A series drying system

A drying system, series technology, applied in the direction of drying solid materials, drying gas arrangement, local agitation dryers, etc., can solve the problems of difficult system matching and adjustment, high cost of environmental protection and hidden safety hazards, etc., to achieve a simple and stable system, The effect of low cost of environmental protection and no potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

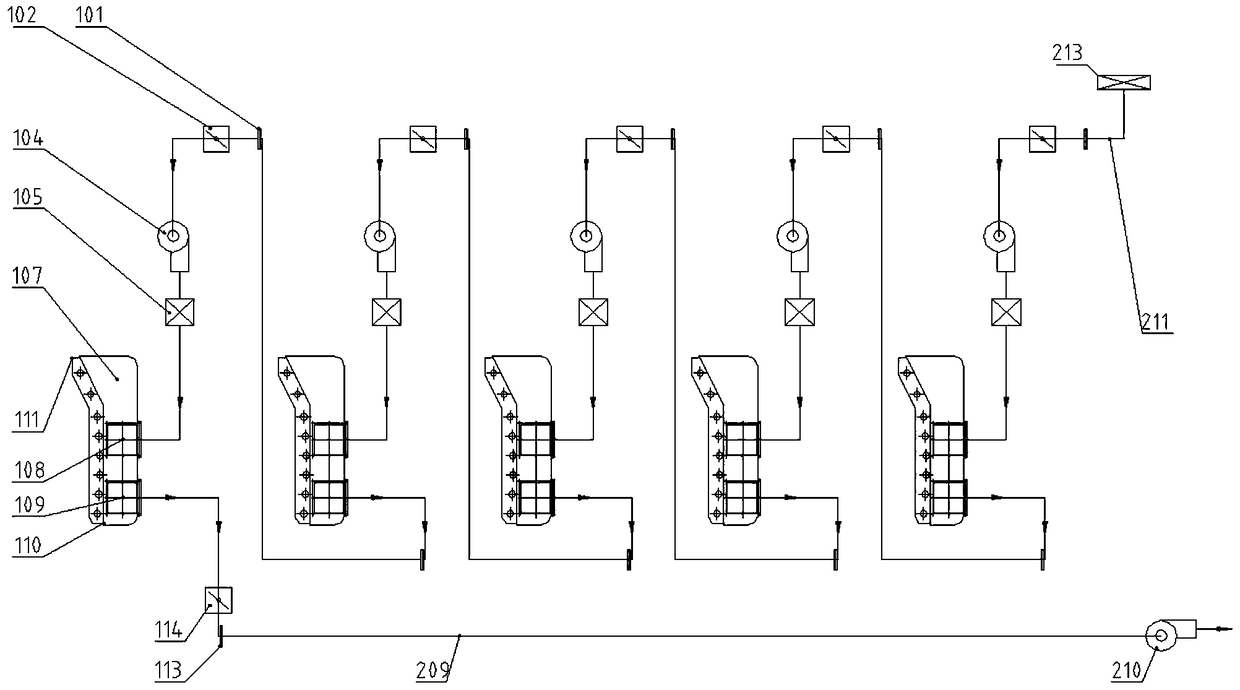

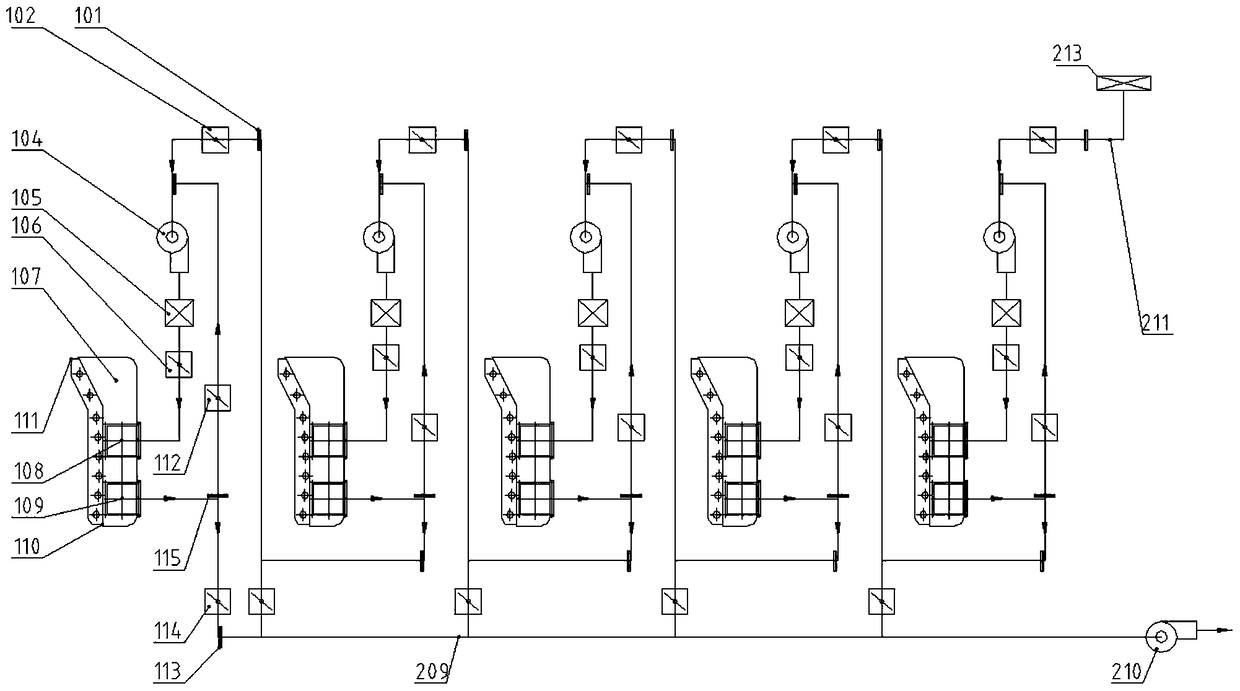

[0032] Embodiment 1: Taking the gravure printing machine as an example, see figure 1 , to describe the implementation of the series drying system:

[0033] The tandem drying system of the present embodiment includes an air supply device, an exhaust device and at least two groups of drying units; the drying unit includes a unit air supply fan 104 and a drying box 107, and the drying unit is provided with a unit air inlet 101 and a Air outlet 113, described drying box 107 is provided with drying box air inlet 108, drying box air outlet 109, drying box feed port 110 and drying box discharge port 111, described unit air inlet 101 and described drying box enter The tuyere 108 is connected, and the unit air outlet 113 is connected with the drying box air outlet 109; the exhaust device includes an exhaust main pipe 209, and the exhaust main pipe 209 is provided with the unit air outlet of the last group of drying units 113 connected exhaust air inlet (the exhaust air inlet and the u...

Embodiment 2

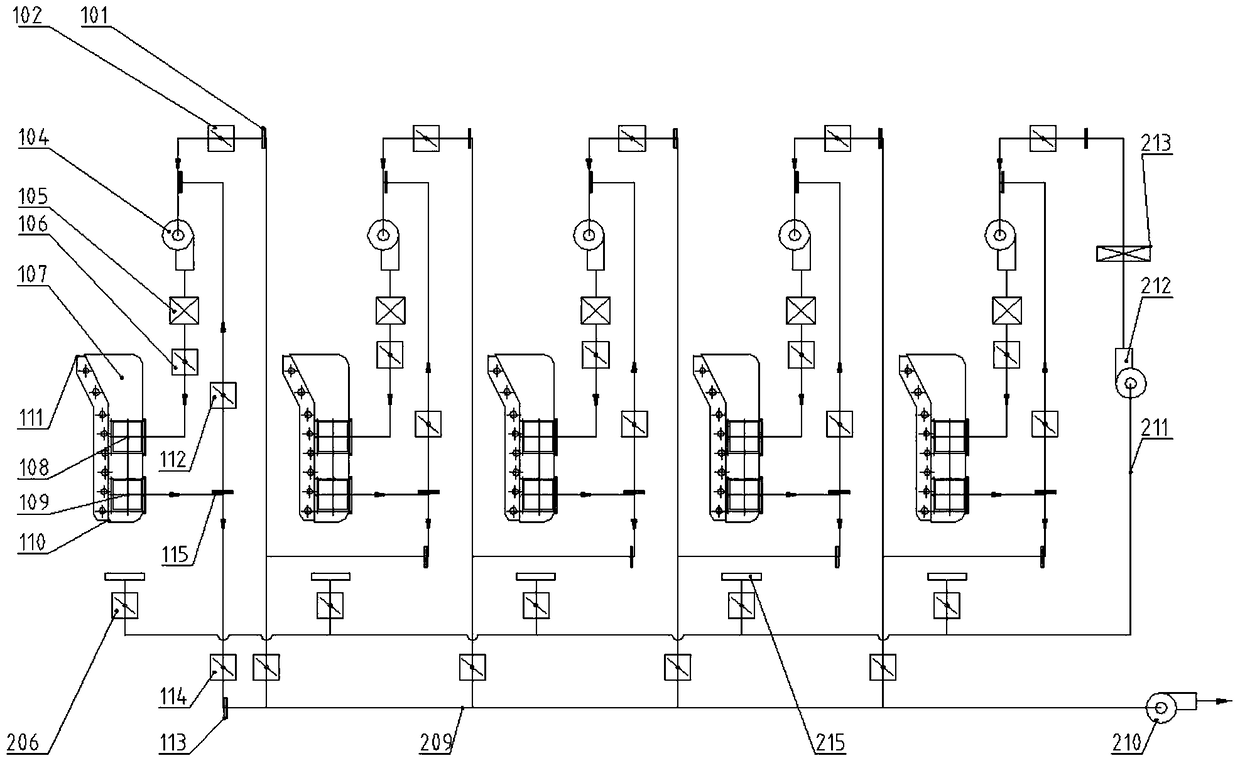

[0041] Embodiment 2: Taking the gravure printing machine as an example, see image 3 , to describe the implementation of the tandem drying system for centralized air suction and centralized air supply from the bottom of the printing unit:

[0042] As in the serial drying system described in Embodiment 1 and the improved Embodiment 1, the main air supply pipe 211 simply and directly enters the air directly from the external environment of the system, while in Embodiment 2, it also has the ability to take into account the leakage of the exhaust gas of the printing unit or the ink tank The air intake form of volatile solvent waste gas exhaust is centralized air supply. On the basis of the above-mentioned embodiment 1, the air supply device also includes an air supply fan 212 and at least two air collecting grooves 215, and the air supply main pipe 211 is provided in parallel with a plurality of air supply inlets corresponding to each group of drying units one by one. , the air c...

Embodiment 3

[0043] Embodiment 3: Take the dry laminating machine as an example, see Figure 4 , to explain the central heating of the series drying system:

[0044] Compared with Embodiment 1, the main difference is that: the air supply device can also use the hot air main pipe 207 to centrally supply hot air to several drying units after external heating, that is, on the basis of the above-mentioned embodiment 1, the air supply device It also includes a hot blast main pipe 207, an air supply fan 212, a hot blast stove 216, an air supply filter 213, and at least two hot blast valves 103; the hot blast main pipe 207 is provided in parallel with a plurality of hot air outlets corresponding to each group of drying units one by one. The hot air outlets are respectively connected to the unit air inlets 101; the hot air valve is arranged between the hot air outlets and the unit air inlets 101; On the header section of the hot blast inlet side of the hot blast main pipe 207. Thus, the air inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com