Patents

Literature

32results about How to "Low cost of environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

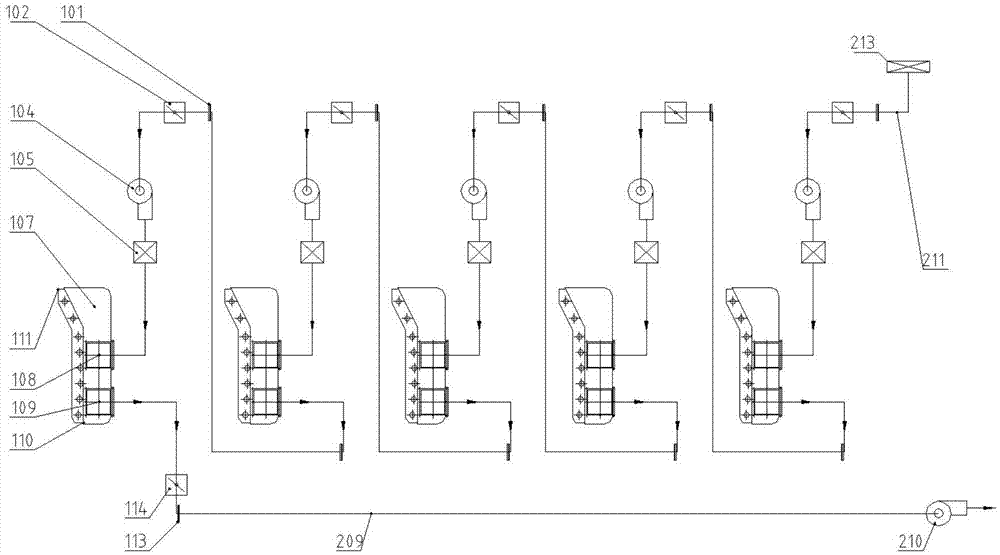

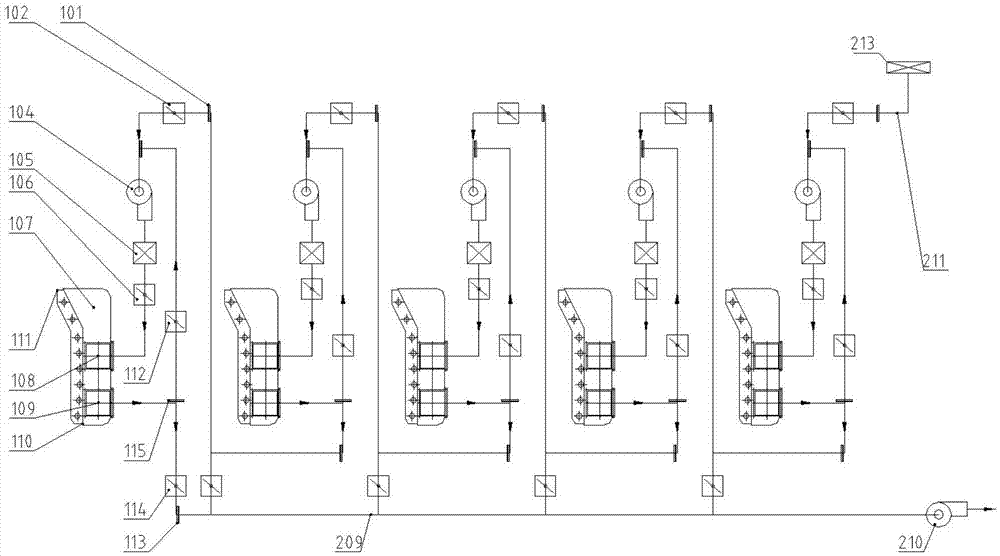

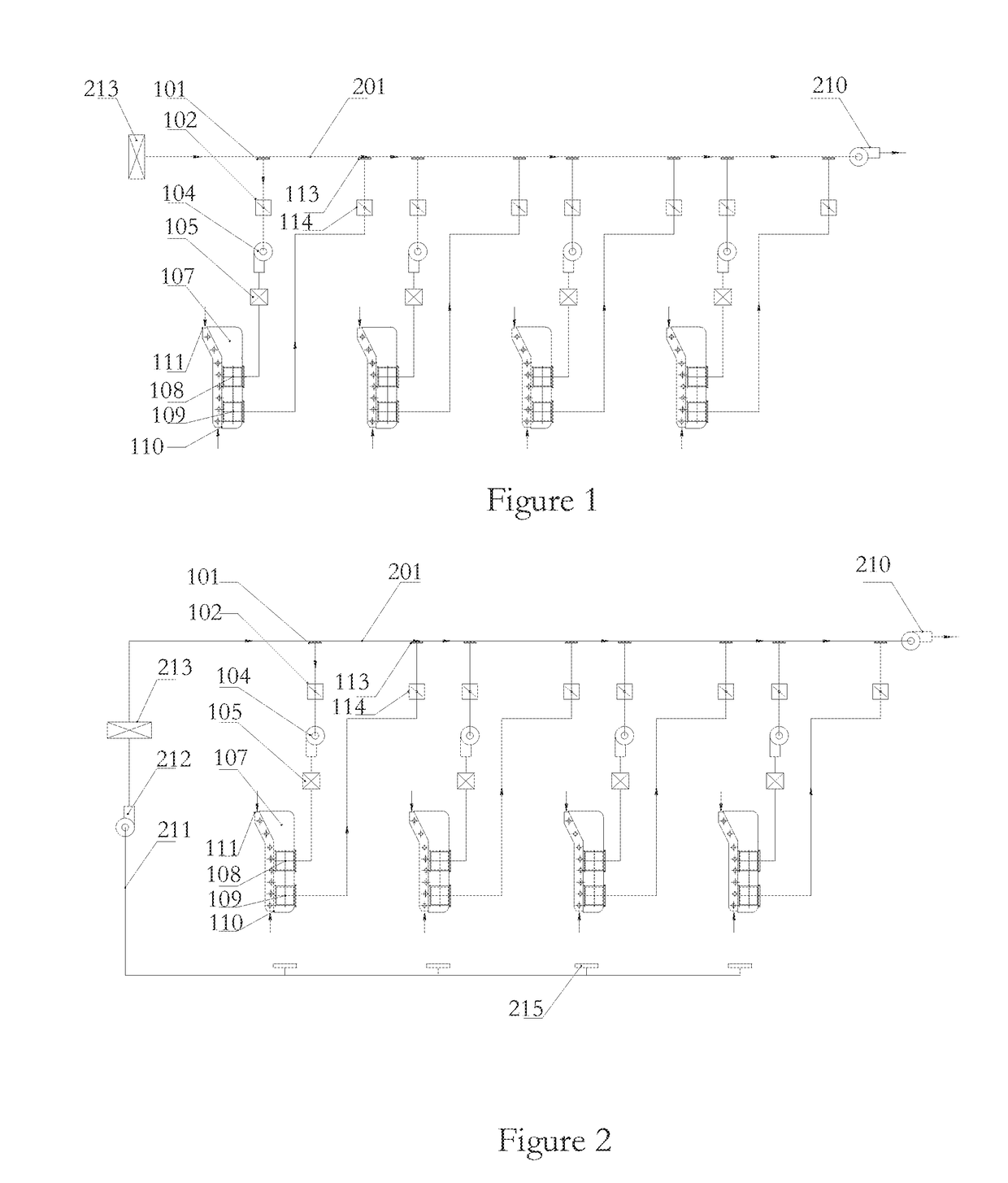

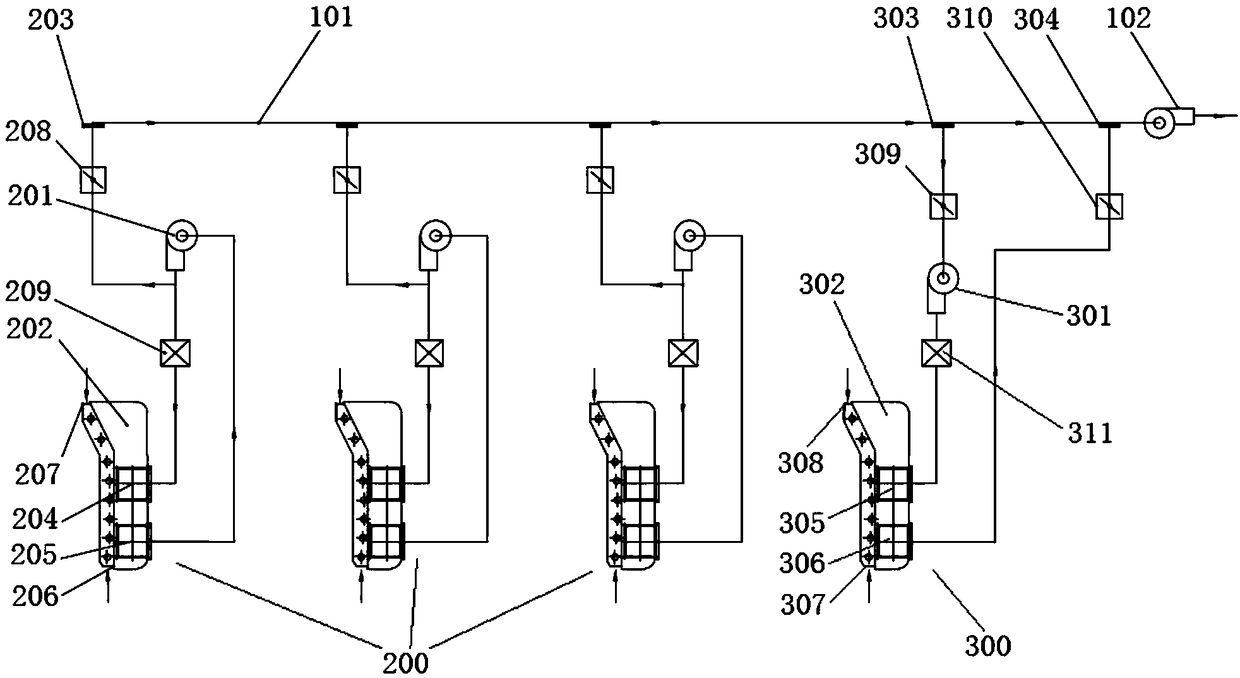

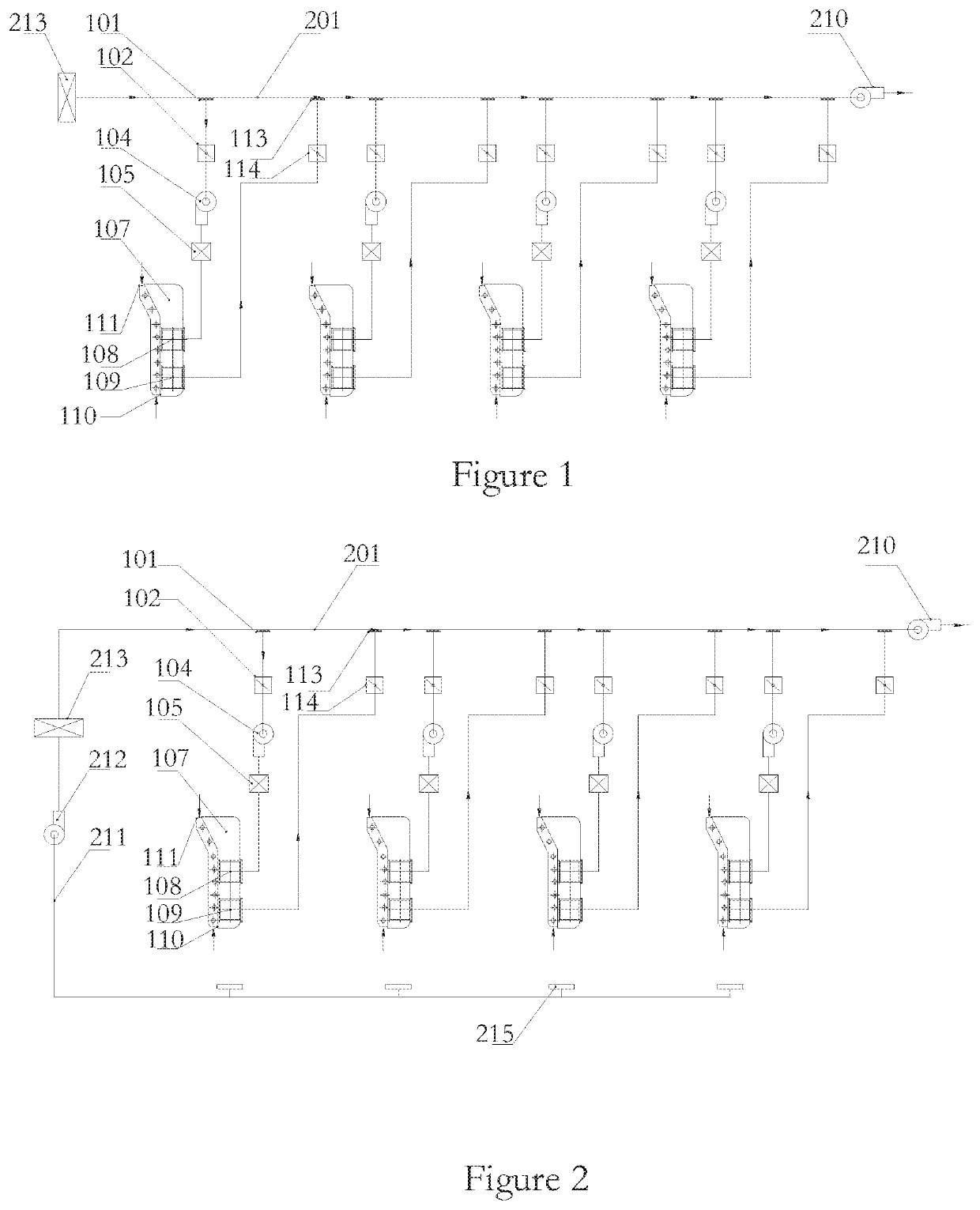

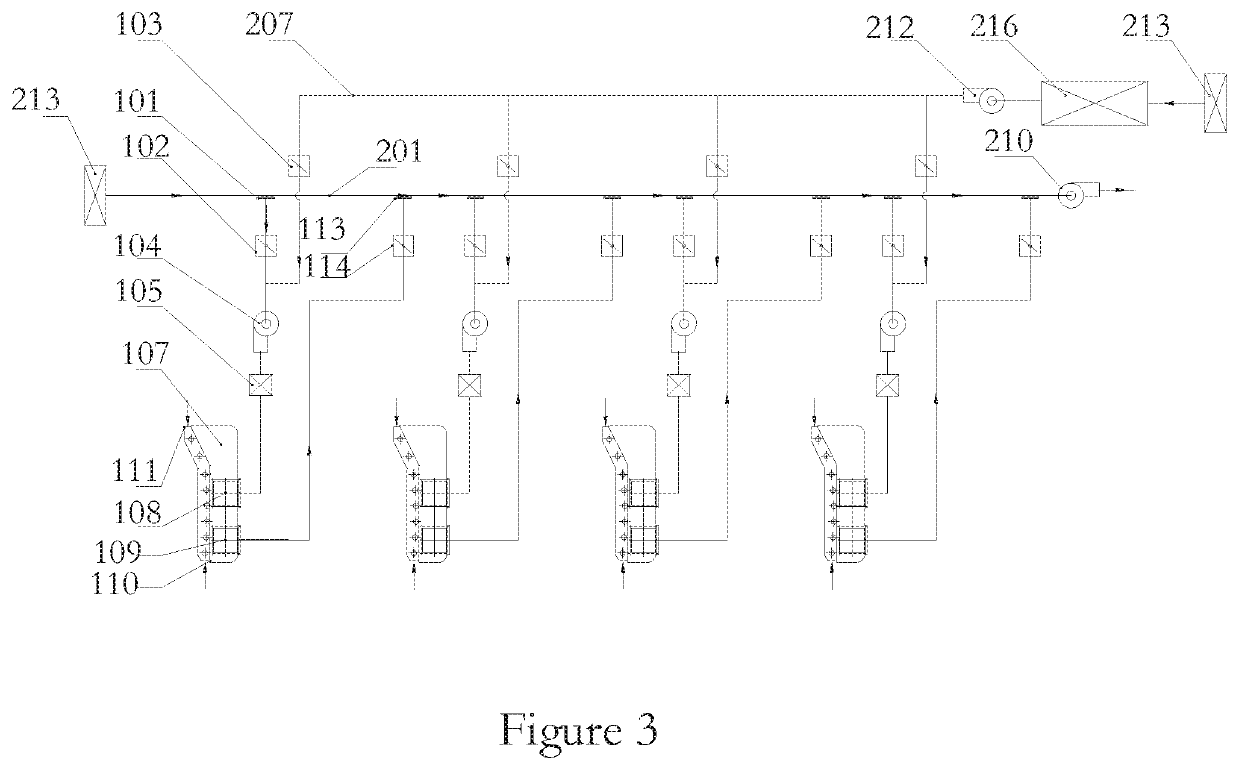

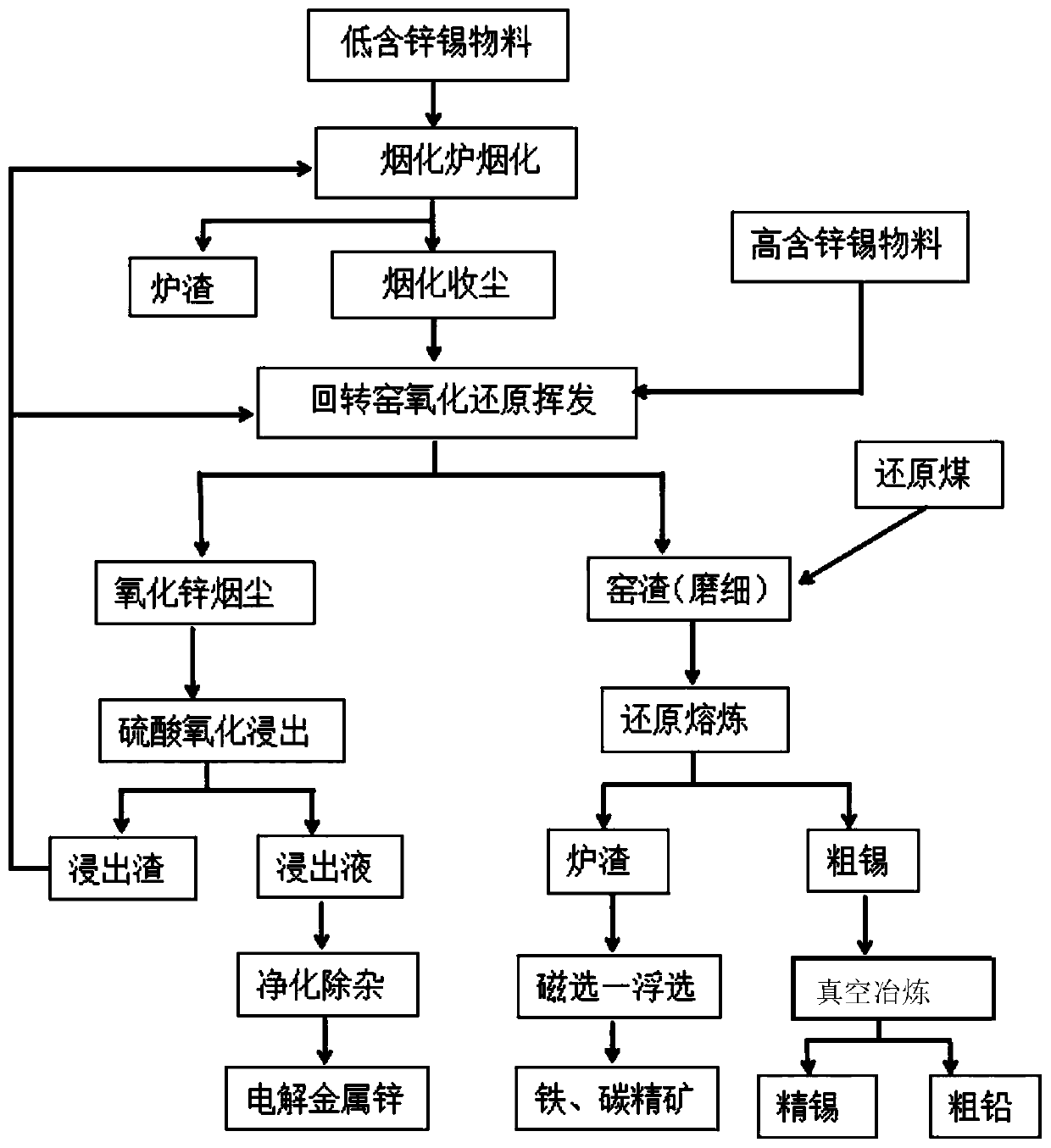

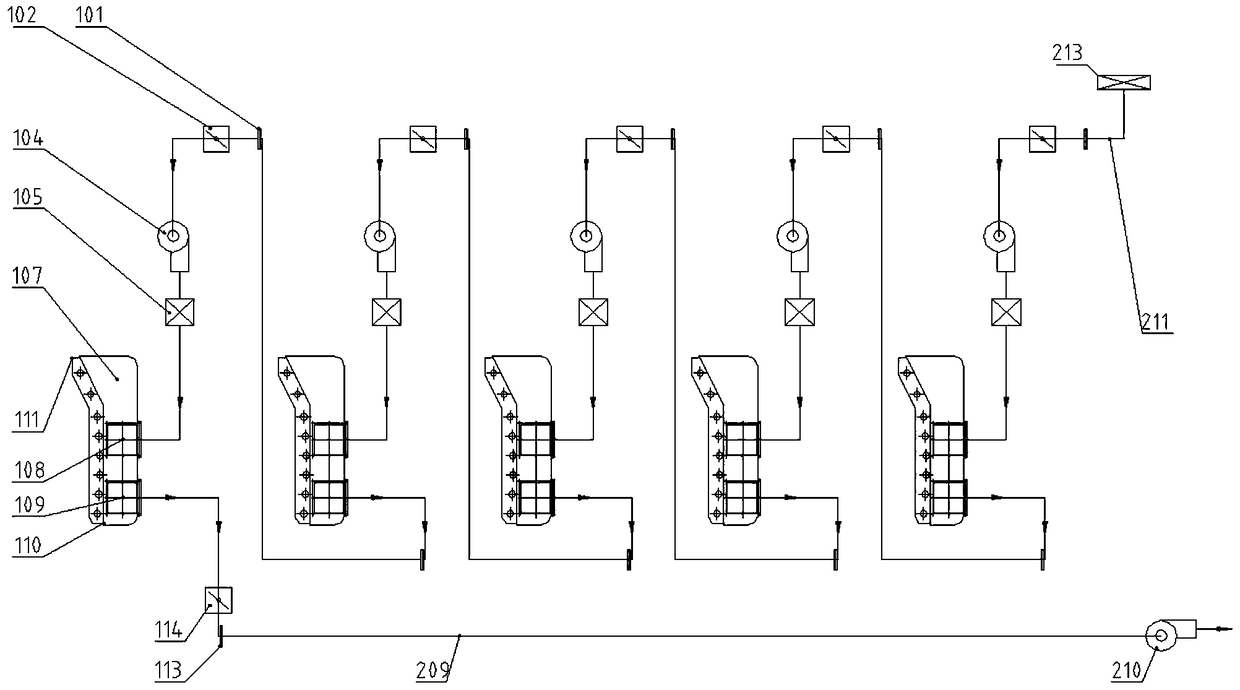

Tandem drying system

ActiveCN105444536AEasy to set upReduce exhaust air volumeDrying gas arrangementsPretreated surfacesWaste management

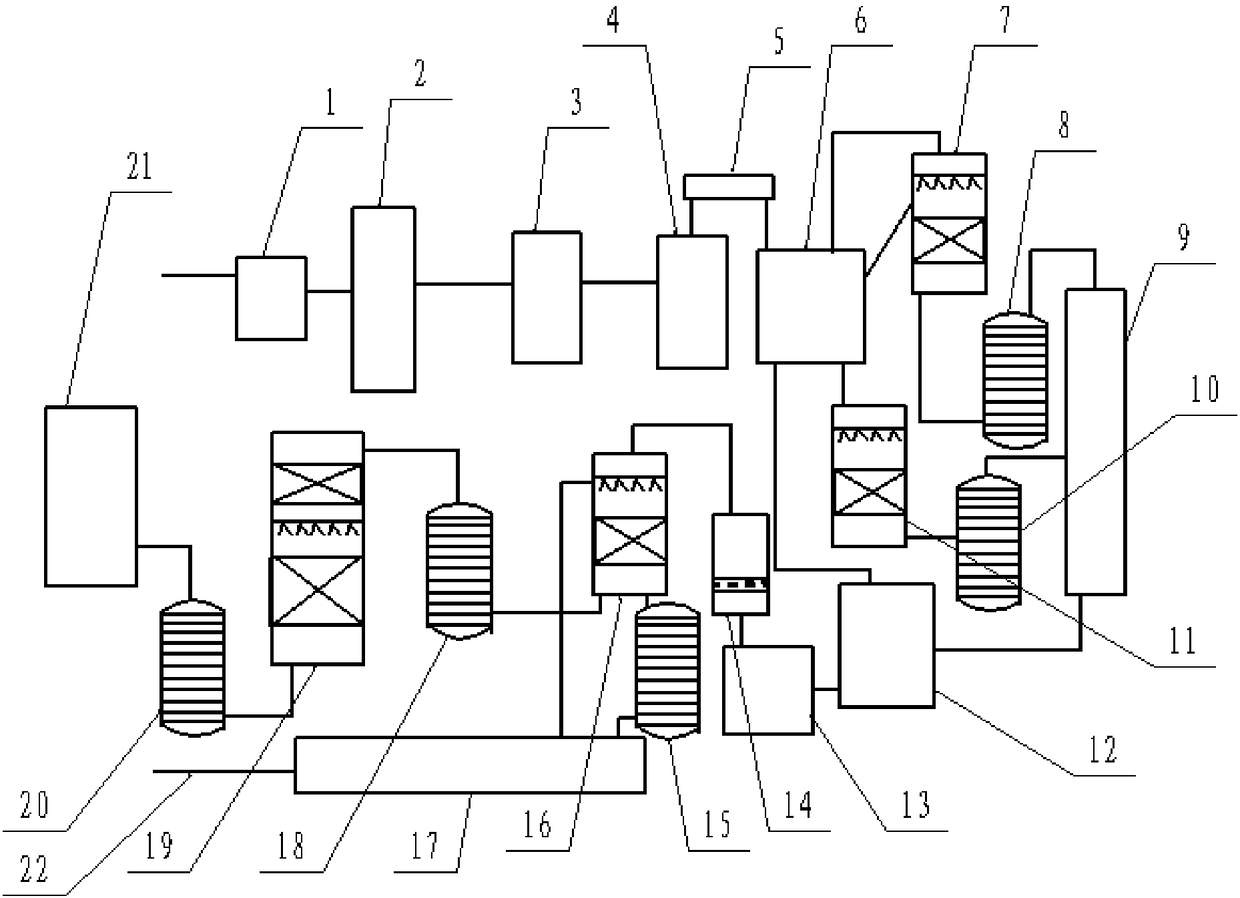

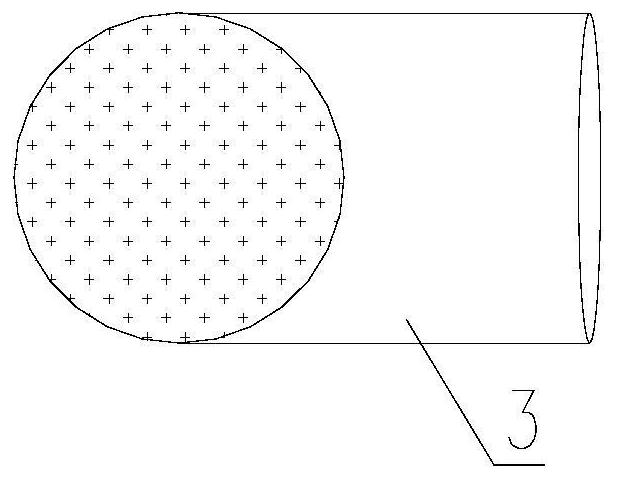

The invention provides a tandem drying system. The tandem drying system comprises at least two drying units, wherein each drying unit comprises a unit air supply fan and a drying box; a unit air inlet and a unit air outlet are formed in each drying unit; a drying box air inlet and a drying box air outlet are formed in each drying box; each unit air inlet is connected with the corresponding drying box air inlet; each unit air outlet is connected with the corresponding drying box air outlet; an exhaust air inlet which is connected with the unit air outlet of the last drying unit is formed in an exhaust air header pipe; a supply air outlet which is connected with the unit air inlet of the first drying unit is formed in a supply air header pipe; in every two adjacent drying units, the unit air outlet of the former drying unit is connected with the unit air inlet of the latter drying unit; each unit air supply fan is arranged between the corresponding unit air inlet and the corresponding drying box air inlet; and an exhaust air fan is arranged on the exhaust air outlet of the exhaust air header pipe. The tandem drying system has the advantages of simplicity and stability, easiness in adjustment, small exhaust air amount, low energy consumption, no potential safety hazards, low environment protection cost and the like.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

Comprehensive recovery method for zinc, nickel and cobalt-containing purification slag

ActiveCN107746969AHigh separation recovery rateEfficient separationPhotography auxillary processesProcess efficiency improvementRecovery methodSulfate radicals

The invention relates to a comprehensive recovery method for zinc, nickel and cobalt-containing purification slag. The method comprises the following steps: washing the zinc, nickel and cobalt-containing purification slag with hot water till the content of sulfate radicals or chlorine ions of a lotion is smaller than 1g / L and then leaching the purification slag with sodium hydroxide; obtaining zinc and cobalt-containing alkaline leaching liquor and leached slag primarily containing nickel; putting the alkaline leaching liquor in a magnetic field and performing diaphragm electrolysis by takinga magnetic material as an anode and a stainless steel plate as a cathode to obtain metal zinc powder in a cathode region and the cathode and anode slurry primarily containing Co2O3 and Co3O4 in an anode region and the anode; washing and drying the anode slurry, reducing the same directly with hydrogen to obtain metal cobalt powder or sulfuric acid leached out, precipitating oxalic acid to obtain cobalt oxalate, then reducing the cobalt oxalate with hydrogen to obtain metal cobalt powder, and electrolyzing metal cobalt; returning the alkaline residual electrolyte to leach zinc, nickel and cobalt purification slag; and washing the nickel-containing leach residue and leaching the same with sulfuric acid, and enriching the same and performing electrolysis to obtain metal nickel. The method provided by the invention is short in process flow, high in separating recovery rate of zinc, nickel and cobalt and small in wastewater and waste residue amount.

Owner:六盘水中联工贸实业有限公司 +1

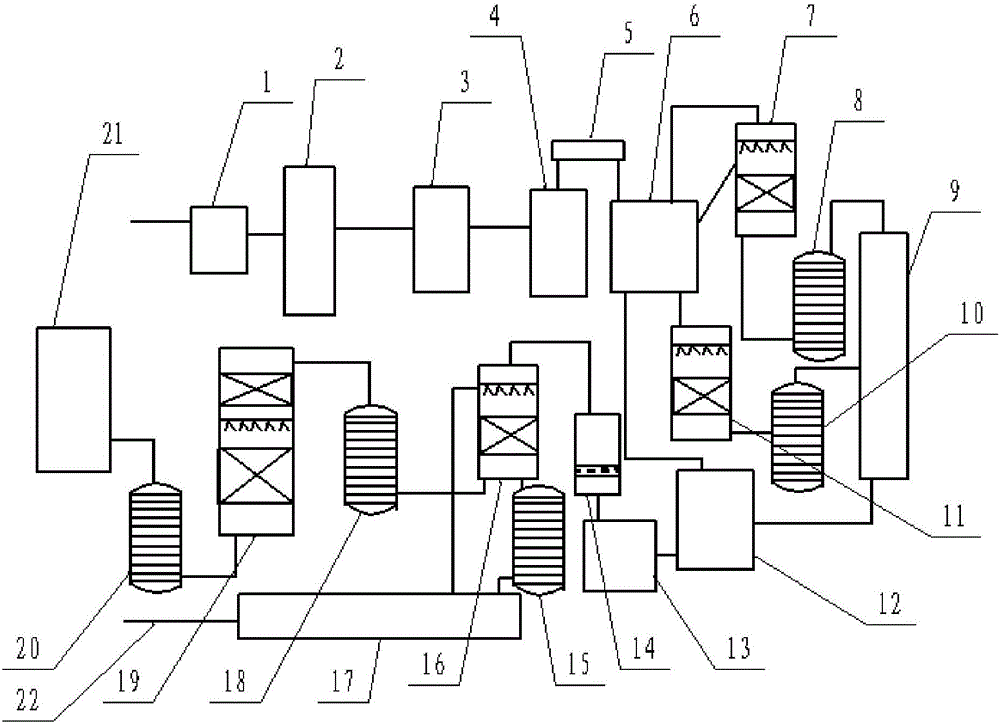

Method for preparing analytical pure sulfuric acid by using smelting flue gas

The invention discloses a method for preparing analytical pure sulfuric acid by using smelting gas, belonging to the field of sulfuric acid preparation. The method comprises the following steps: (1) carrying out deep purification to obtain high-purity flue gas; (2) transforming and absorbing to obtain industrial sulfuric acid; (3) evaporating: evaporating the industrial sulfuric acid until SO3-containing gas is obtained; (4) purifying: purifying the SO3-containing gas, obtained by evaporation, for a second time; (5) absorbing: absorbing the purified SO3-containing gas to obtain refined sulfuric acid; (6) removing SO2, removing the SO2 of the refined sulfuric acid to obtain the analytical pure sulfuric acid. In the preparation process, the SO3-containing gas, obtained by evaporating the prepared industrial sulfuric acid, rather than the flue gas is directly adopted as a source of the sulfuric acid to be prepared, so that the purity of the sulfuric acid is improved. Furthermore, the SO3-containing gas obtained by evaporating the industrial sulfuric acid is also demisted by using a demister, and nitrogen oxides are absorbed by using expanded graphite, so that impurities such as the nitrogen oxides which are produced in the preparation process are further removed, and the prepared sulfuric acid reaches the grade of analytical pure.

Owner:河池市生富冶炼有限责任公司

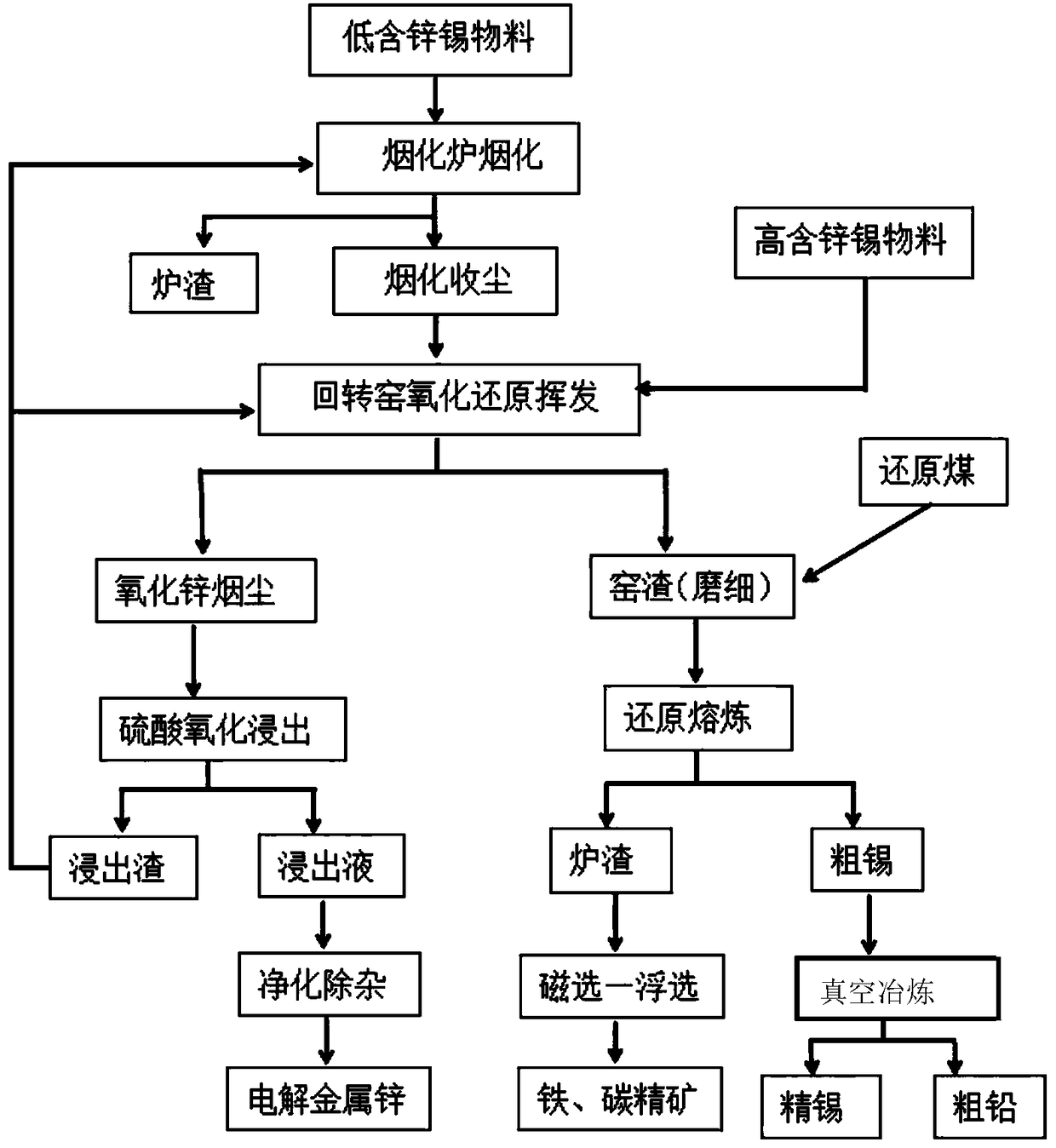

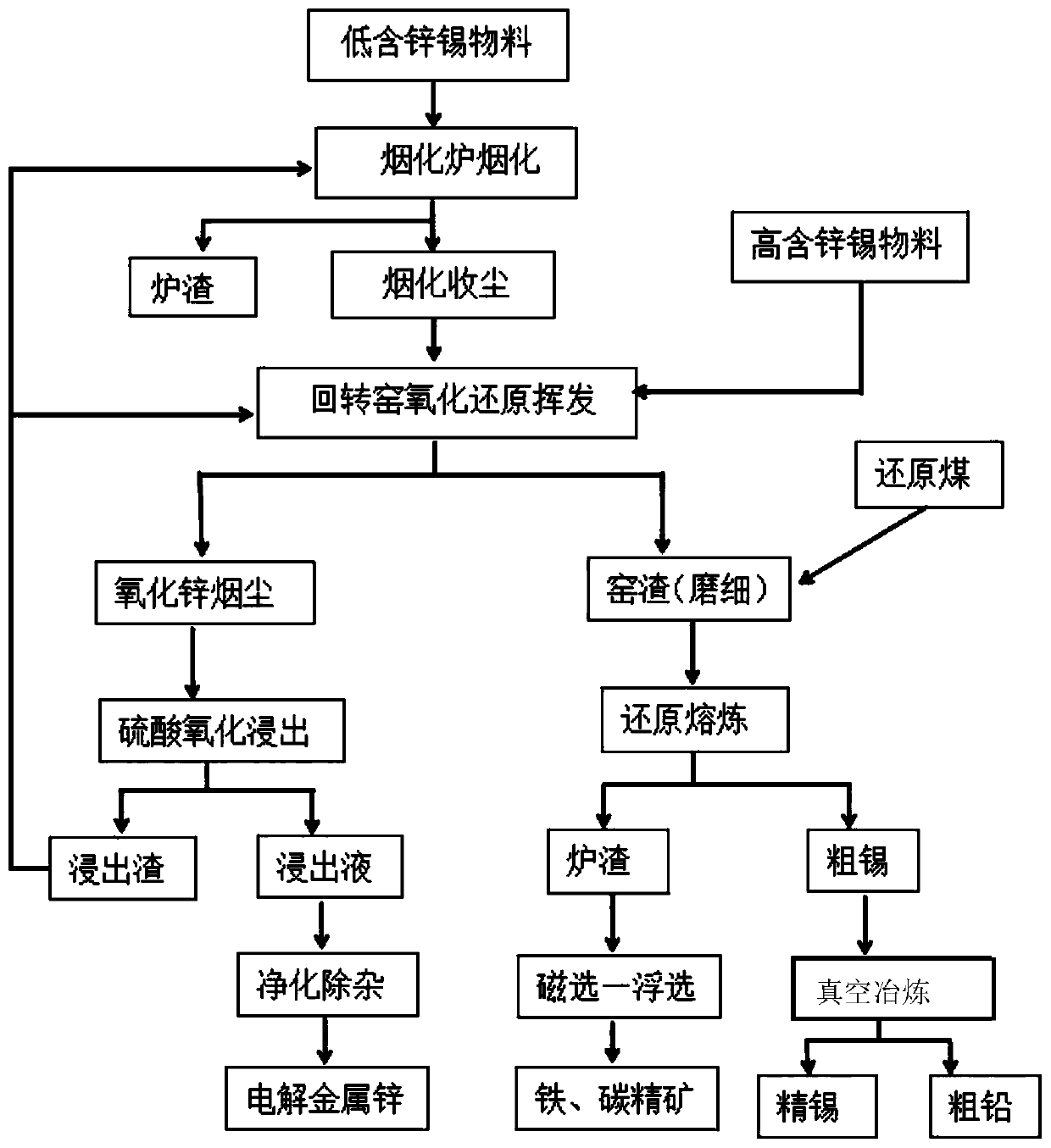

Method for recycling valuable metals from zinc-containing tin materials

InactiveCN109338111AEfficient separation and recoveryLess investmentPhotography auxillary processesProcess efficiency improvementIndiumSlag

The invention belongs to the field of metal smelting, and particularly relates to a method for recycling valuable metals from zinc-containing tin materials. The method comprises the following steps that 1, the zinc-containing tin materials and reducing raw coal are mixed and added into a rotary kiln for roasting to obtain smoke dust and kiln slag; 2, the smoke dust is oxidized and leached with sulfuric acid and an oxidizing agent to obtain leachate and leached residues; 3, the leachate is carried out purification and impurity removal after the leachate is subjected to extraction to recycle indium and germanium, then the leachate is electrolyzed to obtain metal zinc, and the leached residues are returned to the rotary kiln or a fuming furnace for treatment; 4, the kiln slag is subjected toball milling and then is mixed with coke to be added into a reduction furnace to be smelted to obtain metal crude tin and reduced furnace slag; and 5, vacuum smelting is carried out on the crude tin to obtain fine tin and metal lead, flotation and magnetic separation are carried out on the reduced furnace slag, and the magnetic separation tailings can be used as raw materials for cement production. According to the method, metals such as lead, zinc and tin can be efficiently separated and recycled, fewer three wastes are generated, the cost is low, the technological process is short, the device is simple, the adaptability is high, and popularization and application are easy to carry out.

Owner:贵州省兴安环保科技有限公司

Energy-saving and environment-friendly fine deep processing method for beaver rabbit skin

InactiveCN101603099AReduced hair removal rateReduced rehumidification timeTanning treatmentPre-tanning chemical treatmentSodium bicarbonateAcetic acid

The invention discloses an energy-saving and environment-friendly fine deep processing method for beaver rabbit skin, which comprises the following steps: 1) shunting and grouping; 2) soaking water; 3) secondarily soaking water; 4) removing meat; 5) softening and soaking acid; 6) tanning; and 7) post finishing, wherein the soaking water solution contains Supralan 80, Actival OLN and Fulguran APC; the secondary soaking water solution contains anhydrous sodium sulfate, formic acid, Supralan 80 and Wetter HAC; the softening and soaking acid solution contains Super lotan A, salt, lactic acid, acetic acid and Wetter HAC, and is added with Pelgrassol LP and Eskatan GLS; and the tanning solution contains edible ammonium alum, salt, mirabilite and Wetter HAC, and is added with Novaltan PF, Novaltan AL, Prinol M31 Spezial and edible sodium bicarbonate. The method simplifies the process, saves the using amount of chemical materials and water, reduces the manpower and energy consumption, reduces sewage production and discharge, greatly reduces the residual quantity of harmful chemical substances on the skin, and remarkably improves the quality of the skin.

Owner:HEBEI SUANG FUR & LEATHER

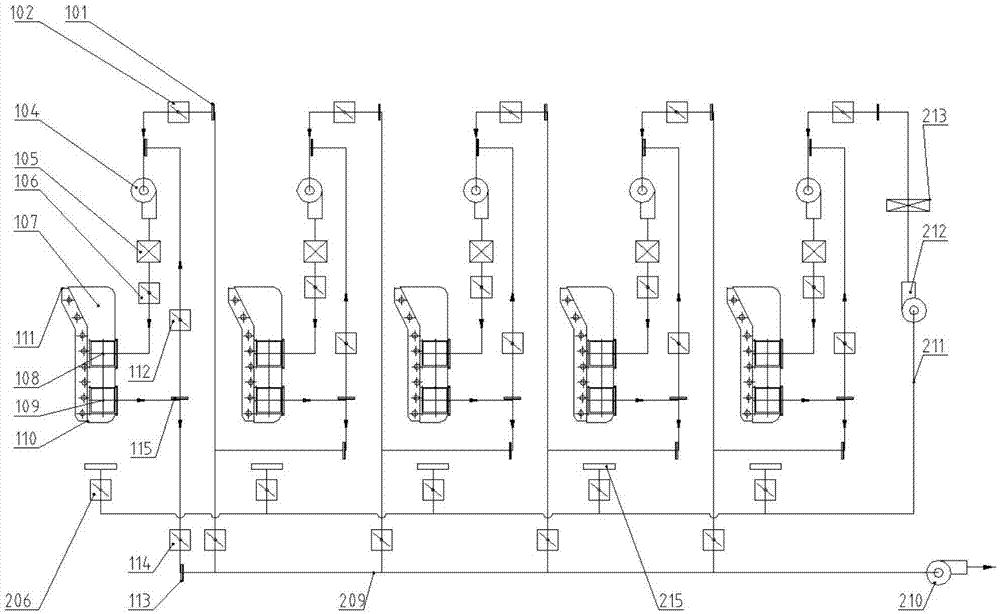

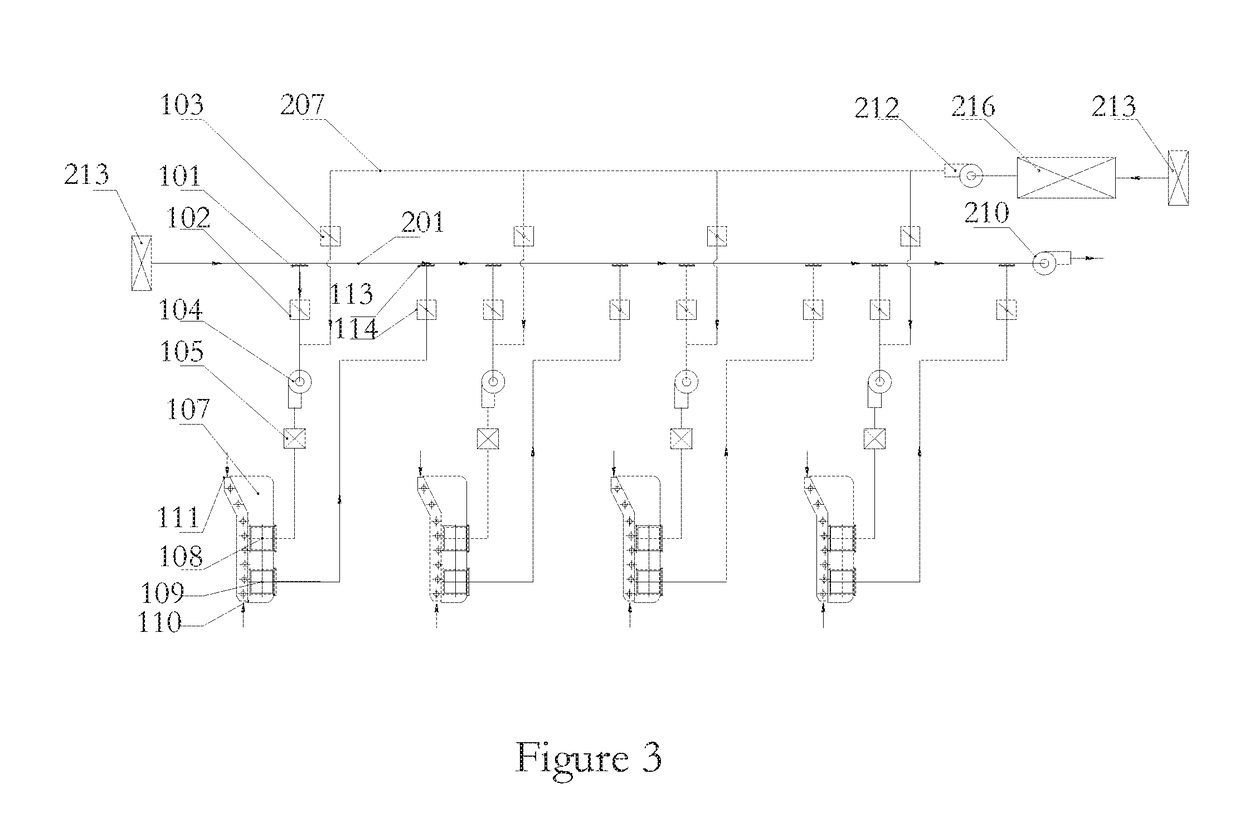

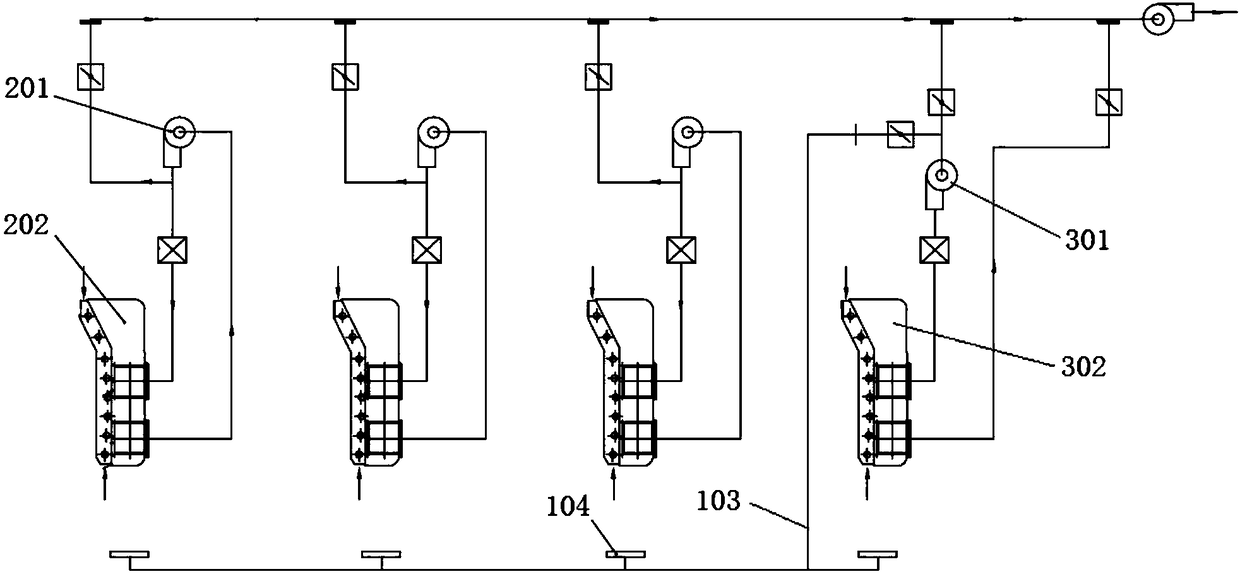

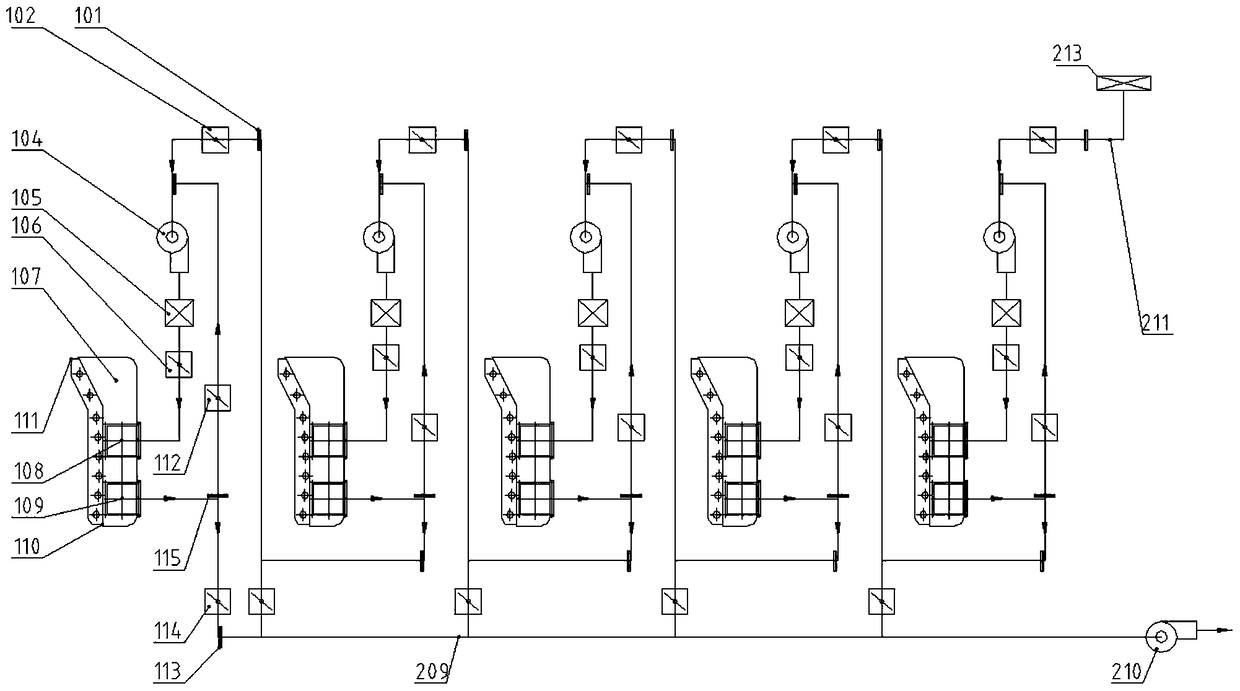

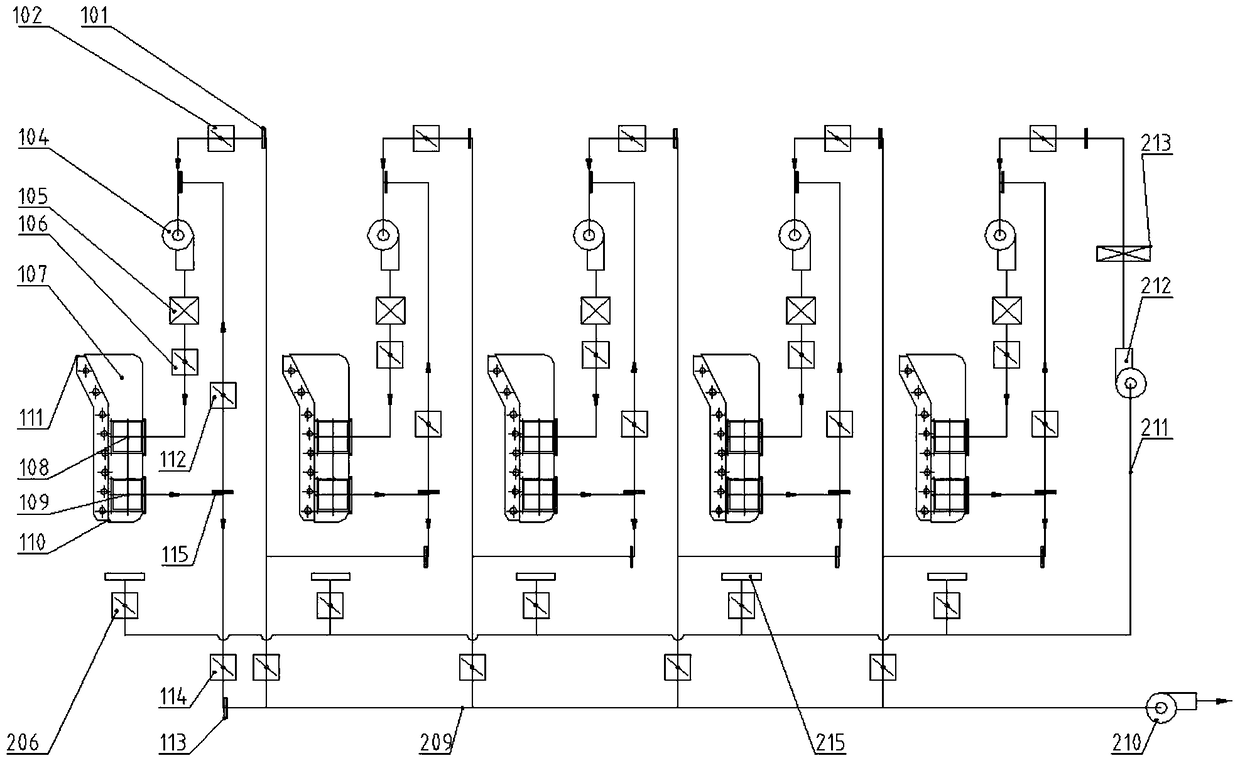

Balanced drying system

ActiveUS20180372407A1Easily implement entire process controlEliminate explosion hazardsDrying solid materials with heatDrying gas arrangementsAir volumeWaste management

The invention provides a balanced drying system, comprising an air supply and exhaust main pipeline, and at least two groups of drying units; the drying units each comprises a unit air supply fan and a drying oven, the drying units each is provided with a unit air inlet and a unit air outlet, the drying oven is provided with a drying oven air inlet and a drying oven air outlet, and all of the groups of the drying units are disposed in pairs at intervals on the air supply and exhaust main pipeline via the unit air inlet and the unit air outlet, the unit air inlet is connected with the drying oven air inlet, and the unit air outlet is connected with the drying oven air outlet. The invention has the advantages of concise and stable system, simple adjustment, low exhaust air volume, low energy consumption and the like.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

Method for recycling indium and germanium from chlorination distillation residual liquor containing indium and germanium

ActiveCN108060305AImprove regenerative abilityReduce separation costsProcess efficiency improvementIndiumDistillation

The invention relates to the technical field of hydrometallurgy, in particular to a method for recycling indium and germanium from chlorination distillation residual liquor containing the indium and the germanium. The method comprises the steps that tartaric acid is added to the distillation residual liquor, so that mixed liquor containing InCl4 or InCl6<3> germanium tartrate acid radical anions (Ge(A)3<2>), A representing the tartaric acid) is obtained; indium extraction and germanium extraction are conducted at the same time through a N235-kerosene system extraction agent; and then, indium reverse extraction is conducted through dilute acid, and germanium reverse extraction is conducted through a sodium hydroxide solution. By means of the method, the indium and germanium separation costis lowered; the extraction agent is high in regeneration capacity; the separation difficulty is lowered; the process is easy to implement; and operation is easy and convenient to conduct.

Owner:GUIZHOU HONGDA ENVIRONMENTAL PROTECTION TECHNOLOGY CO LTD

Method for preparing sulfuric acid from iron pyrite smelting flue gas

The invention discloses a method for preparing sulfuric acid from iron pyrite smelting flue gas. The method comprises the following steps: (1) filtering raw material flue gas through a flue gas filterafter performing once cooling, dust removal, pickling and once demisting treatment on sulfur-containing flue gas obtained by iron pyrite smelting; (2) feeding the filtered flue gas into a converter containing a catalyst bed layer, enabling the flue gas to perform heat exchange through the converter, and converting sulfur dioxide in flue gas into sulfur trioxide; (3) introducing converted gas discharged by the converter into an absorption tower to directly contact concentrated sulfuric acid, sufficiently absorbing, and separately discharging absorbed sulfuric acid and tail gas; and (4) performing secondary demisting on the discharged tail gas through a demister after secondary cooling, and discharging. According to the method, a series of deep purifying treatment is performed on the sulfur-containing flue gas, purity and quality of sulfuric acid are improved, a sulfur element recovery rate greater than 92% can be realized, product income of enterprises is increased, environment-friendly cost is reduced, and the economic benefit is obvious.

Owner:广西生富锑业科技股份有限公司

Method for preparing sulfuric acid from smelting fume

InactiveCN108147373AHigh purityImprove qualityDispersed particle filtrationSulfur compoundsFiltrationEconomic benefits

The invention discloses a method for preparing sulfuric acid from smelting fume. The method includes steps of (1), carrying out cooling and drying treatment on the sulfur-containing fume which is already subjected to depth purification; (2), delivering the sulfur-containing fume into a converter with catalyst bed layers after the drying treatment is carried out on the sulfur-containing fume, carrying out heat exchange on the fume by the aid of the converter, and converting sulfur dioxide in the fume into sulfur trioxide; (3), allowing converted gas exhausted from the converter to flow into anabsorption tower to be in direct contact with concentrated sulfuric acid, carrying out sufficient absorption, and discharging the sulfuric acid and the tail gas subjected absorption; (4), carrying outstandard reaching treatment on the tail gas discharged at the step (3) and then carrying out evacuation. The drying treatment includes drying the sulfur-containing fume by the aid of dilute sulfuricacid with the concentration of 30-45%, so that water in the sulfur-containing fume can be transferred into the dilute sulfuric acid. The method has the advantages that filtration, dust removal and purification can be effectively carried out by the aid of the method, accordingly, more than 95% of dust in the fume can be removed, the purity and the quality of the sulfuric acid can be improved, the sulfur element recycling rate can be higher than 94%, and the method has an obvious economic benefit.

Owner:广西生富锑业科技股份有限公司

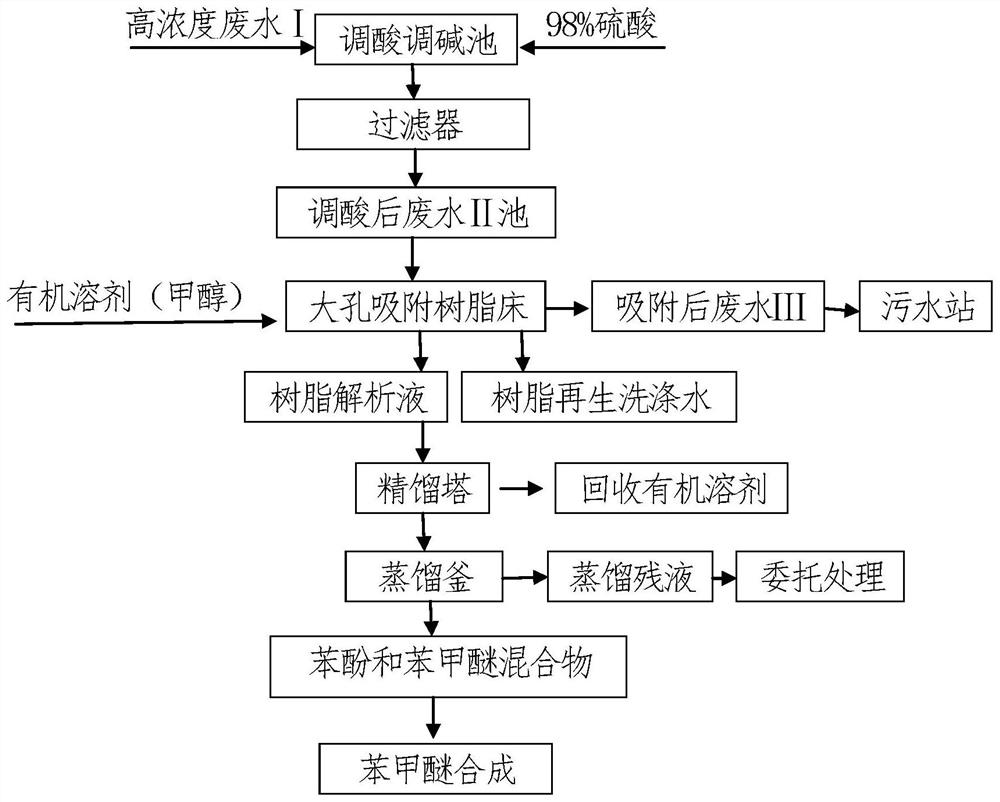

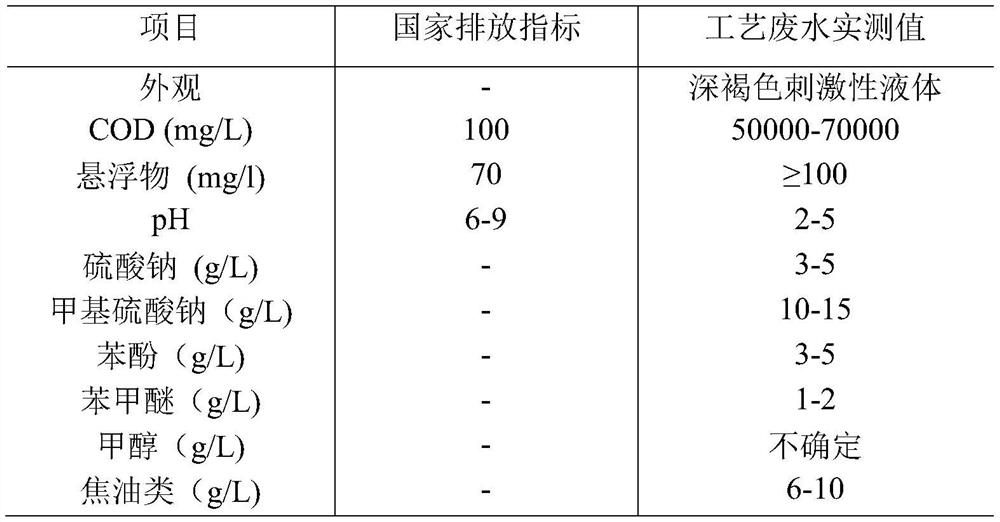

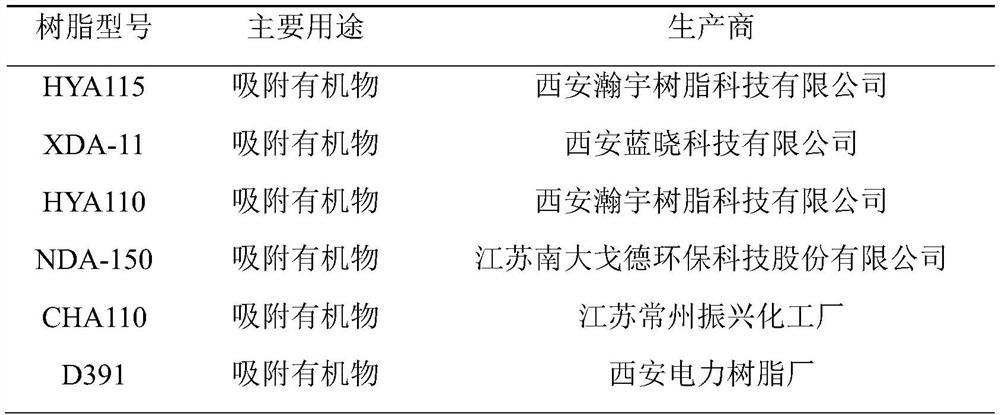

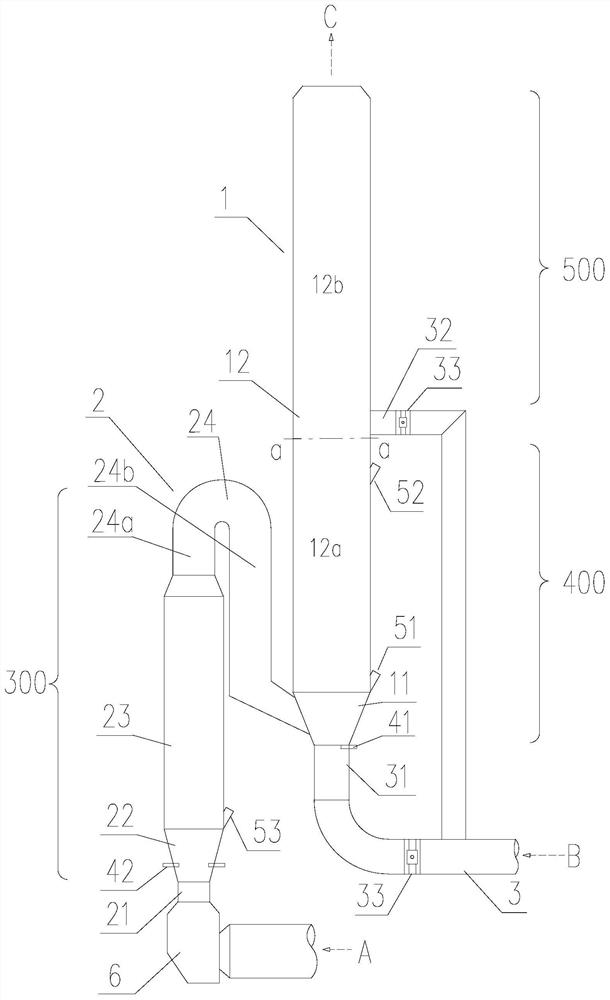

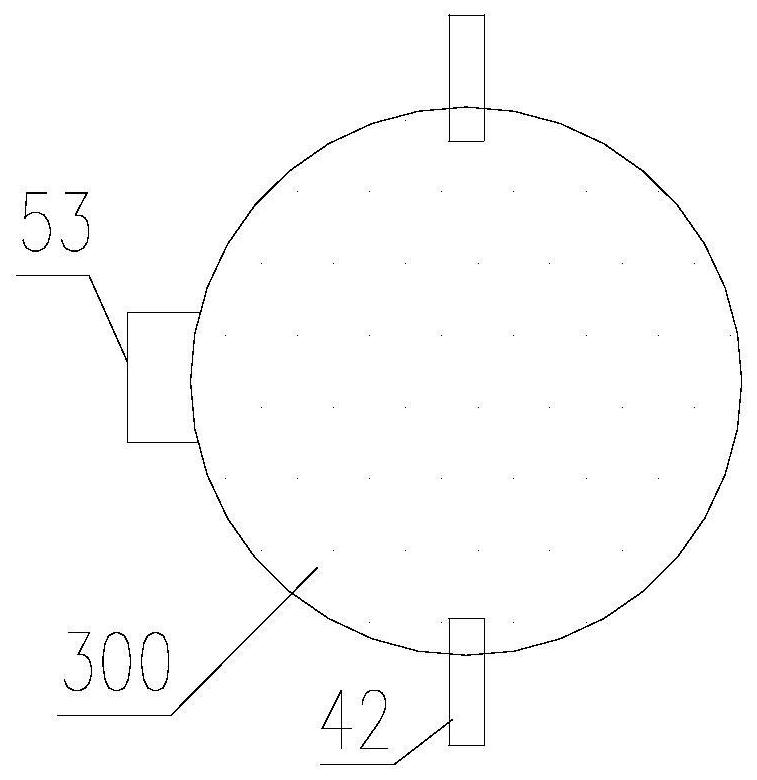

Method for treating high-concentration wastewater generated when anisole synthesized from methyl sodium sulfate waste residues

ActiveCN111995152ASolve pollutionLow cost of environmental protectionWater treatment parameter controlEther separation/purificationDistillationOrganosolv

The invention discloses a treatment method of high-concentration wastewater generated during synthesis of anisole from sodium methyl sulfate waste residues, sequentially comprising the following stepsof: regulating the pH value of high-concentration wastewater I to 3-4, and filtering to obtain acid-regulated wastewater II; adsorbing the acid-adjusted wastewater II through a macroporous adsorptionresin bed to obtain adsorbed wastewater III; carrying out desorption and elution on the macroporous adsorption resin after adsorption by using an organic solvent, and then washing the macroporous adsorption resin by using acid-adjusted wastewater II to respectively obtain a resin desorption solution and resin regeneration washing water; rectifying the resin desorption solution through the rectifying still to respectively obtain an organic solvent, water and rectifying still bottom residual liquid I; carrying out reduced pressure distillation on the residual liquid I at the bottom of the rectifying still to respectively obtain a mixture of phenol and anisole and a distillation residual liquid II; the method not only can solve the problem of wastewater pollution, but also can recover phenol, and realizes economic and environmental protection benefits.

Owner:ZHEJIANG DAYANG BIOTECH GROUP

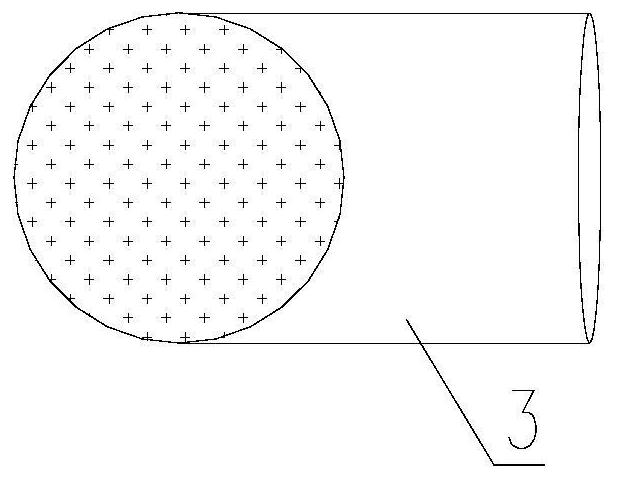

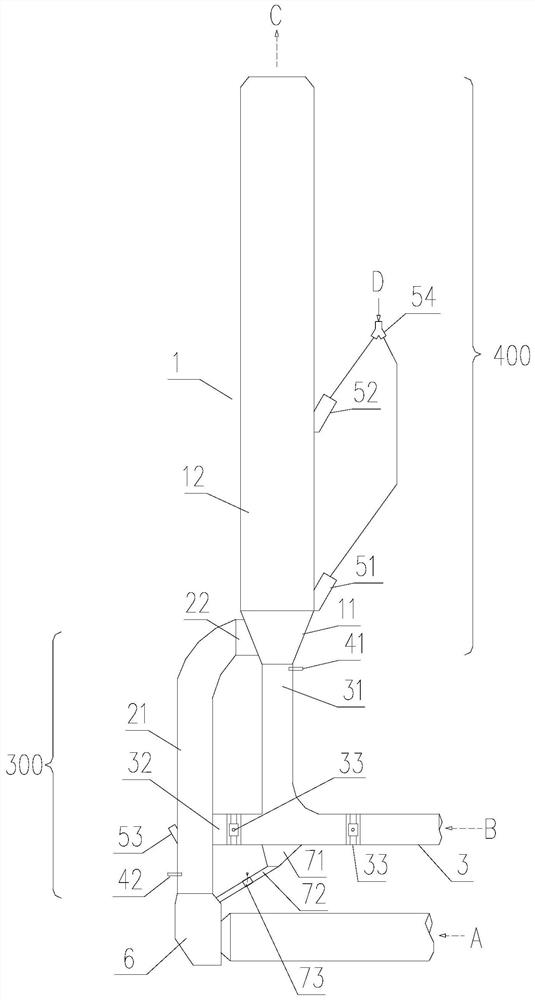

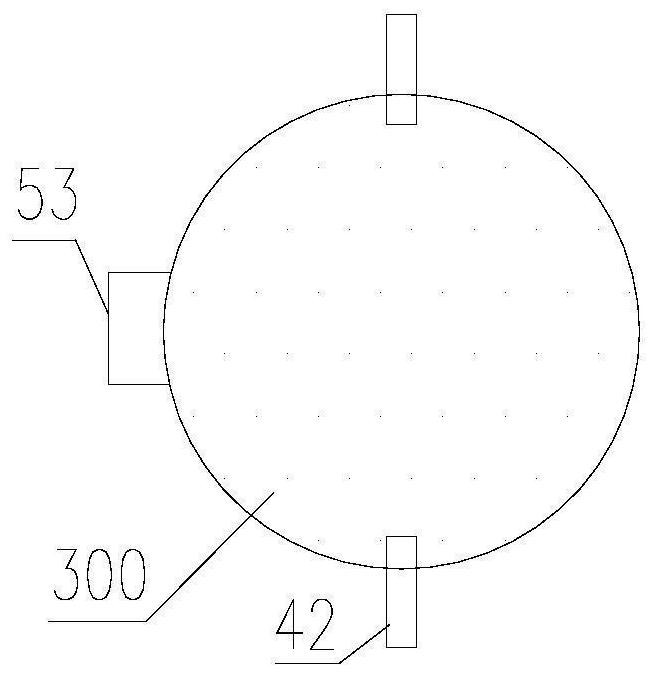

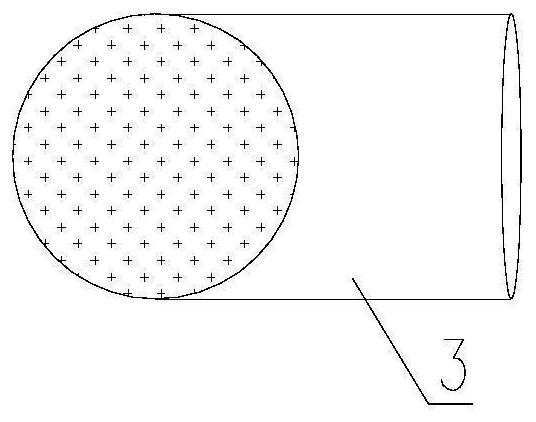

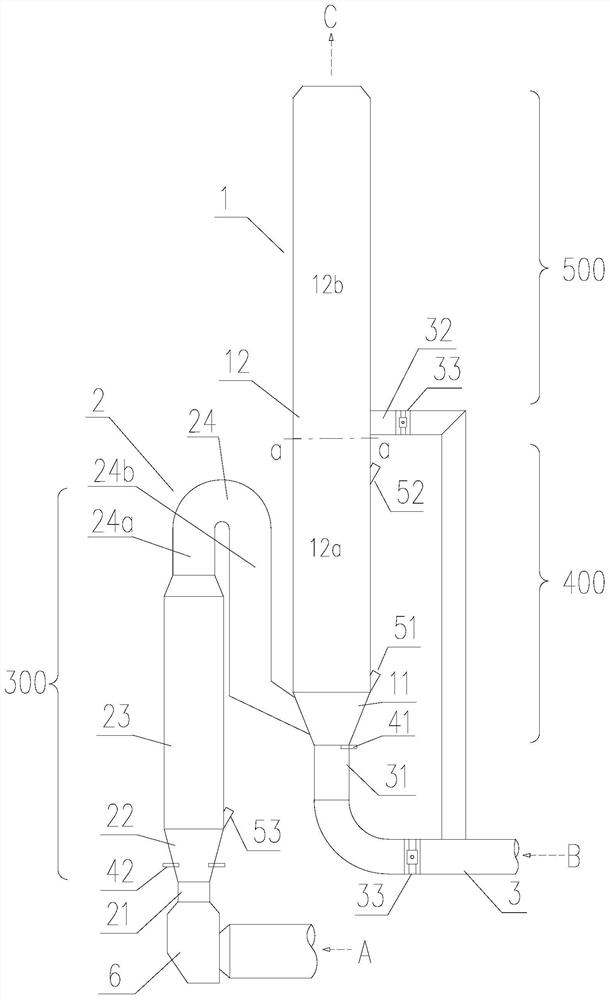

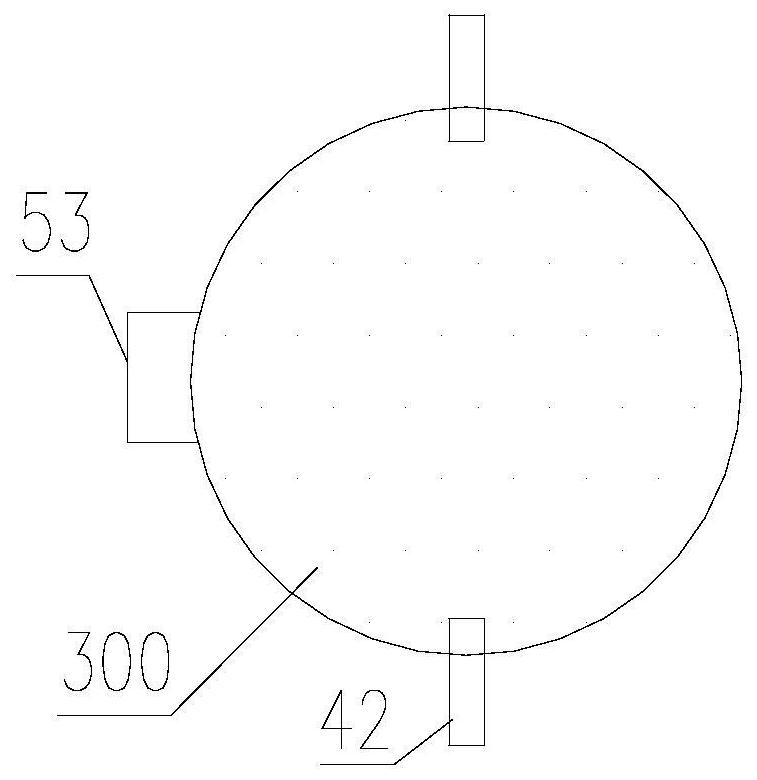

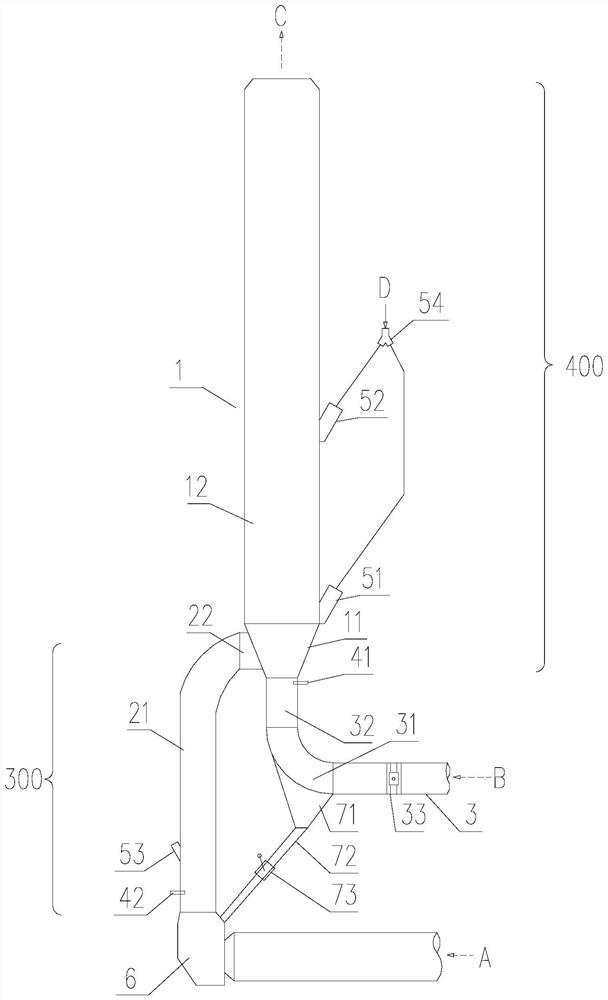

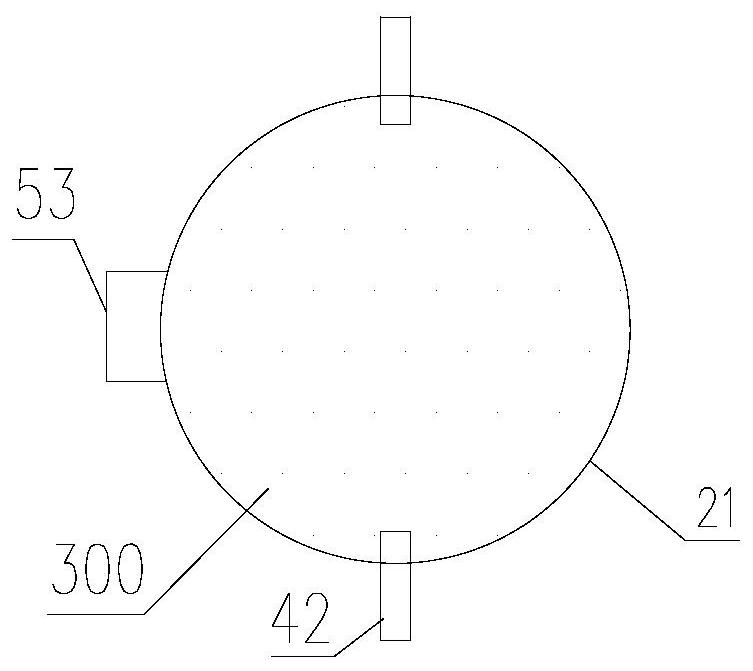

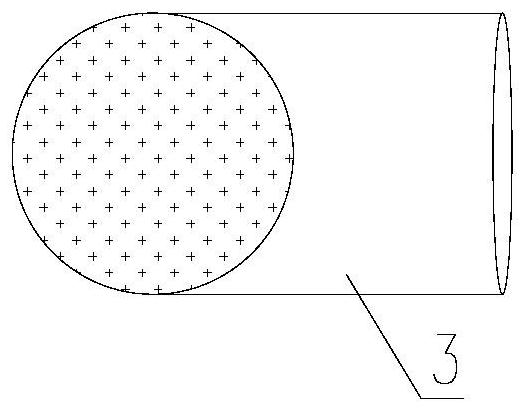

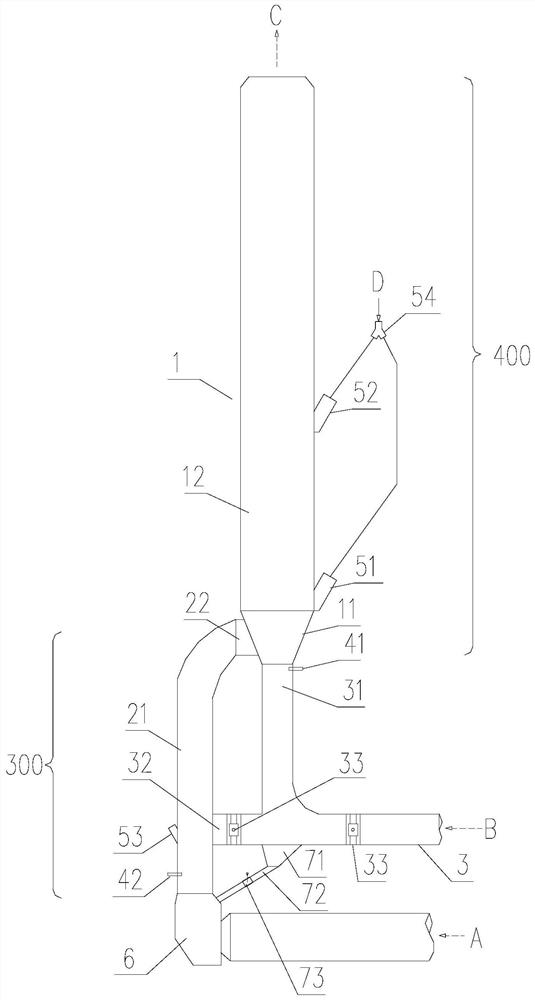

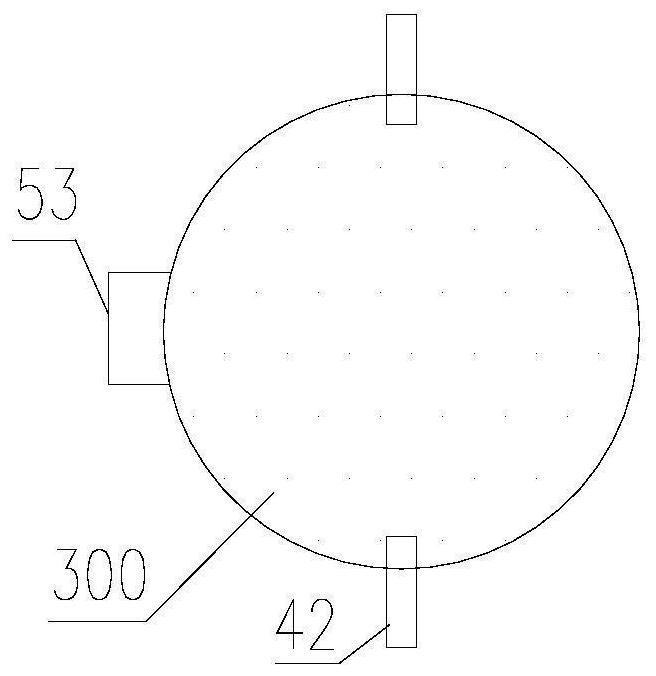

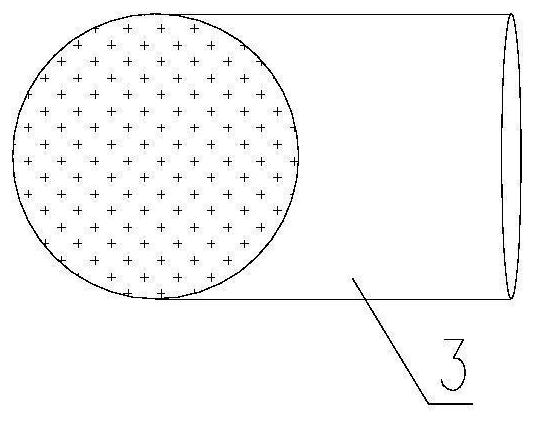

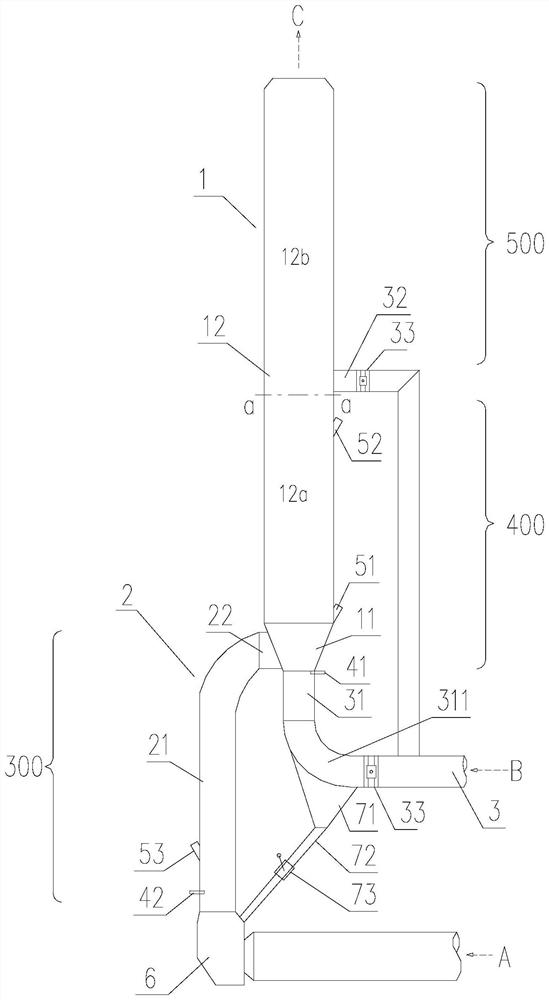

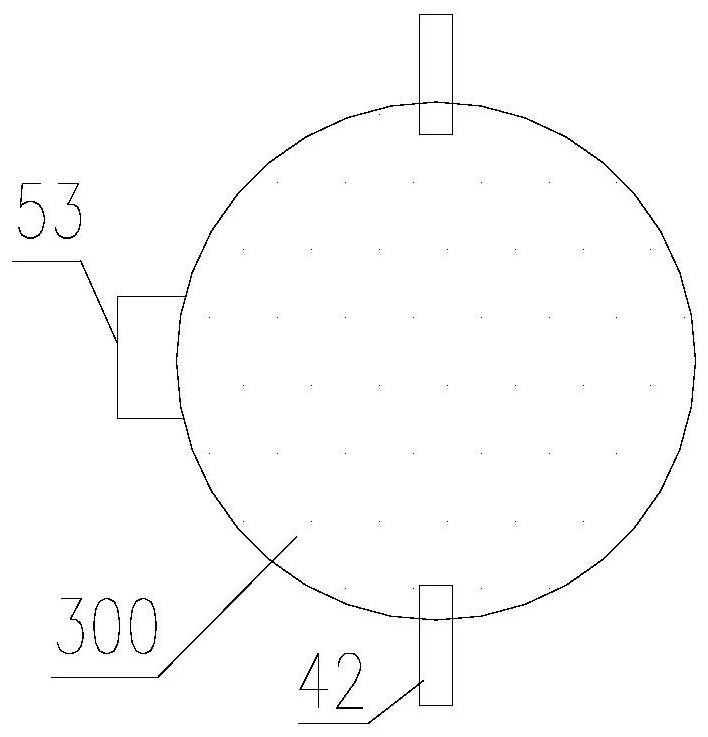

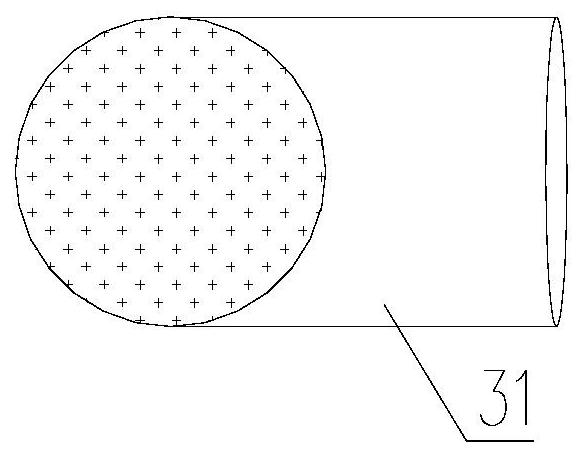

Partition organization combustion self-denitration system with reduction furnace and decomposing furnace and process

ActiveCN111750670ARaise the combustion temperatureLow cost of environmental protectionGas treatmentDispersed particle separationThermodynamicsCombustion

The invention discloses a partition organization combustion self-denitration system with a reduction furnace and a decomposing furnace and a process. The reduction furnace is arranged between a kiln tail smoke chamber and the decomposing furnace, an outlet of the reduction furnace is connected with the side face of the decomposing furnace, a tertiary air lower branch pipe is connected with the bottom of a decomposing furnace cone, and a transverse partition combustion environment of a central concentrated oxygen area and a peripheral light oxygen area is formed on the cross section of the decomposing furnace; a tertiary air upper branch pipe is connected with the middle of a decomposing furnace column, a strong reduction area is arranged in the reduction furnace, the space, below the tertiary air upper branch pipe, in the decomposing furnace is a weak reduction area, the space, above the tertiary air upper branch pipe, in the decomposing furnace is a burnout area, and a longitudinal gradient combustion environment combining the strong reduction area, the weak reduction area and the burnout area is formed. The transverse partition combustion environment is realized by longitudinallyand upwards feeding tertiary air from the center of the bottom of the decomposing furnace and tangentially rotating flue gas from the side surface of the decomposing furnace; the longitudinal gradient combustion environment is achieved through fuel graded feeding and tertiary air distribution. According to the system, partition organization combustion self-denitration is realized on the whole, and the self-denitration efficiency is improved.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Method for eliminating silicon dioxide emulsion of organic extracting agent

ActiveCN108486370ADoes not damage the structureLow cost of environmental protectionProcess efficiency improvementPhase splittingEmulsion

The invention relates to a method for eliminating silicon dioxide emulsion of an organic extracting agent. The method comprises the following steps: performing the microwave radiation for an organic extracting agent silicon dioxide emulsion, stirring while performing radiation for a given time, standing, performing the phase splitting, obtaining a loading organic phase and a water phase containingsilicon dioxide flocculent precipitates which are separated and clarified, and reusing the loading organic phase, wherein the microwave radiation frequency is 2 to 100 GHz, the power is 100 to 500 W,and the stirring and radiating time is 10 to 30 minutes; and the standing and phase-splitting time is 10 to 20 minutes, or the organic phase and the water phase are separated after 80 percent of silicon dioxide emulsion or more is eliminated, and the emulsion in the residual organic phase is returned to be treated by virtue of microwave. The silicon dioxide emulsion of the organic extracting agent is eliminated by utilizing the characteristic that the microwave radiation can losslessly penetrate through the organic phase with high dielectric constant such as kerosene and can be easily absorbed by the silicon dioxide hydrate emulsion to lead to the instantaneous high-temperature dehydration. The method has the characteristics of short time, high efficiency, low cost, no waste, and no wastewater.

Owner:六盘水中联工贸实业有限公司 +1

Decomposing furnace partitioned organization combustion self-denitration system and process capable of adjusting oxygen concentration of reduction zone

ActiveCN111750683ADoes not reduce burning rateComplete decomposition without reductionWaste heat treatmentThermodynamicsCombustion

The invention discloses a decomposing furnace partitioned organization combustion self-denitration system and process capable of adjusting an oxygen concentration of a reduction zone. According to thesystem and the process, a kiln gas flue is arranged between a kiln tail flue chamber and a decomposing furnace, a furnace inlet of the kiln gas flue is connected with the side face of the decomposingfurnace, a tertiary air pipe is connected with the bottom of a decomposing furnace cone, and a transverse partitioned combustion environment with a central concentrated oxygen area and a peripheral light oxygen area is formed on the transverse section of the decomposing furnace; a strong reduction area is arranged in the kiln gas flue, a burnout area is arranged in the decomposing furnace, and longitudinal staged combustion environments with different peroxide coefficients are formed in a combined combustion space of the kiln gas flue and the decomposing furnace; and a tertiary air branch pipe is arranged between the tertiary air pipe and the kiln gas flue. The transverse partitioned combustion environment is realized by longitudinally and upwards feeding tertiary air from the center of the bottom of the decomposing furnace and tangentially feeding flue gas from the side surface of the decomposing furnace in a rotating and volute mode, and the longitudinal staged combustion environments are realized through fuel staged feeding. According to the system and the method, partitioned organization combustion self-denitration is realized on the whole, the self-denitration efficiency is improved, and the utilization of space in the strong reduction area is improved.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

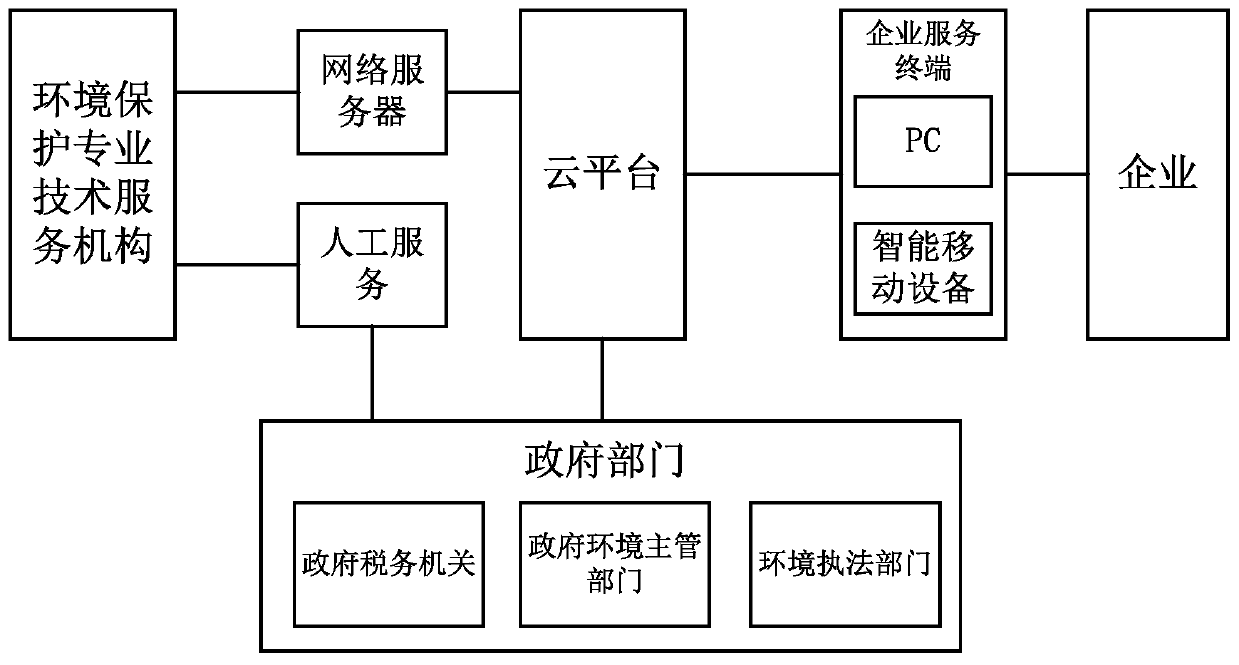

Environment-friendly cloud housekeeper for agency of environment-friendly affairs for enterprises based on network cloud platform

InactiveCN110827173ALow cost of environmental protectionData processing applicationsTransmissionEnvironmental resource managementBusiness enterprise

The invention discloses an environment-friendly cloud housekeeper for agency of environment-friendly affairs for enterprises based on a network cloud platform, relates to the field of environmental protection and the environment-friendly cloud housekeeper comprises a cloud platform, enterprises, government departments and environmental protection professional technical service institutions, the cloud platform is used for providing environmental protection services for the enterprises, and the environmental protection services comprise environmental protection government affair services provided by the government departments and environmental protection agency services provided by the environmental protection professional technical service institution; the enterprises are used for logging in the cloud platform to accept the environmental protection service provided by the cloud platform; the government department is used for providing government affair environmental protection service for the enterprise through a cloud platform or an environmental protection professional technical service institutions; and the environmental protection professional technical service mechanism is usedfor providing environmental protection agency service for the enterprises through the cloud platform. Environmental protection affairs of enterprises are agented through an environmental protection professional technical service mechanism, so that the environmental protection cost of the enterprises is effectively reduced.

Owner:余继跃

A kind of comprehensive recovery method of zinc, nickel, cobalt purification slag

ActiveCN107746969BHigh separation recovery rateEfficient separationPhotography auxillary processesProcess efficiency improvementRecovery methodElectrolysis

The invention relates to a comprehensive recovery method for zinc, nickel and cobalt-containing purification slag. The method comprises the following steps: washing the zinc, nickel and cobalt-containing purification slag with hot water till the content of sulfate radicals or chlorine ions of a lotion is smaller than 1g / L and then leaching the purification slag with sodium hydroxide; obtaining zinc and cobalt-containing alkaline leaching liquor and leached slag primarily containing nickel; putting the alkaline leaching liquor in a magnetic field and performing diaphragm electrolysis by takinga magnetic material as an anode and a stainless steel plate as a cathode to obtain metal zinc powder in a cathode region and the cathode and anode slurry primarily containing Co2O3 and Co3O4 in an anode region and the anode; washing and drying the anode slurry, reducing the same directly with hydrogen to obtain metal cobalt powder or sulfuric acid leached out, precipitating oxalic acid to obtain cobalt oxalate, then reducing the cobalt oxalate with hydrogen to obtain metal cobalt powder, and electrolyzing metal cobalt; returning the alkaline residual electrolyte to leach zinc, nickel and cobalt purification slag; and washing the nickel-containing leach residue and leaching the same with sulfuric acid, and enriching the same and performing electrolysis to obtain metal nickel. The method provided by the invention is short in process flow, high in separating recovery rate of zinc, nickel and cobalt and small in wastewater and waste residue amount.

Owner:六盘水中联工贸实业有限公司 +1

A method for recovering indium germanium from chlorinated distillation raffinate containing indium germanium

The invention relates to the technical field of hydrometallurgy, in particular to a method for recycling indium and germanium from chlorination distillation residual liquor containing the indium and the germanium. The method comprises the steps that tartaric acid is added to the distillation residual liquor, so that mixed liquor containing InCl4 or InCl6<3> germanium tartrate acid radical anions (Ge(A)3<2>), A representing the tartaric acid) is obtained; indium extraction and germanium extraction are conducted at the same time through a N235-kerosene system extraction agent; and then, indium reverse extraction is conducted through dilute acid, and germanium reverse extraction is conducted through a sodium hydroxide solution. By means of the method, the indium and germanium separation costis lowered; the extraction agent is high in regeneration capacity; the separation difficulty is lowered; the process is easy to implement; and operation is easy and convenient to conduct.

Owner:GUIZHOU HONGDA ENVIRONMENTAL PROTECTION TECHNOLOGY CO LTD

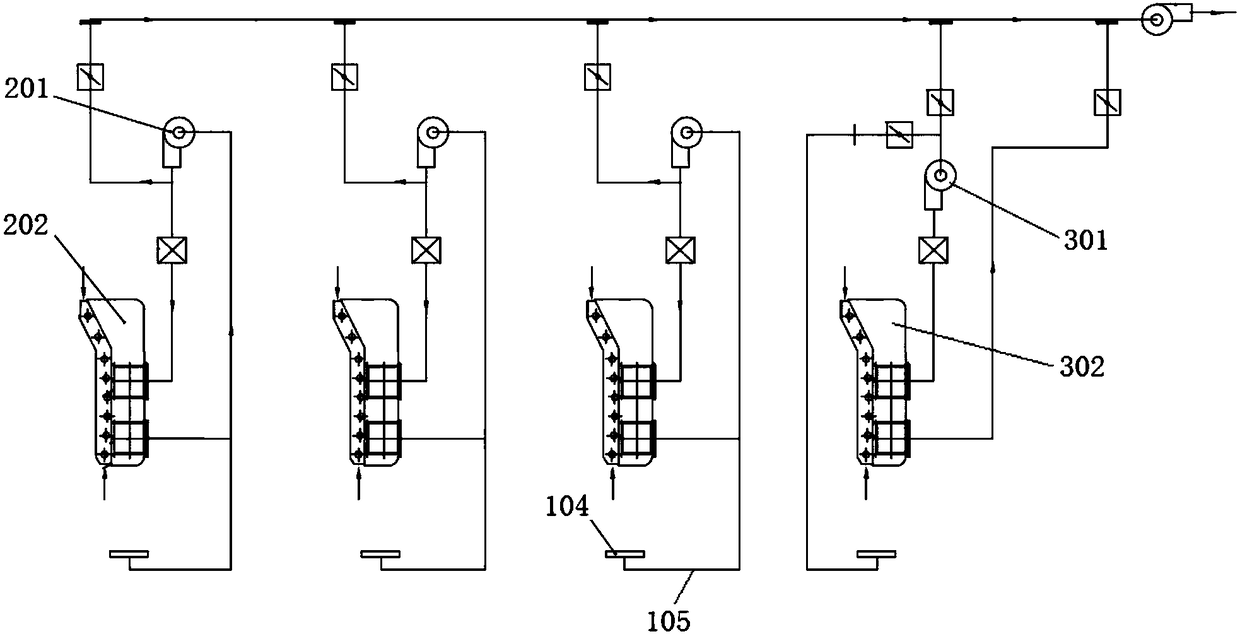

An exhaust hot air drying system

ActiveCN105972979BSimple structureImprove cleanlinessDrying gas arrangementsAir volumeEnergy consumption

The invention provides an exhaust hot air drying system. The exhaust hot air drying system comprises an exhaust manifold, an exhaust fan and at least two first drying units, wherein the exhaust fan is arranged at the tail end of the exhaust manifold; the first drying units comprise first unit air supply fans and first drying boxes, and are provided with first unit exhaust holes; the first drying boxes are provided with first drying box air inlets, first drying box air outlets, first drying box feed inlets and first drying box discharge holes; the first drying units are sequentially connected on the exhaust manifold through the first unit exhaust holes; air outlets of the first unit air supply fans are connected with the first drying box air inlets; the air outlets of the first unit air supply fans are connected with the first unit exhaust holes; and the first drying box air outlets are connected with air inlets of the first unit air supply fans. The exhaust hot air drying system can radically achieve the purpose of energy conservation and emission reduction, and has the advantages that the system is concise and stable, the adjustment is simple, the exhaust volume is small, the energy consumption is low, the potential safety hazard is avoided, the environmental protection treatment cost is low, and the like.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

A method for producing analytically pure sulfuric acid from smelting flue gas

The invention discloses a method for preparing analytical pure sulfuric acid by using smelting gas, belonging to the field of sulfuric acid preparation. The method comprises the following steps: (1) carrying out deep purification to obtain high-purity flue gas; (2) transforming and absorbing to obtain industrial sulfuric acid; (3) evaporating: evaporating the industrial sulfuric acid until SO3-containing gas is obtained; (4) purifying: purifying the SO3-containing gas, obtained by evaporation, for a second time; (5) absorbing: absorbing the purified SO3-containing gas to obtain refined sulfuric acid; (6) removing SO2, removing the SO2 of the refined sulfuric acid to obtain the analytical pure sulfuric acid. In the preparation process, the SO3-containing gas, obtained by evaporating the prepared industrial sulfuric acid, rather than the flue gas is directly adopted as a source of the sulfuric acid to be prepared, so that the purity of the sulfuric acid is improved. Furthermore, the SO3-containing gas obtained by evaporating the industrial sulfuric acid is also demisted by using a demister, and nitrogen oxides are absorbed by using expanded graphite, so that impurities such as the nitrogen oxides which are produced in the preparation process are further removed, and the prepared sulfuric acid reaches the grade of analytical pure.

Owner:河池市生富冶炼有限责任公司

A zoned tissue combustion self-denitration system and process with a reduction furnace and a decomposition furnace

ActiveCN111750670BLow cost of environmental protectionAdaptableGas treatmentDispersed particle separationCombustionFlue gas

The invention discloses a self-denitrification system and process for zoned tissue combustion with a reduction furnace and a decomposition furnace. A reduction furnace is installed between the kiln tail smoke chamber and the decomposition furnace. The bottom of the calciner cone is connected to form a horizontally partitioned combustion environment with a central oxygen-rich zone and a peripheral low-oxygen zone on the calciner cross-section; The space inside the calciner below the upper branch pipe is the weak reduction zone, and the space inside the calciner above the upper branch pipe of the tertiary air is the burnout zone, forming a longitudinal gradient combustion environment combining strong reduction zone-weak reduction zone-burnout zone. The horizontal partition combustion environment is realized by the tertiary air entering vertically upward from the bottom center of the calciner, and the flue gas is realized by the spiral tangential rotating air entering from the side of the calciner; the vertical gradient combustion environment is realized by fuel graded feeding and tertiary air distribution. The present invention realizes self-denitrification through zoned organization combustion as a whole, and improves self-denitrification efficiency.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Production method of sodium silicate

ActiveCN110894073AAvoid it happening againLow cost of environmental protectionAlkali metal silicatesCyclohexanoneEngineering

The invention provides a production method of sodium silicate, which comprises the following steps: by using a waste alkali solution generated in cyclohexanone production process by cyclohexane oxidation method, or a concentrated solution generated in caprolactam refining process as a sodium source, providing a silicon source by quartz sand, and incinerating to obtain sodium silicate. Dangerous wastes such as sodium carbonate and sodium sulfate generated in the incineration treatment process of the waste alkali solution or the concentrated solution are avoided; waste is turned into wealth, theenvironment-friendly treatment cost of enterprises is reduced, meanwhile, energy needed by sodium silicate production is provided through incineration of the waste alkali solution or the concentratedsolution, and therefore the use amount of fuel is reduced, the sodium silicate production cost is reduced, energy consumption and carbon dioxide emission are reduced, and environmental pollution is reduced.

Owner:昌德新材科技股份有限公司

Balanced drying system

ActiveUS10995988B2Solve the real problemSimple equipmentDrying solid materials with heatDrying gas arrangementsAir volumeProcess engineering

The invention provides a balanced drying system, comprising an air supply and exhaust main pipeline, and at least two groups of drying units; the drying units each comprises a unit air supply fan and a drying oven, the drying units each is provided with a unit air inlet and a unit air outlet, the drying oven is provided with a drying oven air inlet and a drying oven air outlet, and all of the groups of the drying units are disposed in pairs at intervals on the air supply and exhaust main pipeline via the unit air inlet and the unit air outlet, the unit air inlet is connected with the drying oven air inlet, and the unit air outlet is connected with the drying oven air outlet. The invention has the advantages of concise and stable system, simple adjustment, low exhaust air volume, low energy consumption and the like.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

A kind of comprehensive recovery method containing zinc chloride solution

InactiveCN108085498BAchieve recyclingEasy extractionProcess efficiency improvementRecovery methodIndium

The invention discloses a comprehensive recovery method for solution containing zinc chloride, and relates to the technical field of hydrometallurgy. According to the invention, ZnCl4<2-> and chloridion are directly extracted under the condition of PH of 3 to 5 by adopting a N235-kerosene extraction agent, then an organic phase loaded with zinc and chlorine is reversely extracted by using 30 to 40% of sodium hydroxide, the obtained alkali reverse-phase extraction liquor is subjected to chlorine salt electrolysis, metal zinc powder is obtained in a cathode region, chlorine gas is obtained in ananode region, and residual electrolysis liquor is regenerative sodium hydroxide, so that comprehensive high-efficiency recovery of zinc, chlorine and sodium hydroxide in the solution containing zincchloride is implemented. According to the invention, the process flow is short; higher separation and recovery of all of chlorine, zinc, indium, gallium, bismuth, antimony, sodium carbonate and sodiumhydroxide are obtained, wherein a recovery rate of zinc in zinc powder reaches 95% or more; the comprehensive recovery method is low in production cost and high in economic value of the product, generates few waste residues and little wastewater, is low in environmental-friendly treatment cost and implements economic benefit maximization.

Owner:贵州省兴安环保科技有限公司

A method for eliminating silicon dioxide emulsions of organic extractants

ActiveCN108486370BDoes not damage the structureLow cost of environmental protectionProcess efficiency improvementEmulsionPhysical chemistry

Owner:六盘水中联工贸实业有限公司 +1

A kind of method for recovering valuable metal from zinc-tin-containing material

InactiveCN109338111BEfficient separation and recoveryLess investmentPhotography auxillary processesProcess efficiency improvementIndiumSlag

The invention belongs to the field of metal smelting, and particularly relates to a method for recycling valuable metals from zinc-containing tin materials. The method comprises the following steps that 1, the zinc-containing tin materials and reducing raw coal are mixed and added into a rotary kiln for roasting to obtain smoke dust and kiln slag; 2, the smoke dust is oxidized and leached with sulfuric acid and an oxidizing agent to obtain leachate and leached residues; 3, the leachate is carried out purification and impurity removal after the leachate is subjected to extraction to recycle indium and germanium, then the leachate is electrolyzed to obtain metal zinc, and the leached residues are returned to the rotary kiln or a fuming furnace for treatment; 4, the kiln slag is subjected toball milling and then is mixed with coke to be added into a reduction furnace to be smelted to obtain metal crude tin and reduced furnace slag; and 5, vacuum smelting is carried out on the crude tin to obtain fine tin and metal lead, flotation and magnetic separation are carried out on the reduced furnace slag, and the magnetic separation tailings can be used as raw materials for cement production. According to the method, metals such as lead, zinc and tin can be efficiently separated and recycled, fewer three wastes are generated, the cost is low, the technological process is short, the device is simple, the adaptability is high, and popularization and application are easy to carry out.

Owner:贵州省兴安环保科技有限公司

A series drying system

ActiveCN105444536BEasy to set upReduce exhaust air volumeDrying gas arrangementsPretreated surfacesWaste management

The invention provides a tandem drying system. The tandem drying system comprises at least two drying units, wherein each drying unit comprises a unit air supply fan and a drying box; a unit air inlet and a unit air outlet are formed in each drying unit; a drying box air inlet and a drying box air outlet are formed in each drying box; each unit air inlet is connected with the corresponding drying box air inlet; each unit air outlet is connected with the corresponding drying box air outlet; an exhaust air inlet which is connected with the unit air outlet of the last drying unit is formed in an exhaust air header pipe; a supply air outlet which is connected with the unit air inlet of the first drying unit is formed in a supply air header pipe; in every two adjacent drying units, the unit air outlet of the former drying unit is connected with the unit air inlet of the latter drying unit; each unit air supply fan is arranged between the corresponding unit air inlet and the corresponding drying box air inlet; and an exhaust air fan is arranged on the exhaust air outlet of the exhaust air header pipe. The tandem drying system has the advantages of simplicity and stability, easiness in adjustment, small exhaust air amount, low energy consumption, no potential safety hazards, low environment protection cost and the like.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

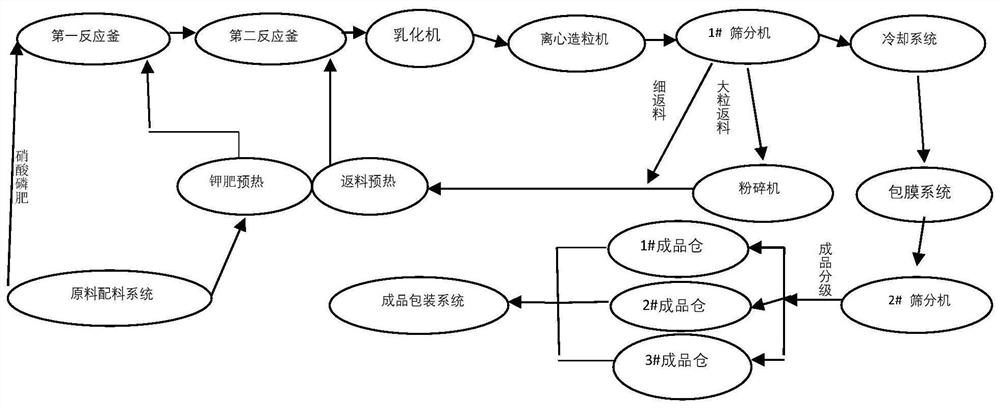

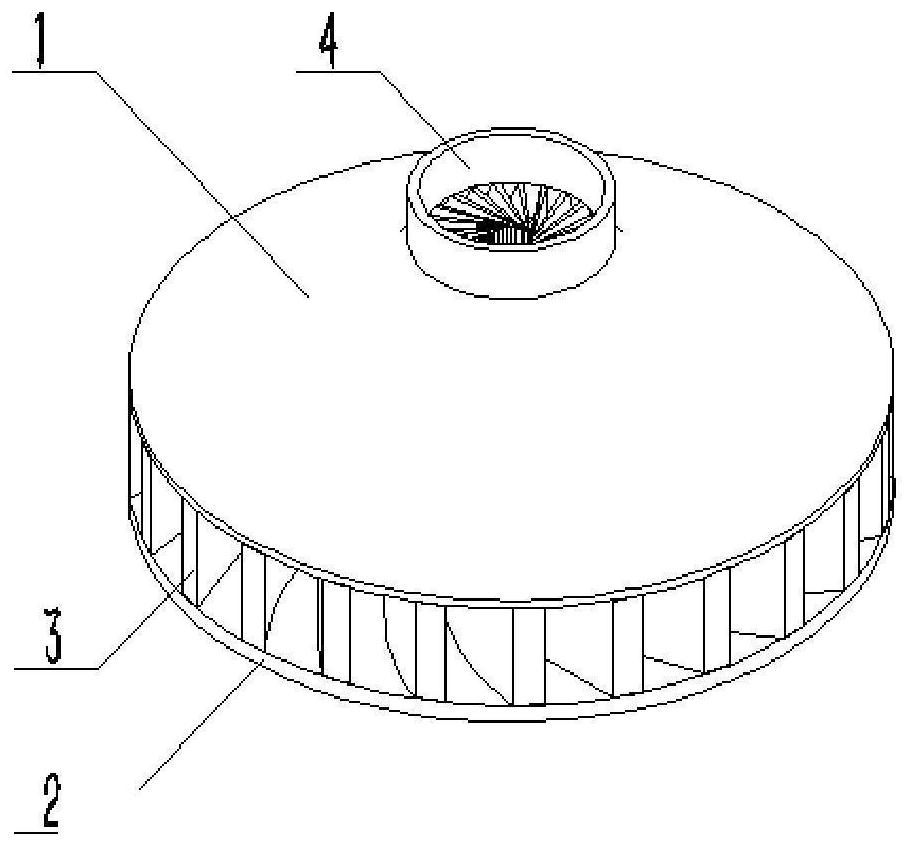

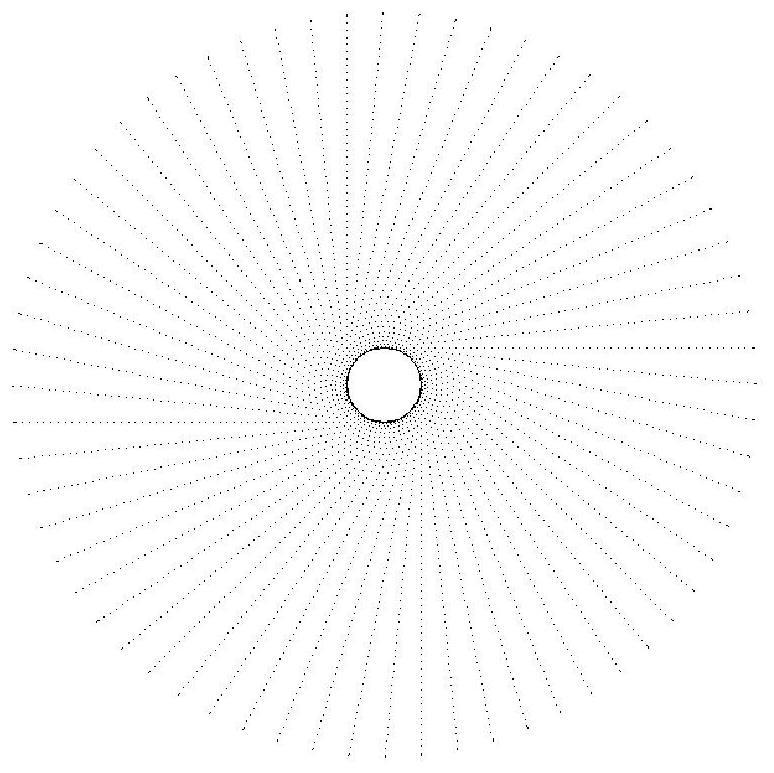

Low-tower preparation method of small-particle phosphorus-potassium nitrate fertilizer

InactiveCN113087574AReasonable NPK contentReduce manufacturing costSolid/semi-solid fertilisersPotassium fertilisersPotassium nitrateSoil science

The invention discloses a low-tower preparation method of a small-particle phosphorus-potassium nitrate fertilizer. The small-particle phosphorus-potassium nitrate fertilizer is prepared from a nitrophosphate fertilizer and a potassium fertilizer in a mass ratio of (0.5-9): 1, wherein the nitrophosphate fertilizer comprises 15-32% of nitrogen and 4-22% of phosphorus pentoxide; the potash fertilizer is selected from potassium sulfate and potassium chloride; the potassium sulfate is powdery potassium sulfate and comprises, in percentage by mass, 45-52% of potassium oxide; and the potassium chloride is powdery potassium chloride and comprises, in percentage by mass, 55-62% of potassium oxide. The nitrophosphate fertilizer and the potash fertilizer are made into slurry, and the slurry is emulsified and granulated to obtain a small-particle product within a range of 0.5-2.5 mm. According to the invention, the height of a granulation tower can be reduced from 100 meters or more to about 30 meters; and by controlling different technical indexes such as slurry temperature, granulator specification, granulator discharging mode, granulator rotating speed and the like, the slurry is atomized and centrifugally granulated to obtain the small-particle product. The atomization centrifugal granulator disclosed by the invention is free of a blocking phenomenon, production operation is easier to control, and production continuity is stronger.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

A self-denitration system and process for combustion and self-denitration in the dense and thin oxygen-containing zones of the calciner

ActiveCN111750684BDoes not reduce burning rateComplete decomposition without reductionWaste heat treatmentThermodynamicsCombustion

The invention discloses a self-denitrification system and process for combustion and self-denitration in the concentration and light oxygen-containing zones of a calciner. The side connection, the tertiary air pipe is connected to the bottom of the calciner cone, forming a horizontally partitioned combustion environment with a central oxygen-rich zone and a peripheral low-oxygen zone on the transverse section of the calciner; the kiln gas flue is a strong reduction zone, and the calciner is a combustion environment. In the ember zone, a vertically graded combustion environment with different oxygen peroxide coefficients is formed in the combined combustion space of the kiln gas flue and the calciner. The horizontal partition combustion environment is realized by making the tertiary air enter vertically upward from the center of the bottom of the calciner, and the flue gas enters the air from the side of the calciner by tangential rotation of the volute; the vertically graded combustion environment is realized by fuel graded feeding. The present invention realizes self-denitrification through zone-organized combustion as a whole, improves self-denitrification efficiency, does not reduce the combustion speed of calciner fuel and completely decomposes raw meal, and has no adverse effect on the cement clinker production process.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

A self-denitration system and process for calciner partitioned organization combustion self-denitration that can adjust the oxygen concentration in the reduction zone

ActiveCN111750683BDoes not reduce burning rateComplete decomposition without reductionWaste heat treatmentThermodynamicsCombustion

The invention discloses a self-denitrification system and process for calcining furnace partitioned organization combustion which can adjust the oxygen concentration in the reduction zone. The side of the furnace is connected, and the tertiary air pipe is connected to the bottom of the calciner cone, forming a horizontally partitioned combustion environment with a central oxygen-rich zone and a peripheral low-oxygen zone on the transverse section of the calciner; the kiln gas flue is a strong reduction zone, and the calciner is a In the embers area, a vertically graded combustion environment with different oxygen peroxide coefficients is formed in the combined combustion space of the kiln gas flue and the calciner; a tertiary air branch pipe is set between the tertiary air duct and the kiln gas flue. The horizontal zoned combustion environment is achieved by the tertiary air entering vertically upward from the bottom center of the calciner, and the flue gas is tangentially rotated into the volute from the side of the calciner to realize the combustion environment; the vertically graded combustion environment is realized by fuel graded feeding. The present invention realizes self-denitrification through zone-organized combustion as a whole, improves self-denitrification efficiency, and improves utilization of space in a strong reduction zone.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

A self-denitrification system and process for calciner compartmentalized combustion self-denitration

ActiveCN111750671BSelf-denitration by combustionImprove reliabilityGas treatmentDispersed particle separationThermodynamicsCombustion

The invention discloses a self-denitrification system and process for calciner combustion by partition organization. A kiln gas flue is set between the kiln tail smoke chamber and the calciner. The furnace inlet of the kiln gas flue is connected to the side of the calciner. The branch pipe is connected to the bottom of the calciner cone, forming a horizontally partitioned combustion environment with a central oxygen-rich zone and a peripheral low-oxygen zone on the calciner cross section; the upper branch pipe of the tertiary air is connected to the middle of the calciner column, and the kiln gas flue is a strong reduction zone , the space inside the calciner below the upper branch pipe of the tertiary air is a weak reduction zone, and the space inside the calciner above the upper branch pipe of the tertiary air is a burnout zone, forming a longitudinal gradient combustion environment combining strong reduction zone-weak reduction zone-burnout zone. The horizontal zoned combustion environment is achieved by making the tertiary air enter vertically upward from the center of the bottom of the calciner, and the flue gas enters the wind from the side of the calciner by tangential rotation of the volute; the vertically graded combustion environment is achieved by fuel graded feeding and tertiary air distribution. The present invention realizes self-denitrification through zoned organization combustion as a whole, and improves self-denitrification efficiency.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

The production method of sodium silicate

ActiveCN110894073BAvoid it happening againLow cost of environmental protectionAlkali metal silicatesCyclohexanoneEngineering

The invention provides a production method of sodium silicate, which uses the waste alkali solution produced in the process of producing cyclohexanone by the cyclohexane oxidation method or the concentrated solution produced in the refining process of caprolactam as the sodium source, and the quartz sand provides the silicon source , Incineration to get sodium silicate. It avoids the generation of "hazardous waste" such as sodium carbonate and sodium sulfate during the incineration of waste lye or concentrated solution, turning waste into treasure, reducing the cost of environmental protection for enterprises, and at the same time, the incineration of waste lye or concentrated solution provides silicon The energy required for the production of sodium silicate reduces the amount of fuel used, thereby reducing the production cost of sodium silicate, reducing energy consumption and carbon dioxide emissions, and reducing environmental pollution.

Owner:昌德新材科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com