Multi-stage apparatus for installing tubular goods

a multi-stage, linear actuator technology, applied in the direction of drilling casings, drilling pipes, borehole/well accessories, etc., can solve the problems of limited lifting capacity or rotating speed of conventional rt devices, and achieve the effect of reducing cost and logistical challenges, and greatly reducing the outside diameter of the actuator assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

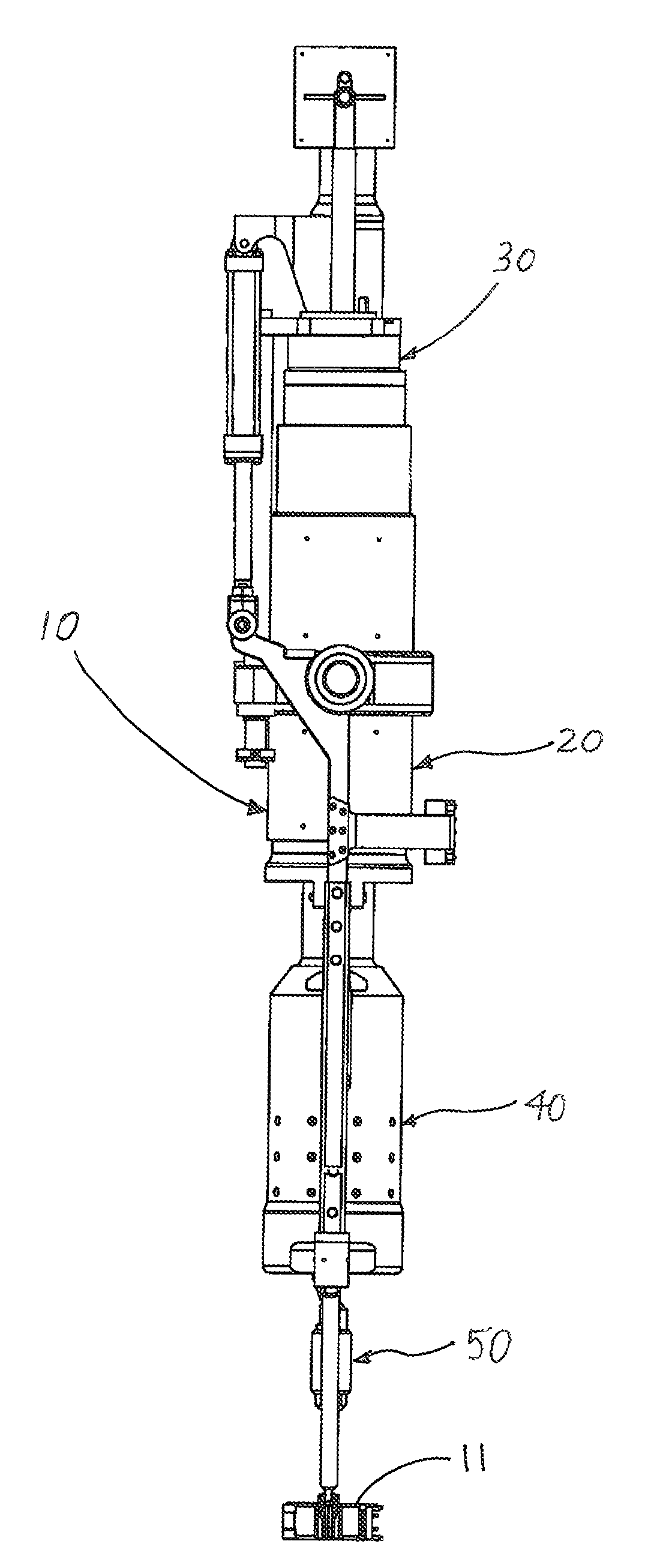

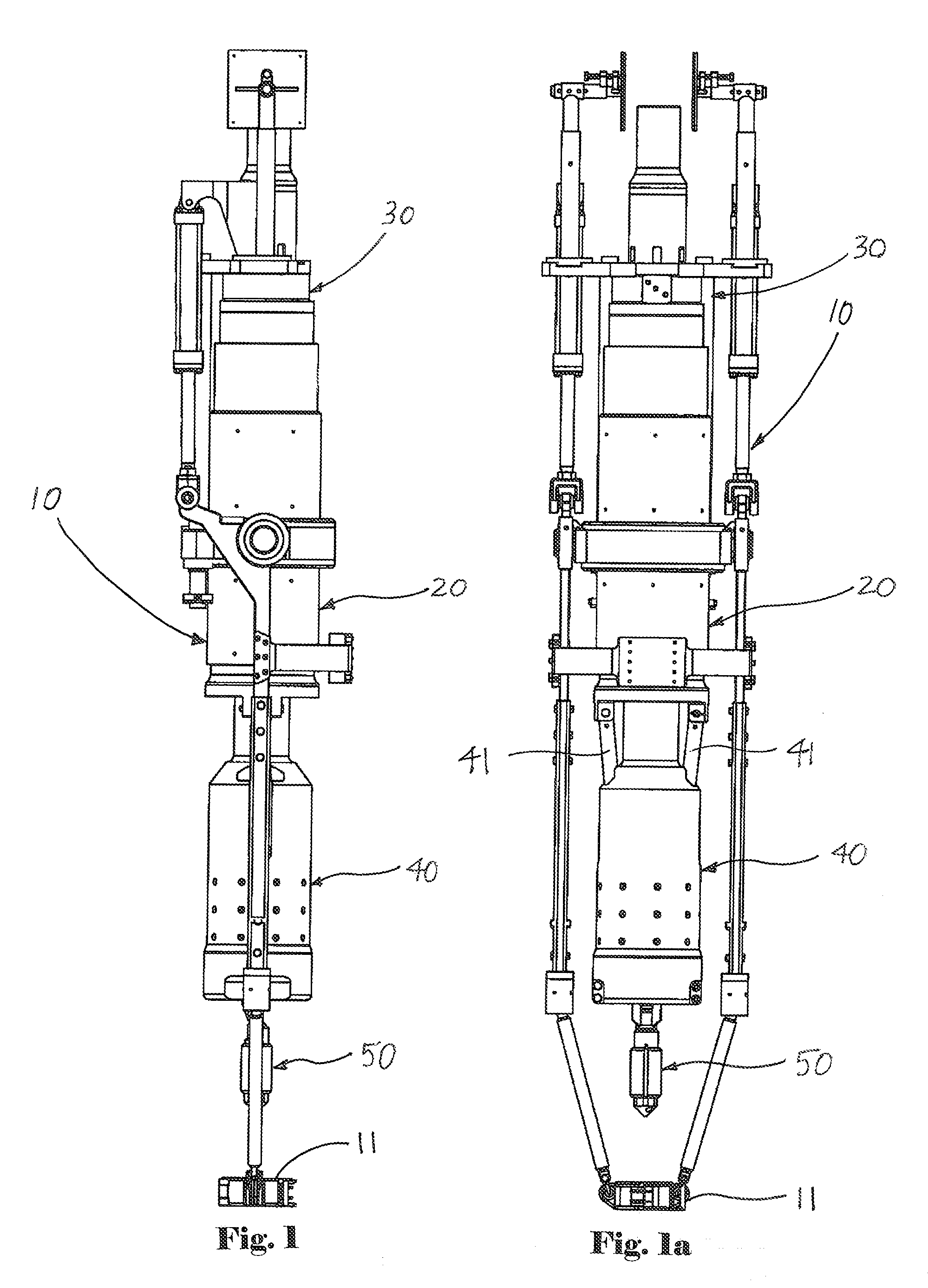

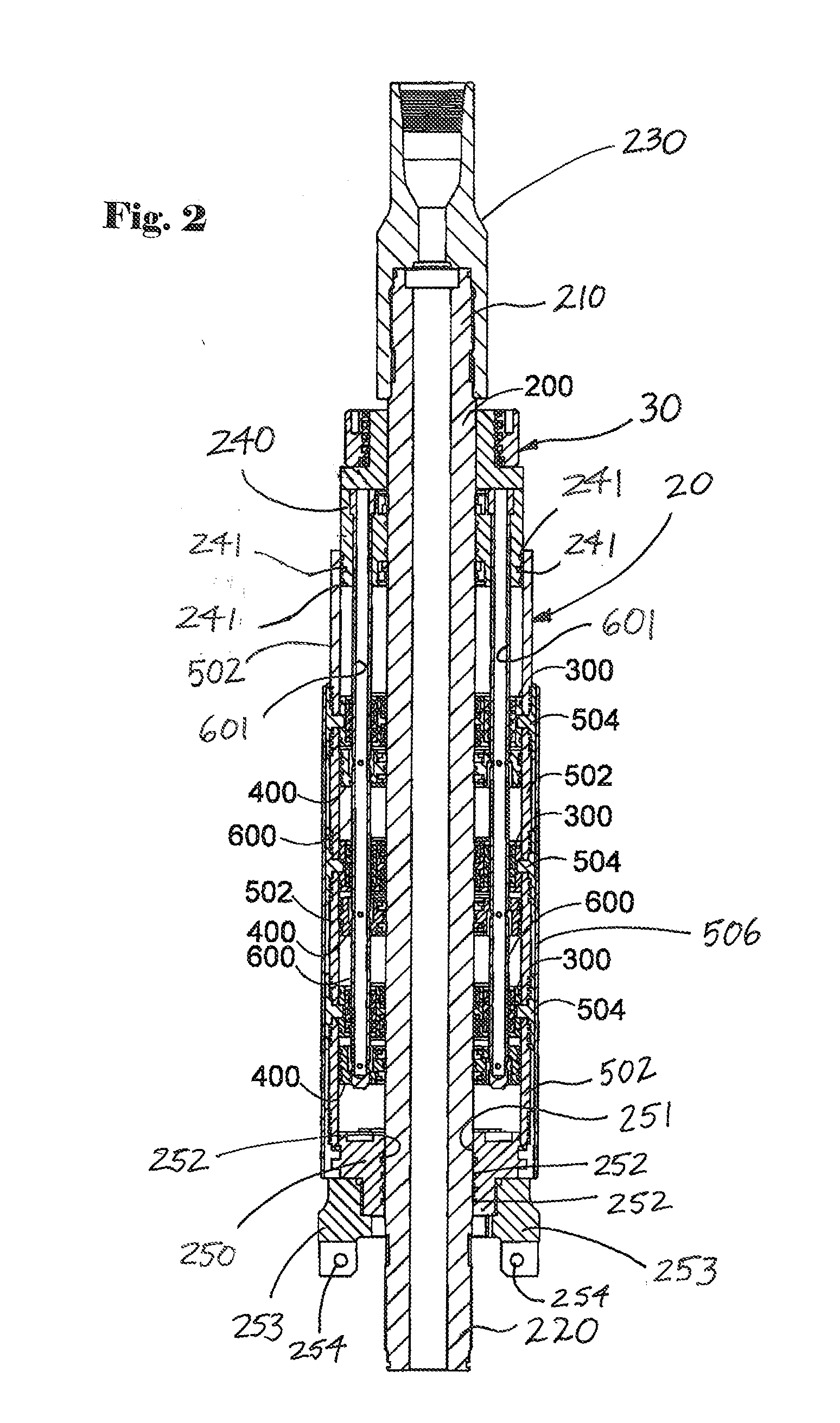

[0034]FIG. 1 depicts side view of a RT assembly 10 equipped with the pipe gripping assembly of the present invention, while FIG. 1a depicts side view of a RT assembly 10 equipped with the pipe gripping assembly of the present invention. Generally, RT assembly 10 comprises fluid swivel assembly 30, linear actuator assembly 20, pipe gripping slip assembly 40 and fluid fill-up assembly 50. Single joint elevators 11 are attached to said RT assembly 10 beneath said fluid fill-up assembly 50.

[0035]As depicted in FIG. 1, fluid swivel assembly 30 can be installed below a top drive unit of a drilling rig to allow for remote powering of tools or equipment (such as RT assembly 10) situated below said top drive unit. In this regard, swivel assembly 30 is generally used to supply control fluid (such as pressurized hydraulic or pneumatic fluid) through said fluid swivel assembly 30 in order to actuate tools or equipment situated below said swivel assembly (including, without limitation, linear ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com