Method for treating high-concentration wastewater generated when anisole synthesized from methyl sodium sulfate waste residues

A technology of high-concentration wastewater and sodium methosulfate, applied in natural water treatment, multi-stage water treatment, water/sewage treatment and other directions, can solve problems such as wastewater pollution, achieve high treatment efficiency, reduce environmental protection treatment costs, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

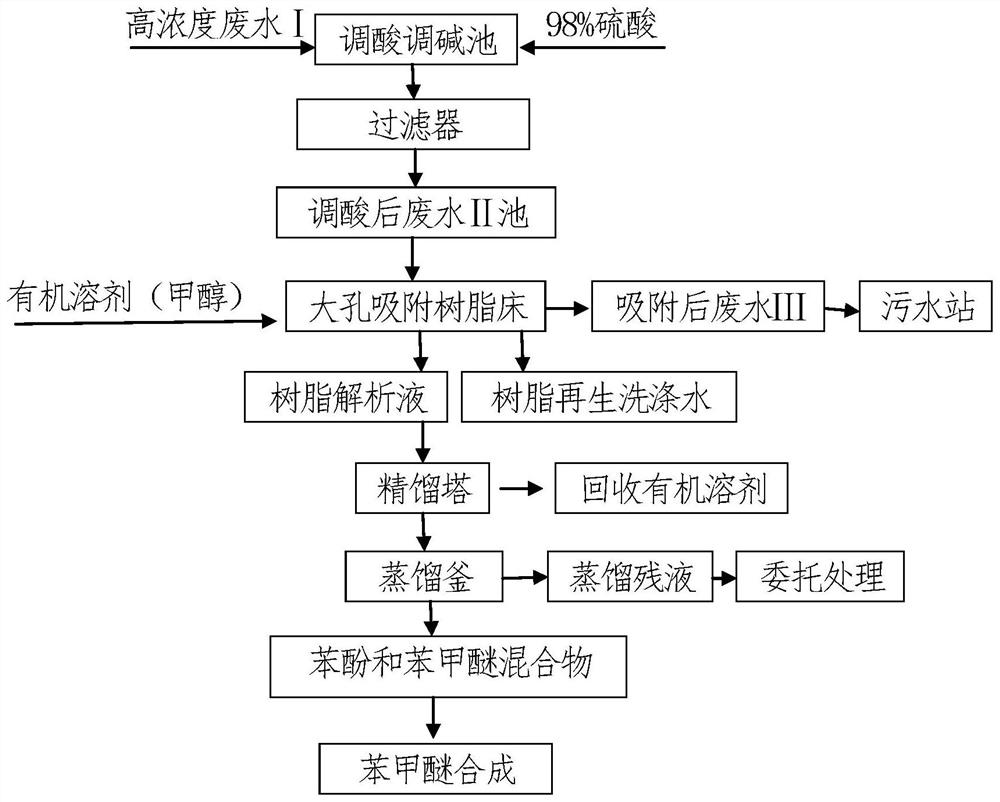

[0057] Embodiment 1, a kind of high-concentration wastewater treatment method that utilizes sodium methyl sulfate waste residue to synthesize anisole to produce, carries out following steps successively:

[0058] 1), take 30 liters of high-concentration wastewater I produced by using sodium methyl sulfate waste residue to synthesize anisole, adjust the pH to 3.0 with sulfuric acid, and filter to remove mechanical impurities and other foreign matter, and obtain 30 liters of acid-adjusted wastewater II , adjust the pH and consume a total of about 5.6g of 98% sulfuric acid;

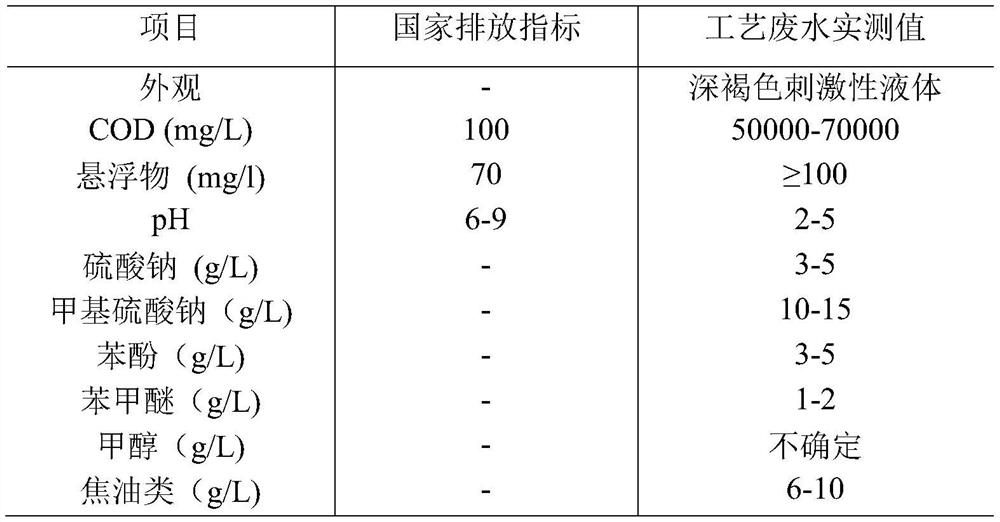

[0059] The quality indicators of high-concentration wastewater I are as follows: COD is 56000mg / L, pH=4.32, phenol is 3600mg / L, anisole is 1500mg / L, tars are 6800mg / L, sodium sulfate is 3600mg / L, sodium methylsulfate It is 12g / L, and the appearance is dark brown irritating liquid.

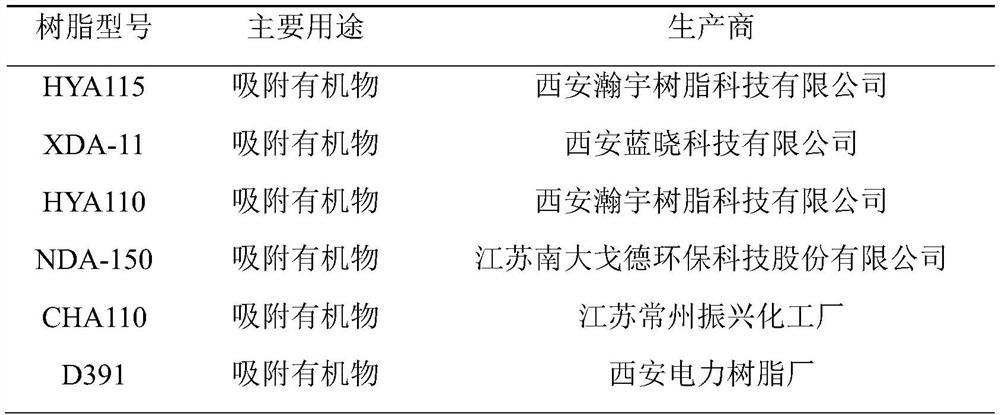

[0060] 2) The 30 liters of acid-adjusted waste water II obtained in step 1) is circulated and adsorbed through a macroporous a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com