A kind of method for recovering valuable metal from zinc-tin-containing material

A technology for valuable metals and materials, applied in the field of recycling valuable non-ferrous metals, can solve the problems of low feasibility, complicated process, high cost, etc., and achieve the effect of strong adaptability, less three wastes, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

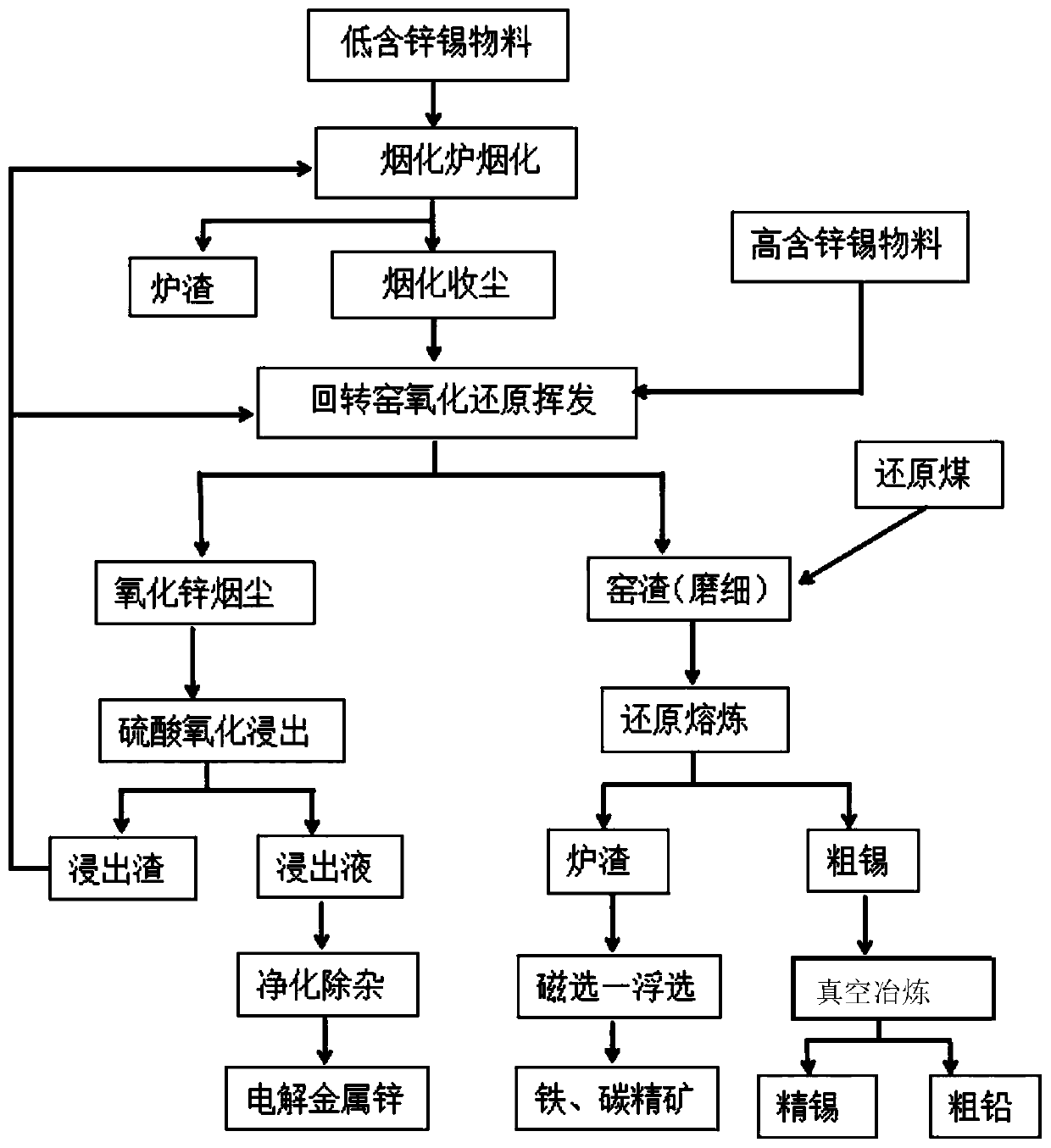

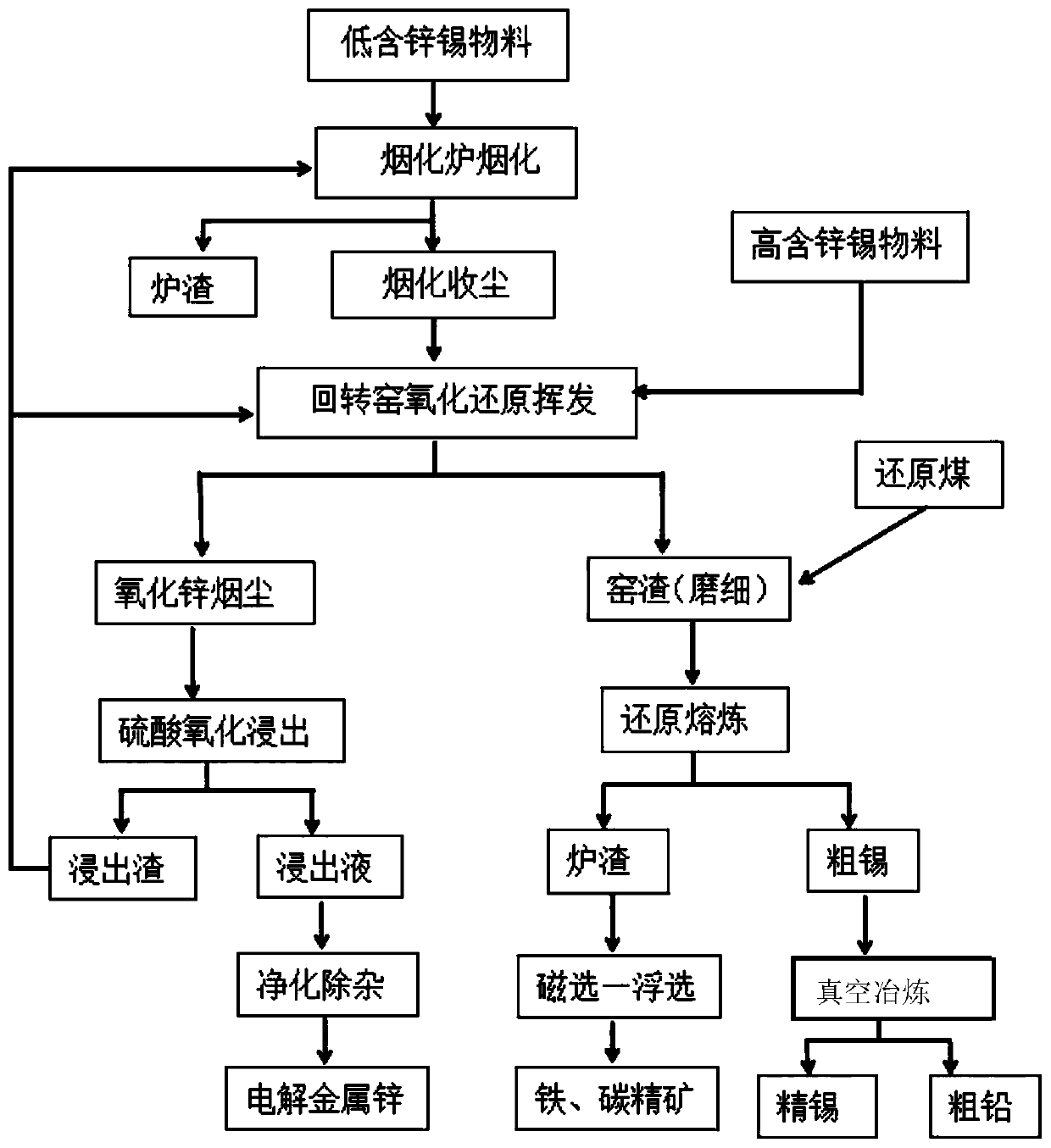

Method used

Image

Examples

Embodiment 1

[0025] The zinc-tin-containing waste slag of a certain enterprise is fumigated and dust-collected by fuming treatment in a fuming furnace. Its main components are Zn5%-10%, Sn15%-25%, Pb10%-15%, Fe3%-10%, and at the same time It also contains a small amount of As, In, Ni, Co.

[0026] Comprehensive recovery and smelting of smoke dust collection, the steps are as follows:

[0027] (1) Mix the reduced coal and fume dust collection at a mass ratio of 0.25, put them into a rotary kiln for redox volatilization at 1250°C, and obtain bag dust collection powder and glass body slag; among them, bag dust collection powder is mainly Contains 35%-40% Zn, 25%-26% Pb, 0.5% Sn, 0.3% As, 0.5% Sb, 0.03% In, the vitreous slag mainly contains 30%-35% Sn, 12%-15% Fe , 1.5%-2%Pb, 20%-30%SiO 2 , 10%-15% coal;

[0028] (2) Leach the bag dust collection powder with a mixture of 100g / L sulfuric acid and 10% hydrogen peroxide at a liquid-solid ratio of 5 and a temperature of 80-90°C for 2 hours, and...

Embodiment 2

[0035] A hydrometallurgy enterprise produced leaching slag containing 1%-2% Sn, 6%-8% Zn, 25%-30% Pb, and 0.8%-1.5% Sn, 10%-15% Zn, 10 %-20% Fe neutralization oxidation iron removal slag, mix leaching residue and neutralization oxidation iron removal slag to obtain material containing 1.8% Sn, 10.5% Zn, 16.5% Pb, 11.2% Fe.

[0036] Comprehensive recovery and smelting of materials, the steps are as follows:

[0037](1) Carry out smoke volatilization enrichment to material with fuming furnace, obtain the volatile soot containing 8.3% Sn, 20.3% Zn, 25.8% Pb, 15.5% Fe; Mix reduced coal and volatile soot by the mass ratio of 0.3, Throw it into a rotary kiln for redox volatilization at 1300°C to obtain zinc oxide dust containing 45.2% Zn, 0.25% Sn, 33.1% Pb and dust containing 10.3% Sn, 2.5% Pb, 18.5% Fe, 0.75% Zn Kiln residue;

[0038] (2) Zinc oxide dust is leached for 3 hours with 80g / L sulfuric acid and manganese dioxide at a liquid-solid ratio of 4 and a temperature of 90-95°...

Embodiment 3

[0045] The tin-rich slag produced by an enterprise contains 4.7% Sn, 3.26% Pb, and 1.2% Zn. It is obtained through fuming furnace treatment. Its chemical composition is: bag dust contains 17%-31.8% Sn, 11.8%-36.4% Zn , 9%-12%Pb; surface cooling powder contains 10%-29%Sn, 16%-22%Zn, 12%-16%Pb; cyclone dust removal powder contains 6%-19%Sn, 12%-20%Zn , 16%-19% Pb.

[0046] Comprehensive recovery and smelting of each fume dust collection, the steps are as follows:

[0047] (1) Mix the reduced coal powder with each fume dust collector at a mass ratio of 0.25, put it into a rotary kiln and carry out redox roasting at 1250° C. to obtain a mixture containing 40%-45% Zn, 0.3%-0.6% Sn, Rotary kiln with 18%-25% Pb reduces volatile dust and kiln slag containing 30%-35% Sn, 0.5%-1% Zn, 2%-3% Pb, 5%-8% Fe;

[0048] (2) leaching the rotary kiln reducing volatile dust with a mixed solution of sulfuric acid containing 100g / L and 10% hydrogen peroxide at a liquid-solid ratio of 5 and a tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com