Lubricant compositions

a technology of compositions and lubricants, applied in the field of lubricant compositions, can solve the problems of reducing effectiveness and often lacking shear stability of vi improvers, and achieve the effects of good metal-to-metal lubrication, increased viscosity index value of lubricant compositions, and acceptabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

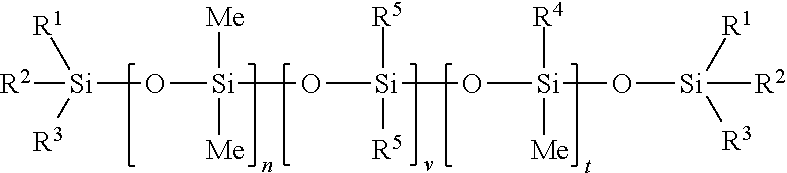

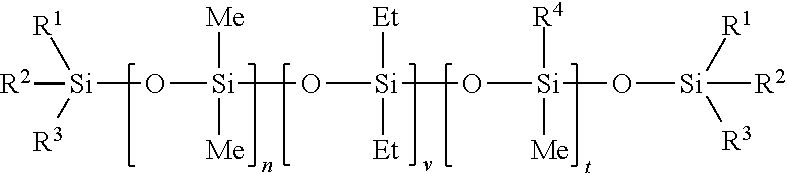

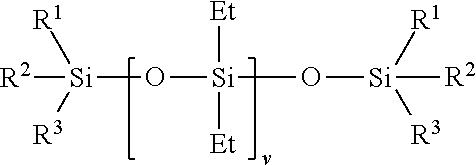

Method used

Image

Examples

example 1a

PDES+PAO

[0136]

PDESPAOLCC(wt %) (B)(wt %) (A)(N)010045059520001090200040602000604015008020750901012001000250

[0137]Example 1a shows that mixtures according to the invention containing PDES have an LCC much higher than the pure oils in the range of between 0.5 and 50% wt of component (B), namely the PDES. The effect can be already seen with a 5% wt % addition level of PDES into the PAO.

example 1b

PDES+PAO

[0138]

Viscosity atViscosity atPDESPAO40° C.100° C.Viscosity(Wt %) (B)(Wt %) (A)(mPa · s)(mPa · s)Index0100—— 143*208030.916.62207406038.278.3222604050.7612.5271802082.3419.332679010118.9328.08285

[0139]Example 1b shows that mixtures according to the invention containing PDES (i.e. component B) have much higher Viscosity Index values (at least 10% greater) than 100% PAO (*: Viscosity Index 143 from suppliers datasheet).

example 2a

PDES+Mineral Oil

[0140]

PDESMineral OilLCC(Wt %) (B)(Wt %) (A)(N)0100100059514001090200020801800406010506040110080204509554501000250

[0141]Example 2 a shows that compositions as hereinbefore described containing PDES and mineral oil have an LCC much higher than 100% mineral oil. The effect can be seen at 5% addition level of PDES into the mineral oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| viscosities | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com