Semi-liquid-state forging method for magnesium alloy rim

A magnesium alloy, semi-liquid technology, applied in the direction of wheels, metal processing equipment, transportation and packaging, etc., can solve the problem of irregular cracks in magnesium alloy forged rims, reduce the mechanical properties of magnesium alloy forged rims, and cast magnesium alloy rods Quality is difficult to guarantee and other problems, to achieve the effect of improving material utilization, saving materials and energy, and small thermal shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

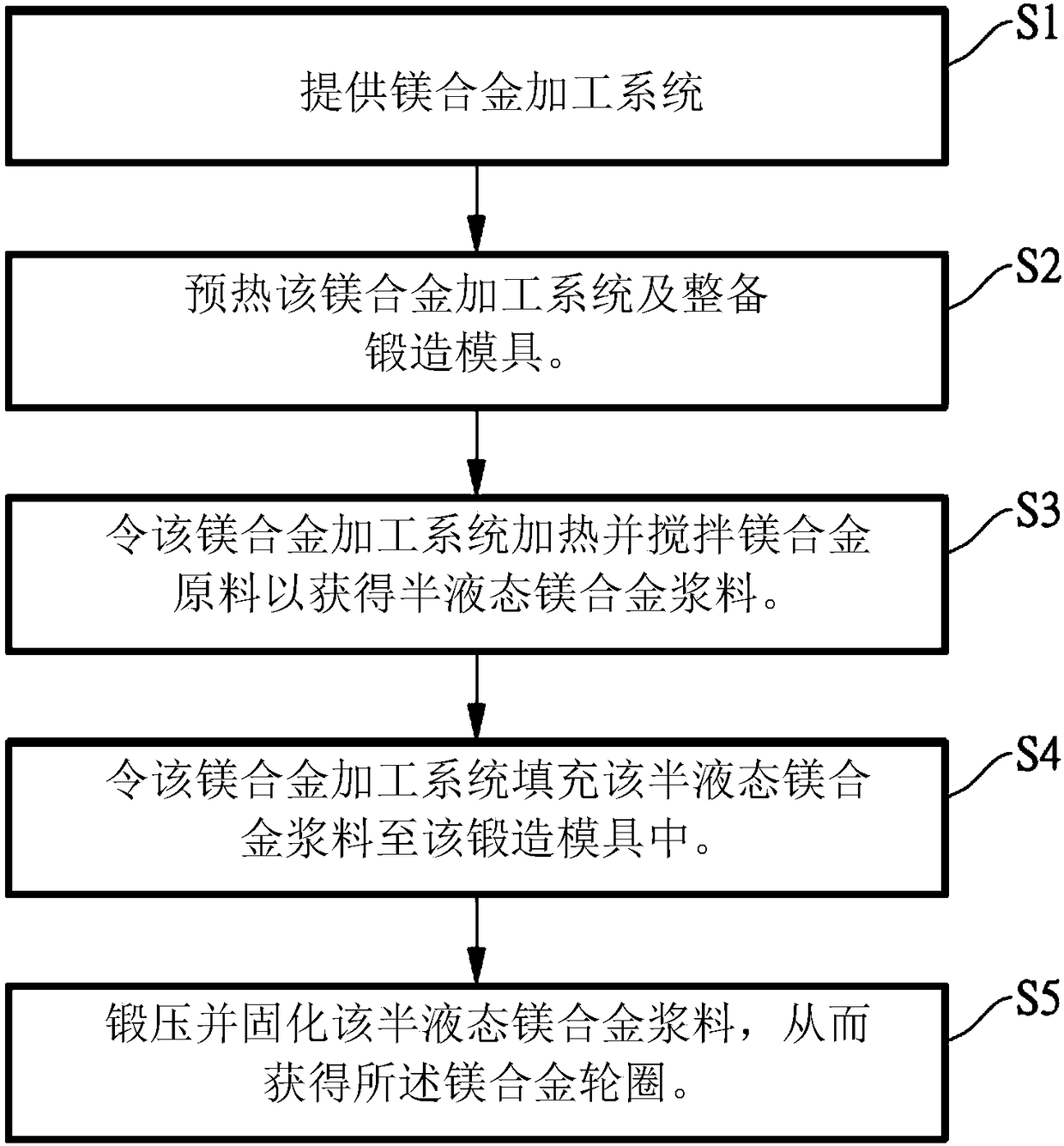

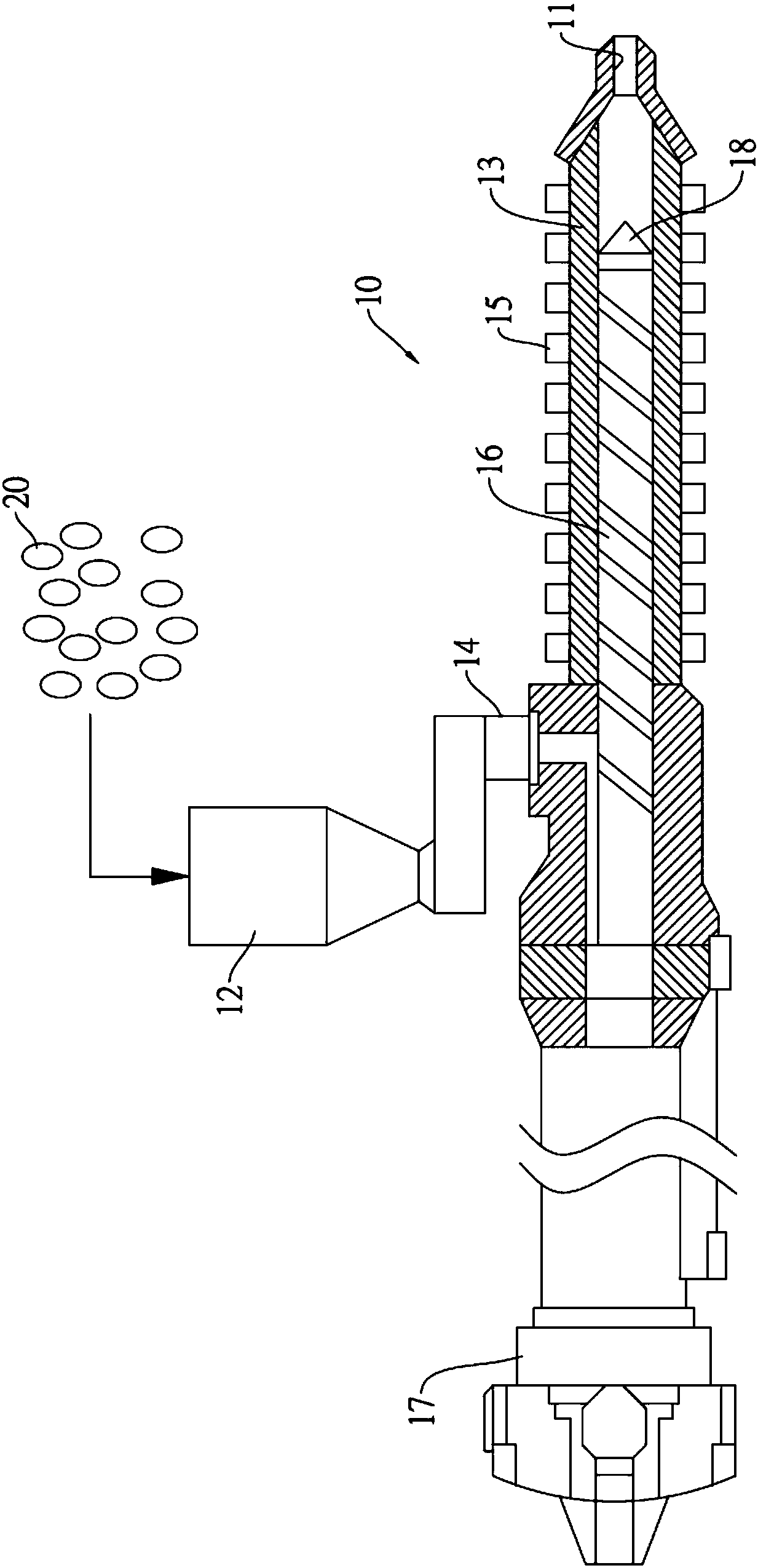

[0032] see figure 1 and figure 2 As shown, in this embodiment, the semi-liquid forging method of the magnesium alloy wheel rim of the present invention includes: step S1 of providing the magnesium alloy processing system 10, step S2 of preheating the magnesium alloy processing system 10 and preparing the forging mold, making The magnesium alloy processing system 10 heats and stirs the magnesium alloy raw material 20 to obtain the step S3 of semi-liquid magnesium alloy slurry, the step S4 of making the magnesium alloy processing system 10 fill the semi-liquid magnesium alloy slurry into the forging mold, and forging And solidifying the semi-liquid magnesium alloy slurry, thereby obtaining the step S5 of the magnesium alloy wheel rim, each step S1, S2, S3, S4, S5 is described in detail as follows:

[0033] see figure 2 As shown, in the step S1 of providing the magnesium alloy processing system 10, the magnesium alloy processing system 10 includes a slurry output channel 11, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com