One-step synthesis method of guanine

A synthesis method and guanine technology, applied in the field of medicine, can solve the problems of difficult by-product treatment and high environmental protection treatment cost, and achieve the effects of reducing environmental protection treatment costs and eliminating potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

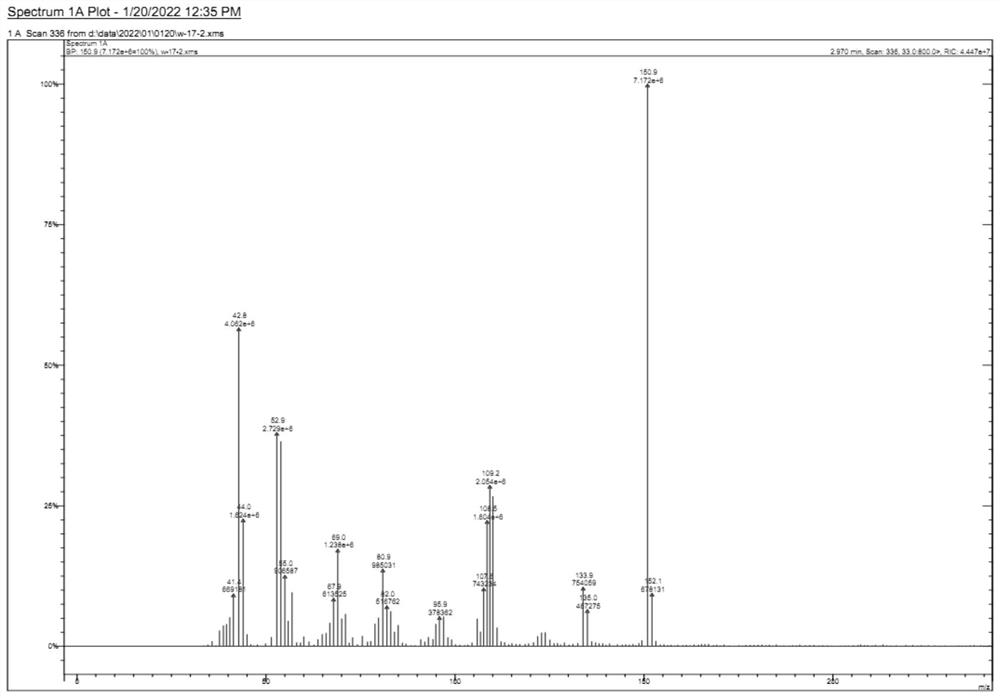

Image

Examples

preparation example Construction

[0034] A kind of one-step synthetic method of guanine, it comprises:

[0035] Mix 2,4-diamino-5-nitroso-6-hydroxypyrimidine with formamide solution, raise the temperature to 80-160°C under the catalyst for formylation reaction, and then raise the temperature to 160-180°C to keep the temperature dehydration reaction.

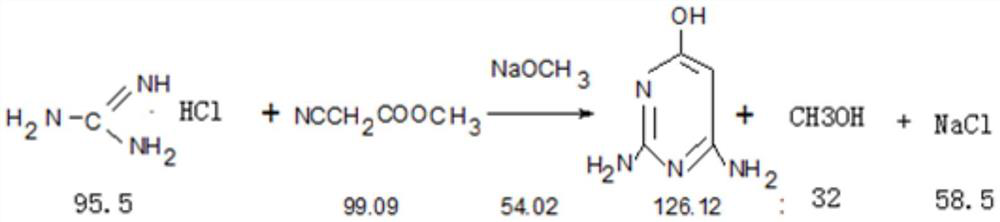

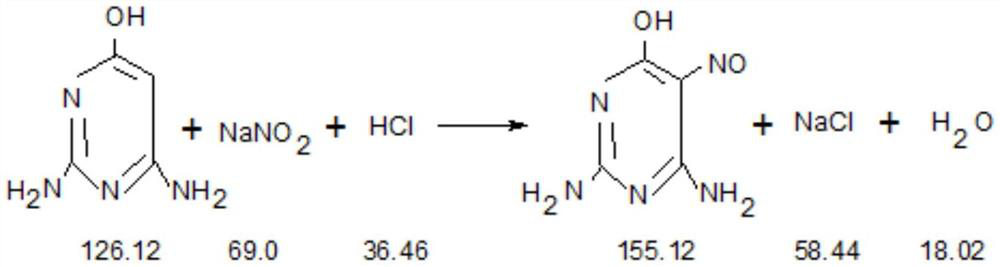

[0036] The reaction process of this synthetic method is as follows:

[0037]

[0038] Using this process, in the synthesis process, 2,4-diamino-5-nitroso-6-hydroxypyrimidine is added to the aqueous formamide solution, and under the catalyst condition, the temperature is slowly raised, and the excess water in the formamide solution Evaporate gradually (because the boiling point of formamide is 210°C, formamide will not evaporate with water), and at the same time, initiate a formylation reaction to obtain a formamidopyrimidine transition intermediate. The transition intermediate can exist stably, and the pure intermediate monomer can be obtained by means of se...

Embodiment 1

[0050] The present embodiment provides a kind of one-step synthesis method of guanine, which comprises:

[0051]Take 31g (0.2mol) of 2,4-diamino-5-nitroso-6-hydroxypyrimidine, add it to 120ml 75% formamide, start stirring, slowly raise the temperature to 80°C, add 2.5g (about 8% ) Sodium dithionite, continue to heat up to trigger the formylation reaction, and at the same time, a large amount of ammonia and carbon dioxide gas overflow, which are absorbed by deionized water circulation. Collect the water continuously evaporated during the heating process, and raise the temperature to 160°C within 7 hours to complete the formylation reaction. Continue to heat up, when the temperature rises to 170°C, stop the water outlet, reflux and keep warm for 2 hours, cool down after the material turns yellow, and filter to obtain crude guanine with a yield of about 99%.

[0052] The crude product was added into 10 times 15% dilute hydrochloric acid to reflux for decolorization and refinemen...

Embodiment 2

[0055] The present embodiment provides a kind of one-step synthesis method of guanine, which comprises:

[0056] Take 60g of 2,4-diamino-5-nitroso-6-hydroxypyrimidine wet product, convert it to 31g (0.2mol), add it to 120ml of 80% formamide, start stirring, slowly heat up to 80°C, add 2.0 g (about 6.5%) sodium dithionite, continue to heat up to trigger the formylation reaction, and a large amount of ammonia and carbon dioxide gas overflow at the same time, and are absorbed by deionized water circulation. Collect the water continuously evaporated during the heating process, and raise the temperature to 160°C within 6 hours to complete the formylation reaction. When the temperature rises to 160° C., stop the water outlet, reflux and keep warm for 3 hours, cool down after the material turns yellow, and filter to obtain crude guanine with a yield of about 98.6%.

[0057] The crude product was added into 10 times 15% dilute hydrochloric acid to reflux for decolorization and refine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com