A method for producing analytically pure sulfuric acid from smelting flue gas

A sulfuric acid and flue gas technology, applied in sulfur trioxide/sulfuric acid, chemical instruments and methods, sulfur compounds, etc., can solve the problems of unfavorable equipment operation and management, restricting production costs, high energy consumption, reducing environmental protection costs, Increase product revenue, obvious effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

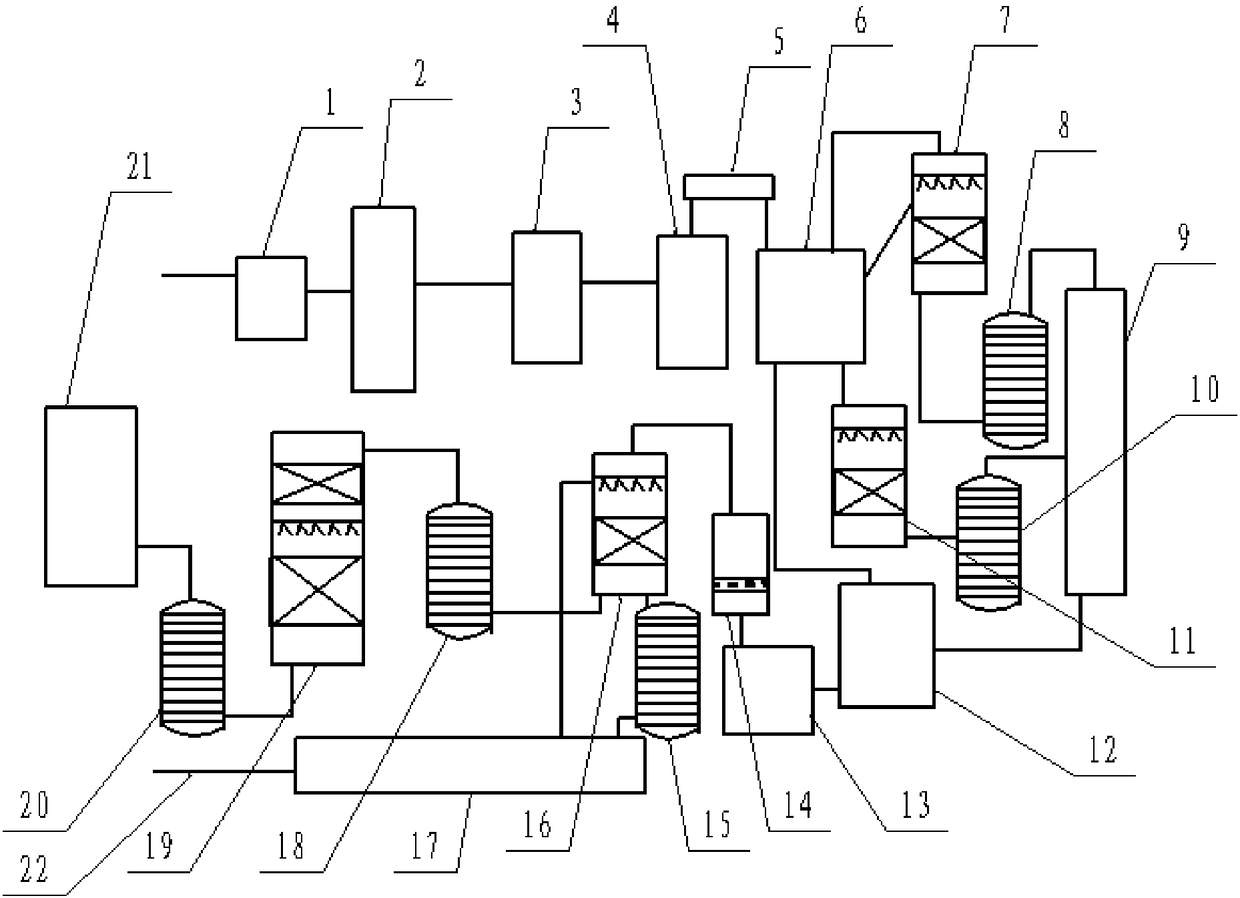

[0027] Such as figure 1 , a method for producing analytically pure sulfuric acid from smelting flue gas, comprising the steps of:

[0028] (1) Deep purification: from the flue gas inlet, the sulfur-containing flue gas is passed through the electrostatic precipitator 1 and the bag filter 2 for dust removal treatment, then passed into the washing tower 3 and the packing tower 4 for washing, separation and purification, and then passed through the flue gas Air filter 5 filters;

[0029] (2) Transformation and absorption: what the embodiment of the present invention adopted is the two-turn-two-suction process, specifically as follows:

[0030] Primary transformation and primary absorption: pass the filtered flue gas through the contact chamber 6 for heat exchange, so that the SO in the flue gas 2 converted to SO 3 , converted to SO 3 Enter the first absorption tower 7 and carry out spray absorption by concentrated sulfuric acid, the liquid obtained after absorption flows out f...

Embodiment 2

[0037] Such as figure 1, a method for producing analytically pure sulfuric acid from smelting flue gas, comprising the steps of:

[0038] (1) Deep purification: from the flue gas inlet, the sulfur-containing flue gas is passed through the electrostatic precipitator 1 and the bag filter 2 for dust removal treatment, then passed into the washing tower 3 and the packing tower 4 for washing, separation and purification, and then passed through the flue gas Air filter 5 filters;

[0039] (2) Transformation and absorption: what the embodiment of the present invention adopted is the two-turn-two-suction process, specifically as follows:

[0040] Primary transformation and primary absorption: pass the filtered flue gas through the contact chamber 6 for heat exchange, so that the SO in the flue gas 2 converted to SO 3 , converted to SO 3 Enter the first absorption tower 7 and carry out spray absorption by concentrated sulfuric acid, the liquid obtained after absorption flows out fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com