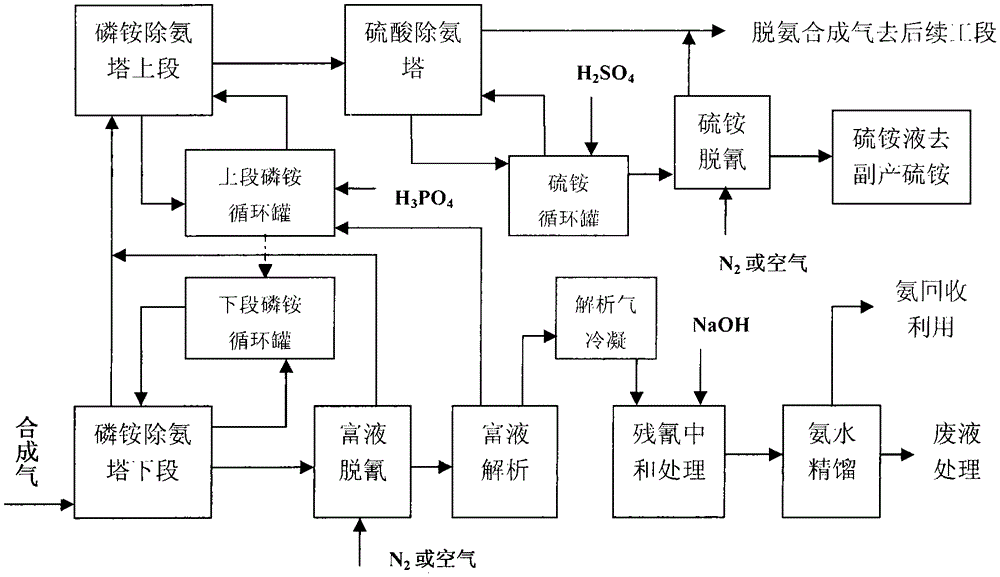

Environmentally friendly process for removing ammonia from ammonia oxidation synthesis gas

A process method and synthesis gas technology, applied in the direction of hydrogen separation, using liquid contact hydrogen separation, etc., can solve the problems that the thoroughness of removal cannot be solved well, the stability of diammonium hydrogen phosphate is limited, and it is difficult to meet the processing requirements, etc. Achieve the effect of breaking through environmental technical barriers, realizing environmentally friendly and clean production, and solving the contradiction between consumption and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Example: Angle method natural gas ammoxidation to synthesize prussic acid, the reaction synthesis gas is combined to remove ammonia to obtain the reaction synthesis gas without ammonia or with a constant amount of ammonia.

[0030] The composition of a certain synthesis gas before ammonia removal is as follows:

[0031] serial number

component name

Component ratio%

serial number

component name

Component ratio%

1

HCN

0.08092

6

N 2

0.54328

2

NH 3

0.01508

7

CO 2

0.00503

3

h 2 o

0.25513

8

CO

0.04705

4

CH 4

0.00462

9

H 2

0.04765

[0032] 5

O 2

0.00020

10

other

0.00104

[0033] The primary ammonia removal synthesis gas is obtained by recycling the free ammonia through primary ammonia removal. The composition of the primary ammonia removal synthesis gas is as follows:

[0034] seria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com