Methods using patatin

a technology of patatin and glycerin, which is applied in the direction of fatty acid chemical modification, enzymology, fatty oil/fat refining, etc., can solve the problem of not hydrolyzing glycerol fatty acid esters with longer chain lengths, or essentially not, and achieves surprising selectivity and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Feasibility of Patatin-Catalyzed Lipolysis in Acid-Coagulated Whole Milk

[0081]1 L of whole milk was heated in a 2 L beaker on a laboratory hot plate. Upon boiling the heating element was switched off and acetic acid was added under stirring from 30% solution until a curd formed. Curds were collected using a cheese cloth in a colander and allowed to cool. The curds were divided into two fractions. A 10 mL 10% w:v solution of patatin (Solanic 206P) were poured slowly over one fraction, while 10 mL of demineralized water were poured over the other to serve as an untreated control. Residual whey was removed from the curds by gentle pressing. Within 5 minutes, the patatin-treated curd mass developed a strong cheese scent, while the untreated control retained a boiled milk scent.

example 2

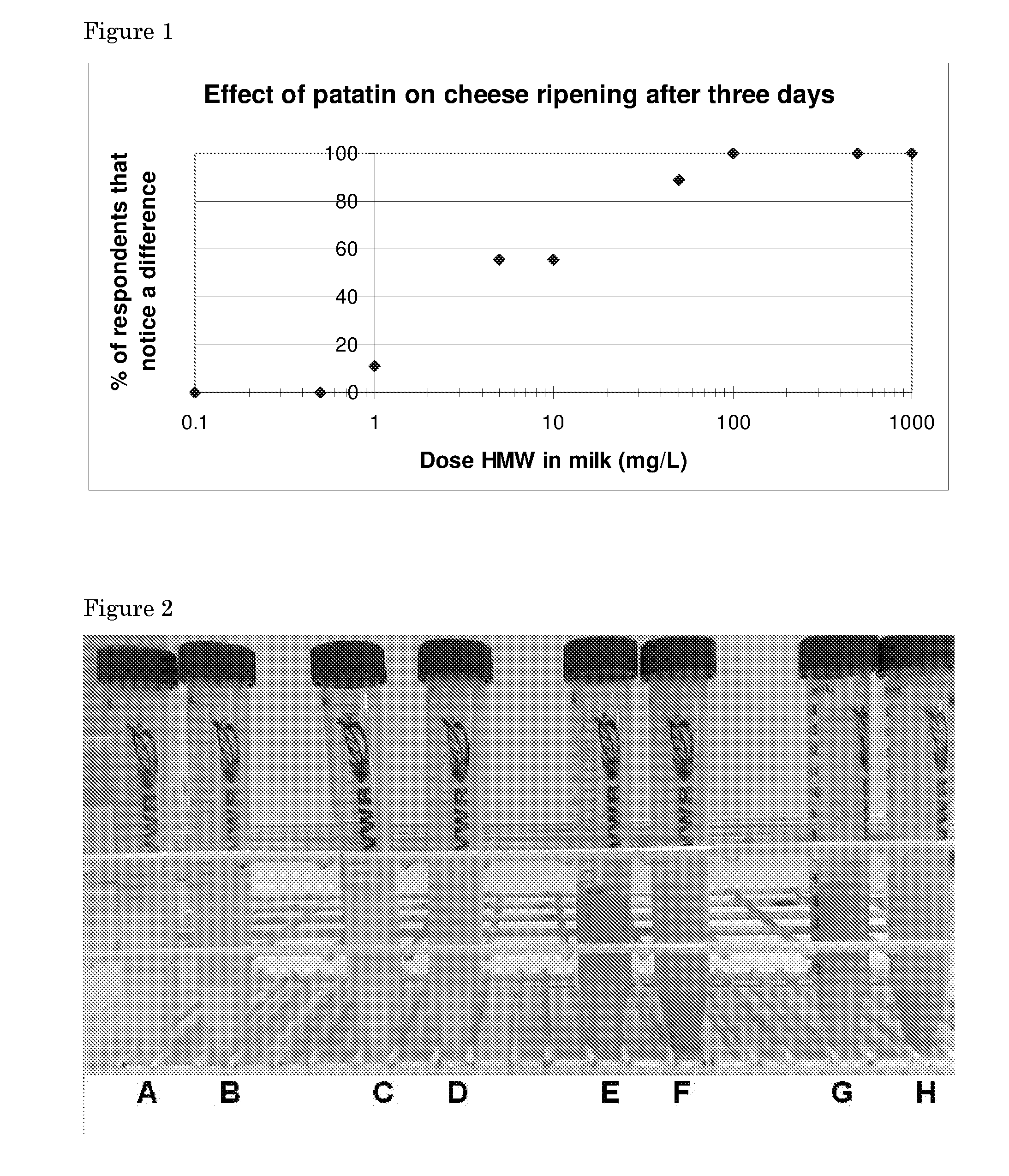

Patatin Dose-Response Relationship in Rennet-Coagulated Cheese

[0082]Rennet was purchased from SigmaAldrich (R5876). 500 mL aliquots of whole milk were supplemented with patatin at concentrations between 0.1 mg / L and 1.0 g / L and coagulated at 35° C. for 90 minutes by the action of 10 mg / L rennet. A reference coagulated milk was prepared similarly without the addition of patatin (“HMW”). The curd fractions were recovered by straining the coagulate through cheese cloth and pressing. The resulting material was brined by complete submersion in a 90 g / L sodium chloride solution for 1 hour and allowed to ripen for three days at ambient temperature. A nine-person test panel composed of resident laboratory personnel was asked to indicate with certainty whether the scent of each cheese was noticeably different from that of the reference cheese containing no patatin. After three days, the cheeses containing 1 mg / L or more patatin had a noticeably different scent from the reference cheese (for ...

example 3

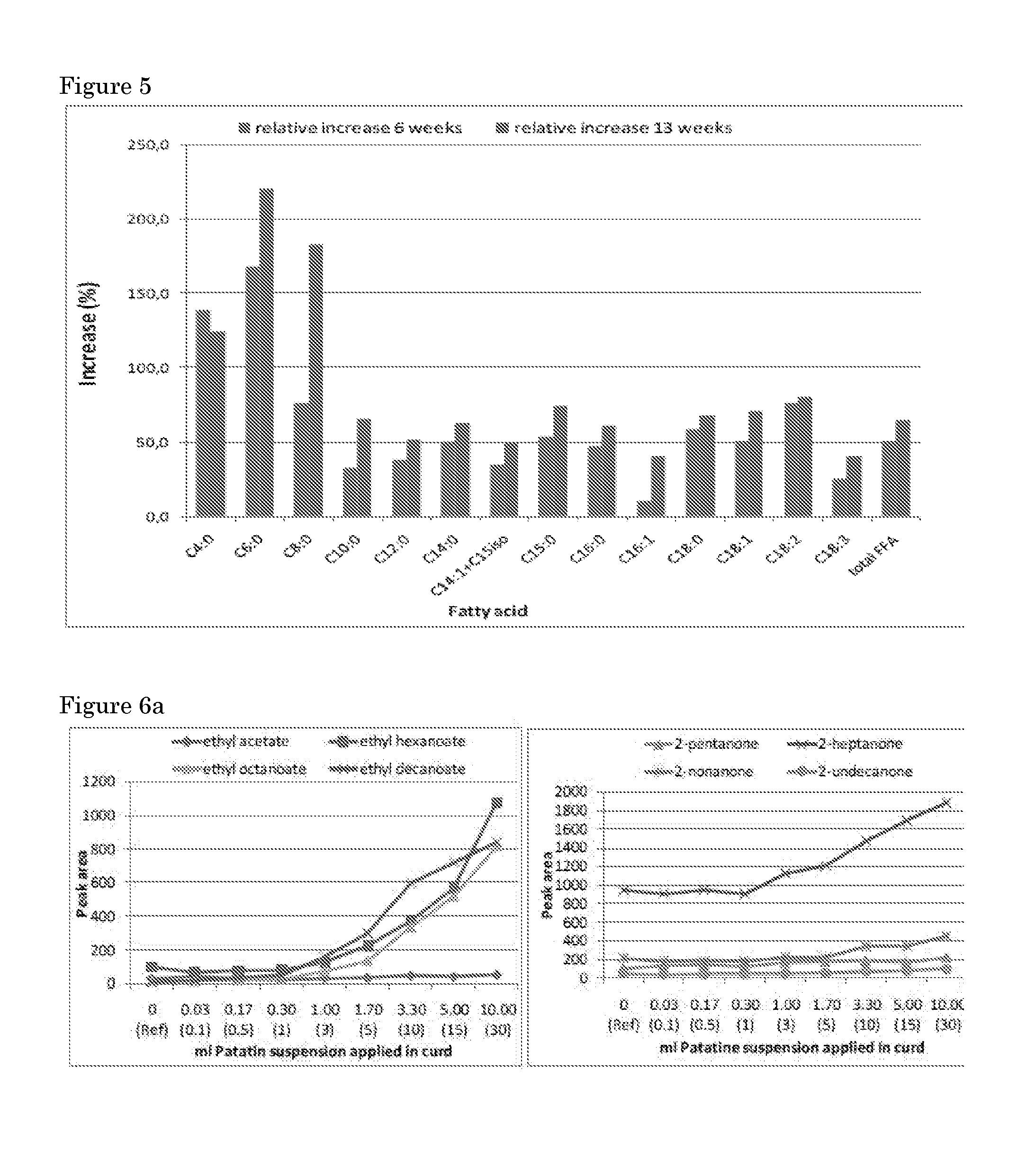

Distribution of Patatin Over Curd and Whey in Rennet-Induced Coagulation

[0083]Patatin Labelling

[0084]Solanic HMW potato protein isolate was used as an essentially pure patatin preparation. Coomassie Brilliant Blue was from Merck (G-250 1.15444, R-250 1.12553). PD10 gel filtration columns were from GE Healthcare. Rennet was purchased from SigmaAldrich (R5876).

[0085]A 4.0% (m:m) solution of patatin was prepared in demineralised water and incubated with equimolar amounts of either Coomassie Brilliant Blue R-250 or Coomassie Brilliant Blue G-250 and incubated at ambient temperature under constant stirring for 30 minutes. After incubation any unbound dye was removed from the protein by gel filtration on PD 10 disposable gel filtration columns. Dye-labelled patatin solutions were stored at −28° C. until use.

[0086]Determination of the Distribution of Patatin Over Curd and Whey Via Labelled Patatin

[0087]5 mL aliquots of milk were supplemented with different doses of labelled patatin between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com