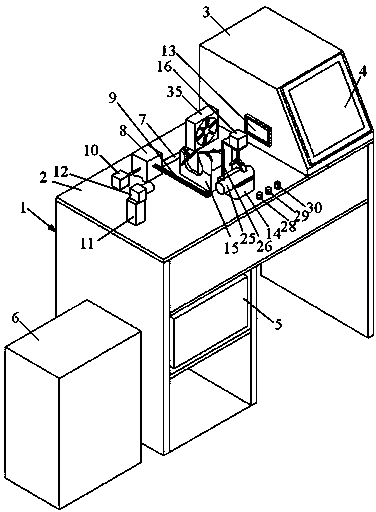

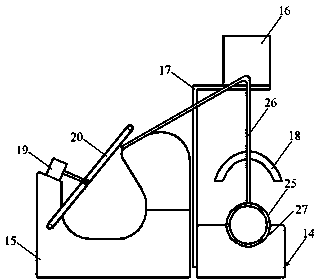

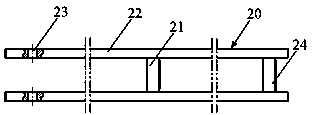

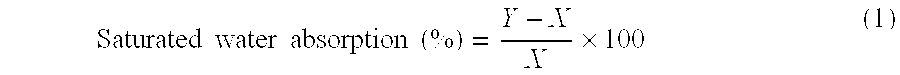

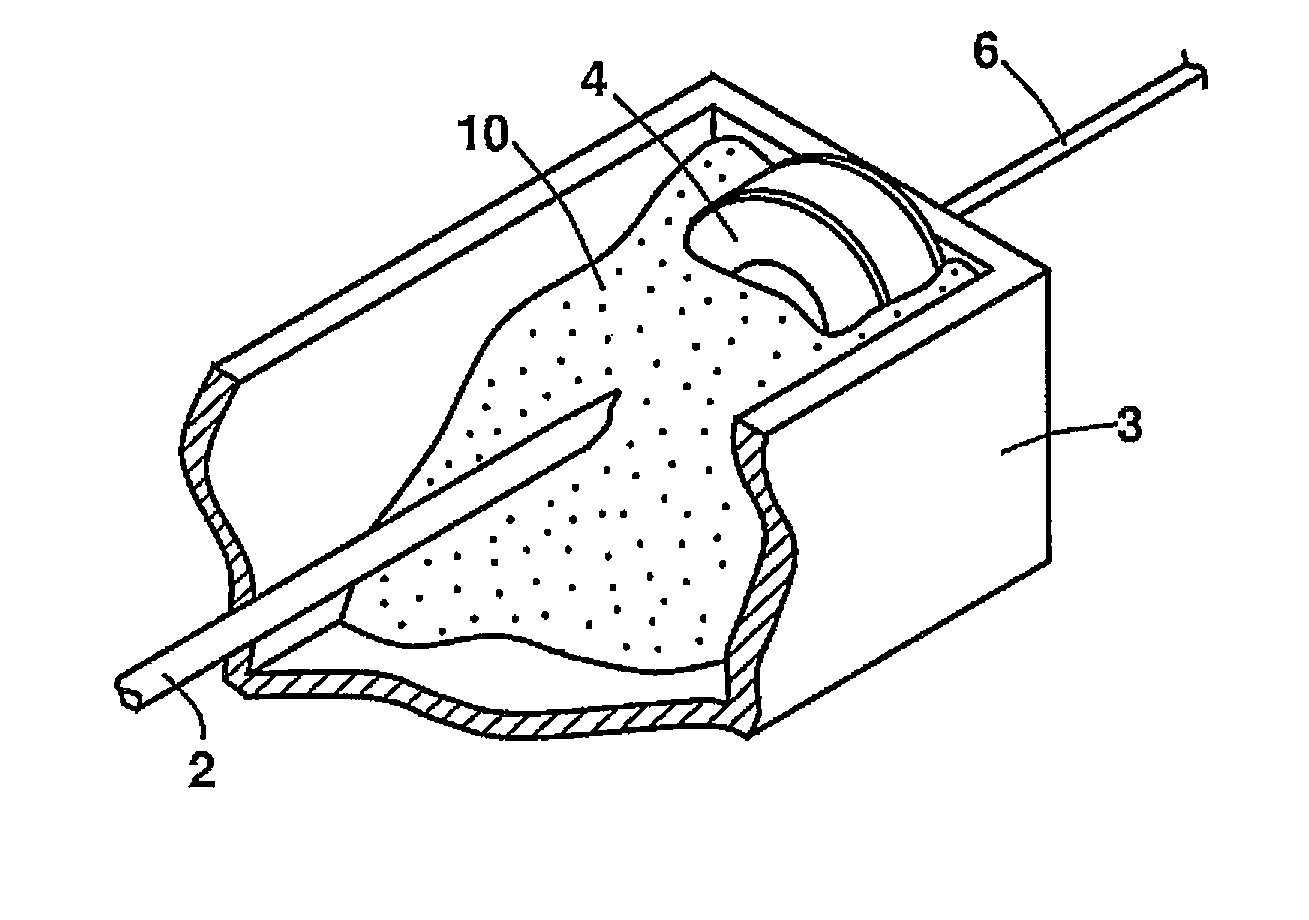

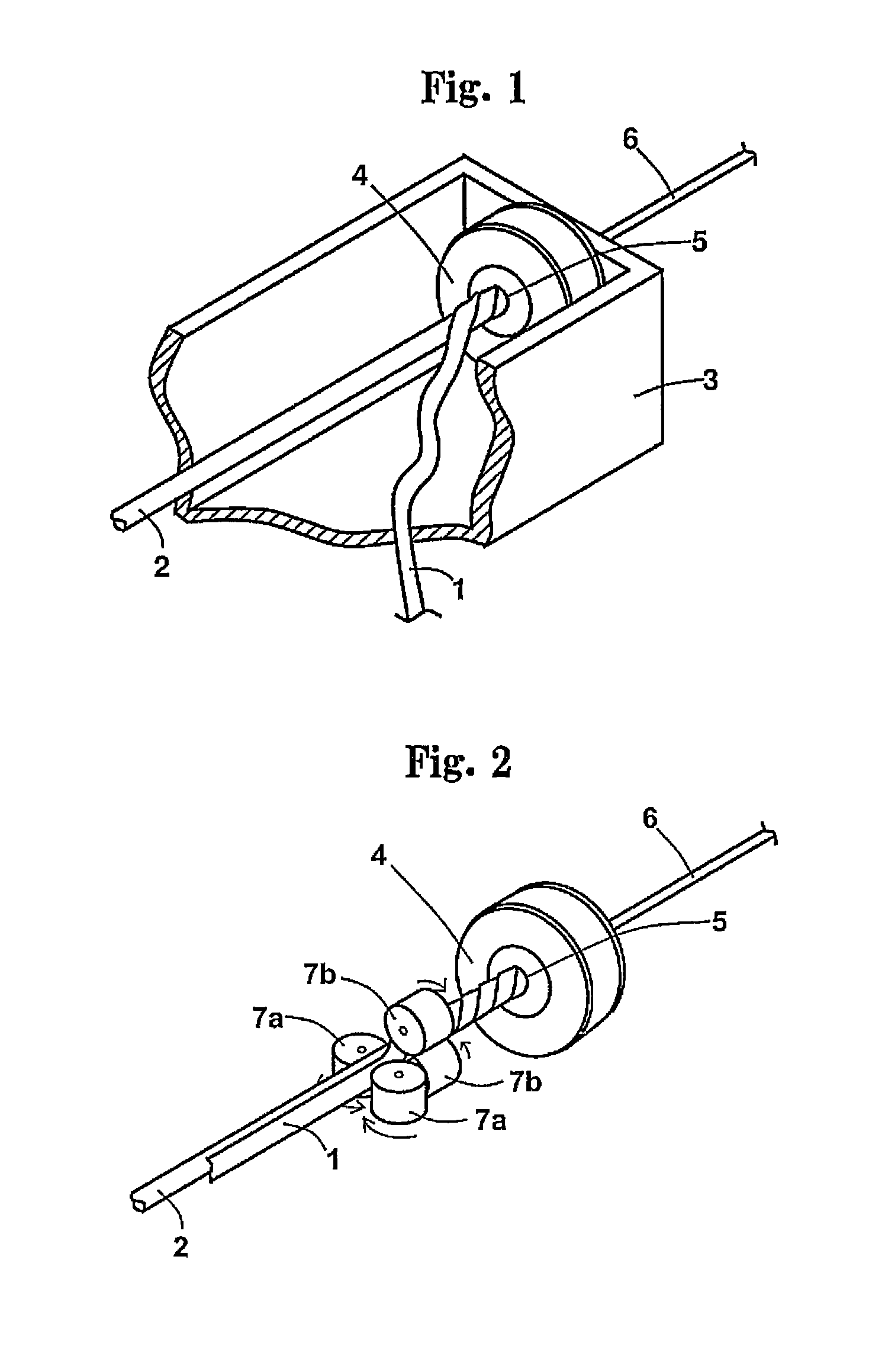

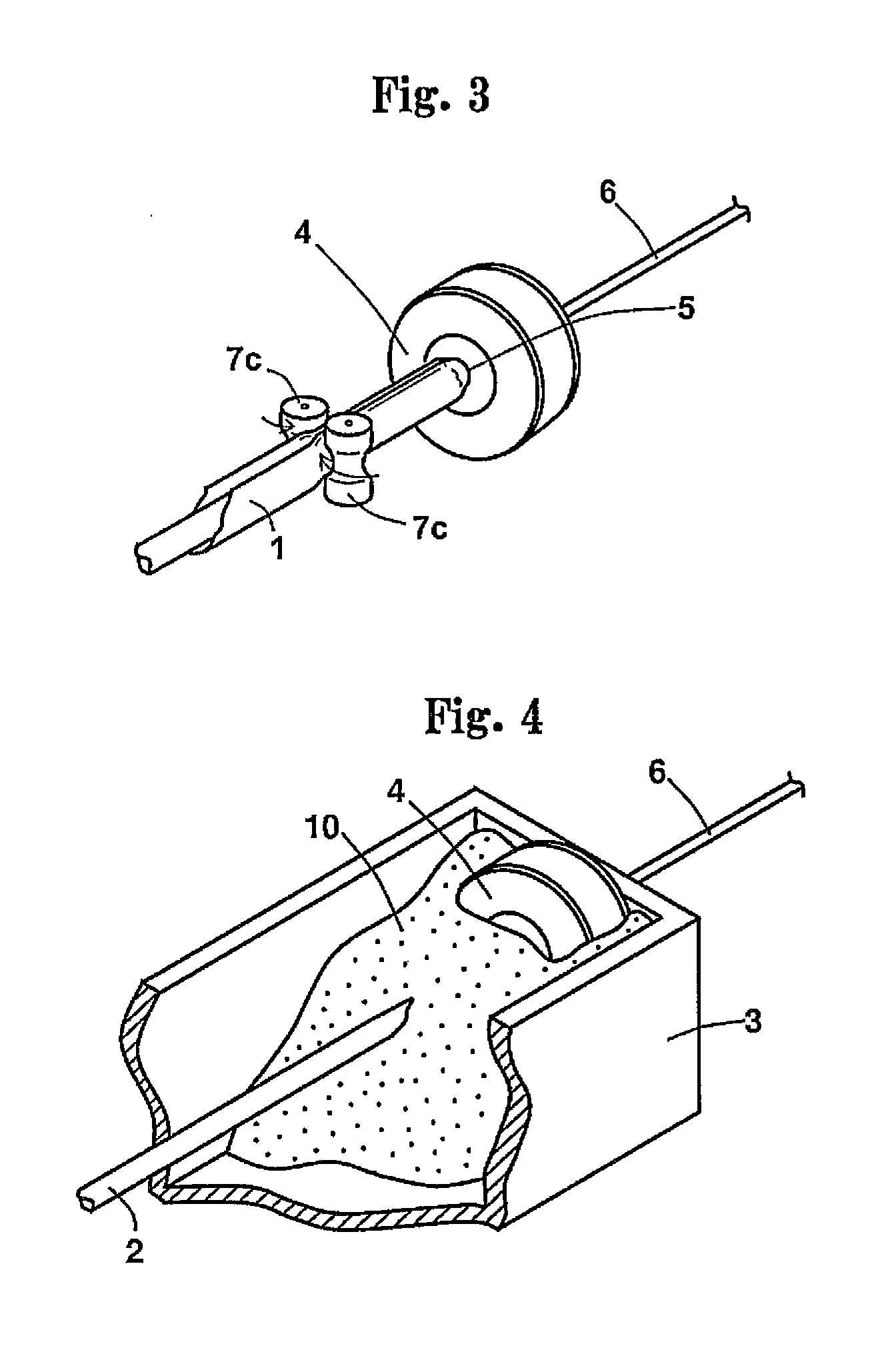

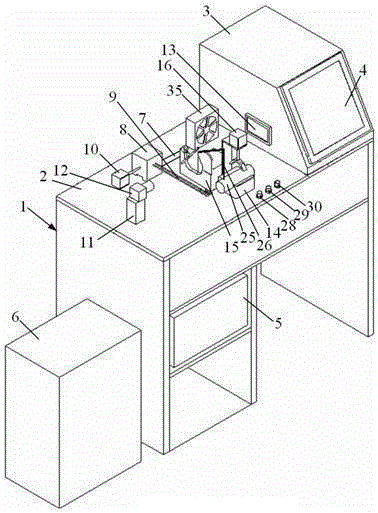

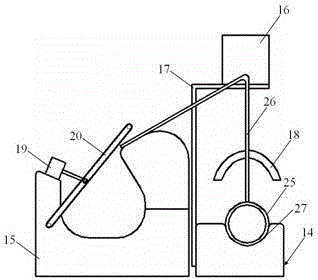

Special-shaped pipe fitting welding equipment

ActiveCN104191059APrevent bump deformationConvenient energy supplyWelding/cutting auxillary devicesAuxillary welding devicesThin walledSoldering

The invention discloses special-shaped pipe fitting welding equipment. The special-shaped pipe fitting welding equipment comprises a workbench, a high-frequency sensing heating unit, an image measurement unit, a mechanical positioning and clamping unit, an exhaust fan and a control cabinet, wherein the exhaust fan is installed behind the mechanical positioning and clamping unit, the mechanical positioning and clamping unit is arranged in the middle of the tabletop of the workbench, and a PLC is installed in the control cabinet. The special-shaped pipe fitting welding equipment is applicable to assembling small-size special-shaped pipe fittings according to a soldering method, and the problem that high assembly accuracy can not be achieved when the positioning standard is not ideal is solved by the adoption of image measurement and positioning; meanwhile, errors caused by clamping force in the welding and heating process are compensated for conveniently and rapidly, welding accuracy is improved, and thin-wall positions of a part can be effectively prevented from collision deformation in the assembly or disassembly process.

Owner:CHINA NTAIONAL NUCLEAR TIANJIN MACHINERY

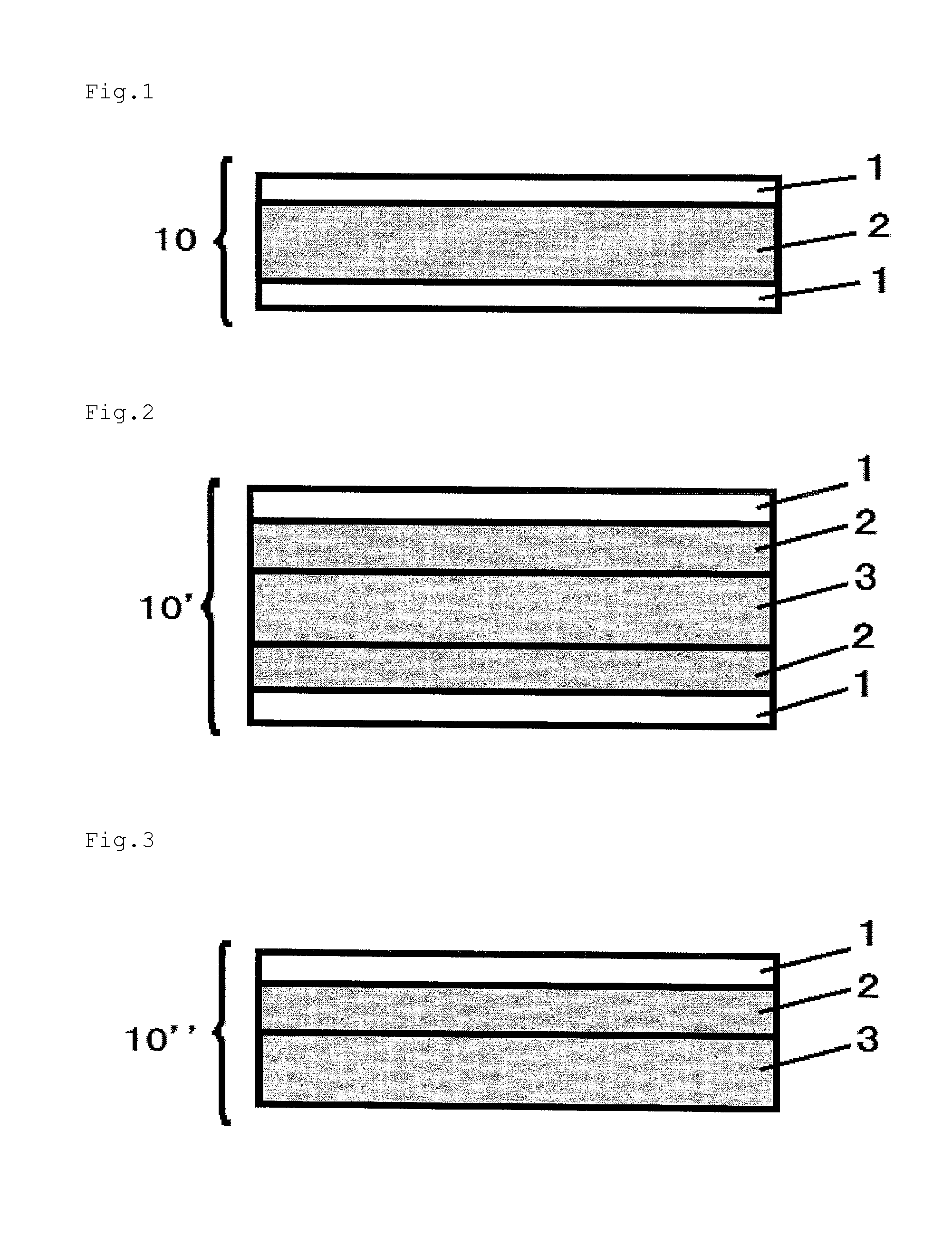

Pressure-sensitive adhesive layer, pressure-sensitive adhesive tape, and double-sided pressure-sensitive adhesive tape

ActiveUS20160017193A1High polymer concentrationReduce molecular weightNon-macromolecular adhesive additivesLayered productsPolyesterOrganic solvent

The purpose of the present invention is to provide: a polyester-based pressure-sensitive adhesive layer, for which a pressure-sensitive adhesive composition (pressure-sensitive adhesive solution) without any acrylic pressure-sensitive adhesive or the like which needs a large amount of an organic solvent and is difficult to apply thickly; to provide a polyester-based pressure-sensitive adhesive layer that is friendly to the global environment, can be applied thickly, has a high level of cost effectiveness and workability, and also has a high level of adhesion, retention, and repulsion resistance; and to provide a pressure-sensitive adhesive tape or double-sided pressure-sensitive adhesive tape having such a pressure-sensitive adhesive layer. The invention is directed to a polyester-based pressure-sensitive adhesive layer including a product made from a polyester-based pressure-sensitive adhesive composition including: a polyester obtained by polycondensation of at least a dicarboxylic acid component and a diol component; and a tackifier, the polyester-based pressure-sensitive adhesive layer having a gel fraction of 15% by weight or more to less than 40% by weight.

Owner:NITTO DENKO CORP

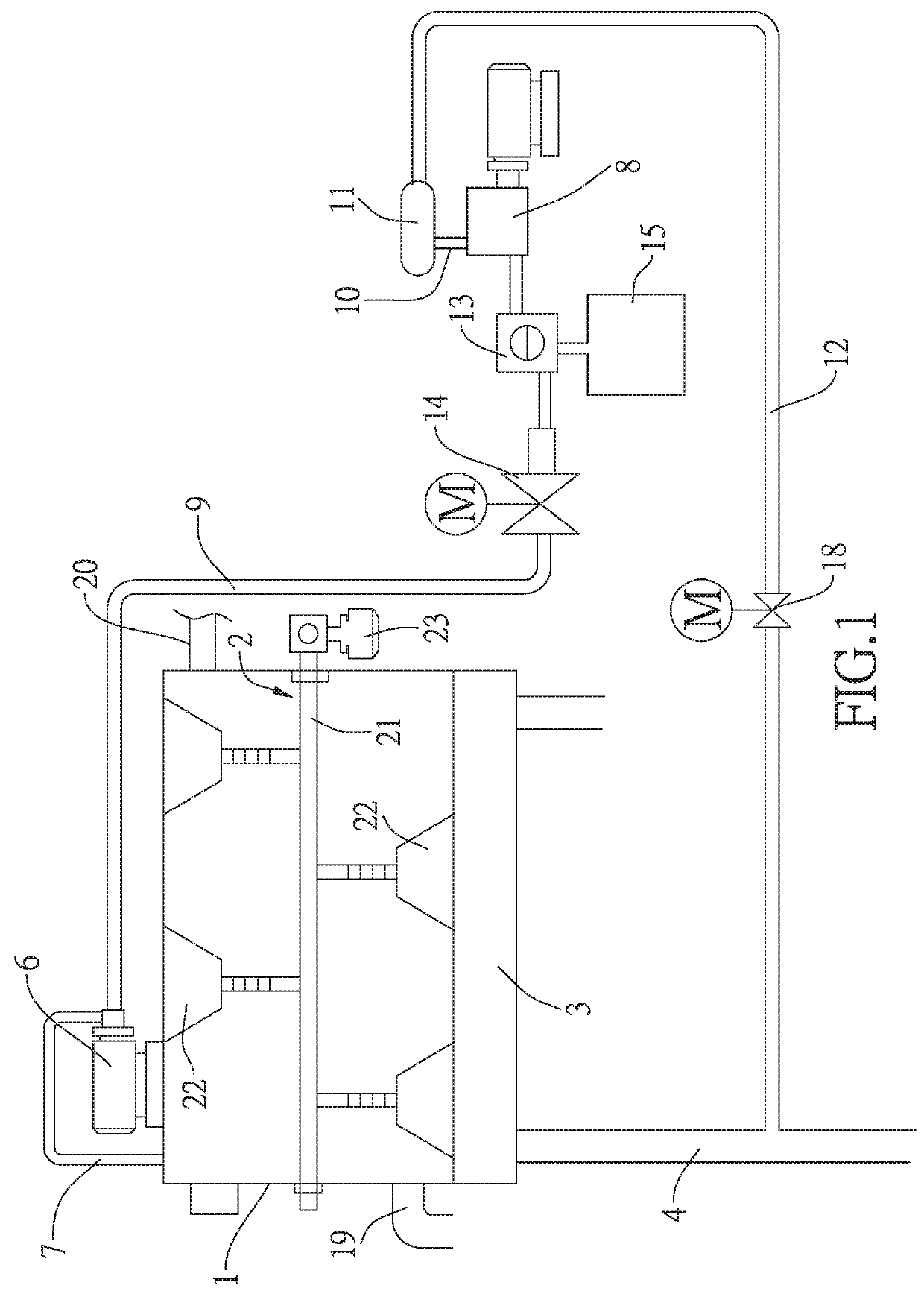

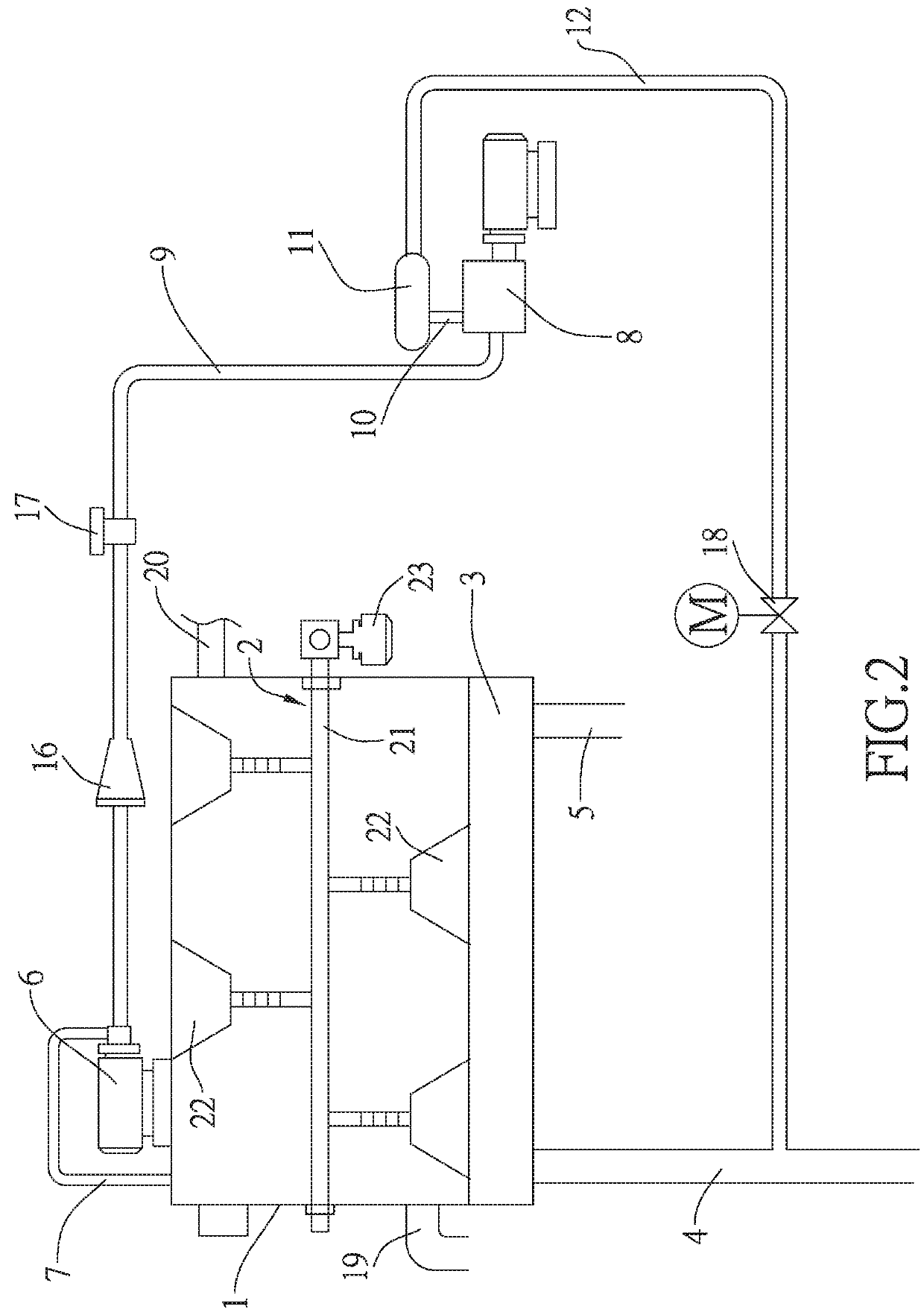

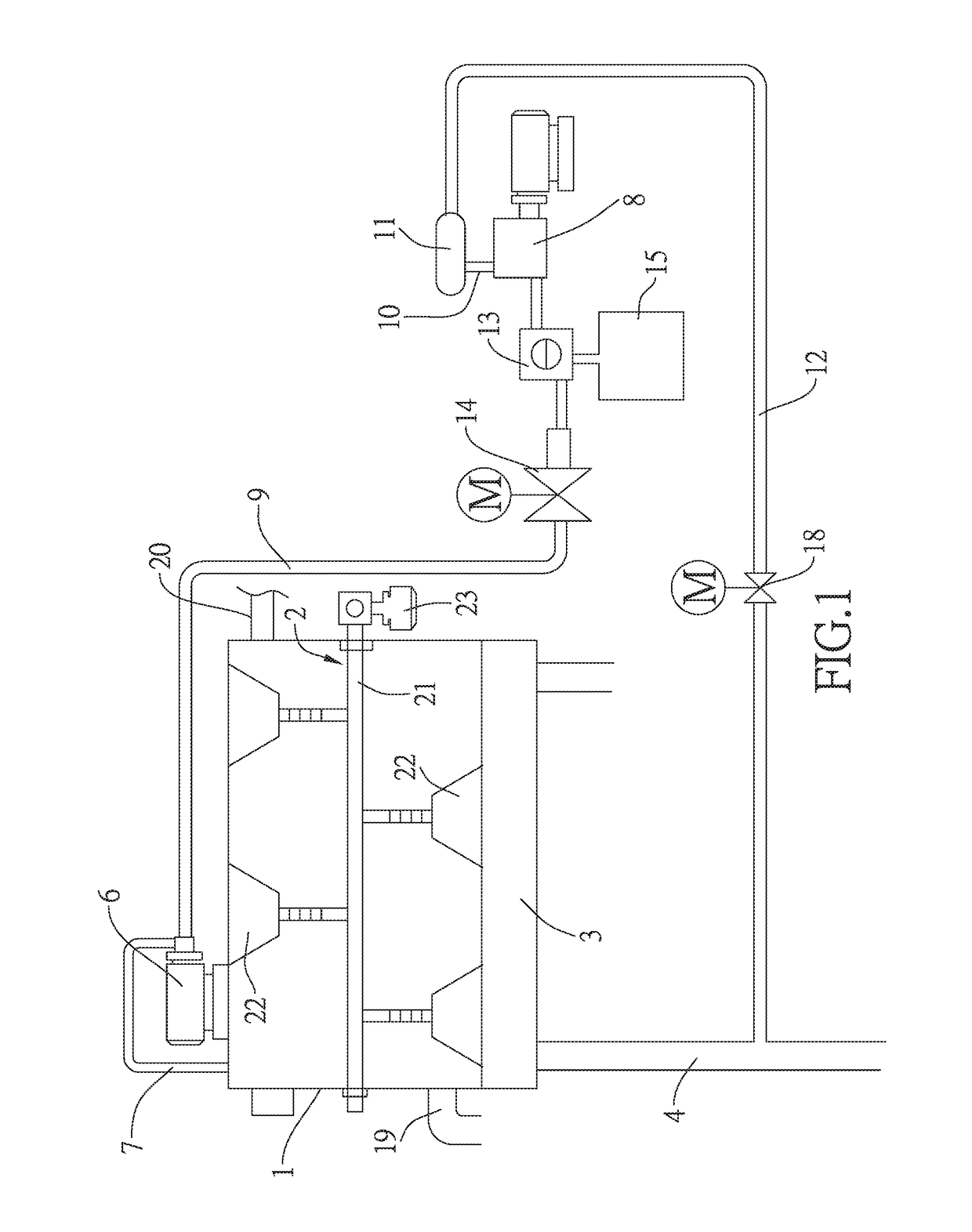

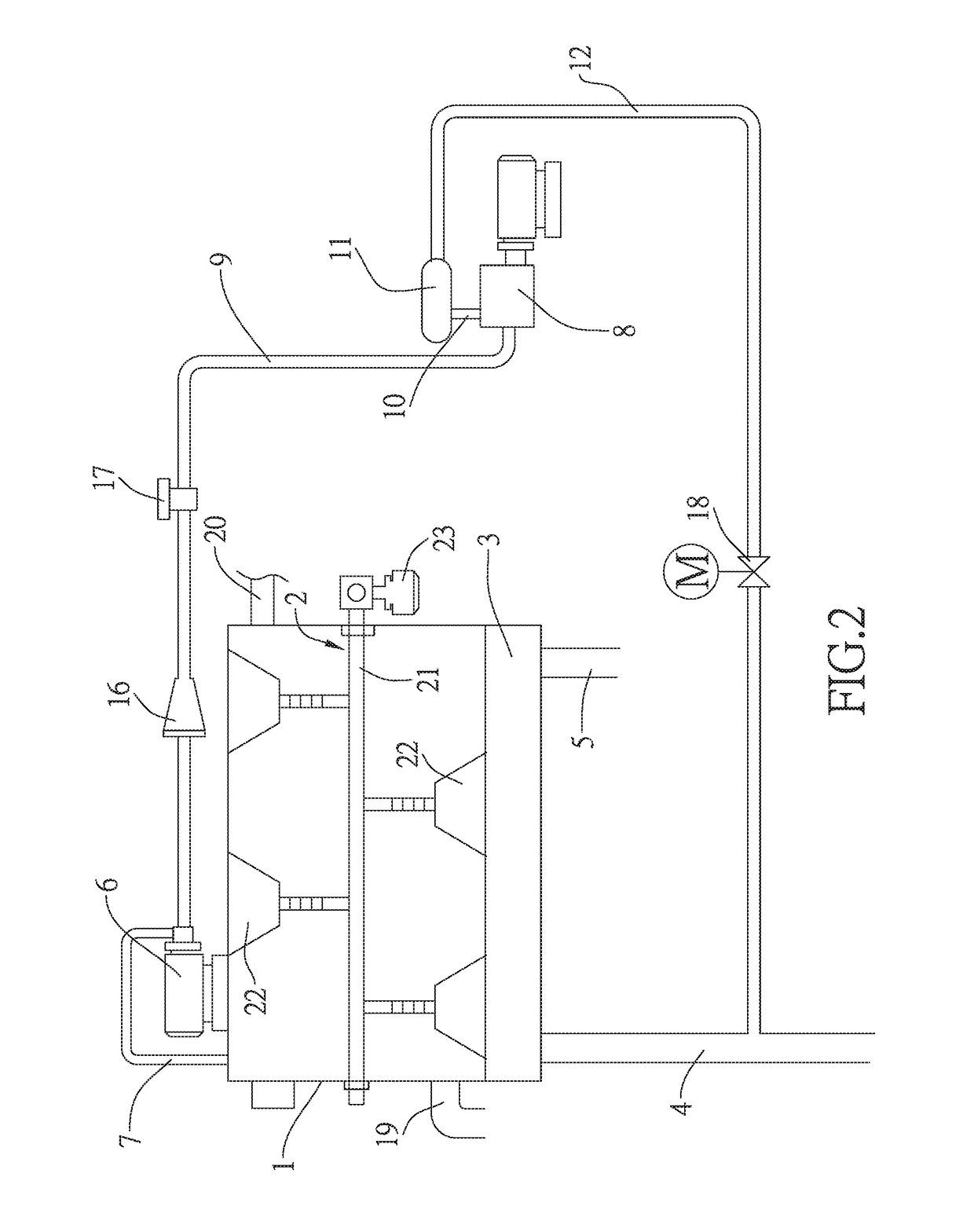

Steam heating type sewage treatment device

ActiveUS20180161692A1Reduce energy wasteEnergy resourceHeat recovery systemsSpecific water treatment objectivesSewageEngineering

A steam heating type sewage treatment device includes: a treatment tank connected to a sewage supply pipe, a stirring device disposed in the treatment tank; a steam heating device disposed on an outer surface of the treatment tank; a vacuuming device fixed to a top of the treatment tank and connected to the treatment tank via a first connecting pipe; a heating device connected to the treatment tank by a second connecting pipe and connected to a steam storage tank by a third connecting pipe, and a fourth connecting pipe connected between the steam input pipe and the steam storage tank to recycle the steam. The heating device pressurizes or heats the steam entering the vacuuming device and the connecting pipes, and the heated steam is guided by pipes into the steam heating device, thus achieving the effect of steam recycling.

Owner:LIAO CHUNG HENG

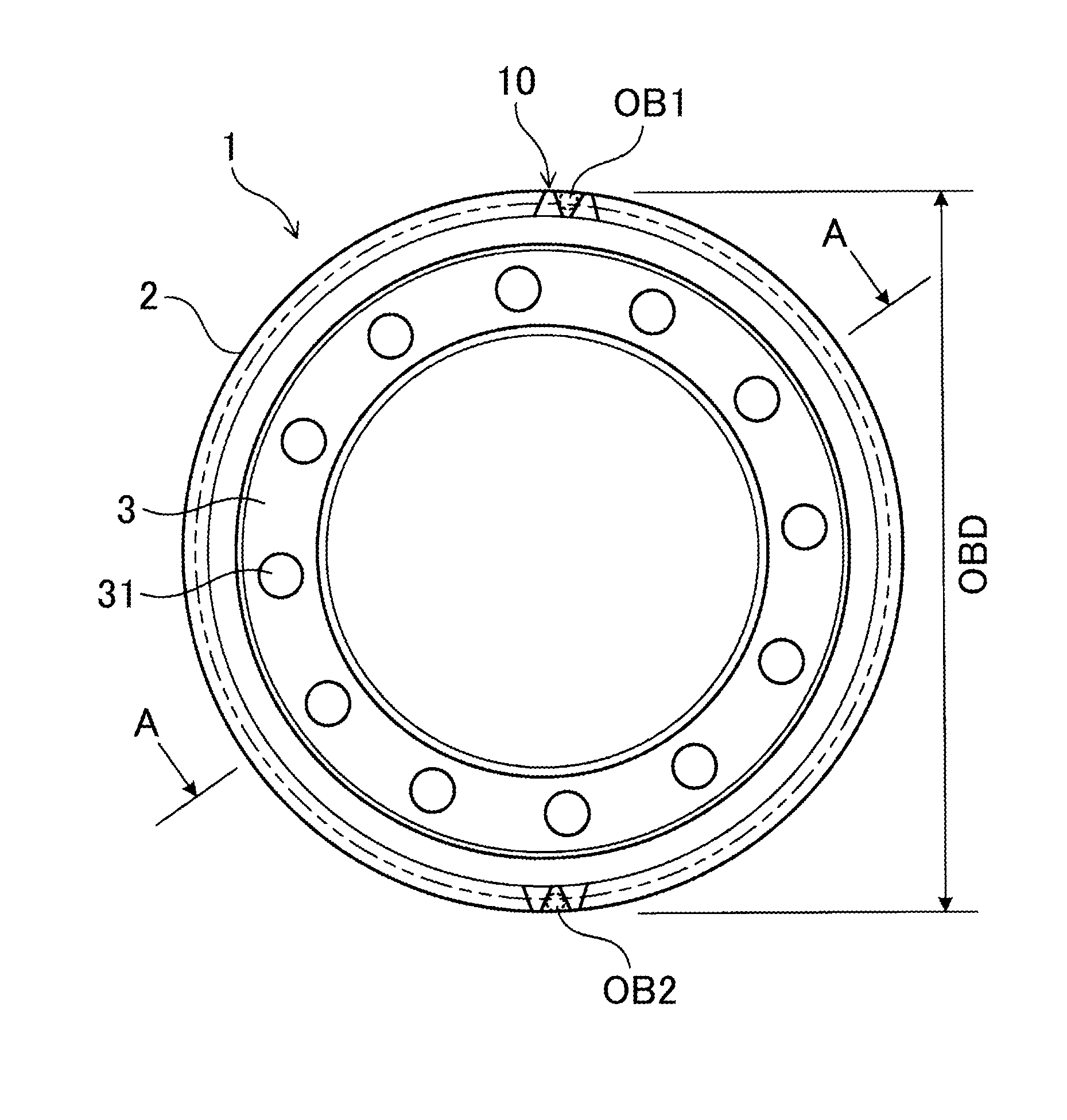

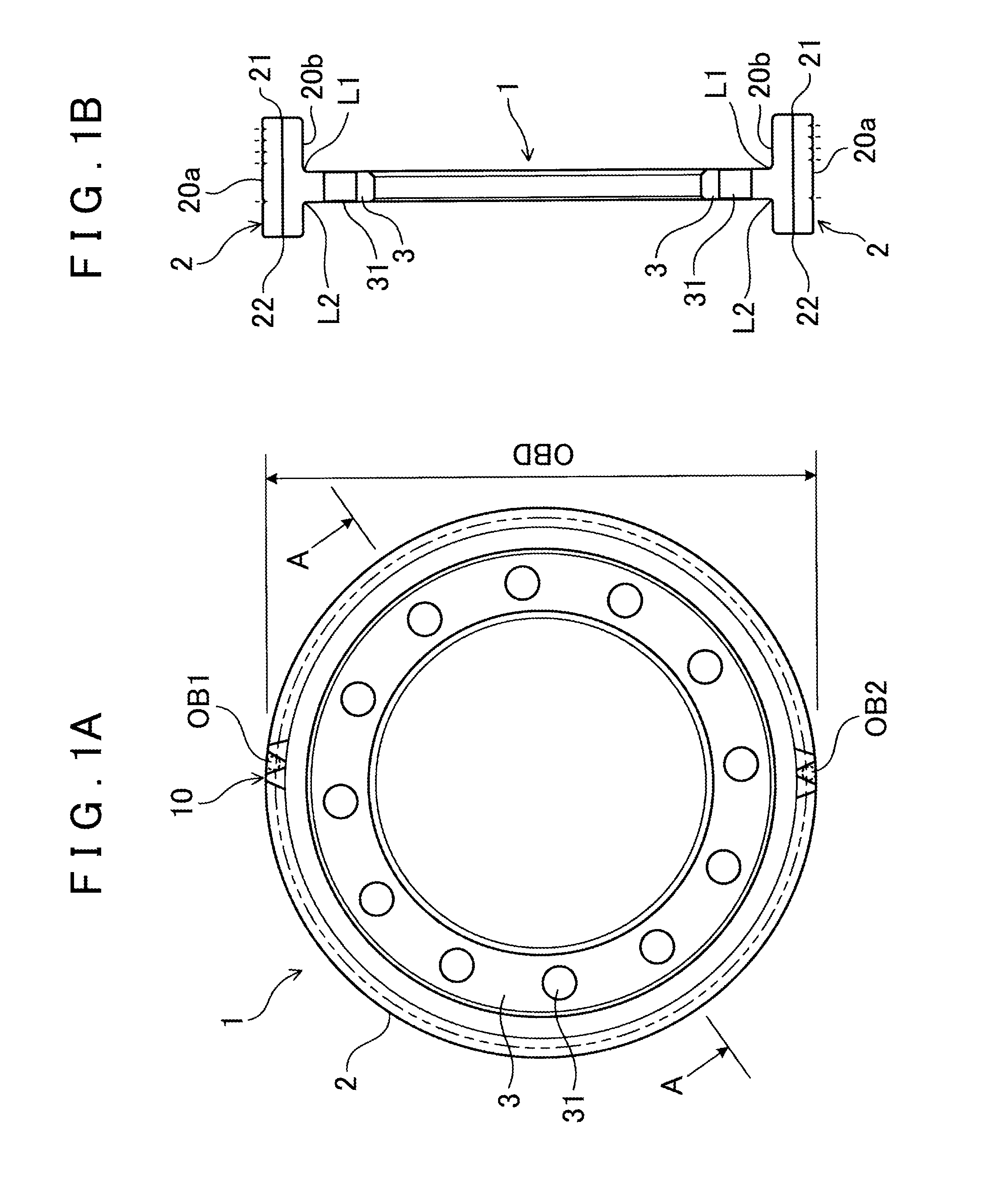

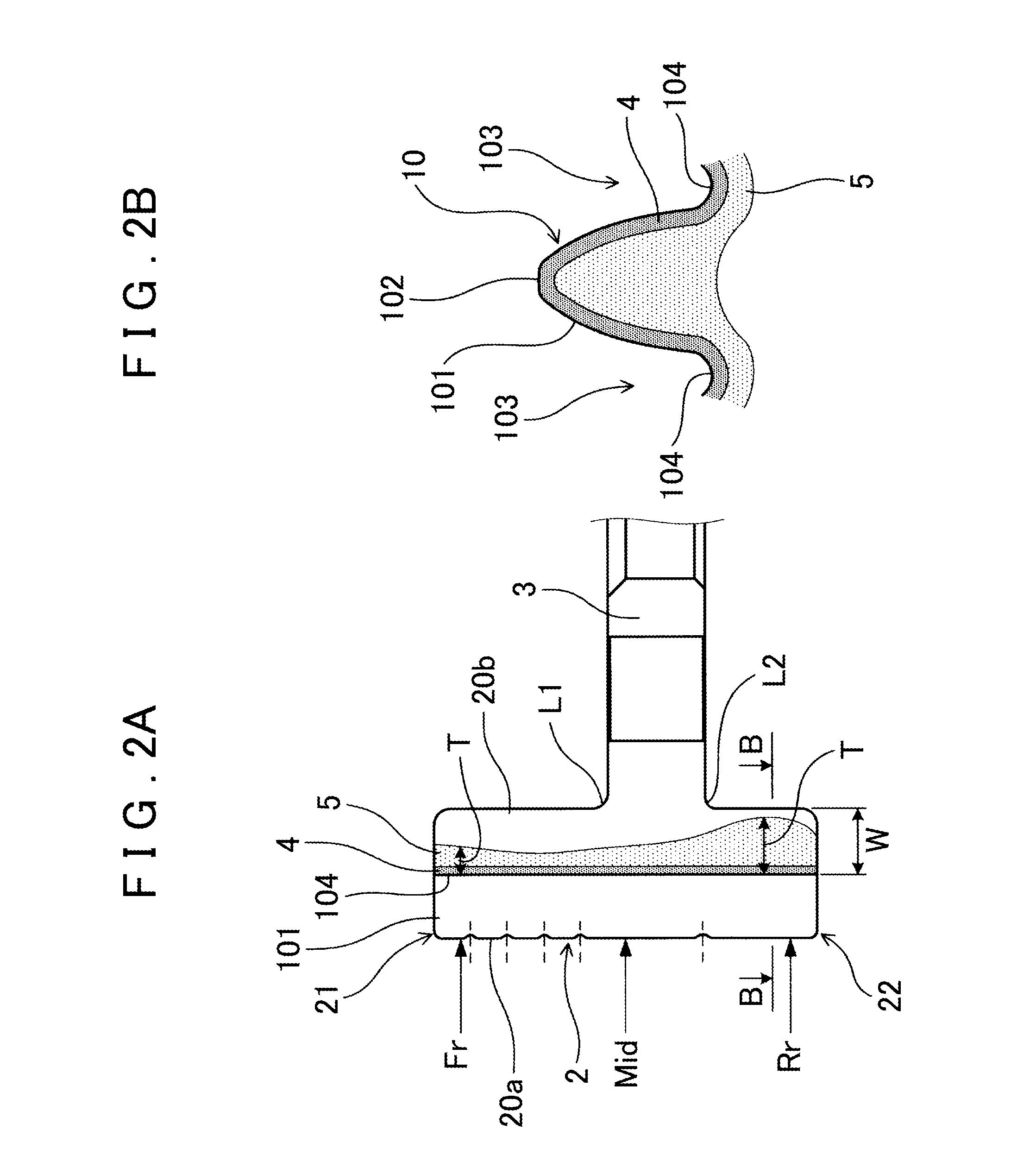

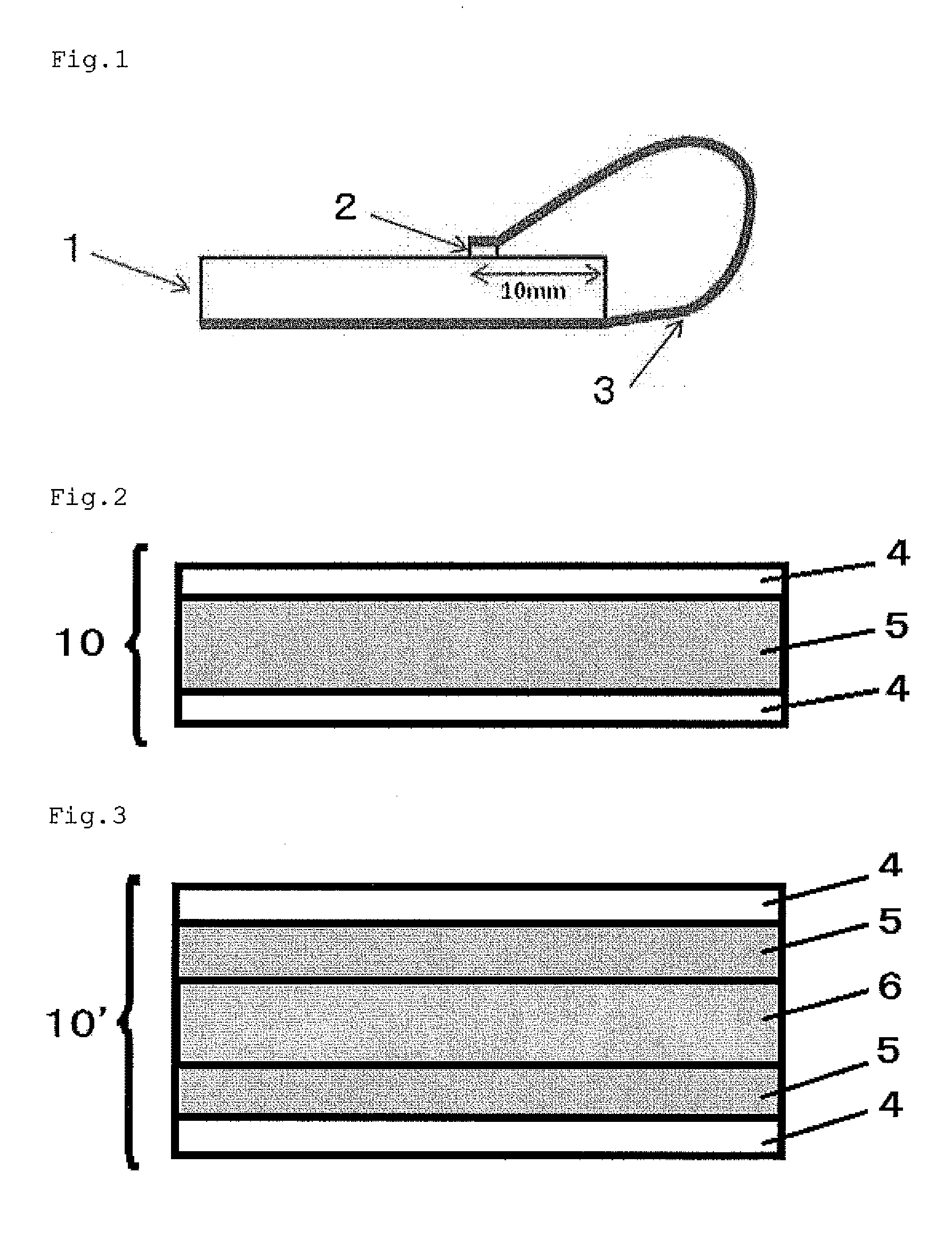

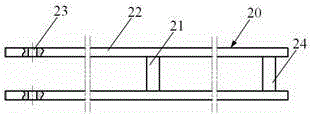

Steel gear and manufacturing method for the same

ActiveUS20130319154A1Increases internal hardnessHigh dimensional accuracyPortable liftingSolid state diffusion coatingSurface layerCoupling

A steel gear 1 includes a generally cylindrical outer peripheral ring portion 2, on an outer peripheral surface 20a of which a toothed shape 10 is formed, and a flange portion 3 provided to extend radially inward from an inner peripheral surface 20b of the outer peripheral ring portion 2. The outer peripheral ring portion 2 includes a first projecting portion 21 that projects toward one side in the axial direction with respect to a coupling position at which the first projecting portion 21 is coupled to the flange portion 3, and a second projecting portion 22 that projects toward the other side in the axial direction with respect to a coupling position at which the second projecting portion 22 is coupled to the flange portion 3. The axial length of the first projecting portion 21 is longer than the axial length of the second projecting portion 22. The outer peripheral ring portion 2 includes a carburized layer 4 formed in a surface layer of the toothed shape 10, and a thermal history layer 5 formed in a region including the carburized layer 4 and at a depth, in the inward direction from the outer peripheral surface 20a, larger than the depth of the carburized layer 4, the thermal history layer 5 having a history of being heated through high-frequency induction heating until becoming austenite. The depth T of the thermal history layer 5 in the inward direction from a tooth bottom 104 of the toothed shape 10 is larger at the second projecting portion 22 than at the first projecting portion 21.

Owner:AISIN AW CO LTD

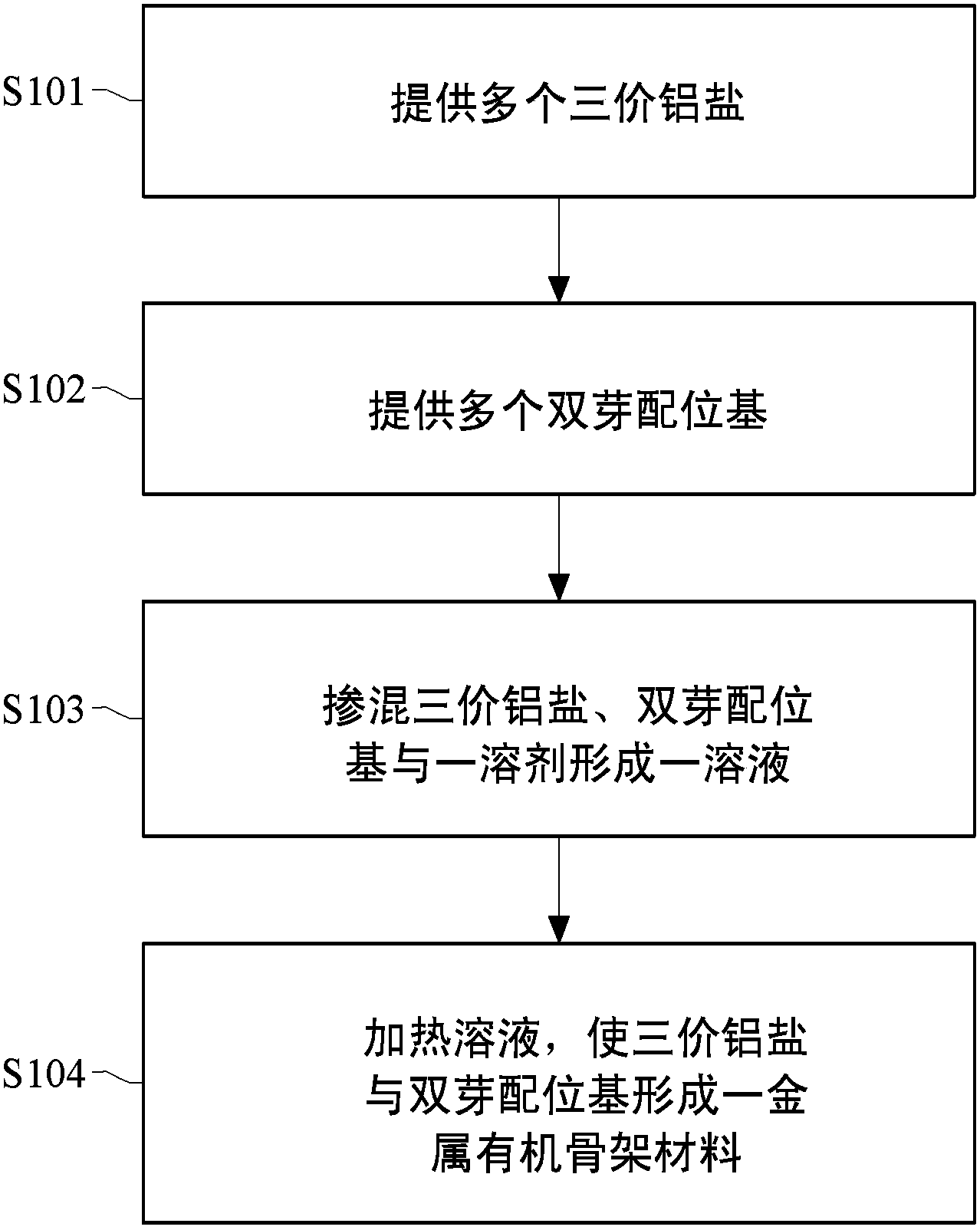

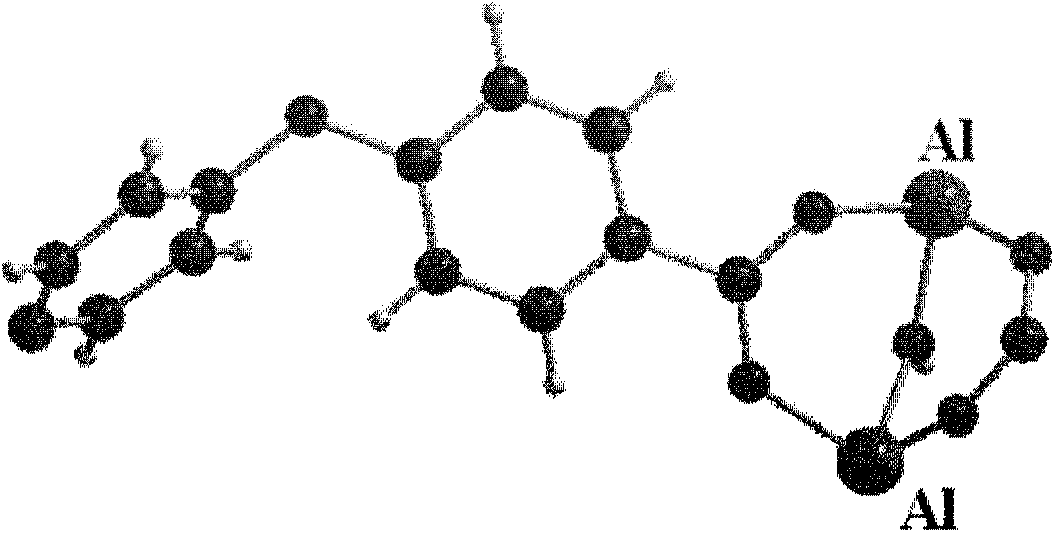

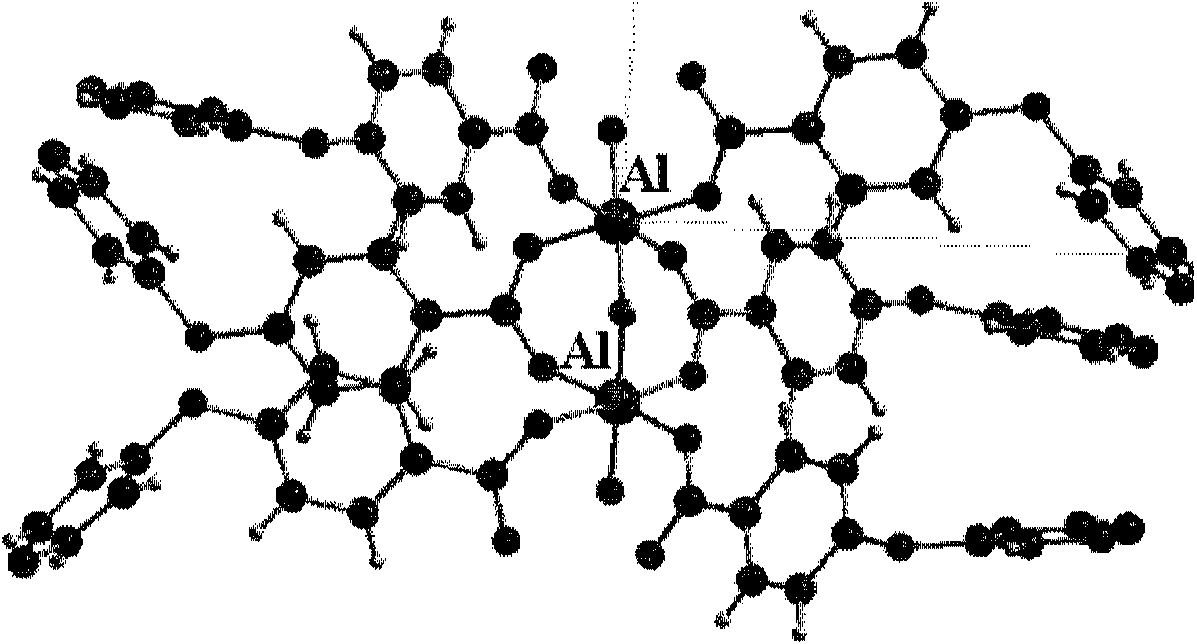

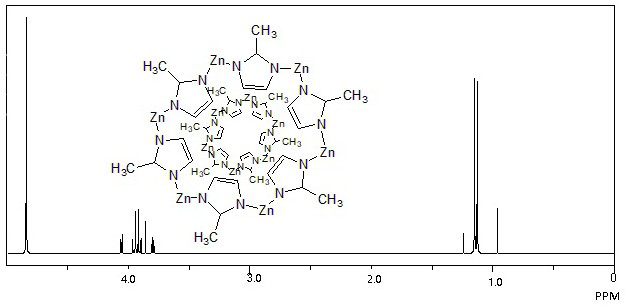

A metal-organic framework material, a preparing method thereof and uses of the material

ActiveCN104338513AEnvironmental friendlyGood resistance to moistureOther chemical processesDispersed particle separationMetal-organic frameworkAluminum Ion

The invention provides a metal-organic framework material, a preparing method thereof and uses of the material. The chemical formula of the material is M(OH)(L), wherein the M is a trivalent aluminum ion, and the L is a bidentate of 4,4'-oxybisbenzoic acid, or 4,4'-stilbenedicarboxylic acid. The preparing method includes blending a trivalent aluminum salt and the bidentate to form a solution, and heating the solution to prepare the material. The material can be used for absorbing gas.

Owner:IND TECH RES INST

Double-sided pressure-sensitive adhesive tape

InactiveUS20160017194A1Improve adhesionSuitable for applicationFilm/foil adhesivesSynthetic resin layered productsPressure sensitiveChemistry

Provided is a double-sided pressure-sensitive adhesive tape that is for fixing an electronic device component, has excellent adhesion, retention, and repulsion resistance, and can be produced with a plant-derived material having a high biomass degree. This double-sided pressure-sensitive adhesive tape for fixing an electronic device component is characterized by comprising a pressure-sensitive adhesive layer having a biomass degree of 50% by weight or more.

Owner:NITTO DENKO CORP

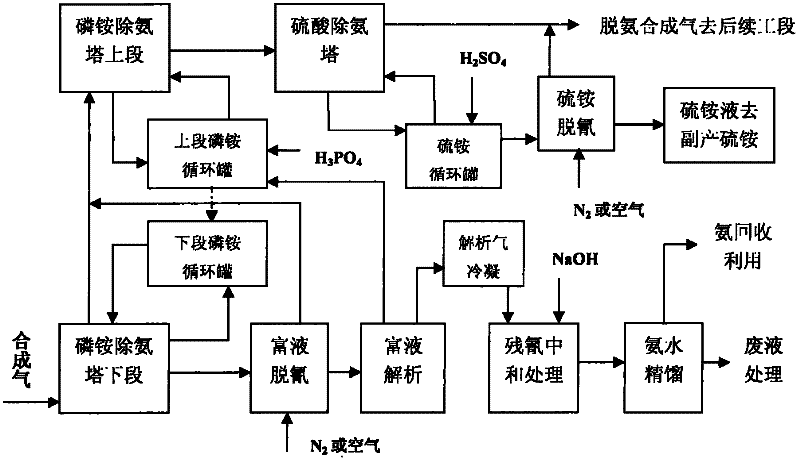

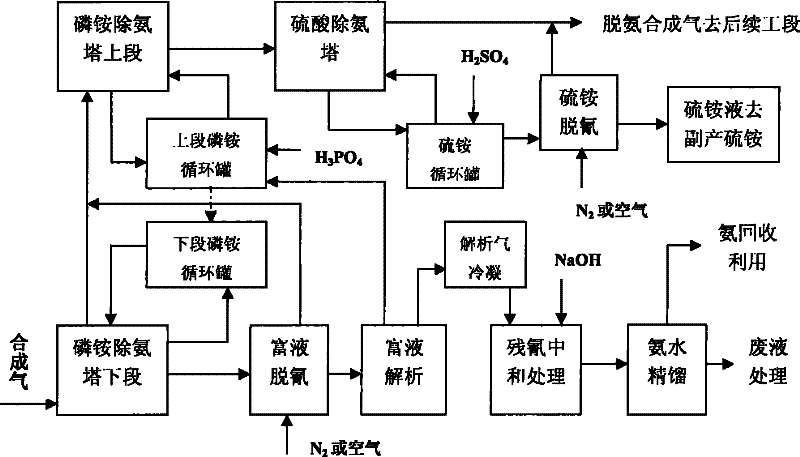

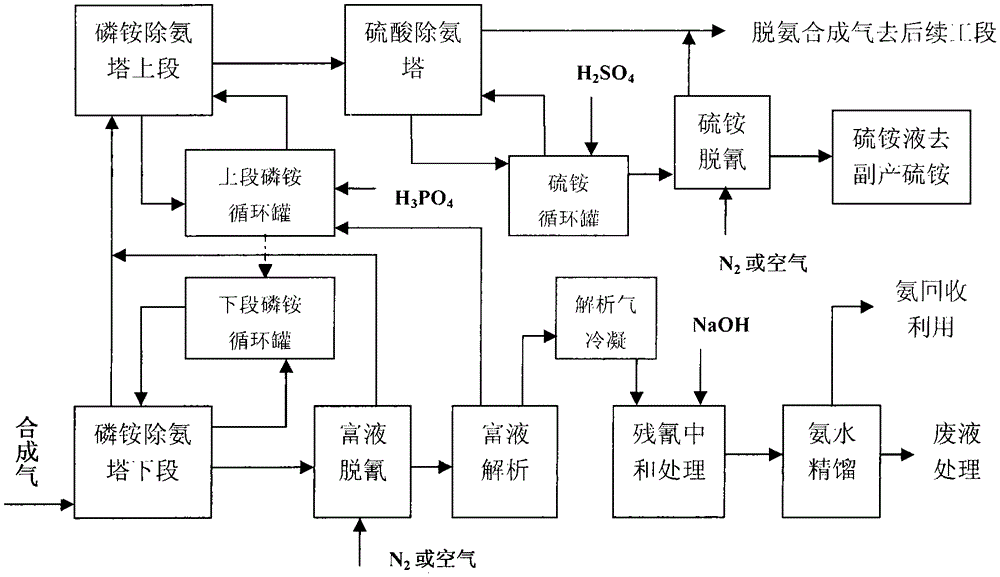

Environmental-protection process method for removing ammonia from ammoxidation synthesis gas

ActiveCN102530868ASave sulfuric acidLow costHydrogen separation using liquid contactSocial benefitsHydrogen phosphate

The invention provides an environmental-protection process method for removing ammonia from ammoxidation synthesis gas. The method is characterized in that a combined ammonia removal technological method composed of a primary ammonia removal process using phosphoric acid or ammonium dihydrogen phosphate and a fine ammonia removal process using sulfuric acid or ammonium bisulfate. In the primary ammonia removal process of ammoxidation synthesis gas, primary ammonia removal and ammonia recovery of the synthesis gas can be achieved through the repeated cycle of the following steps: phosphoric acid or ammonium dihydrogen phosphate absorbs free ammonia in the synthesis gas as a carrier in a primary ammonia removal tower, and is transformed to diammonium hydrogen phosphate; and diammonium hydrogen phosphate produces free ammonia in a desorption tower, and is transformed to ammonium dihydrogen phosphate. The ammoxidation synthesis gas enters a fine ammonia removal tower after the primary ammonia removal process, and fine ammonia removal process is achieved by using sulfuric acid or ammonium bisulfate as an absorber to absorb remaining ammonia in the synthesis gas after the primary ammonia removal process in a fine ammonia removal tower, wherein sulfuric acid or ammonium bisulfate is transformed to ammonium sulfate byproducts. The combined ammonia removal method can recover free ammonia in the ammoxidation synthesis gas to save resources and achieve real environmental protection property of the ammonia removal process, and has good economic and social benefits.

Owner:李宽义

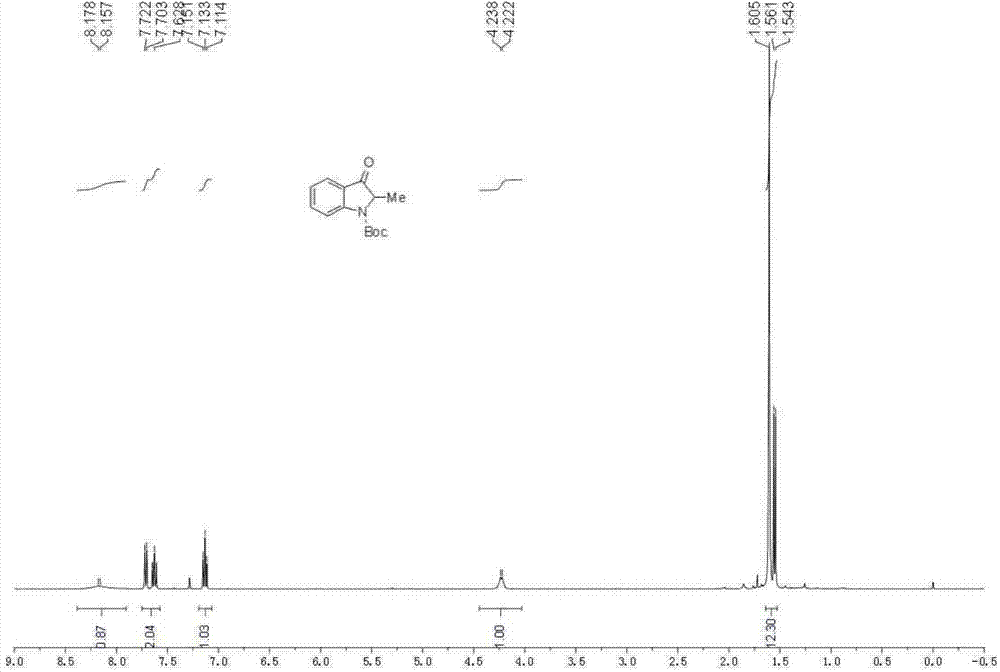

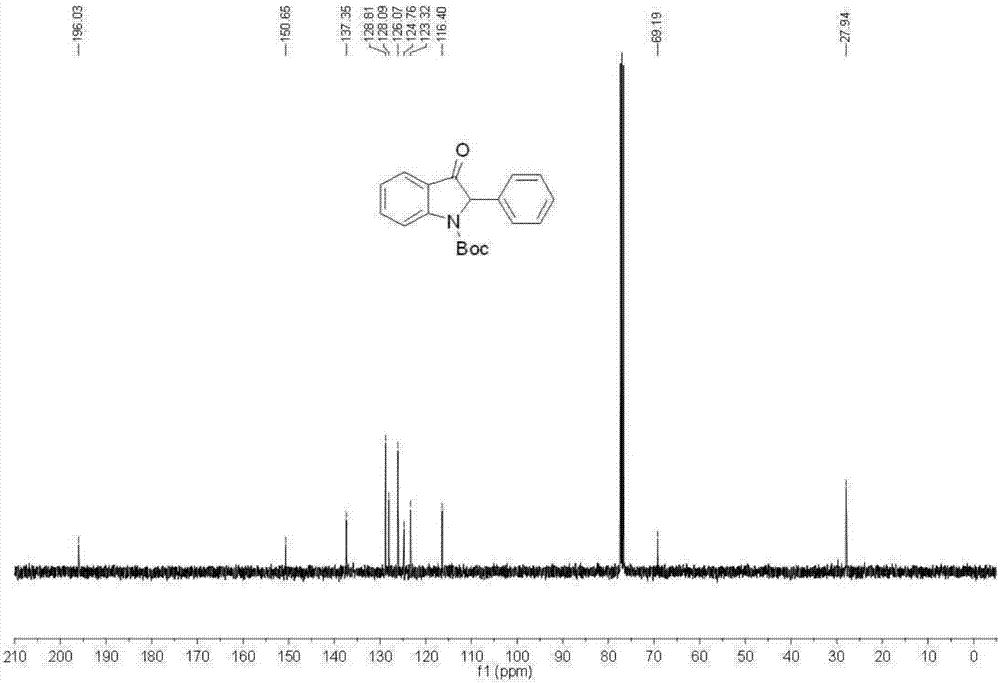

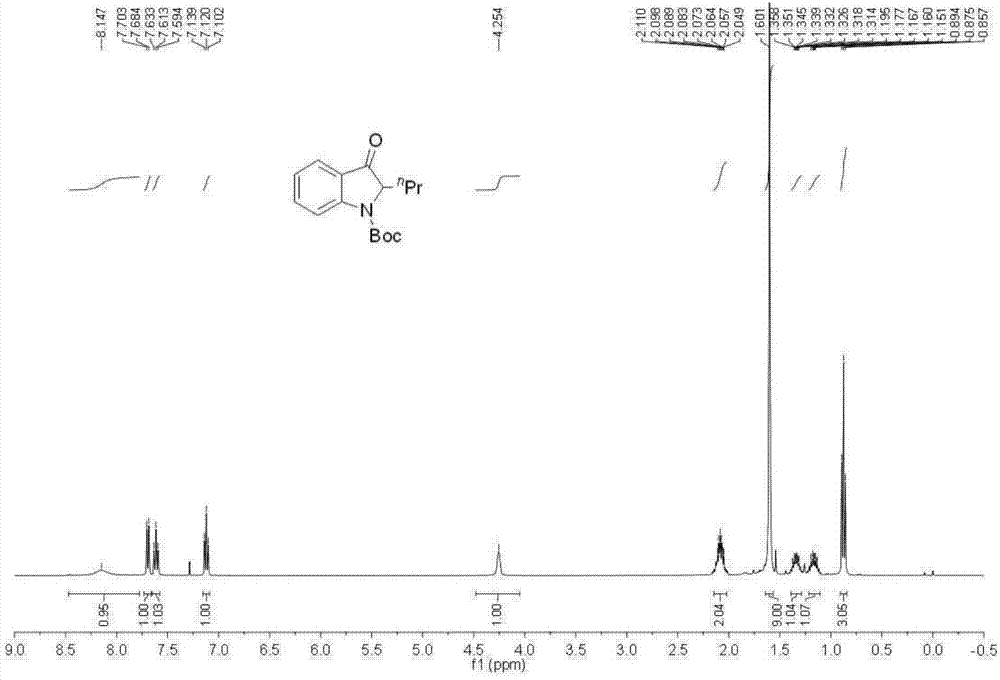

Preparation method of 3-oxoindoline compounds

InactiveCN104496884AAchieving oxidative dearomatization reactionsShort synthetic routeOrganic chemistryOrganic synthesisOxygen

The invention belongs to the field of medical and chemical intermediates and related chemical technology, and relates to a preparation method of 3-oxoindoline compounds, which is a method for synthesizing 3-oxoindoline compounds based on N-Boc indole. In the method, N-Boc indole is used as a raw material, the oxidation-dearomatization reaction of N-Boc indole is catalyzed by a ruthenium catalyst, the oxidation reaction of N-Boc indole is realized, and the aromaticity of an indole ring on the N-Boc indole is broken to obtain the 3-oxoindoline compounds. The method provided by the invention has the advantages of mild reaction conditions, good compatibility of functional groups, wide substrate range and environmental friendliness; and prepared 3-oxoindoline is an important organic synthesis intermediate which is widely used in the fields of organic synthesis and pharmacy.

Owner:DALIAN UNIV OF TECH

Method for producing an array substrate for a liquid crystal display device

ActiveCN103026293AEnvironmental friendlyPrevent poor wiringNon-linear opticsSurface treatment compositionsLiquid-crystal displayPhysical chemistry

The present invention relates to method for producing an array substrate for a liquid crystal display device, wherein an etching solution composition is used which comprises, with respect to the entire weight of the composition, a) from 5 to 25 percent by weight of hydrogen peroxide (H2O2); b) from 0.1 to 5 percent by weight of sulphuric acid; c) from 0.01 to 1.0 percent by weight of a fluorine-containing compound; d) from 0.1 to 5 percent by weight of an azole compound; e) from 0.1 to 5 percent by weight of an imidazole compound; and f) a balance of water.

Owner:DONGWOO FINE CHEM CO LTD

Polyoxamide resin having excellent impact resistance and impact-resistant part

Provided is a polyoxamide resin which has excellent impact resistance and is characterized in that the polyoxamide resin is obtained from a diamine in which the diamine component has 10 to 18 carbons and in that the polyoxamide resin has a relative viscosity (ηr) of 2.1 or greater as determined at 25° C. using 96% sulfuric acid as a solvent and a solution having a concentration of 1.0 g / dL, and also provided is an impact-resistant part comprising this resin. The polyoxamide resin has a higher molecular weight than a conventional polyoxamide resin, a large moldable temperature range as estimated from the difference between the melting point and the thermal decomposition temperature and therefore excellent molten moldability, and furthermore excellent impact resistance when compared to a conventional aliphatic polyoxamide resin without losing the low water absorbency, chemical resistance, hydrolysis resistance, high elasticity, and high strength seen with aliphatic straight-chain polyoxamide resins.

Owner:UBE IND LTD

Band-shaped lubricating material for dry wiredrawing and process for producing same

InactiveUS20140290320A1Processing state is stableAvoid seizuresWork treatment devicesCeramic shaping apparatusLow speedBand shape

Provided is an innovative belt-shaped lubricating material for dry wiredrawing which not only can be used under severe wiredrawing processing conditions such as those of high temperature / high pressure / high speed as well as conventional powdered or granular lubricants for dry wiredrawing but also can cope with diameter reduction to a wide range of wire diameters ranging from a small diameter to a large diameter and a wide range of linear speeds ranging from a low speed to a high speed, has excellent functionalities such as lubricity, followability, spreadability, adhesiveness, heat resistance, processability, workability, safety, durability and productivity irrespective of a processed shape, is effective in improving work environments and is friendly to the global environment.The belt-shaped lubricating material for dry wiredrawing includes a film containing 10 to 90% by weight of a metal salt of a saturated fatty acid and 10 to 90% by weight of a thermoplastic resin.

Owner:KYOEISHA CHEM CO LTD

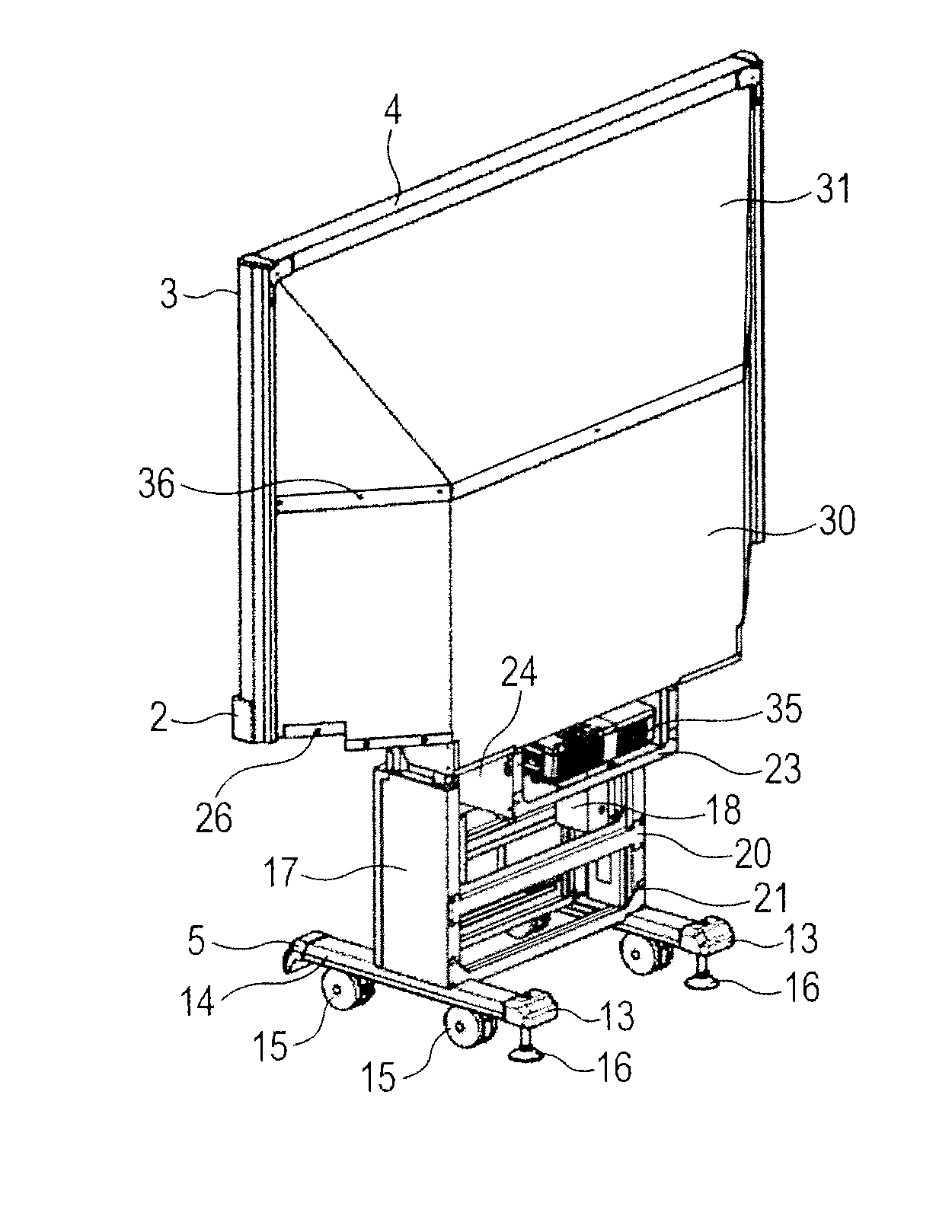

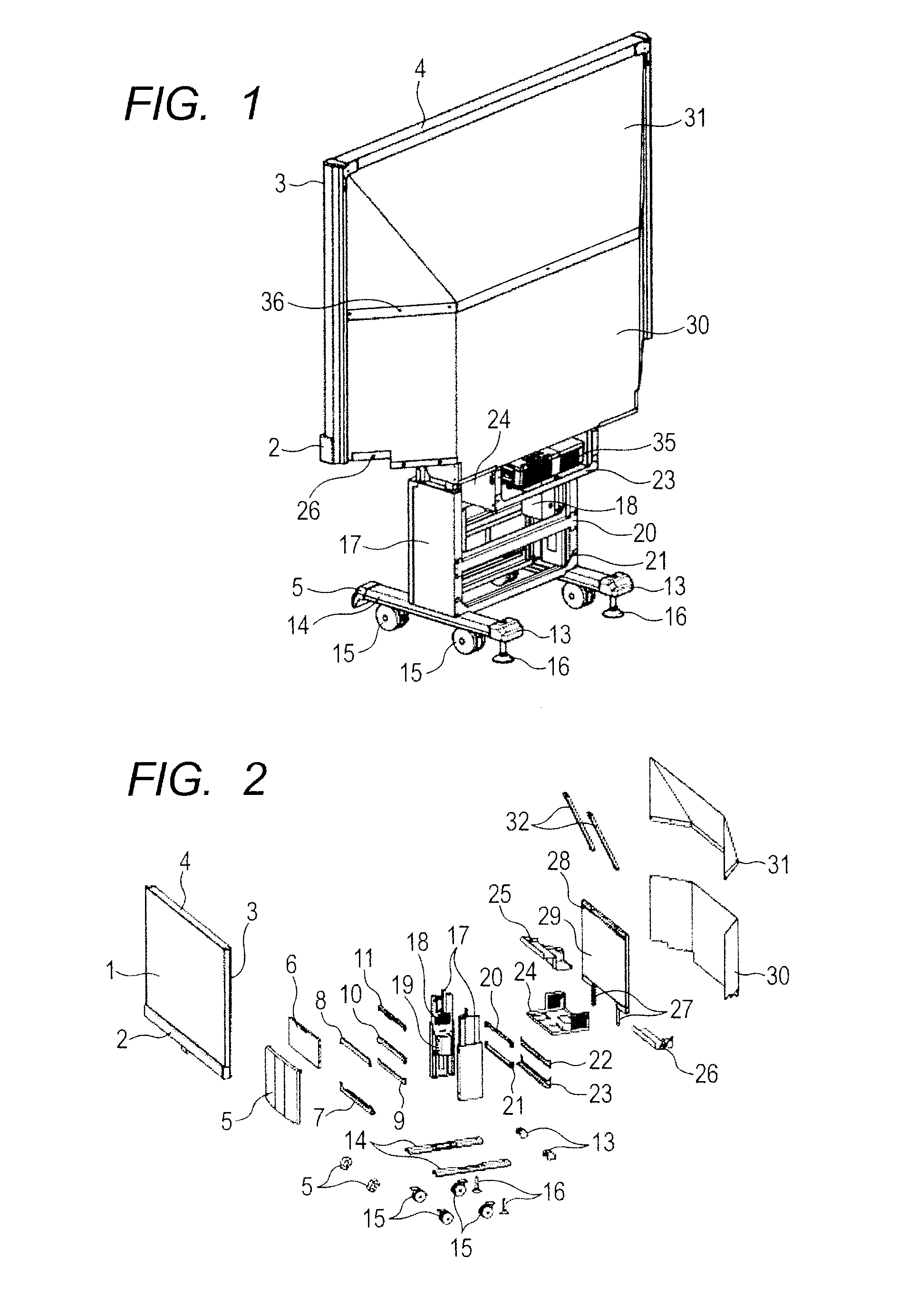

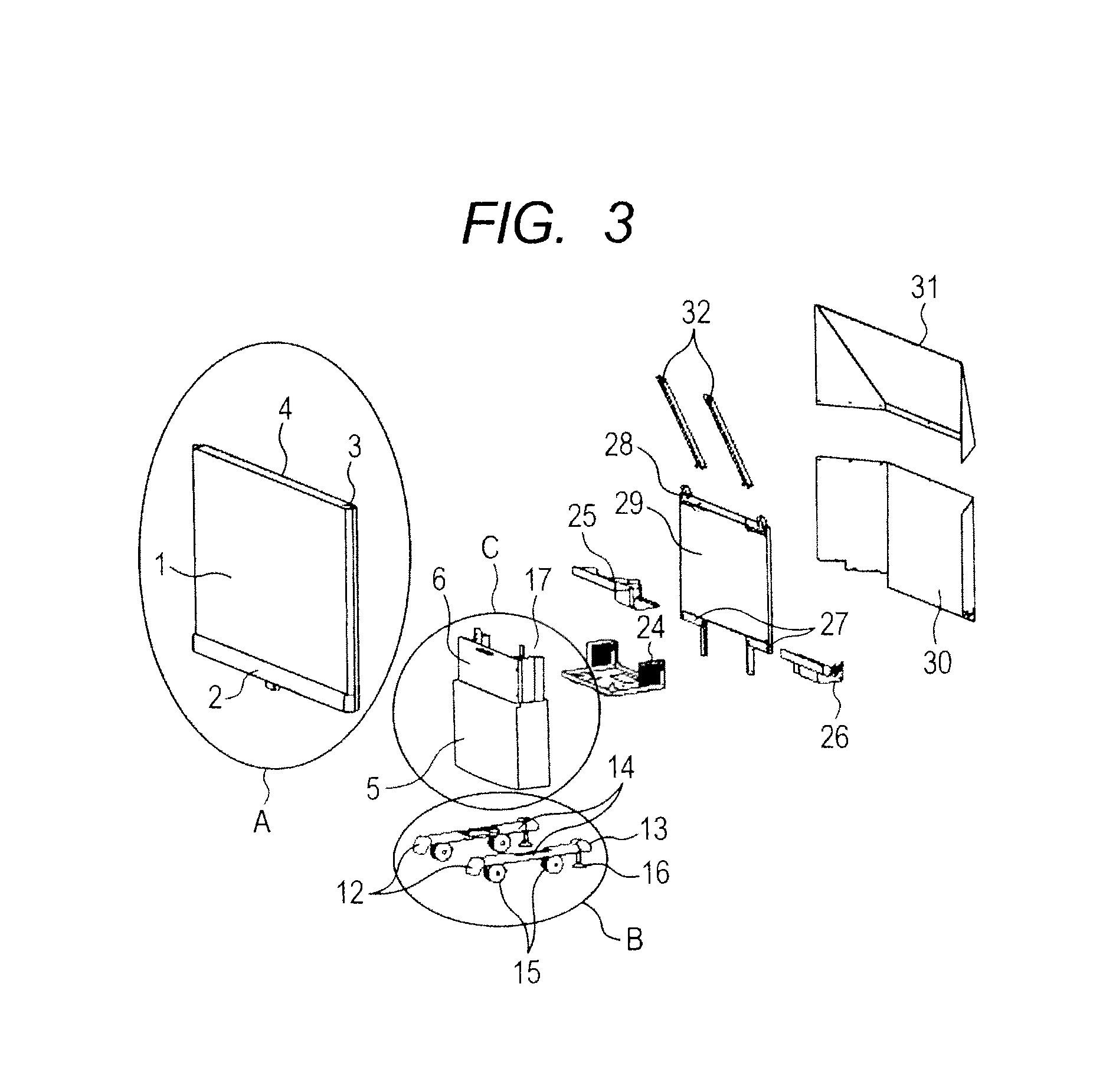

Projection-type video display apparatus

ActiveUS20140009694A1Suppression of manufacturing cost increaseLarge display sizeTelevision system detailsBuilt-on/built-in screen projectorsComputer graphics (images)Plane mirror

Projection-type video display apparatus, for base of transportation / conveyance if a display screen thereof is large-sized, and reducing energy necessary for the transportation and / or carbon dioxide discharging, thereby being friendly to the global environment.In the projection-type video display apparatus, for enlargedly projecting an image light, which is projected from a video projection unit 35, for projecting an image displayed on a video display screen as the image light, on a rear surface of a transmission-type screen, the video projection unit builds up an oblique projection optic system, and further a transmission-type screen 1 and a plane mirror 29 are disposed on a cabinet portion “C” including a side plate 17, being perpendicularly fixed, independently, in parallel with each other, and on the rear surface of the transmission-type screen are attached foldable back covers 30 and 31, detachably, so as to cover a rear surface of the plane mirror.

Owner:MAXELL HLDG LTD

Algaecide containing marine biological components

InactiveCN104522052AGuangpu bactericidal abilityEffective penetrationBiocideFungicidesBiotechnologyPhosphate

The invention discloses an algaecide containing marine biological components and a preparation method of the algaecide. The composition comprises the following components in percentage by weight: 0.5-1.5% of EM probiotics, 0.2-0.8% of didecyldimethylammonium chloride, 0.2-0.5% of potassium ferrate, 1.0-5.0% of nitrate, 2-8.0% of phosphate, 1.0-5.0% of quaternary ammonium salts, 0.2-0.8% of chitosan, 20.0-40.0% of active carbon and 15.0-20.0% of calcium carbonate. The algaecide belongs to a composite preparation which has broad-spectrum bactericidal ability and can be used for effectively permeating cell walls and decomposing cell DNA, so that cells are killed, and cell reproduction is inhibited. The algaecide is suitable for killing algae and microorganisms of various water body systems.

Owner:QINGDAO HIFUN MARINE BIOLOGICAL TECH

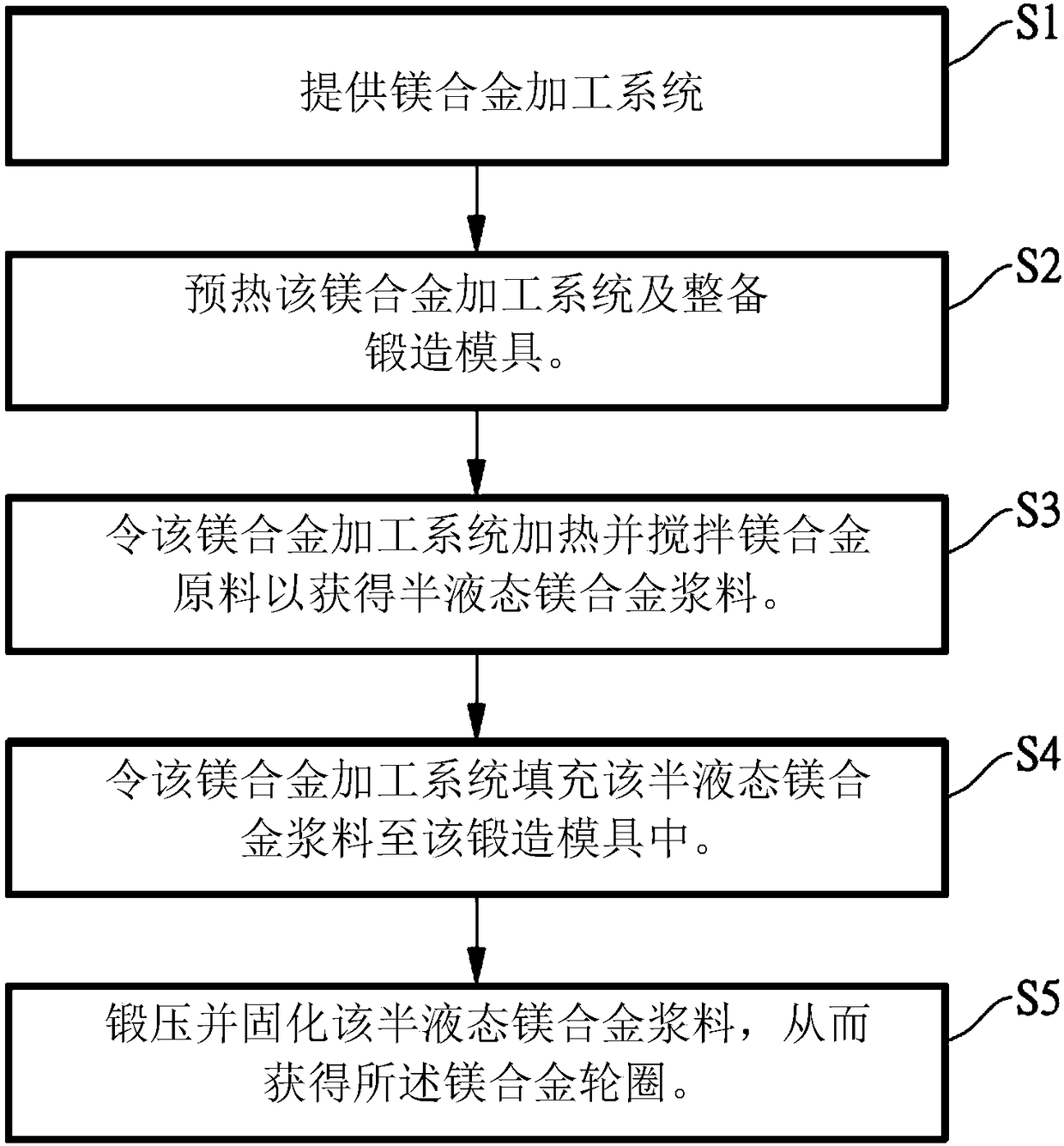

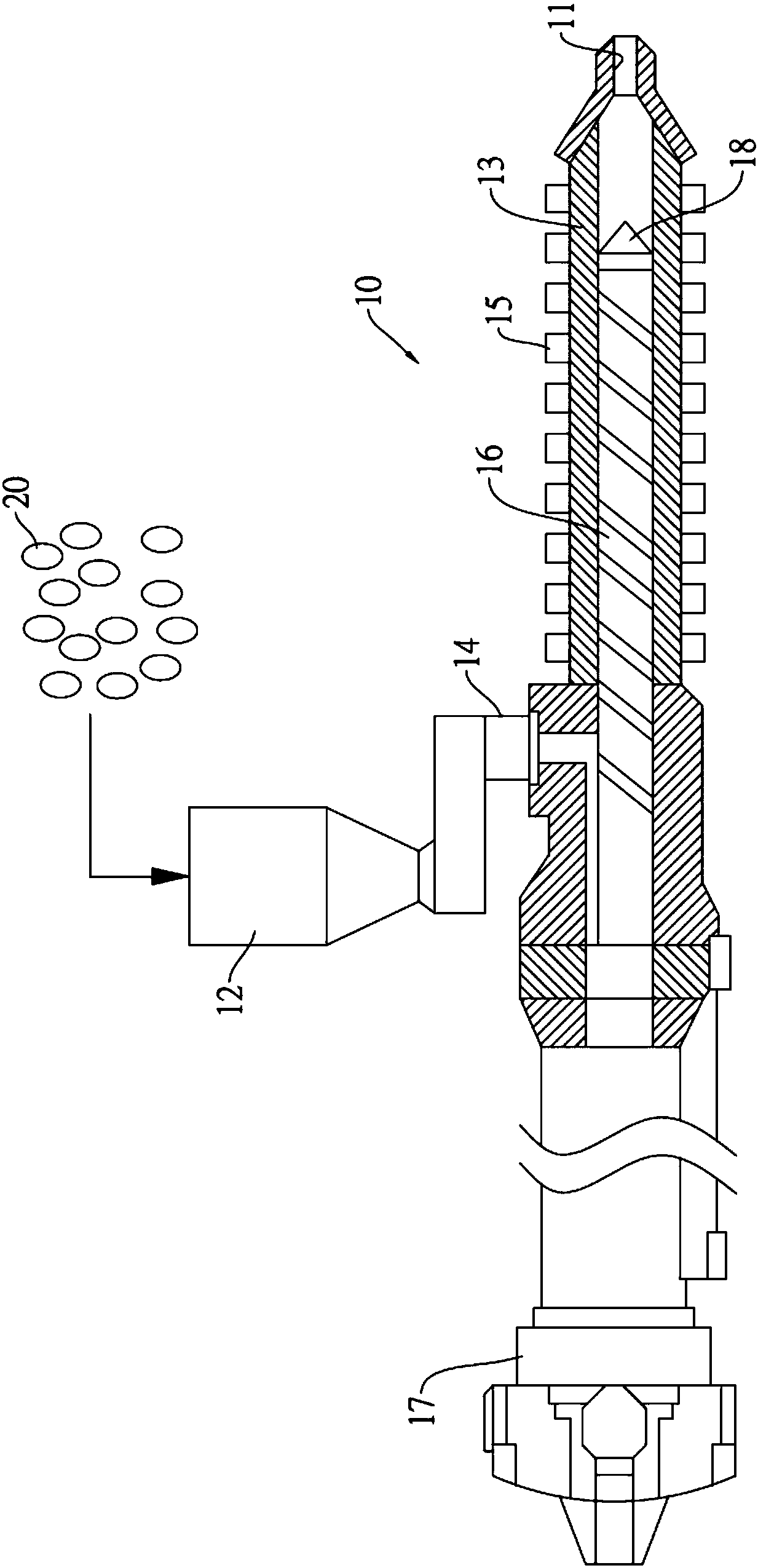

Semi-liquid-state forging method for magnesium alloy rim

InactiveCN109014012AHigh dimensional accuracyIncrease profitMetal-working apparatusWheelsLiquid stateSlurry

The invention relates to a semi-liquid-state forging method for a magnesium alloy rim. The semi-liquid-state forging method comprises the following steps that a magnesium alloy processing system including a slurry outputting flow pass, a storing pipe, a screw and a heater is provided; a magnesium alloy raw material located in the storing pipe is heated through the heater and is stirred through thescrew, and thus semi-liquid-state magnesium alloy slurry where spherical magnesium alloy crystal particles and a liquid-state magnesium alloy coexist in a solid-liquid mode is obtained; a forging mold is filled with the semi-liquid-state magnesium alloy slurry by the screw through the slurry outputting flow pass; and thus the semi-liquid-state magnesium alloy slurry which the forging mold is filled with is forged, pressed and solidified, and thus the magnesium alloy rim is obtained. The semi-liquid-state forging method for the magnesium alloy rim has the advantages of lowering the manufacturing cost of the magnesium alloy rim and improving the quality of the magnesium alloy rim.

Owner:张无量

Rubber composition for tread and pneumatic tire

InactiveUS20110028630A1Guaranteed uptimeReduce oil supplyFibre treatmentSynthetic resin layered productsEngineeringRoad surface

The present invention provides a rubber composition for a tread, which is friendly to the global environment and can prepare for the decrease in oil supply in the future because of its high content of non-fossil resources, as well as shows an excellent running performance (braking performance) on a wet road surface and a dry road surface, and has an improved abrasion resistance. The present invention also provides a pneumatic tire in which the rubber composition for a tread is used for a tread of the tire. The rubber composition for a tread of the present invention includes a rubber component containing butadiene rubber and 35% by mass or more of epoxidized natural rubber, and a white filler.

Owner:SUMITOMO RUBBER IND LTD

A special-shaped pipe fitting welding equipment

ActiveCN104191059BEasy to controlAchieve integrationWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingEngineering

The invention discloses special-shaped pipe fitting welding equipment. The special-shaped pipe fitting welding equipment comprises a workbench, a high-frequency sensing heating unit, an image measurement unit, a mechanical positioning and clamping unit, an exhaust fan and a control cabinet, wherein the exhaust fan is installed behind the mechanical positioning and clamping unit, the mechanical positioning and clamping unit is arranged in the middle of the tabletop of the workbench, and a PLC is installed in the control cabinet. The special-shaped pipe fitting welding equipment is applicable to assembling small-size special-shaped pipe fittings according to a soldering method, and the problem that high assembly accuracy can not be achieved when the positioning standard is not ideal is solved by the adoption of image measurement and positioning; meanwhile, errors caused by clamping force in the welding and heating process are compensated for conveniently and rapidly, welding accuracy is improved, and thin-wall positions of a part can be effectively prevented from collision deformation in the assembly or disassembly process.

Owner:CHINA NTAIONAL NUCLEAR TIANJIN MACHINERY

Pressure-sensitive adhesive layer, pressure-sensitive adhesive tape, and double-sided pressure-sensitive adhesive tape

ActiveUS10287465B2High levelImprove workabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyesterOrganic solvent

The purpose of the present invention is to provide: a polyester-based pressure-sensitive adhesive layer, for which a pressure-sensitive adhesive composition (pressure-sensitive adhesive solution) without any acrylic pressure-sensitive adhesive or the like which needs a large amount of an organic solvent and is difficult to apply thickly; to provide a polyester-based pressure-sensitive adhesive layer that is friendly to the global environment, can be applied thickly, has a high level of cost effectiveness and workability, and also has a high level of adhesion, retention, and repulsion resistance; and to provide a pressure-sensitive adhesive tape or double-sided pressure-sensitive adhesive tape having such a pressure-sensitive adhesive layer. The invention is directed to a polyester-based pressure-sensitive adhesive layer including a product made from a polyester-based pressure-sensitive adhesive composition including: a polyester obtained by polycondensation of at least a dicarboxylic acid component and a diol component; and a tackifier, the polyester-based pressure-sensitive adhesive layer having a gel fraction of 15% by weight or more to less than 40% by weight.

Owner:NITTO DENKO CORP

Environmentally friendly process for removing ammonia from ammonia oxidation synthesis gas

ActiveCN102530868BSave sulfuric acidLow costHydrogen separation using liquid contactSocial benefitsHydrogen phosphate

The invention provides an environmental-protection process method for removing ammonia from ammoxidation synthesis gas. The method is characterized in that a combined ammonia removal technological method composed of a primary ammonia removal process using phosphoric acid or ammonium dihydrogen phosphate and a fine ammonia removal process using sulfuric acid or ammonium bisulfate. In the primary ammonia removal process of ammoxidation synthesis gas, primary ammonia removal and ammonia recovery of the synthesis gas can be achieved through the repeated cycle of the following steps: phosphoric acid or ammonium dihydrogen phosphate absorbs free ammonia in the synthesis gas as a carrier in a primary ammonia removal tower, and is transformed to diammonium hydrogen phosphate; and diammonium hydrogen phosphate produces free ammonia in a desorption tower, and is transformed to ammonium dihydrogen phosphate. The ammoxidation synthesis gas enters a fine ammonia removal tower after the primary ammonia removal process, and fine ammonia removal process is achieved by using sulfuric acid or ammonium bisulfate as an absorber to absorb remaining ammonia in the synthesis gas after the primary ammonia removal process in a fine ammonia removal tower, wherein sulfuric acid or ammonium bisulfate is transformed to ammonium sulfate byproducts. The combined ammonia removal method can recover free ammonia in the ammoxidation synthesis gas to save resources and achieve real environmental protection property of the ammonia removal process, and has good economic and social benefits.

Owner:李宽义

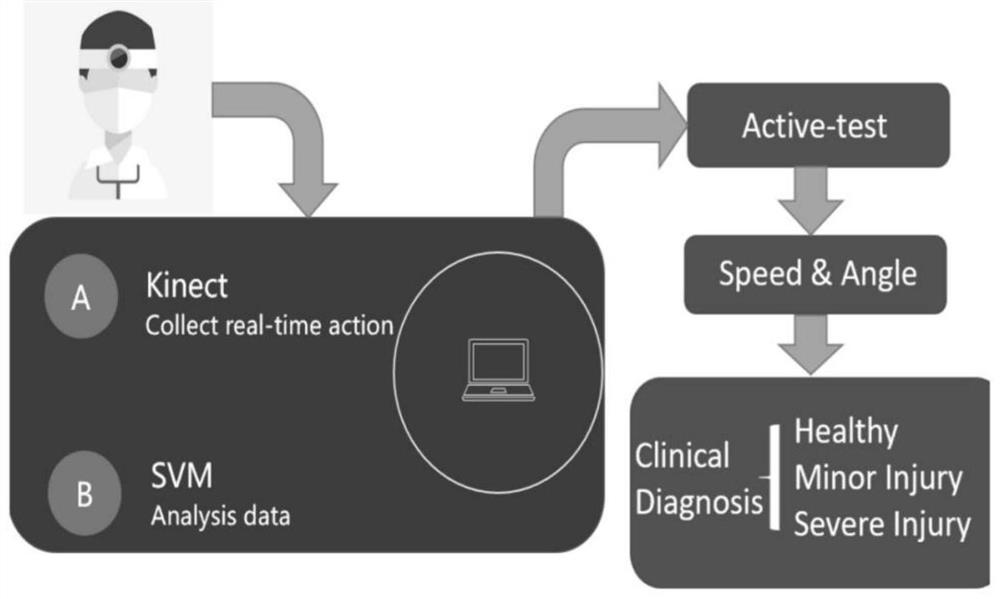

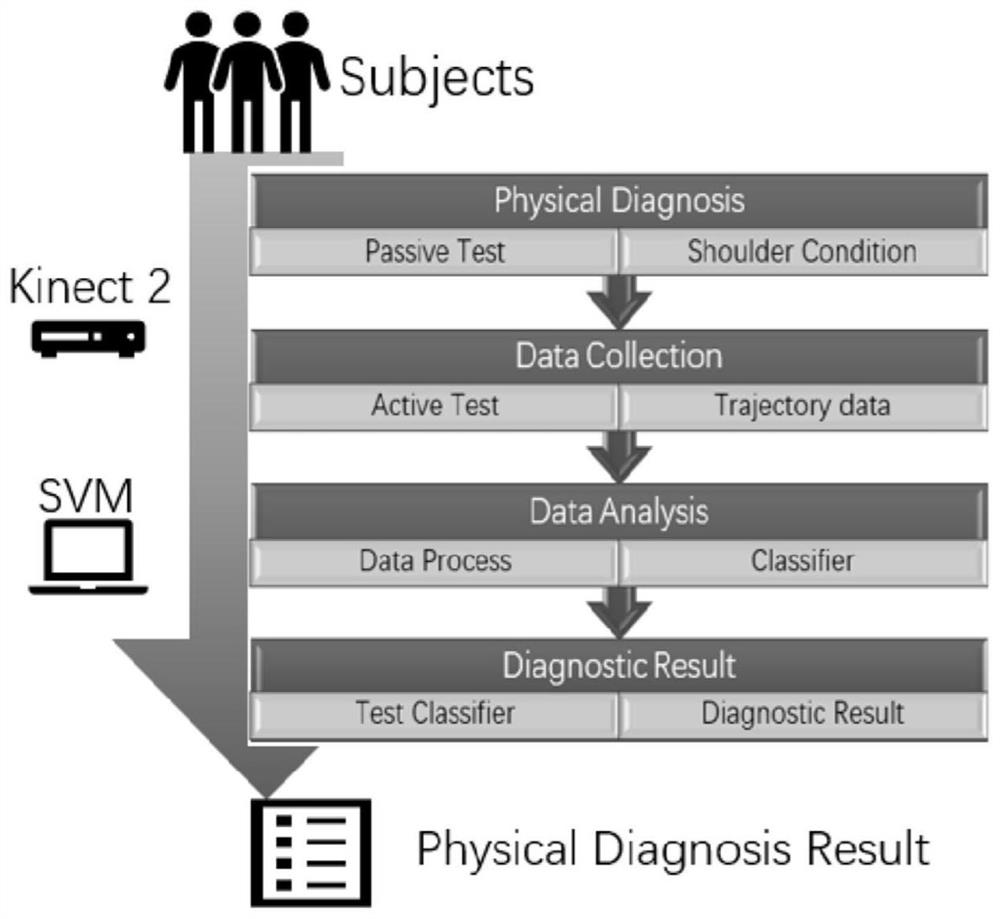

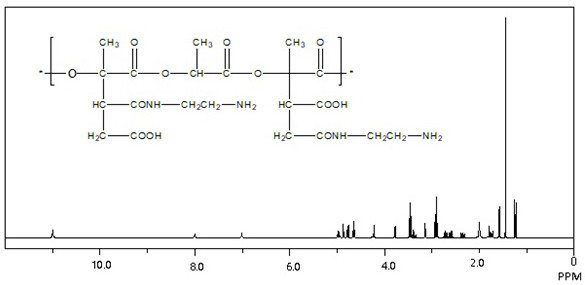

Equipment applied to examination, diagnosis and later rehabilitation of muscle injury based on optical motion capture equipment and artificial intelligence system

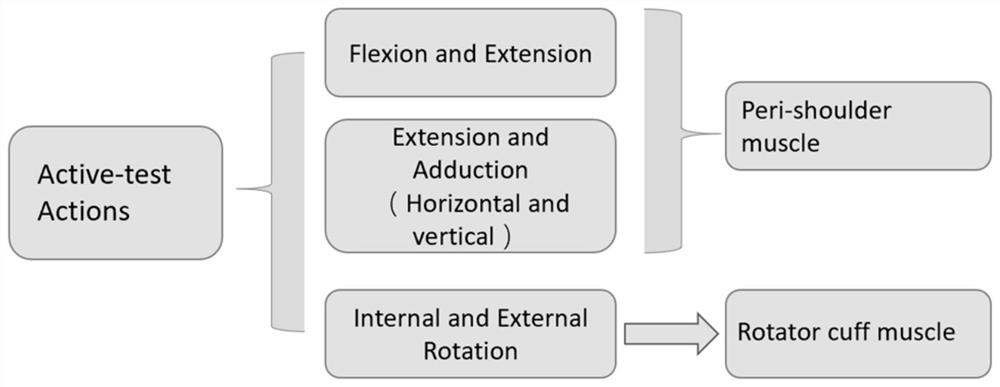

PendingCN112336303AHigh precisionImprove accuracyDiagnostic recording/measuringSensorsPhysical medicine and rehabilitationSimulation

The invention belongs to the field of computers, robots and medical auxiliary products. Based on the lack of medical products which are convenient, practical and capable of providing accurate diagnosis and treatment service in the market at the present stage, the invention provides equipment applied to examination, diagnosis and later rehabilitation of muscle injury based on optical motion captureequipment and an artificial intelligence system. Complex manual labor is changed into time-saving and labor-saving mechanical labor through an artificial intelligence algorithm and the optical motioncapture equipment. A full-automatic, accurate and effective diagnosis and treatment service which is simple and convenient to use can be provided. The working intensity of medical workers can be reduced, and a real-time and effective diagnosis and treatment scheme can be provided for patients. An effective treatment method and professional evaluation can be provided for the patients through tracking of diagnosis and treatment records. Help is provided for establishing efficient connection between doctors and patients.

Owner:侯宇

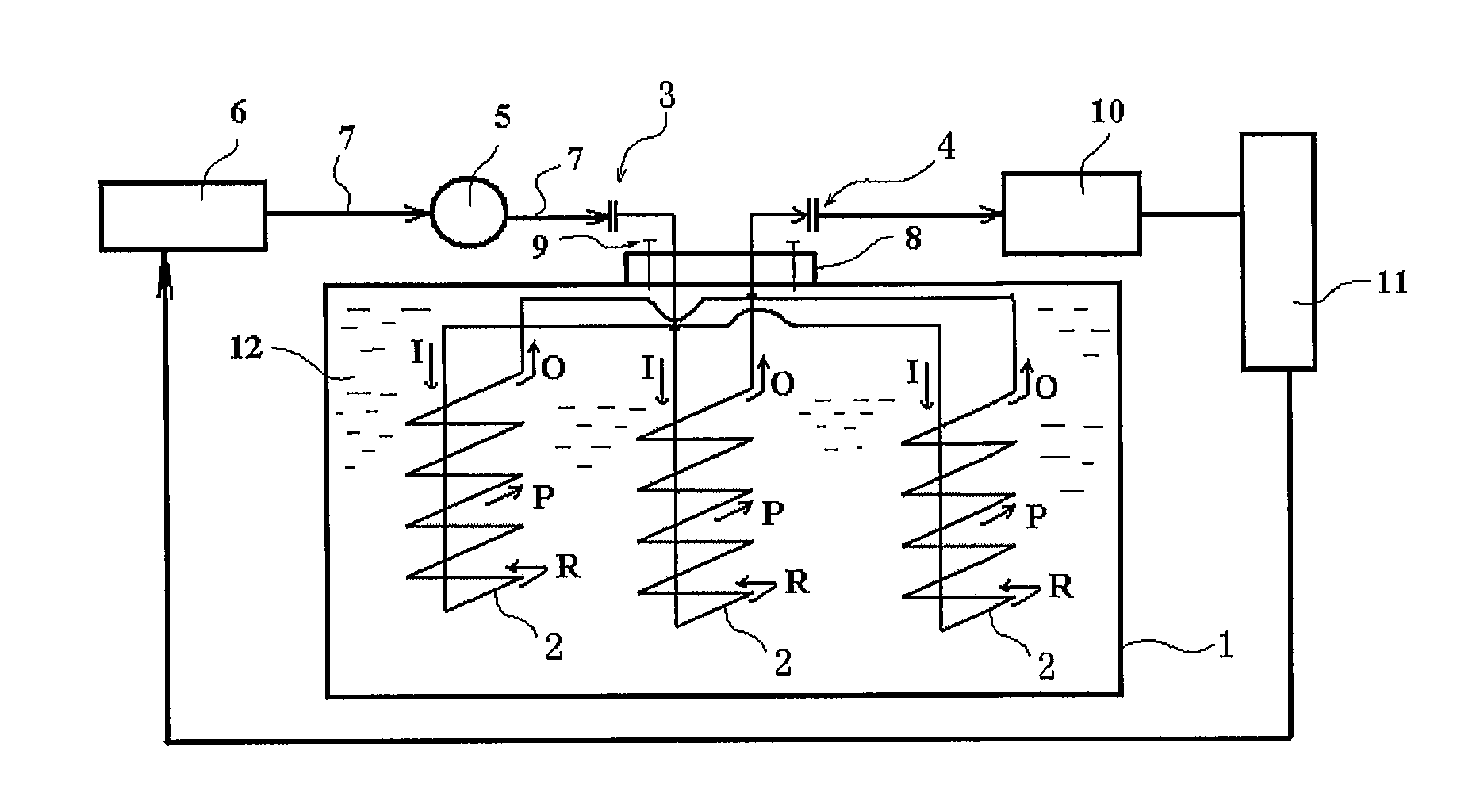

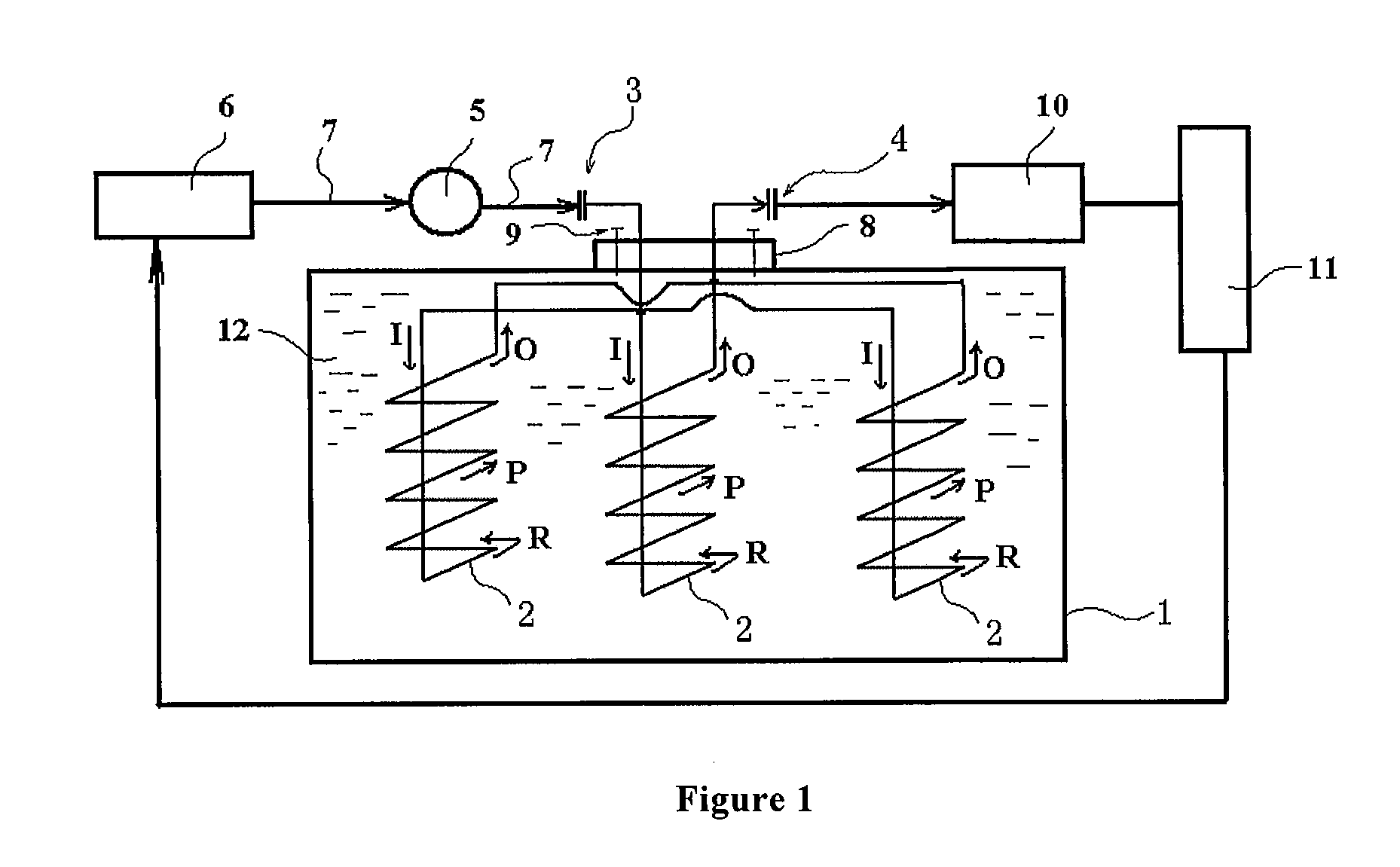

Heater and heating method for wet extraction tank

InactiveUS20140328581A1Reduce energy consumptionClean and friendly environmentSolvent extractionCooking vesselsSteam pressureEngineering

A heater and a heating method for a wet extraction tank, said heater comprising a heating tube comprising a spiral glass tube with an air inlet and an air outlet; the air inlet is connected to a steam supply apparatus via a steam tube, and the air outlet is in communication with an apparatus containing micro-steam or hot water; the steam tube has with a pressure regulating valve for adjusting the steam pressure inside the heating tube; the glass tube is fixedly connected to the extraction tank by a wooden material fixed to the tank via a stainless steel bolt; the glass tube is fixed to the wooden material by wrapping and welding a heat and chemical resistant soft plastic sheeting. The heating method comprises maintaining the liquid inside the tank in a constant state of ebullition so that heat is evenly and uniformly distributed throughout the tank.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP

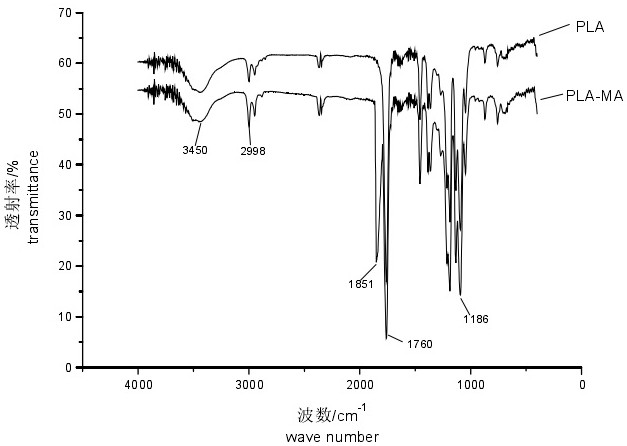

A kind of slow-release algae-killing microcapsule with bimolecular structure and preparation method thereof

ActiveCN109769807BGuangpu bactericidal abilityEffective penetrationBiocideFungicidesMicro nanoAlgaecide

The invention relates to the technical field of microcapsules. In order to solve the problems in control of green torreya grandis algae at present, the invention provides a slow-release alga-removingmicrocapsule adopting a bimolecular structure and a preparation method thereof. A modified polylactic acid bio-based material is used as a capsule wall, a composite non-toxic and high-efficiency photosensitive catalytic material uses Ce-doped micro-nano ZnO composite sterilizing and alga-removing material as a core material, and a slow-release nano-molecular capsule is formed through self-assembly. The nanocapsule combines advantages such as physical alga removal, chemical alga removal and a slow-release effect of an intelligent material, is a novel environment-friendly algicide and a novel high-efficiency and low-residue antibacterial pesticide dosage form, and has a very important significance in prolonging the lasting period of the alga-removing effect, reducing the application amount of a high-toxic algaecide, efficiently utilizing a pesticide and protecting the environment.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Steam heating type sewage treatment device

ActiveUS10220327B2Reduce energy wasteEnergy resourceHeat recovery systemsSpecific water treatment objectivesEngineeringSewage

A steam heating type sewage treatment device includes: a treatment tank connected to a sewage supply pipe, a stirring device disposed in the treatment tank; a steam heating device disposed on an outer surface of the treatment tank; a vacuuming device fixed to a top of the treatment tank and connected to the treatment tank via a first connecting pipe; a heating device connected to the treatment tank by a second connecting pipe and connected to a steam storage tank by a third connecting pipe, and a fourth connecting pipe connected between the steam input pipe and the steam storage tank to recycle the steam. The heating device pressurizes or heats the steam entering the vacuuming device and the connecting pipes, and the heated steam is guided by pipes into the steam heating device, thus achieving the effect of steam recycling.

Owner:LIAO CHUNG HENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com