Freezing expansion type chlorine liquefying method

A technology of chlorine gas and liquefier, which is applied in the chemical industry, can solve the problems of the earth's biological living environment hazards, susceptibility to sulfuric acid pollution, and lower energy-saving effects, and achieve the effects of avoiding sulfuric acid pollution of products, protecting the living environment, and reducing the risk of explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

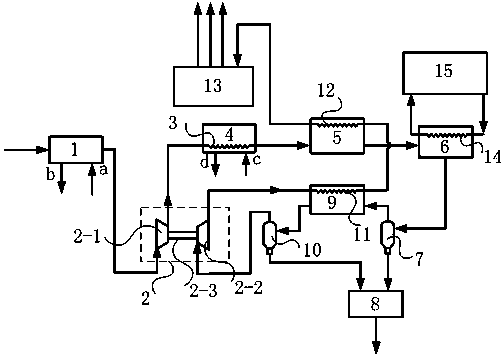

[0023] like figure 1 As shown, the equipment used in a freeze-expansion chlorine gas liquefaction method includes a turbine chlorine gas compressor unit 1, a pressurized expansion unit 2, a first cooling pipe 3, a brake cooler 4, a precooler 5, and a main chlorine gas liquefaction unit. Device 6, main gas-liquid separator 7, liquid chlorine storage tank 8, auxiliary chlorine gas liquefier 9, auxiliary gas-liquid separator 10, second cooling pipe 11, third cooling pipe 12, tail chlorine distribution table 13, fourth cooling Pipe 14 and refrigerating unit 15.

[0024] The booster expansion unit 2 includes a booster brake fan 2-1, an expander 2-2 and a drive shaft 2-3, and the drive shaft 2-3 passes between the booster brake fan 2-1 and the expander 2-2 connect.

[0025] The input end of the turbine-type chlorine gas compressor unit 1 is open, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com