A kind of slow-release algae-killing microcapsule with bimolecular structure and preparation method thereof

A molecular structure and microcapsule technology, applied in the field of slow-release algae killing microcapsules and their preparation, can solve problems such as threatening human health, interfering with algae growth, heavy metal pollution, etc. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

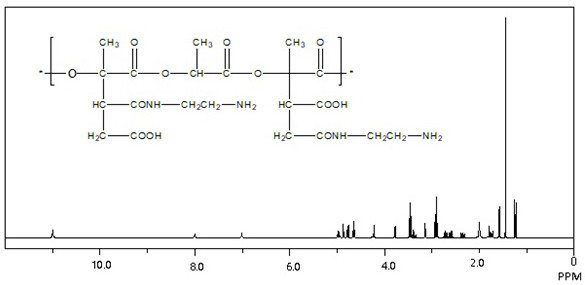

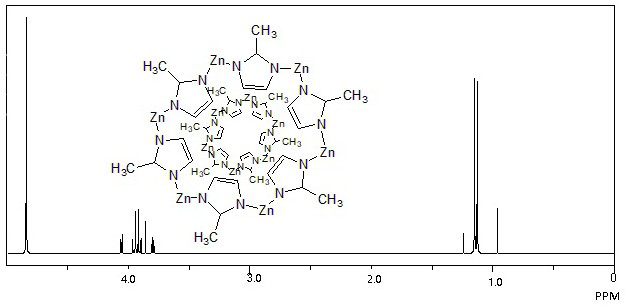

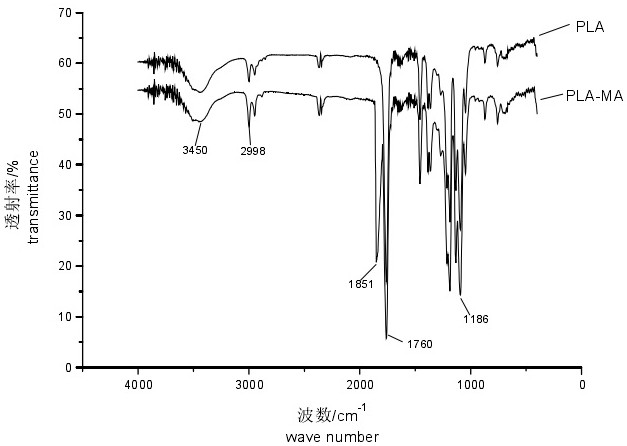

[0047] (1) First, weigh 15g of polylactic acid, add it into a three-necked flask with a stirrer, then add 100mL of toluene to dissolve it and put it in a constant temperature water bath, add 5g of maleic anhydride and 0.15g of initiator after heating to 95°C ( 2,5-dimethyl-2,5-di-tert-butyl-peroxy-hexane), reacted at 95°C for 2.5h under constant temperature stirring, precipitated with methanol, and washed repeatedly with methanol to remove the remaining maleic anhydride Post drying to obtain maleic anhydride graft modified polylactic acid (MPLA). Then add 5 mL of THF solution containing 9 g of ethylenediamine to a three-necked flask equipped with a stirrer and a thermometer; completely dissolve 4.5 g of MPLA in 50 mL of THF solution, drop into the three-necked flask under stirring, and control the temperature of the reaction system at 19°C . After the dropwise addition is completed, keep warm for ten minutes, then raise the temperature to 25°C and react for 30 minutes, stir a...

Embodiment 2

[0056] (1) First, weigh 20g of polylactic acid, add it to a three-necked flask with a stirrer, then add 120mL of toluene to dissolve it, put it into a constant temperature water bath, heat it to 100°C, add 8g of maleic anhydride and 0.2g of initiator ( 2,5-dimethyl-2,5-di-tert-butyl-peroxy-hexane), reacted at 100°C for 2 hours with stirring, then precipitated with methanol, washed repeatedly with methanol to remove the remaining maleic anhydride, and then dried , to obtain maleic anhydride graft modified polylactic acid (MPLA). Then add 5mL THF solution containing 10g ethylenediamine to a three-necked flask equipped with a stirrer and a thermometer; completely dissolve 4g MPLA in 70mL THF solution, drop into the three-necked flask under stirring, and control the temperature of the reaction system at 18°C. After the dropwise addition is completed, keep warm for 15 minutes, then raise the temperature to room temperature (20°C) and react for 60 minutes, stir and dissolve the reac...

Embodiment 3

[0065] (1) First, weigh 15g of polylactic acid, add it into a three-necked flask with a stirrer, add 90mL of toluene to dissolve it, put it into a constant temperature water bath, add 5g of maleic anhydride and 0.17g of initiator after heating to 90°C ( 2,5-dimethyl-2,5-di-tert-butyl-peroxy-hexane), reacted at a constant temperature of 90°C for 3h while stirring. The solution after the reaction is completed is precipitated with methanol, washed repeatedly with methanol to remove the remaining maleic anhydride, and then dried to obtain maleic anhydride graft-modified polylactic acid (MPLA). Then add 5mL THF solution containing 9g of ethylenediamine to a three-necked flask equipped with a stirrer and a thermometer; completely dissolve 3.75g MPLA in 60mL THF solution, drop into the three-necked flask under stirring, and control the temperature of the reaction system for 17 ℃. After the dropwise addition was completed and kept warm for 15 minutes, the temperature was raised to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com