Powerful toy blower

a blower and toy technology, applied in the field of air blowers, can solve the problems of weak fan capacity, unstable operation, unneeded vibration, etc., and achieve the effects of facilitating heat dissipation and air flow, enhancing the volume of air flow and fan capacity, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

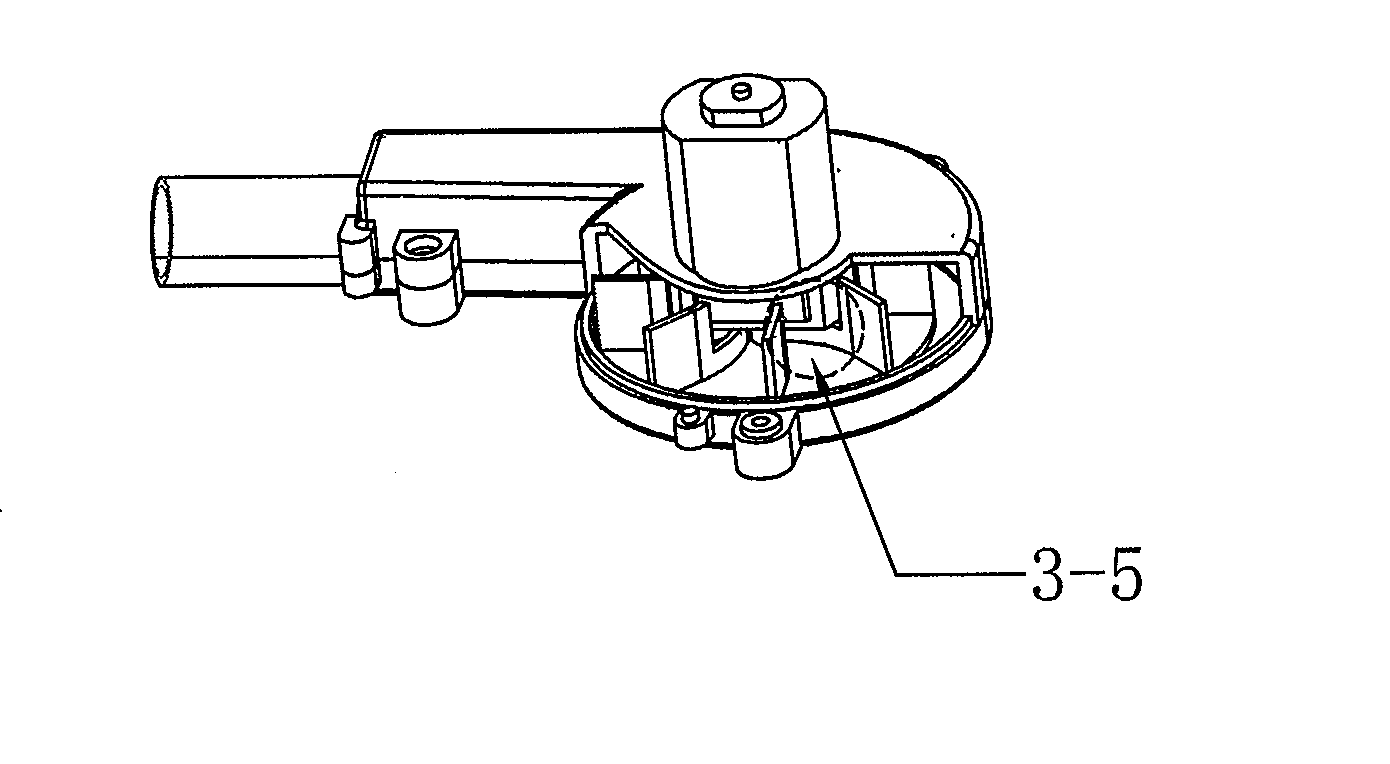

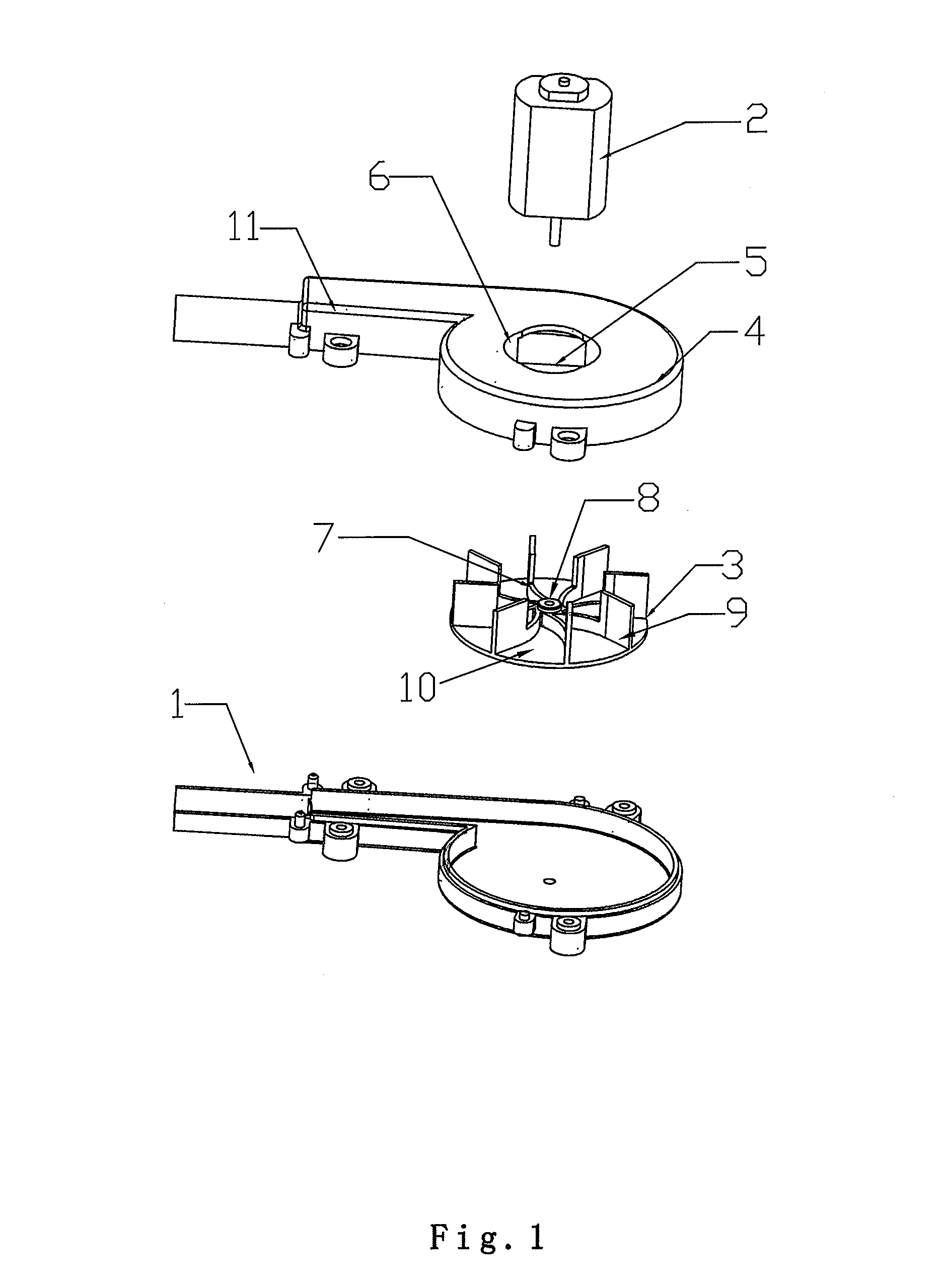

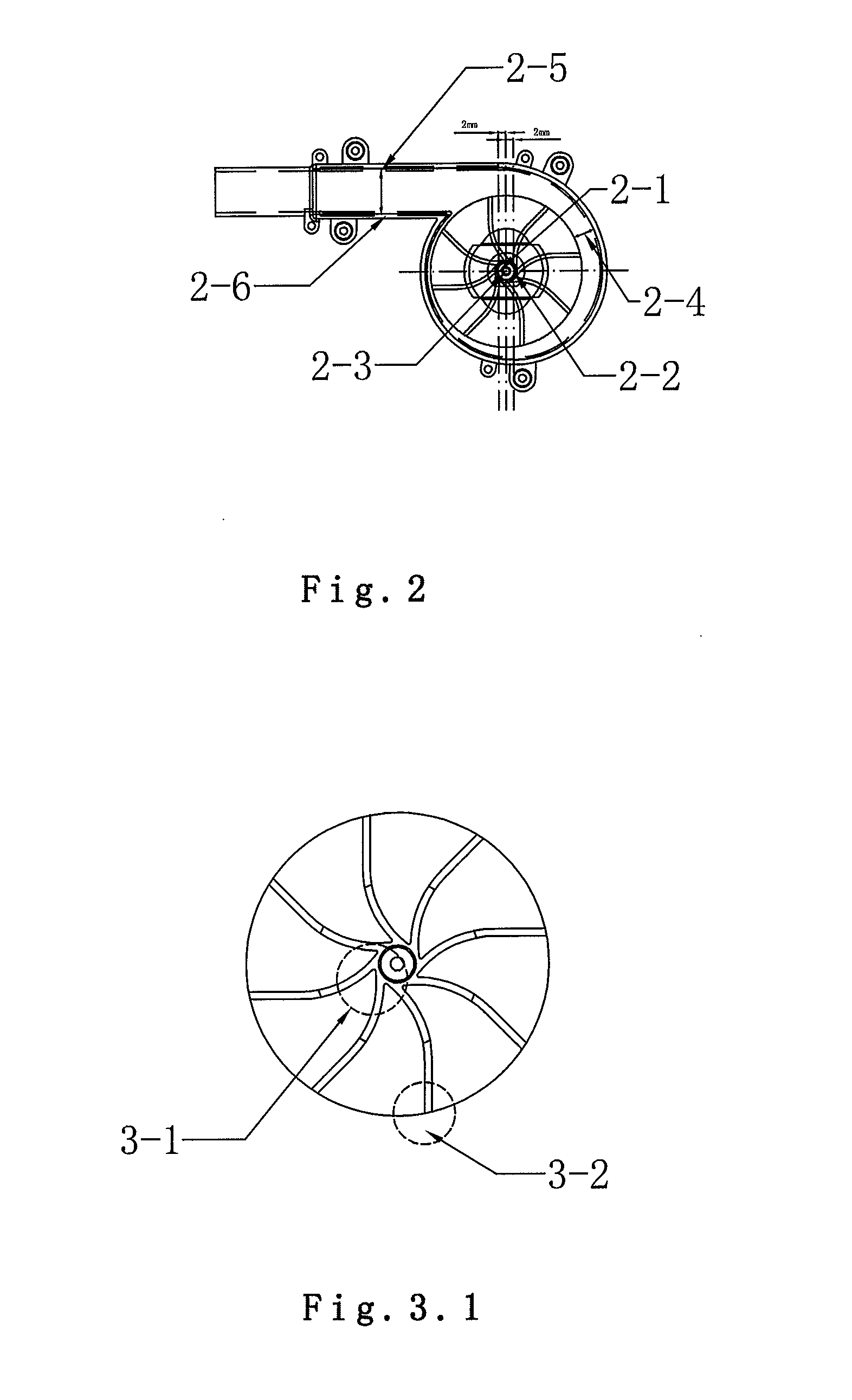

[0019]The embodiment of the utility model, a powerful toy blower as shown on FIG. 1, comprises three basic parts, including a housing 1 that has an air outlet, a motor 2 and a fan 3 that is disposed in the housing. The housing 1 is composed of an upper and a lower half shells. Inside the housing 1 are a fan chamber and an air flow channel 11. The fan 3 is disposed in the said fan chamber with a centrifugal design that the center of the annular hub of the fan 3 is away from the center of the fan chamber in the housing 1.

[0020]On the upper shell 4 is there a motor fixing socket 5, with two air inlets 6 located at opposite sides of the said motor fixing socket 5. A motor mounting socket 7 is disposed within the center top of the fan 3. The motor 2 is to be installed in the motor mounting socket 7 through the motor fixing socket 5. As all the parts put together and the power turned on, the motor 2 drives the fan 3 to rotate at high speeds, producing strong air flow.

[0021]Referring to FI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com