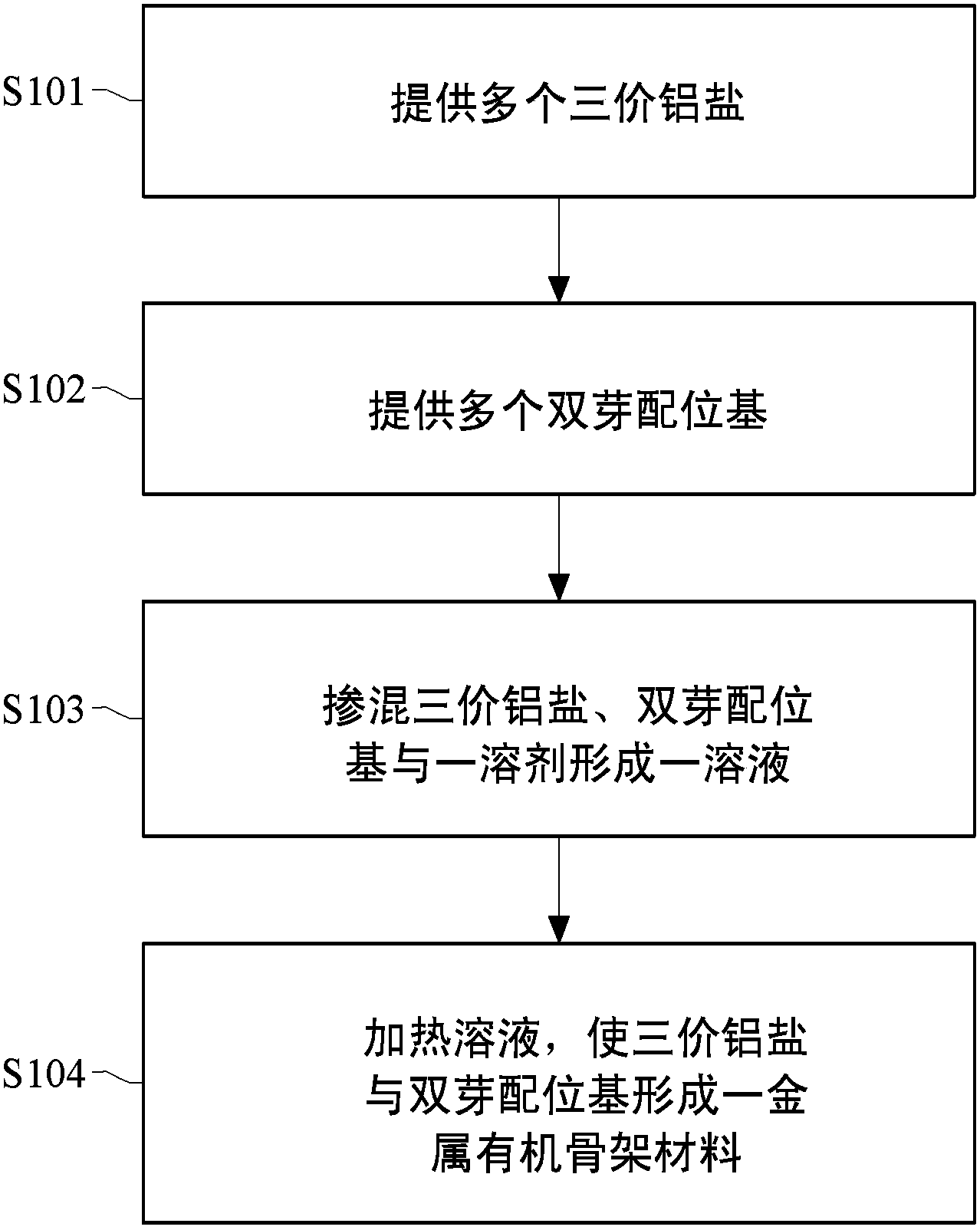

A metal-organic framework material, a preparing method thereof and uses of the material

A metal-organic framework, double-bud ligand technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve problems such as environmentally unfriendly transition metals, and achieve improved heat resistance and moisture resistance. Ability, good resistance to water vapor, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] First, 0.25 millimoles (mmol) of Al(NO 3 ) 3 9H 2 O, 0.25 mmol of 4,4'-diphenyl ether dicarboxylic acid (H 2 OBA) and 6.0 milliliters (mL) of N,N-dimethylformamide (DMF) into a Teflon inner cup. Then, put the Teflon inner cup in an iron cup, and put the iron cup into a high temperature furnace. In the high temperature furnace, the temperature was raised to 120° C. at a heating rate of 60° C. / hr. Then, the reaction was carried out at a reaction temperature of 120° C. for 2 days. After the reaction was completed, it was cooled down to room temperature at a cooling rate of 6°C / hr. Finally, suction filtration was performed, and the product was washed with ethanol and water. After drying, the product Compound 1 was obtained as a white powder.

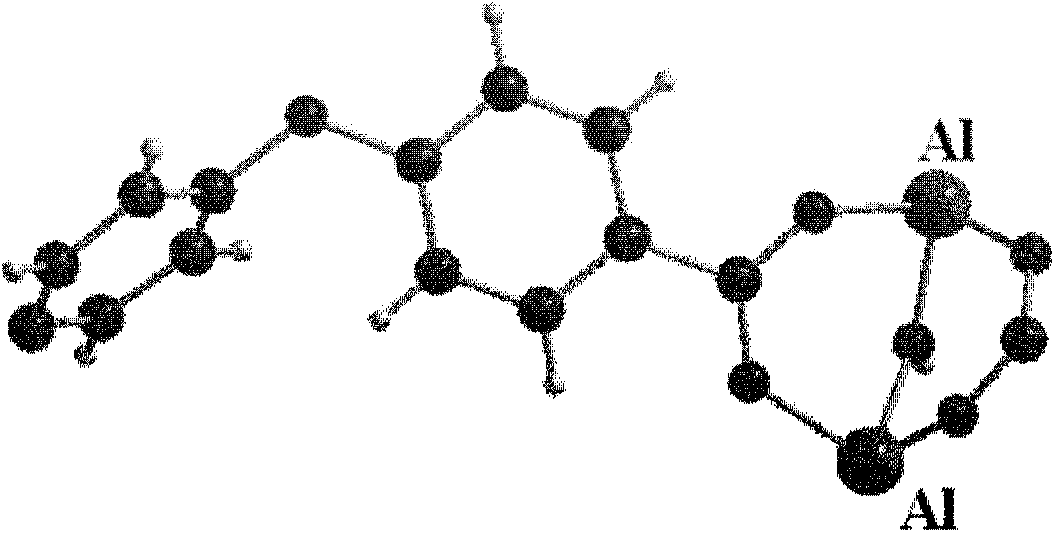

[0047] The crystal system of compound 1 is tetragonal, and the space group is I4 1 / a. see Figure 2A to Figure 2D , Figure 2A It is a schematic diagram of the coordination environment of 4,4′-diphenyl ether dicarboxylic a...

Embodiment 2

[0053] First, 0.5 millimoles (mmol) of Al(NO 3 ) 3 9H 2 O, 0.5 mmol of 4,4'-stilbene dicarboxylic acid (H 2 SDA) and 10.0 milliliters (mL) of N,N-diethylformamide (DEF) into a Teflon inner cup. Then, put the Teflon inner cup in an iron cup, and put the iron cup into a high temperature furnace. In the high-temperature furnace, the temperature was raised to 180° C. at a heating rate of 60° C. / hr. Then, reaction was carried out at a reaction temperature of 180° C. for 1 day. After the reaction was completed, it was cooled down to room temperature at a cooling rate of 6°C / hr. Finally, suction filtration was performed, and the product was washed with ethanol and water. After drying, the milky white powder of product compound 2 can be obtained.

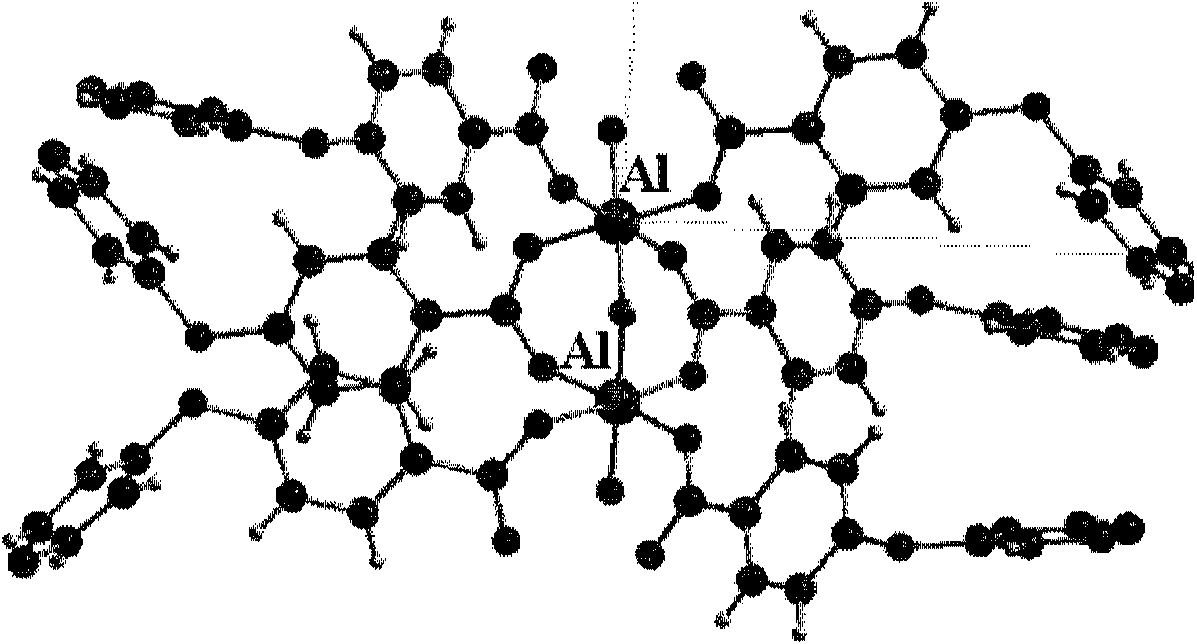

[0054] The crystal system of Compound 2 is orthorhombic, and the space group is Imma. see Figure 6A to Figure 6D , Figure 6A It is a schematic diagram of the coordination environment of 4,4'-stilbene dicarboxylic acid disclosed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com