System for Managing a Cleanroom Environment

a cleanroom environment and management system technology, applied in space heating and ventilation control systems, lighting and heating equipment, heating types, etc., can solve problems such as contamination or defect, internal source of contamination of clean room workforce, cracks,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The features of the present invention are set forth in the appended claims which may be best understood by reference to the following description taken in conjunction with the accompanying drawings.

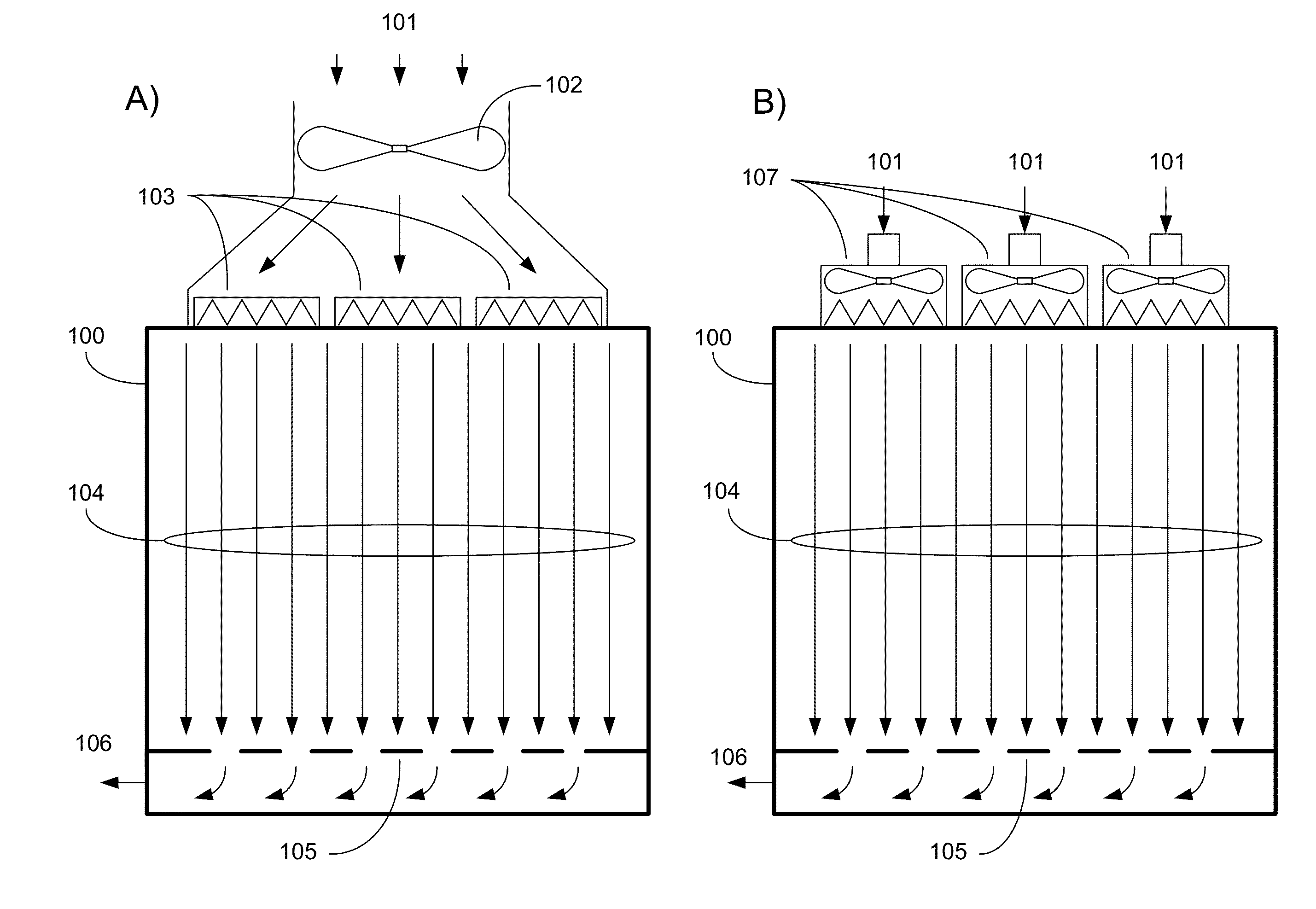

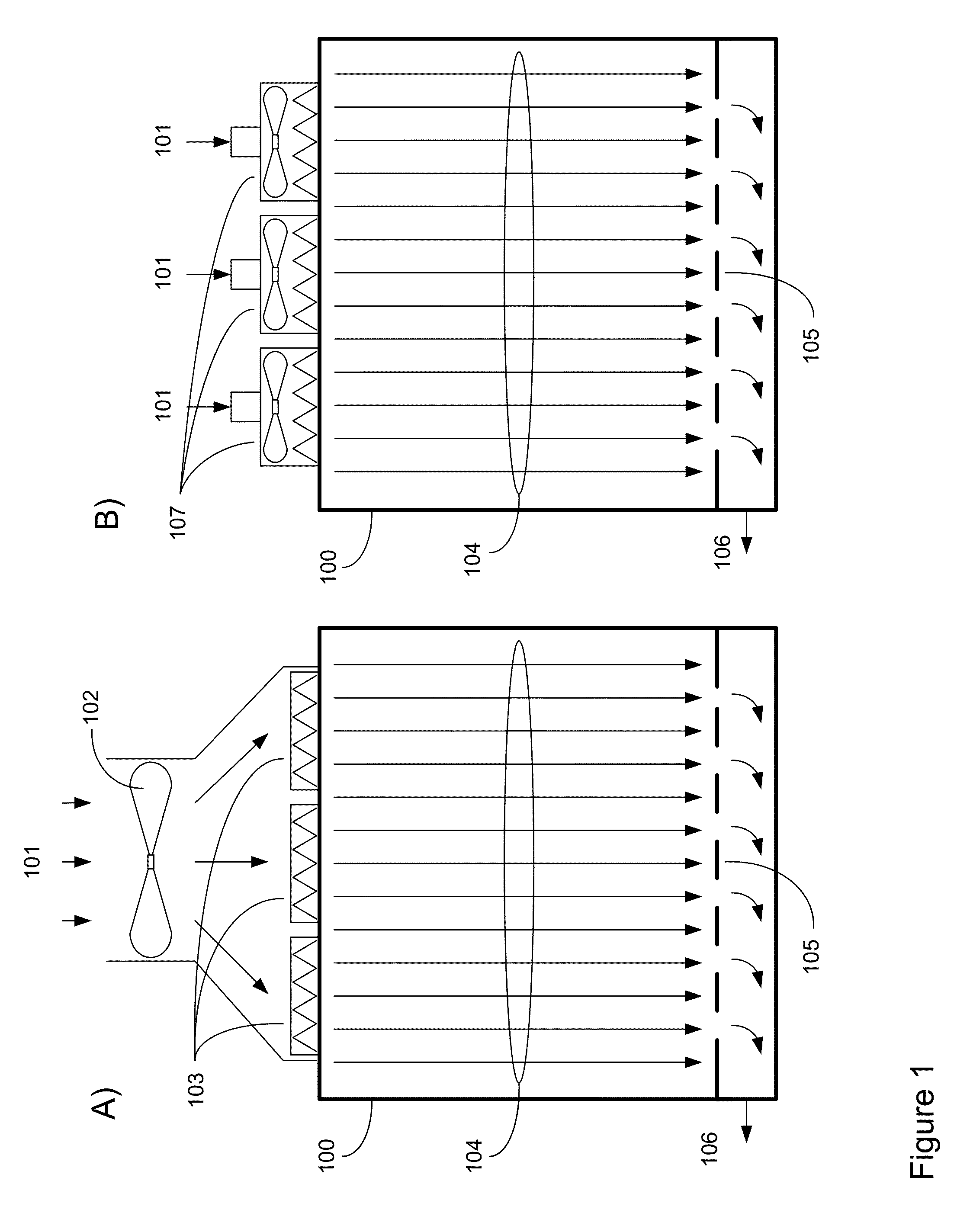

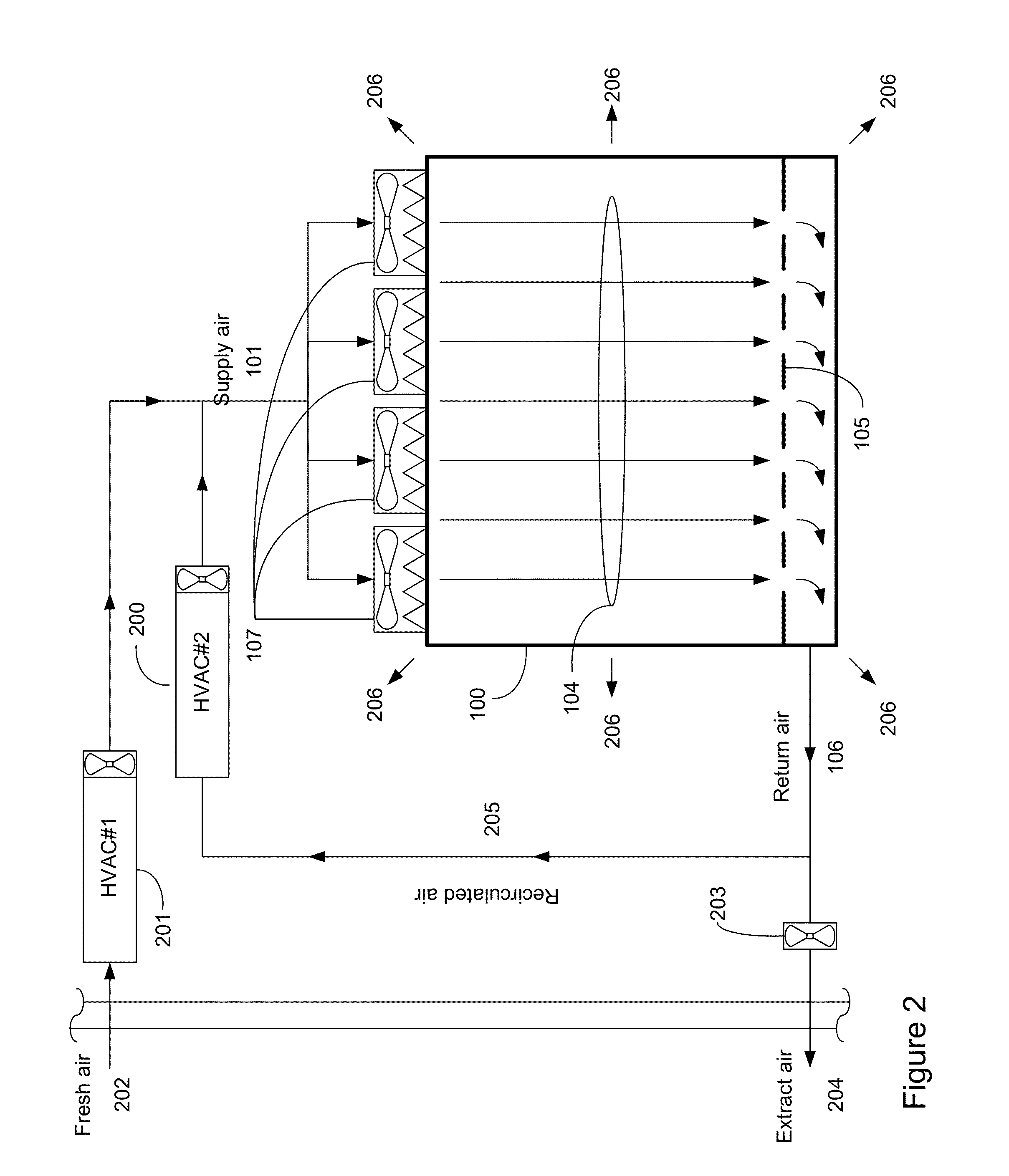

[0030]Cleanrooms have evolved into two major types differentiated by their method of ventilation: unidirectional airflow and non-unidirectional airflow cleanrooms. Unidirectional airflow cleanrooms are characterized by a design that attempts to maintain airflow at a constant level throughout the cleanroom. In non-unidirectional airflow cleanrooms, the airflow is constant only over a limited work area within the cleanroom, and is allowed to diminish elsewhere within the cleanroom. Unidirectional airflow cleanrooms are generally required to achieve the lowest cleanroom classes. FIG. 1 depicts the two basic configurations used to achieve unidirectional airflow cleanrooms. FIG. 1A shows a cleanroom 100 wherein conditioned air 101 is pressurized by a single large fan 102 and is directed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com