Low-tower preparation method of small-particle phosphorus-potassium nitrate fertilizer

A technology of potassium nitrate fertilizer and nitrate phosphate fertilizer, which is applied in the direction of potassium fertilizer, inorganic fertilizer, fertilization equipment, etc., can solve the problems of high investment in high-tower granulation production lines, large diffusion radius of environmental pollution, and inability to completely remove infusible materials, etc. Pollution is easy to control, product specifications are abundant, and the effect of environmental protection treatment is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

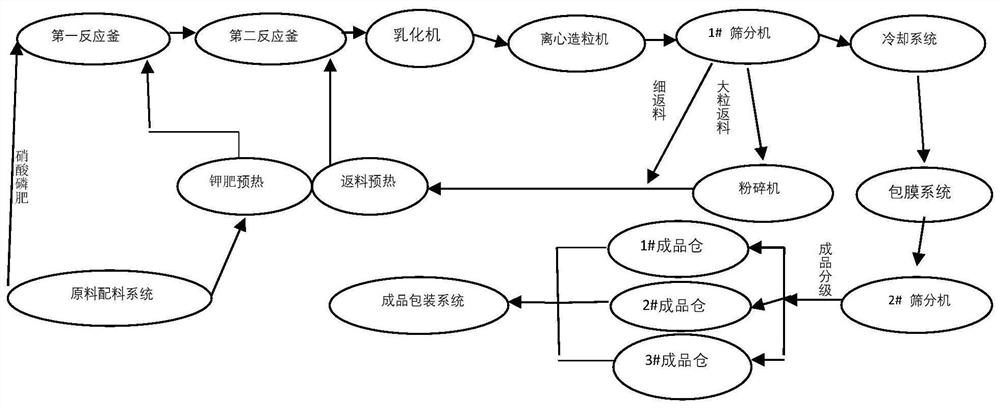

Method used

Image

Examples

Embodiment 1

[0063] A kind of low-tower preparation method of small particle phosphorus potassium nitrate fertilizer:

[0064] 1. Turn on the steam heating system of the first reactor, and slowly add 7000 kg of nitrophosphate fertilizer (32% nitrogen, 6% phosphorus pentoxide) into the first reactor. When all the materials are melted, the slurry will continue to heat up to about 150°C for later use.

[0065] 2. Turn on the potassium fertilizer preheating device, and slowly add 3000 kg of powdered potassium sulfate (potassium oxide 52%) into the preheating device. When the temperature of potassium sulfate reaches 150°C, open the discharge valve of the potassium sulfate preheating device, so that potassium sulfate is slowly added to the first reaction kettle. The powdery material is fully mixed with the nitrate fertilizer slurry under the action of the mixer. Control the steam heating system of the first reactor to keep the internal slurry temperature within the range of 150-160°C for stand...

Embodiment 2

[0080] A kind of low-tower preparation method of small particle phosphorus potassium nitrate fertilizer:

[0081] 1. Turn on the steam heating system of the first reactor, and slowly add 6000 kg of nitrophosphate fertilizer (30% nitrogen, 8% phosphorus pentoxide) into the first reactor. When all the materials are melted, the slurry will continue to heat up to about 140°C for later use.

[0082] 2. Turn on the potassium fertilizer preheating device, and slowly add 4000 kg of powdered potassium sulfate (potassium oxide 51%) into the preheating device. When the temperature of potassium sulfate reached 155°C, the discharge valve of the potassium sulfate preheating device was opened, so that potassium sulfate was slowly added to the first reaction kettle. The powdery material is fully mixed with the nitrate fertilizer slurry under the action of the mixer. Control the steam heating system of the first reactor to keep the internal slurry temperature within the range of 155-160°C fo...

Embodiment 3

[0095] A kind of low-tower preparation method of small particle phosphorus potassium nitrate fertilizer:

[0096] 1. Turn on the steam heating system of the first reactor, and slowly add 7700 kg of nitrophosphate fertilizer (nitrogen 26%, phosphorus pentoxide 17%) into the first reactor. When all the materials are melted, the slurry will continue to heat up to about 145°C for later use.

[0097] 2. Turn on the potassium fertilizer preheating device, and slowly add 2300 kg of powdered potassium chloride (potassium oxide 60%) to the preheating device. When the temperature of potassium chloride reaches 145°C, open the discharge valve of the potassium fertilizer preheating device, so that potassium chloride is slowly added to the first reaction kettle. The powdery material is fully mixed with the nitrate fertilizer slurry under the action of the mixer. Control the steam heating system of the first reactor to keep the internal slurry temperature within the range of 145-150°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com