A treatment method for chromium-containing sodium sulfate waste liquid and sulfuric acid pickling waste liquid in stainless steel production

A technology of sulfuric acid pickling and chromic sodium sulfate, which is applied in the treatment of waste liquid and waste residue, the treatment of chromium-containing sodium sulfate waste liquid and sulfuric acid pickling waste liquid in stainless steel production, can solve waste, the treatment speed cannot keep up with the increase of pollution, Free acid and ferrous ion waste, etc., to achieve the effect of improving recycling rate, realizing resource treatment, and reducing the consumption of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

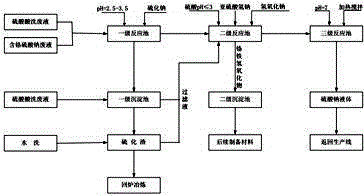

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

[0021] A cold-rolled stainless steel sheet factory has an average hourly discharge of chromium-containing sodium sulfate waste liquid of 900L / h and an average hourly discharge of sulfuric acid pickling waste liquid of 400L / h, and put them into the wastewater storage tank. Under normal discharge conditions, within a certain hour, it was detected that the pH value of chromium-containing sodium sulfate waste liquid was 5.7, Cr 6+ Concentration 15g / L, Cu 2+ Concentration 3g / L, Ni 2+ Concentration 7g / L, Na 2 SO 4 The concentration is 248g / L, and the pH value of the sulfuric acid pickling waste liquid is 1.2, Fe 2+ and Fe 3+ Total concentration 30g / L, SO 4 2- Concentration 65g / L, free H 2 SO 4 Concentration 20g / L, Ni 2+ Concentration 4g / L, Cr 6+ Concentration 0.8g / L, Cu 2+ The concentration is 1.5g / L.

[0022] Firstly, the chromium-containing sodium sulfate was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com