Bi-component fiber for the production of spunbonded fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

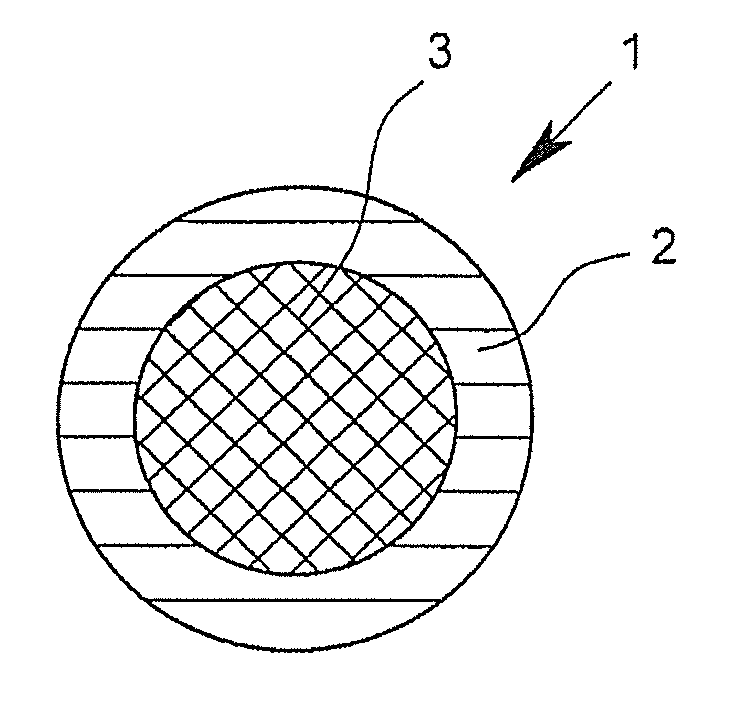

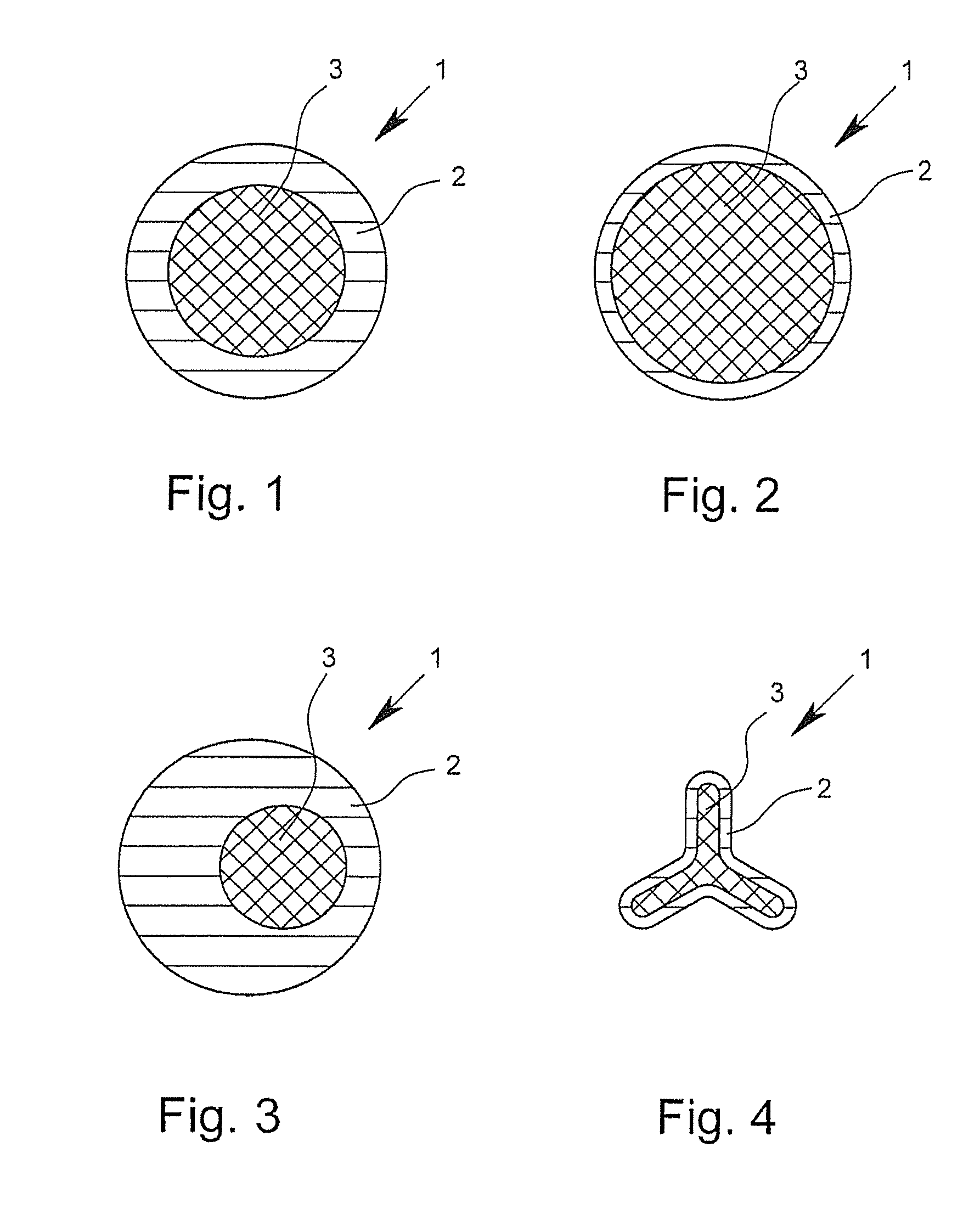

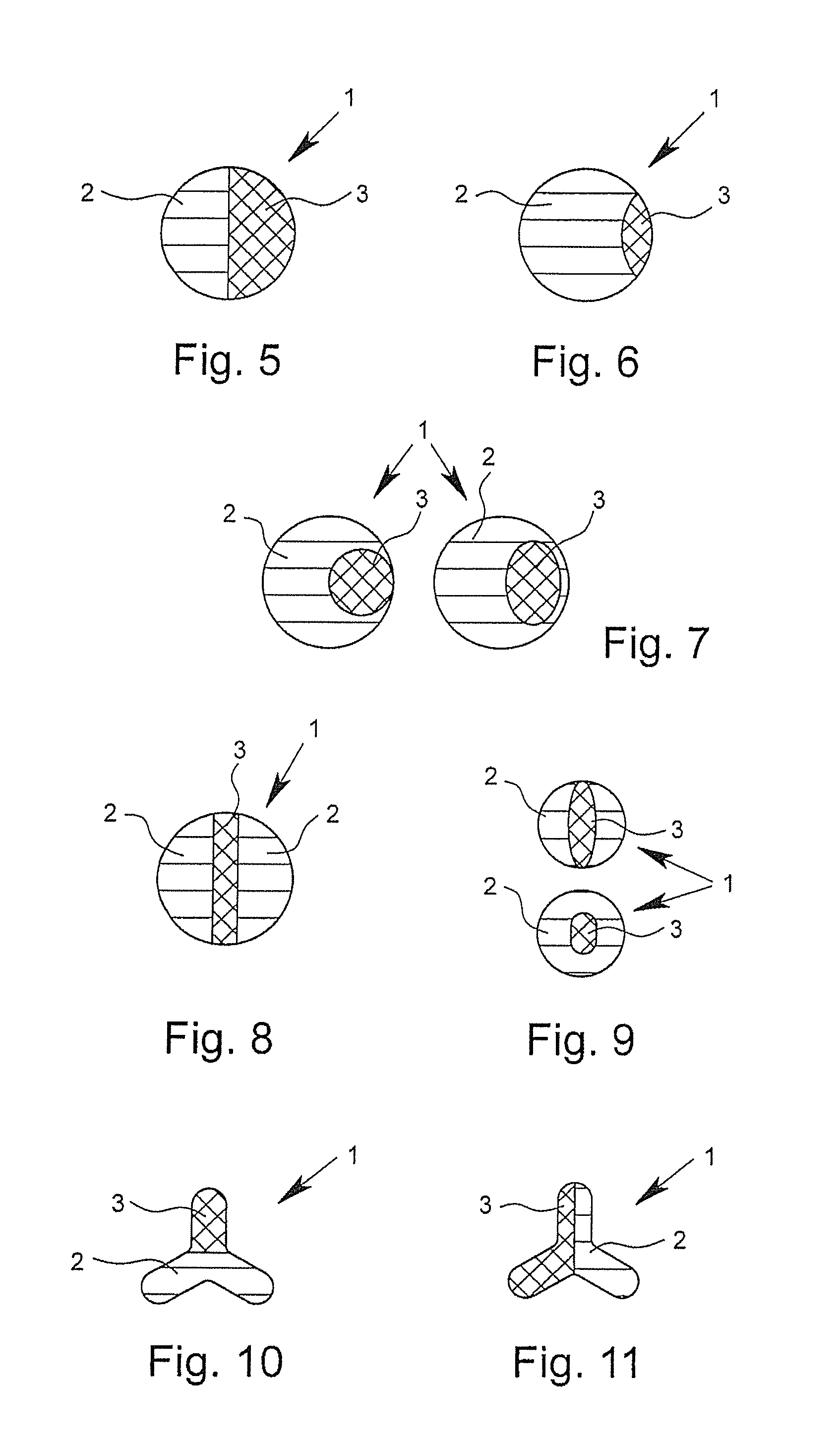

[0096]FIGS. 1 to 16 show cross-sectional views of bi-component fibers 1 according to the invention by way of example. The depicted bi-component fibers 1, in each case, have a first component 2 and a second component 3. In the core-sheath fibers depicted in FIGS. 1 and 4, in this case, the first component 2 surrounds the second component 3 and thus forms the outer surface of the fiber. In this case, the bi-component fibers 1 depicted in FIGS. 1 to 3 have an at least approximately circular or round geometry in cross-section. The bi-component fiber depicted in FIG. 4 shows, however, a trilobal cross-section. Such trilobal cross-sections, like other multilobal cross-sections as well, have the effect that the fiber has a larger outer surface in relation to its mass than is the case with fibers with a circular cross section. In the case of “core-sheath fibers,” in which the proportion of the components forming the sheath is very small, for example approximately 2%, but certainly even in “...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com