Flexible sachet having a triangular shape

a sachet and flexible technology, applied in the direction of caps, liquid handling, closures using stoppers, etc., can solve the problems of not being able to easily hold by one hand and possibly share with others, packaging has a shape from the beginning which cannot be easily transported in a flat condition, and is difficult to open

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

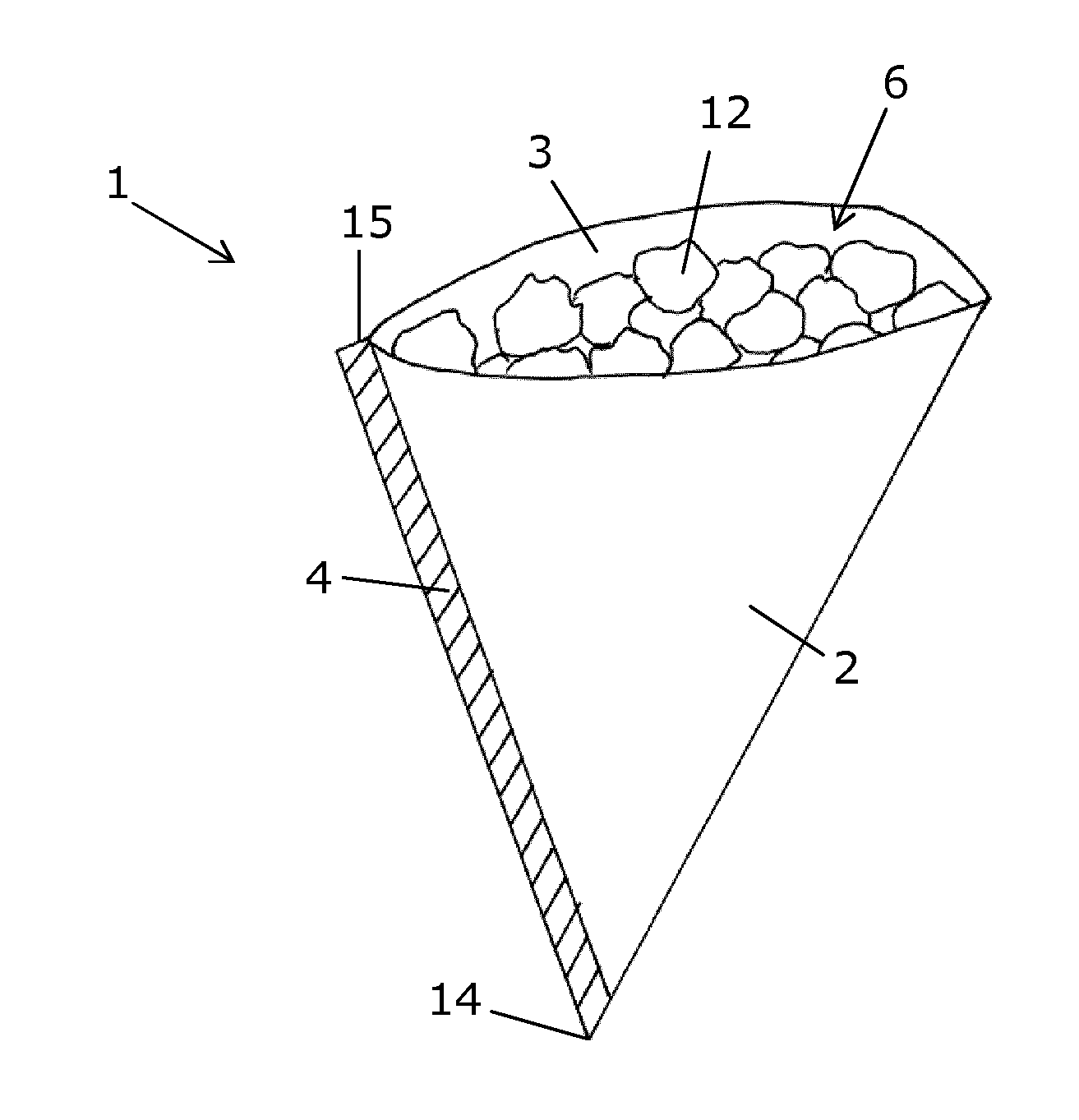

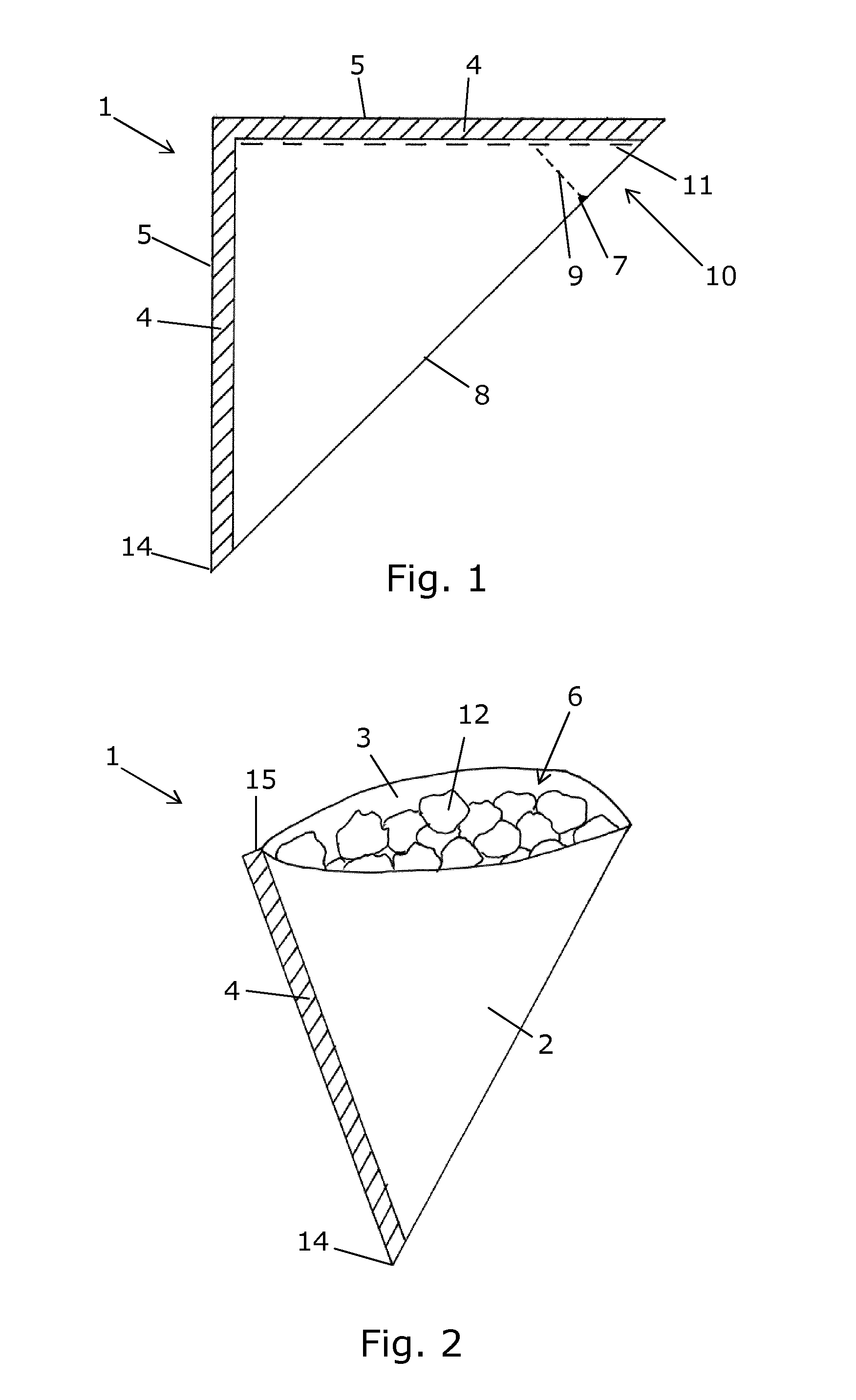

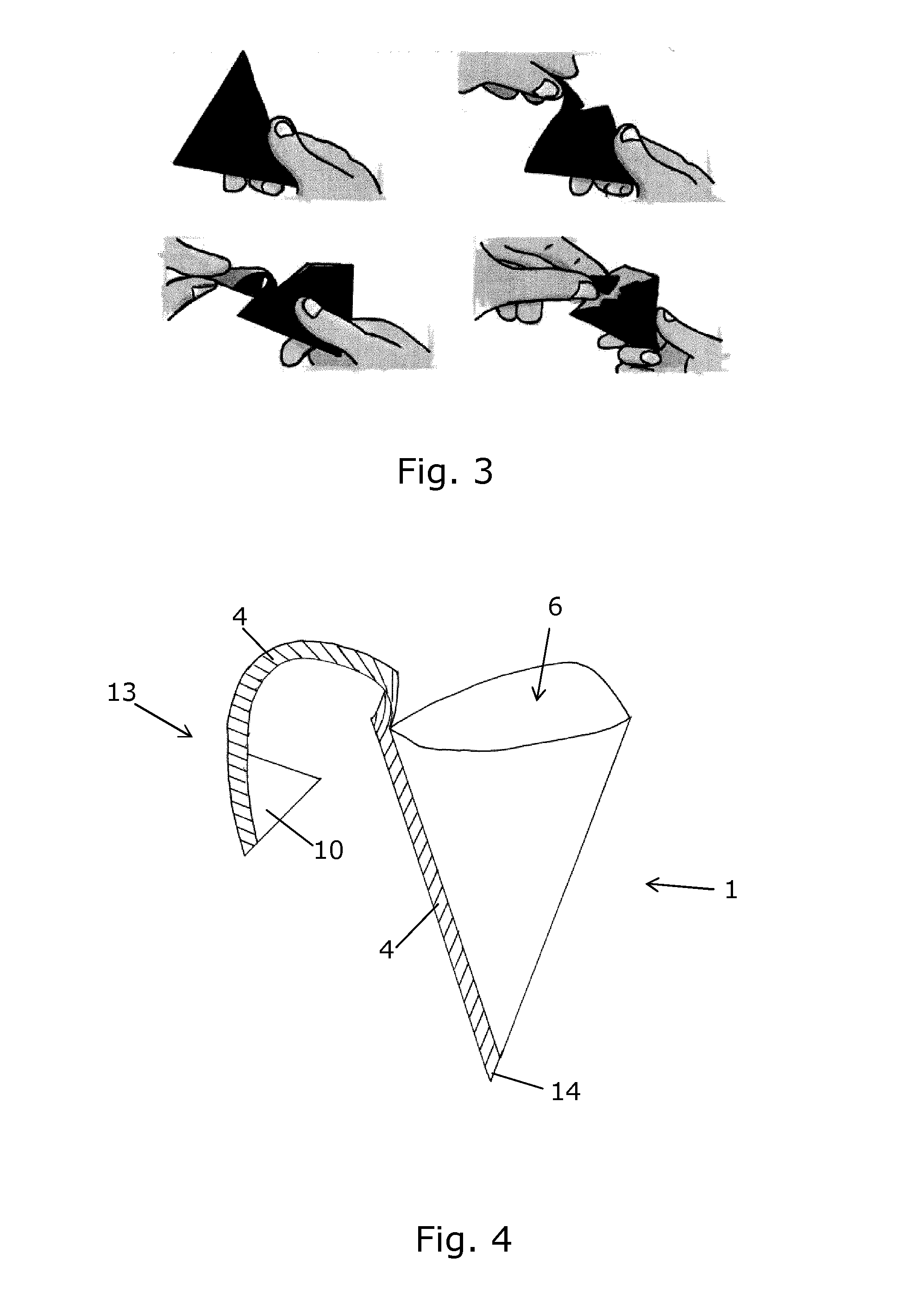

[0067]FIG. 1 shows schematically a triangularly shaped sachet 1 in a closed condition. The sachet 1 looks flat in the figure for illustrative purposes only. An un-opened sachet 1 will normally look more bulky to an extend depending on the amount and type of product located inside it. Such a product will typically be an eatable product intended for human, particularly discrete pieces of a food product of a size convenient to be picked up by hand. The sachet according to the invention is particularly suitable for snack products such as savory or sweet snack products in discete “bite-size” pieces, for example such as crisps, nuts, sweets, dried fruits, chocolate pieces, wafer or extruded cereal snack pieces, crackers, biscuits, or other snack food items. However, the sachet 1 may also contain e.g. pet food.

[0068]The sachet 1 is formed by one sheet of flexible blank material, which has been folded upon itself to form a front layer 2 and a rear layer 3 of the sachet 1; the front layer 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com