Decomposing furnace partitioned organization combustion self-denitration system and process capable of adjusting oxygen concentration of reduction zone

A technology of partition organization and decomposition furnace, applied in the field of flue gas denitrification in the cement industry, can solve the problems of limited space in the lean combustion area, small contribution of fuel combustion, inability to adjust flexibly, etc., to achieve strong operability and practicability, improve The effect of fuel combustion speed and reduction of environmental protection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

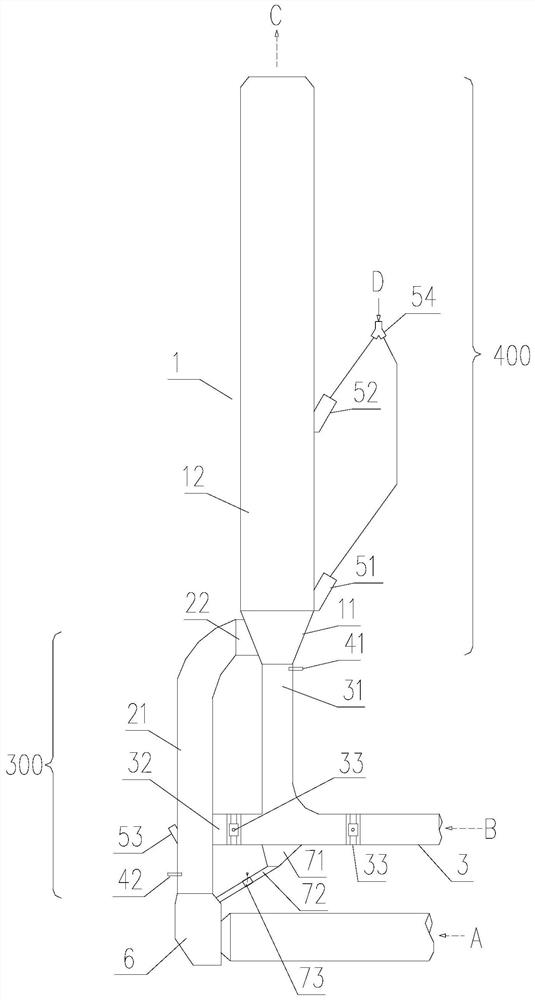

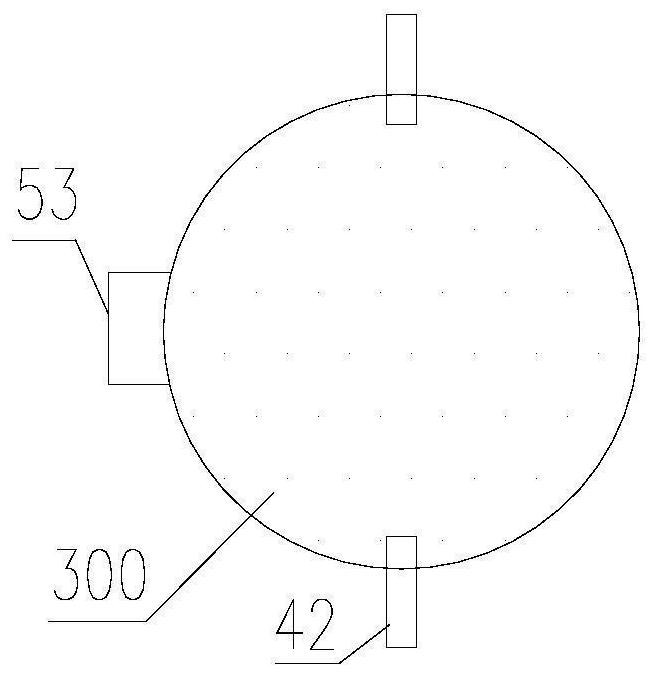

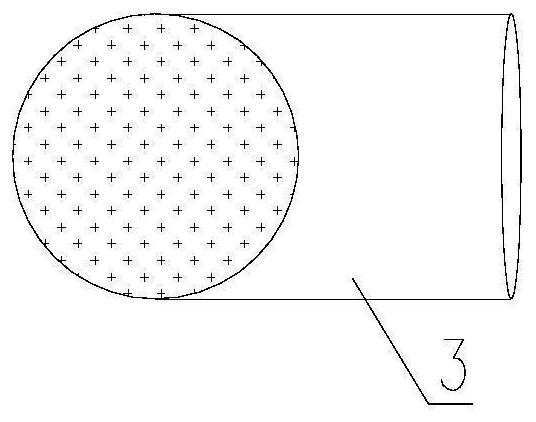

[0060] see Figure 1~4 , the embodiment of the present invention provides a denitrification system for denitrification by combustion in the rich and light oxygen-containing zones of the calciner, including a rotary kiln, a kiln tail smoke chamber 6 connected to the kiln tail of the rotary kiln, a calciner 1, a kiln tail smoke chamber 6 and a decomposition furnace. The kiln gas flue 21 of the furnace 1 and the tertiary air duct 3; the calciner 1, the kiln gas flue 21 and the tertiary air duct 3 are all equipped with refractory materials.

[0061] Rotary kiln flue gas A is the flue gas produced by fuel combustion in the rotary kiln. The temperature is generally 900-1150°C, the oxygen content is generally within 5%, and the NOx concentration in the flue gas is generally 800-1500ppm. The flue gas A of the rotary kiln moves upwards into the kiln gas flue 21 after passing through the kiln tail smoke chamber 6, and enters the calciner cone 11 through the furnace inlet 22 of the kiln ...

Embodiment 2

[0071] The difference from Embodiment 1 is that the calciner cylinder 12 is provided with a narrowing 13 in the middle of the calciner.

[0072] see Figure 5 . Preferably, the calciner column 12 is provided with a calciner middle neck 13 . The shrinkage 13 in the middle of the calciner is located below the upper feeding point 52 of the raw meal of the calciner. The raw meal that enters from the feed point 52 on the raw meal of the calciner moves downward under the action of gravity. By setting the neck 13 in the middle of the calciner, the cross-sectional wind speed at the neck becomes larger than that of the cylinder, which can effectively reduce the raw material. The falling height of the material can be adjusted to prevent material collapse in the calciner.

Embodiment 3

[0074] The difference from Embodiment 1 is that a calciner bottom column section 14 is provided between the calciner cone 11 and the furnace inlet 31 of the tertiary air pipe. The lower feed point 51 of the calciner raw meal and the calciner fuel feed point 41 located below the furnace inlet of the kiln gas flue are located on the column section 14 at the bottom of the calciner.

[0075] see Figure 6 . Preferably, a calciner bottom column section 14 is provided between the calciner cone 11 and the furnace inlet 31 of the tertiary air duct. The tertiary air first passes through the column section 14 at the bottom of the calciner, and then enters the cone 11 of the calciner. At this time, the calciner fuel feed point 41 located below the inlet of the kiln gas flue and the lower feed point 51 of the calciner raw material are located on the column section 14 at the bottom of the calciner. The mixture of smoke and gas is more conducive to the ignition of fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com