Thermal break bracket for a support frame of covering elements

a technology of supporting frame and covering element, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of low elasticity, high production cost, and difficulty in absorbing vibrations and adapting to the different working tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]We shall now refer in detail to the various forms of embodiment of the present invention, of which one or more examples are shown in the attached drawing. Each example is supplied by way of illustration of the invention and shall not be understood as a limitation thereof. For example, the characteristics shown or described insomuch as they are part of one form of embodiment can be adopted on, or in association with, other forms of embodiment to produce another form of embodiment. It is understood that the present invention shall include all such modifications and variants.

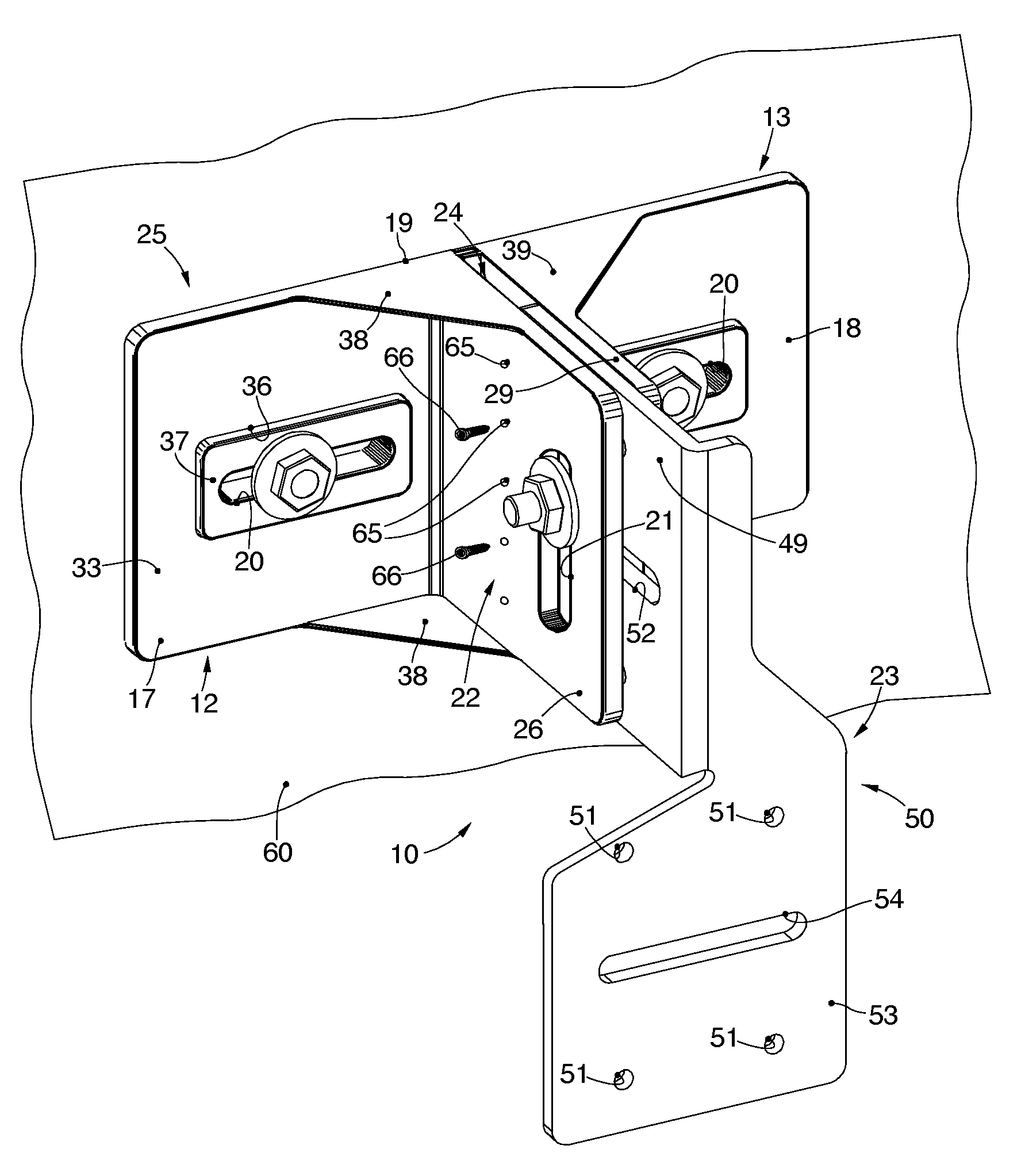

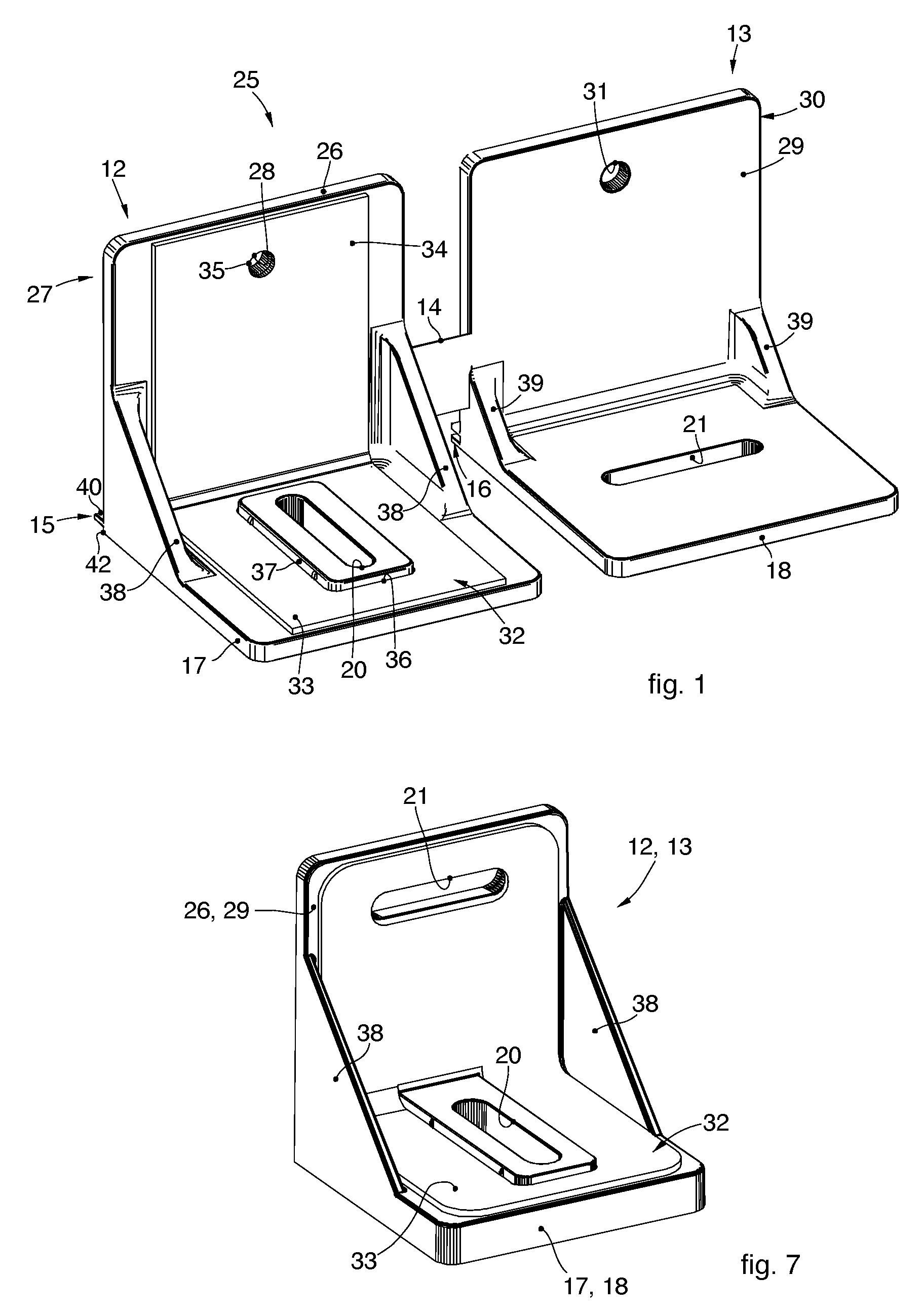

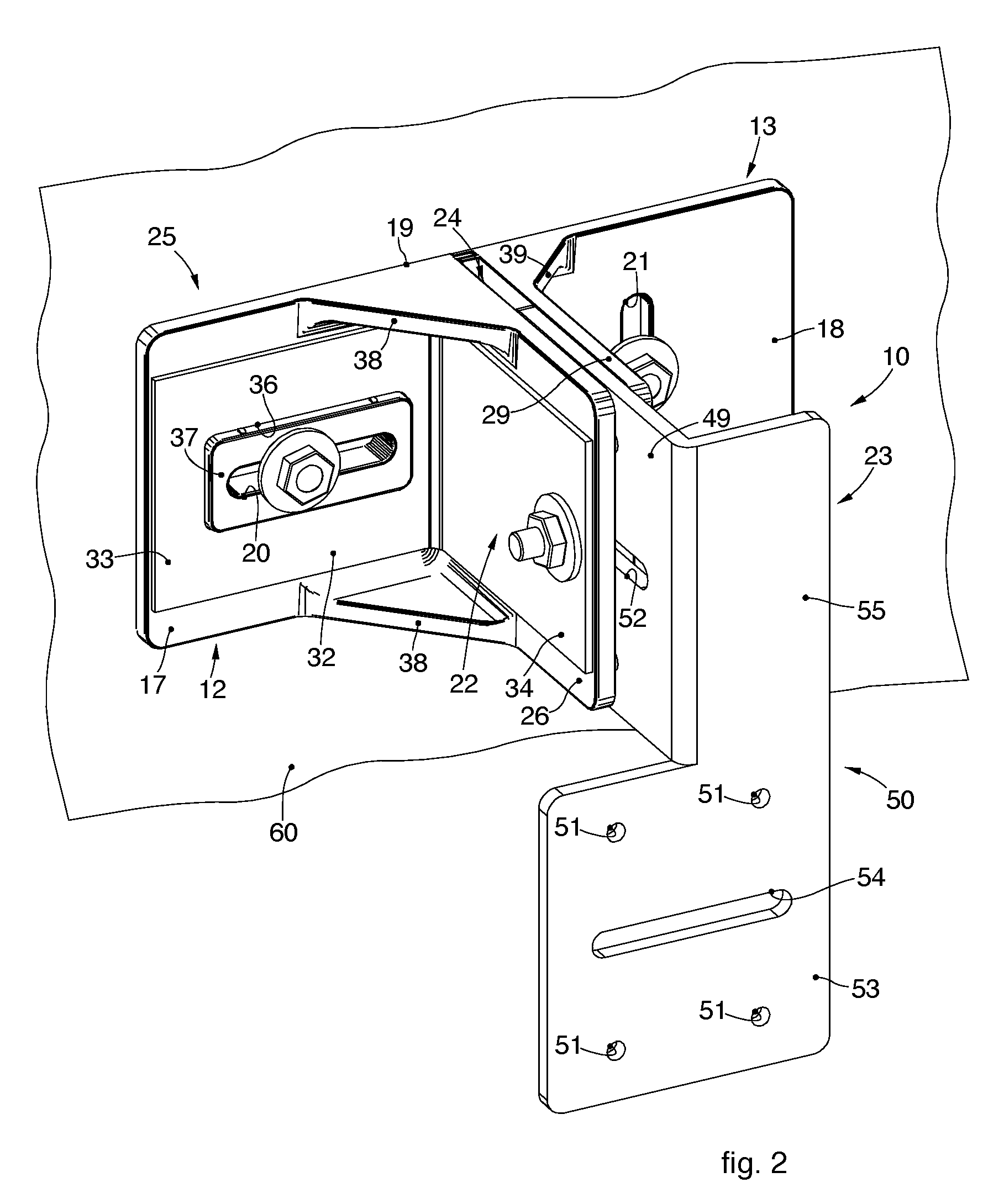

[0043]FIGS. 1-7 are used to describe forms of embodiment of a thermal break bracket 10 used to attach a support frame 11 to an attachment wall 60, shown schematically in FIGS. 2 and 3.

[0044]The thermal break bracket 10 has a first component 25 (FIGS. 1, 7) made at least partly, advantageously wholly, of polymer material, such as polyamide for example, obtainable by molding or other suitable working process.

[0...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap