Methods and systems for monitoring well integrity and increasing the lifetime of a well in a subterranean formation

a technology of subterranean formation and well integrity, which is applied in the direction of survey, borehole/well accessories, etc., can solve the problems of cement deformation, cracking, cement deformation, corrosion, scaling and/or other degradation of equipment within the well, etc., and achieve the effect of reducing degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

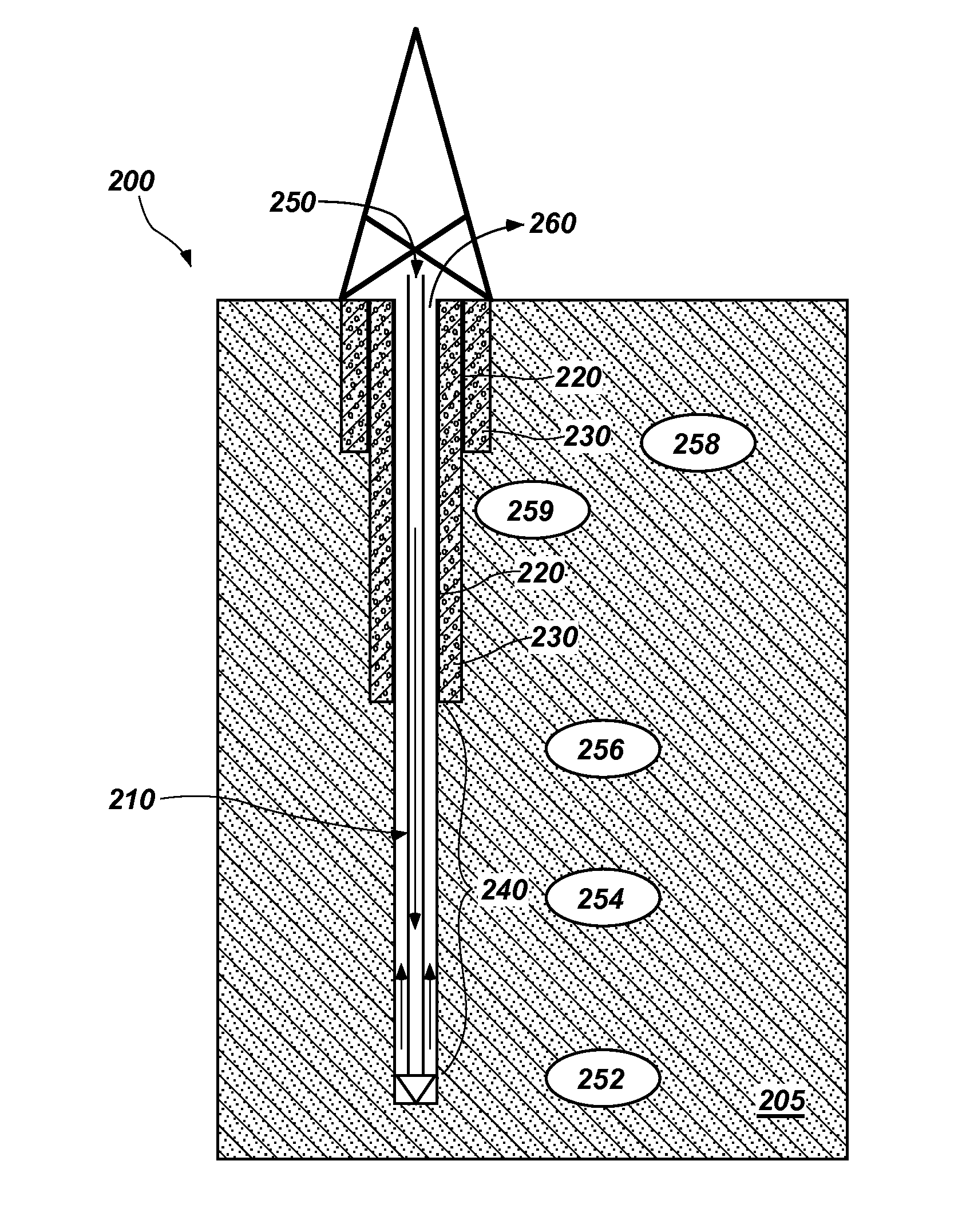

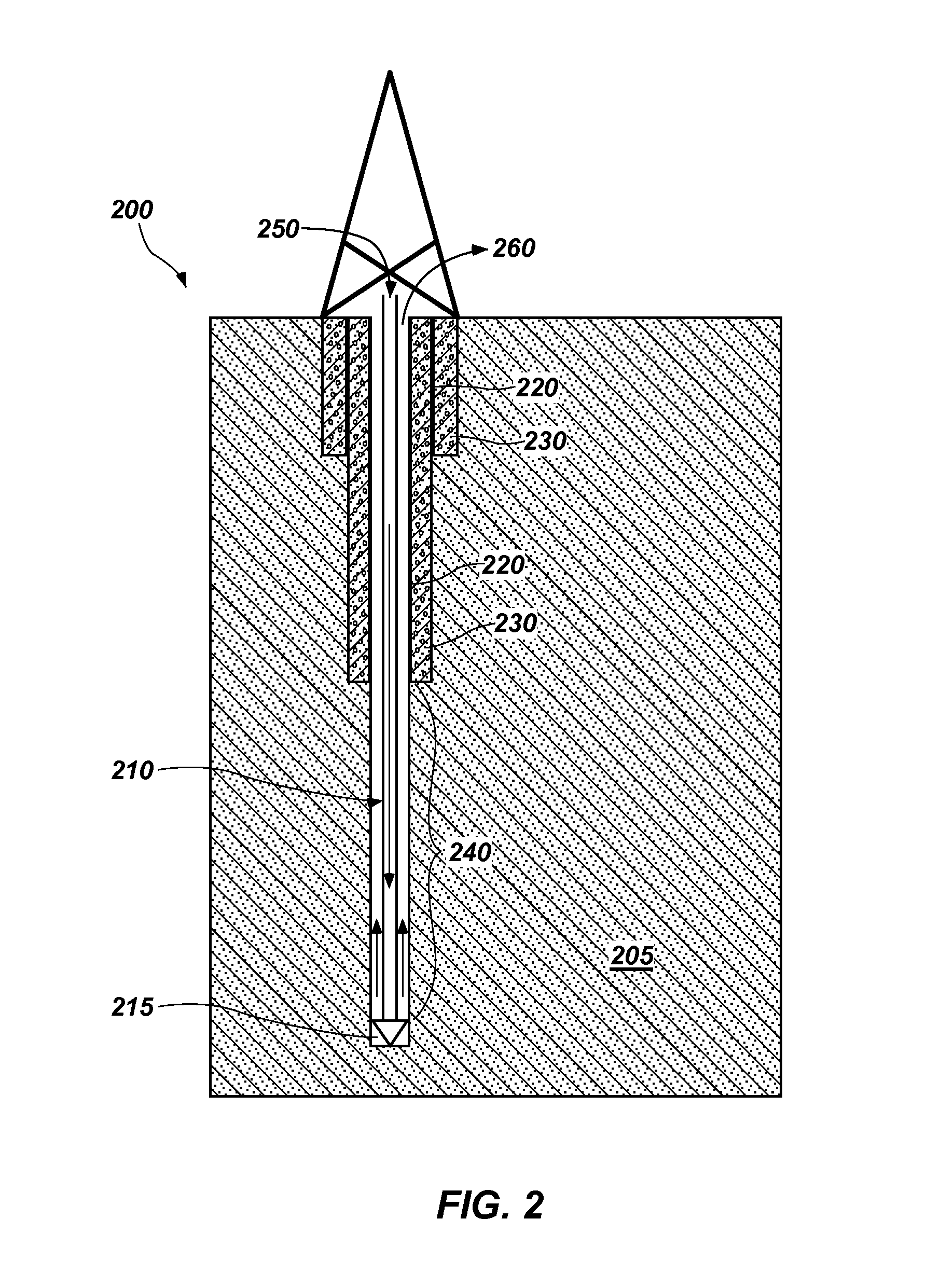

[0018]The illustrations presented herein are not meant to be actual views of any particular material, apparatus, system, or method, but are merely idealized representations that are employed to describe certain embodiments of the present invention. For clarity in description, various features and elements common among the embodiments of the invention may be referenced with the same or similar reference numerals.

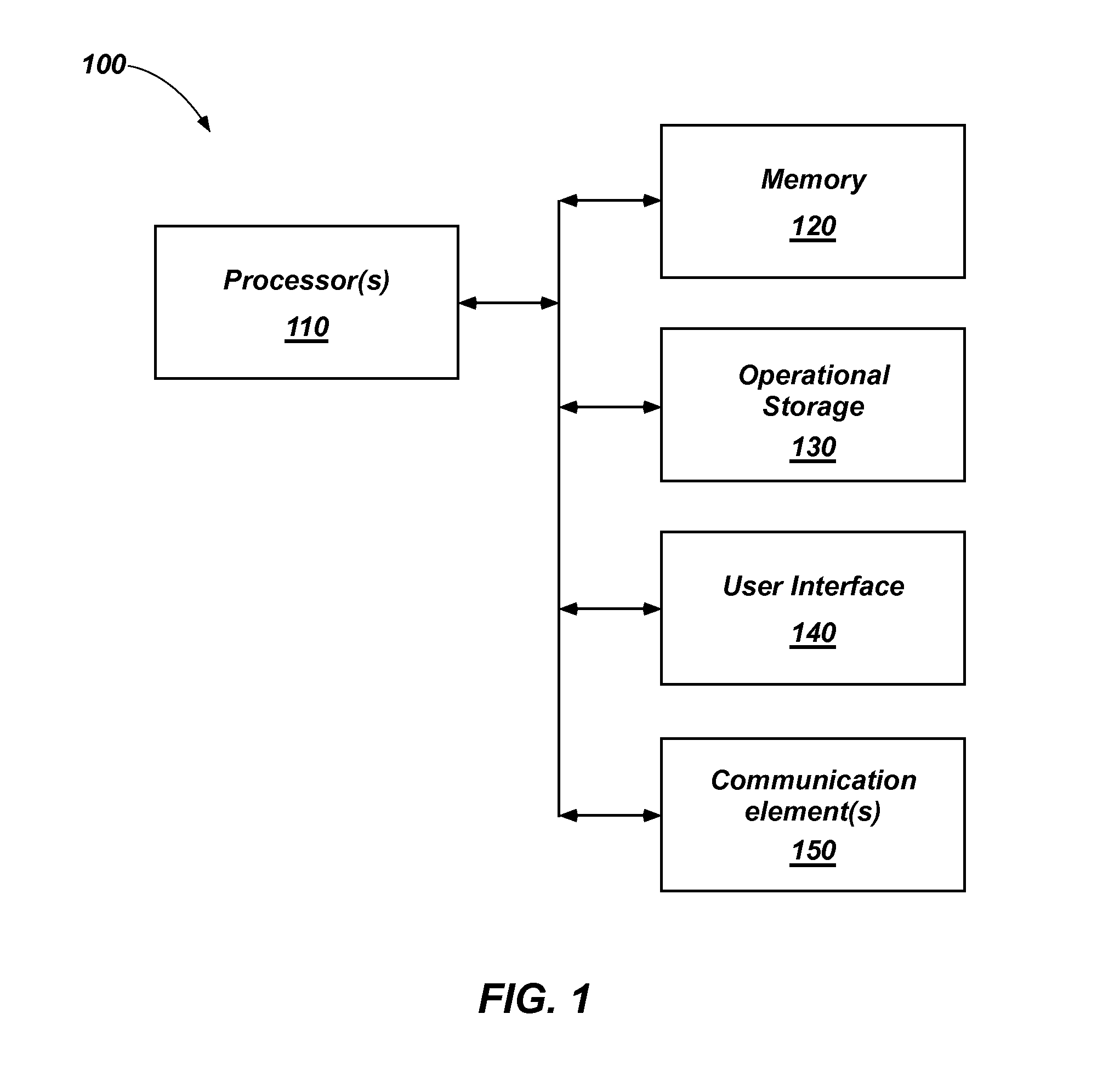

[0019]Those of ordinary skill would appreciate that the various illustrative logical blocks, modules, circuits, and algorithm acts described in connection with embodiments disclosed herein may be implemented as electronic hardware, computer software, or combinations of both. To clearly illustrate this interchangeability of hardware and software, various illustrative components, blocks, modules, circuits, and acts are described generally in terms of their functionality. Whether such functionality is implemented as hardware or software depends upon the particular application an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com