Special-shaped pipe fitting welding equipment

A pipe fitting welding and special-shaped technology, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of special-shaped pipe fittings that are difficult to have positioning references, parts are deformed, and it is difficult to accurately ensure the assembly size, etc., to achieve on-site environmental friendliness , Ensure the working environment, avoid the effect of bumping and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] A special-shaped pipe fitting welding equipment of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the specification:

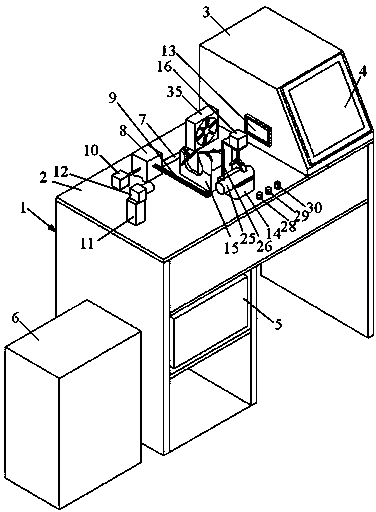

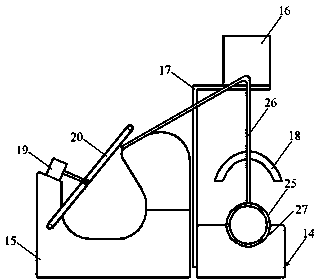

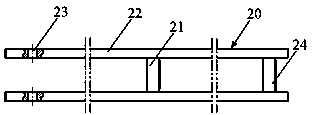

[0040] like figure 1 As shown, a special-shaped pipe fitting welding equipment includes a workbench 1, a high-frequency induction heating unit, an image measurement unit, a mechanical positioning clamping unit, an exhaust fan 35 installed behind the mechanical positioning clamping unit, a control box 3, and a mechanical positioning clamp The tight unit is set in the middle of the table 2 of the workbench 1, and the PLC controller 4 is installed in the control box 3;

[0041] The high-frequency induction heating unit includes a high-frequency machine 5 installed under the workbench 1, a chiller 6, a guide rail 7, a welding head 8, an induction heating coil 9 and a push cylinder 10, wherein the guide rail 7 is installed on the table 2, The welding head 8 is installed on the guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com