Textile fabric, use and production of a textile fabric and furniture element

a technology of textile fabric and textile fabric, which is applied in the field of textile fabric, can solve the problems of limited configuration freedom of design or outer appearance of three-dimensional surface structures produced with flocked yarns, and achieve the effect of high configuration freedom and good shape recovery behavior of fabri

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

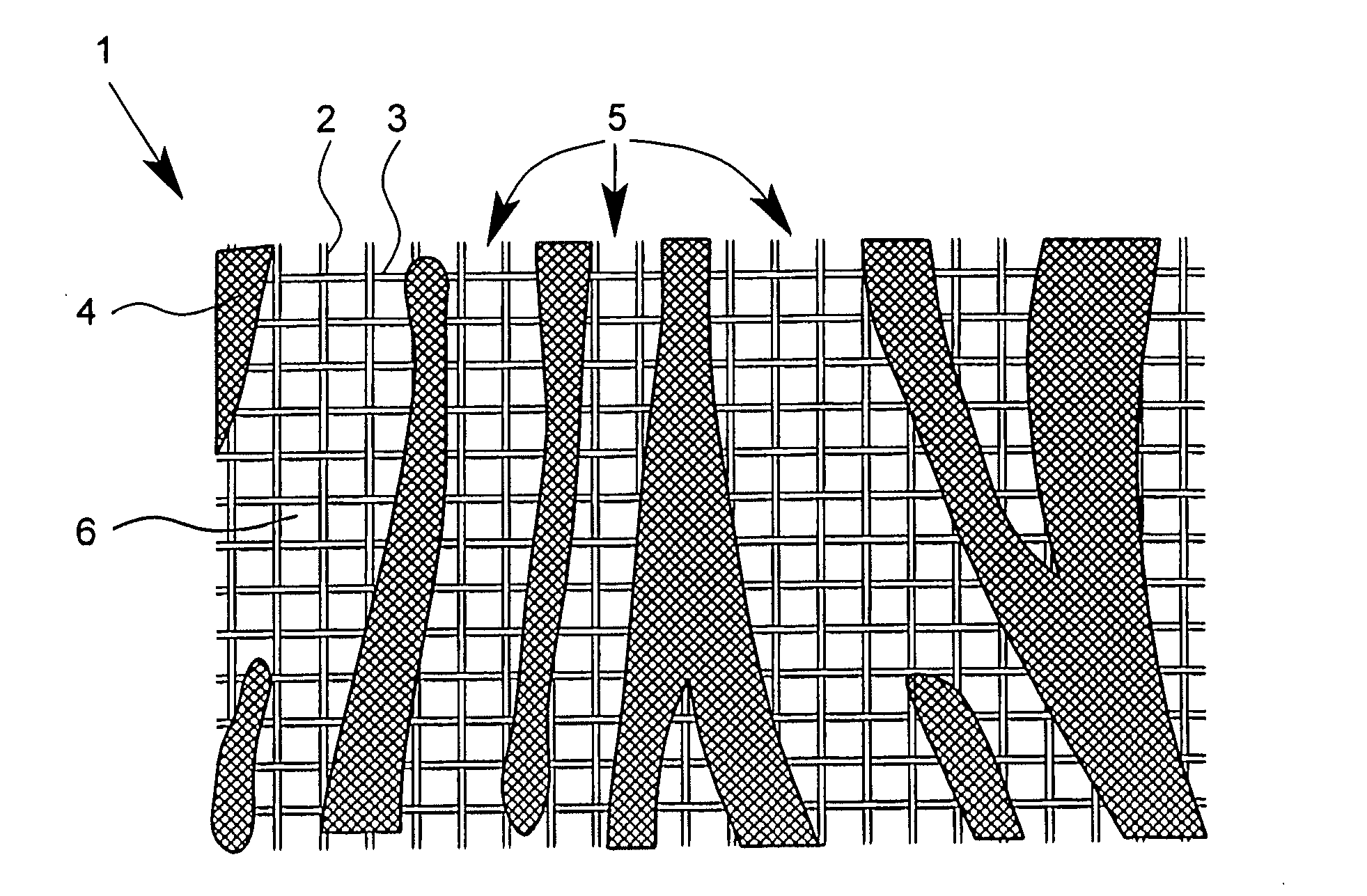

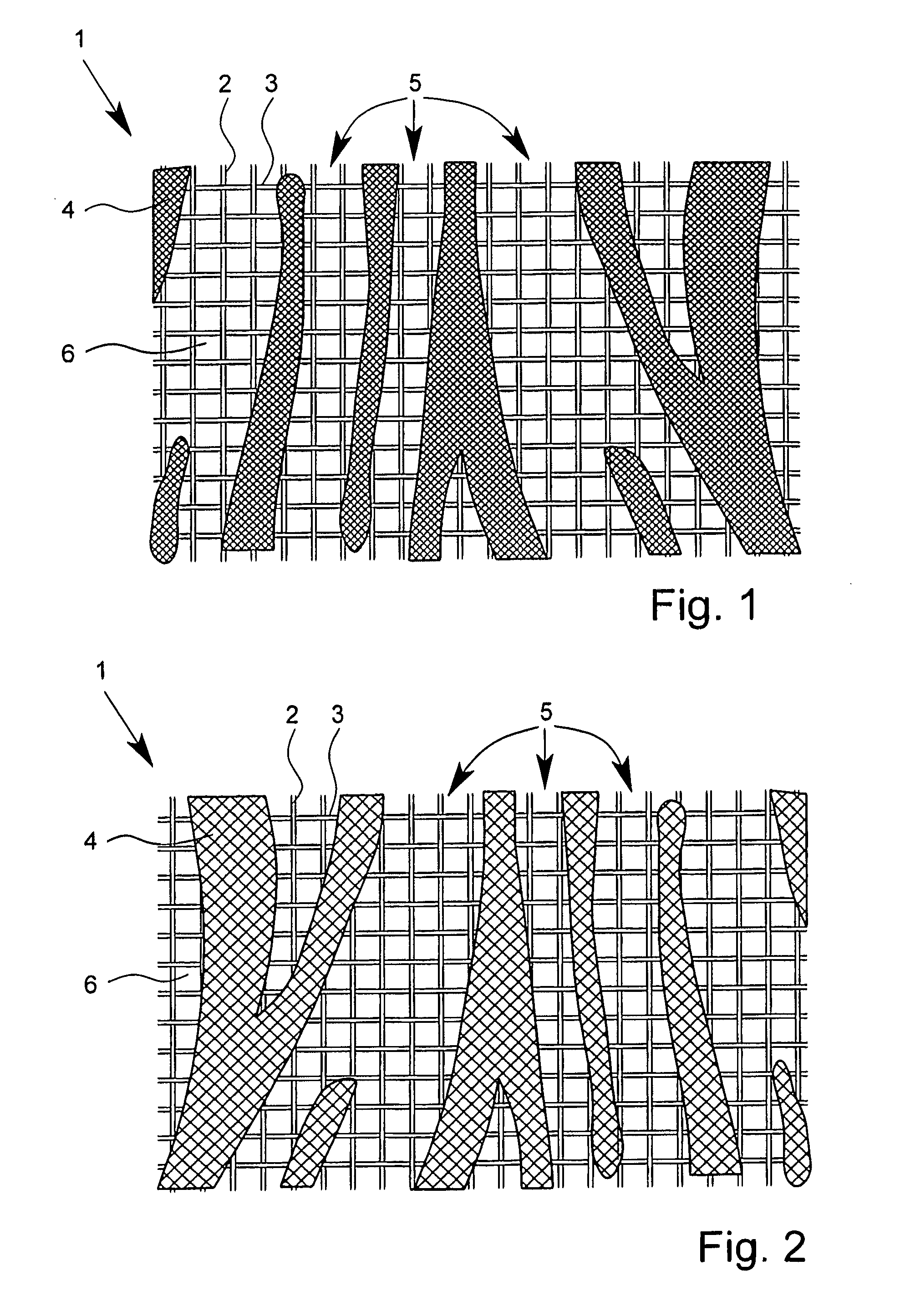

[0031]In FIGS. 1 and 2, a textile fabric 1 according to the invention is depicted with elastic properties for use as upholstery material or covering for support or frame structures, for example, for seating furniture, furniture elements, ducts, automobile accessories, or the like. The fabric 1 has a base material designed as cloth, which is self-supporting and is formed by a number of elastic monofilaments 2 in the warp direction and elastic monofilaments 3 in the weft direction. The fabric 1 thus has a net-like structure. FIG. 1 shows the fabric 1 in a top view, while FIG. 2 shows the same fabric 1 in a view from below. It is understood that in FIGS. 1 and 2, a partial area of the fabric 1 is depicted only diagrammatically.

[0032]The monofilaments 2, 3 can have a diameter of approximately 0.1 to 0.3 mm, preferably 0.2 mm. Instead of monofilaments 2, 3, elastic multifilaments can also be used for the production of base material. The elasticity of the base material is in this case con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile force | aaaaa | aaaaa |

| total elongation | aaaaa | aaaaa |

| total elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com