Thermoplastic elastomer composites for stiff core golf balls and method for making same

a composite material and golf ball technology, applied in the field of golf balls with stiff cores, can solve the problems of golf balls that cannot be designed, manufactured or intentionally modified to have properties, metal sphere designs that are not durable enough, and golf balls that have hollow metal patents, etc., to achieve high stiffness cores, rebound and flight trajectory, and maintain structural integrity and symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

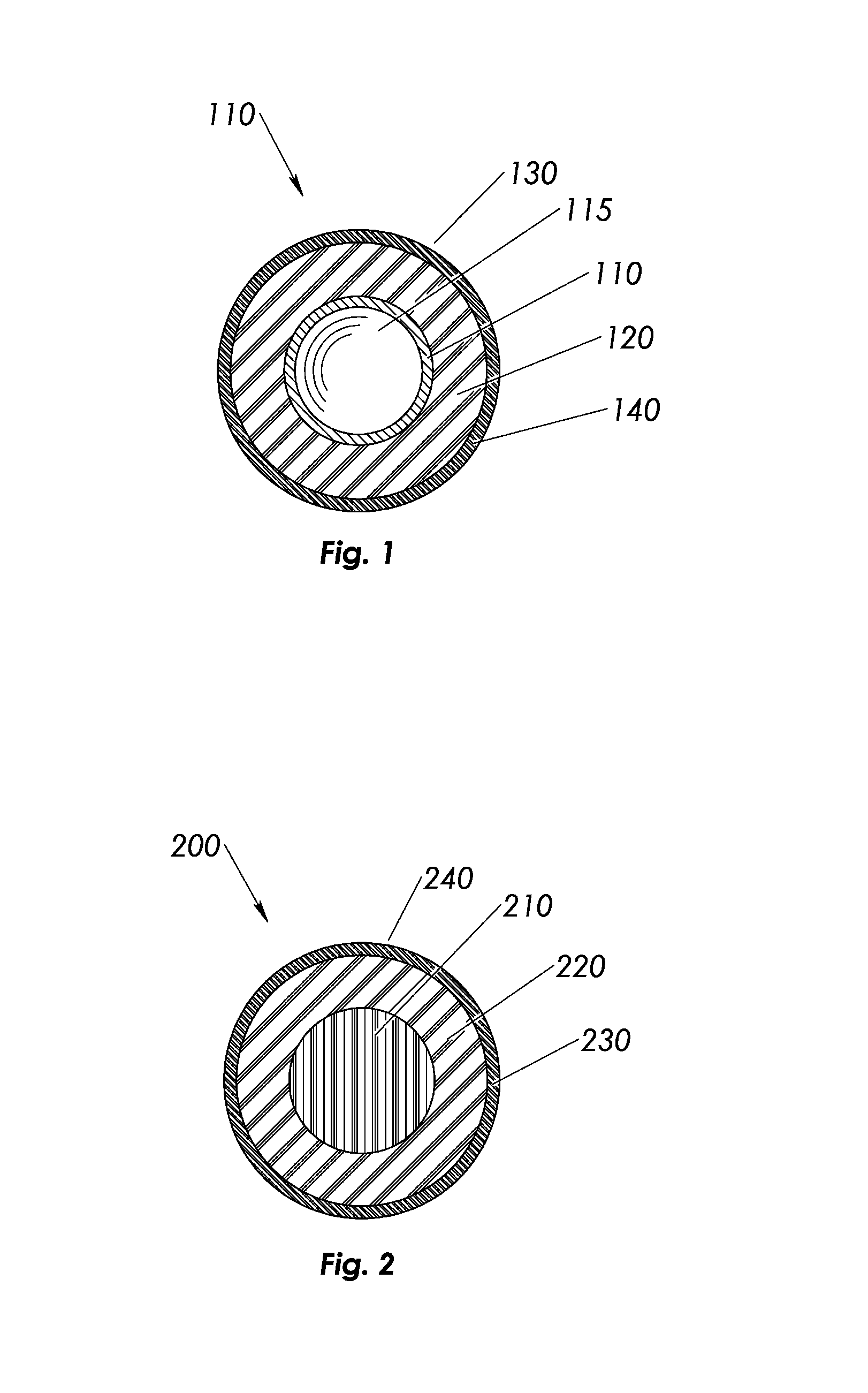

[0051]Three piece ball: hollow 301 stainless steel core having an elastic modulus of 193 GigaPascals (GPa) and a thickness of approximately 0.039 inches and a diameter of 1.1 inches, surrounded by a polyether block amide as the transition agent which has an elastic modulus of 290 MegaPascals (MPa), and then further surrounded by a layer of polymeric resin having an elastic modulus of 86 MPa, and covered with an ionomer with an elastic modulus of approximately 350 MPa and a thickness of 0.063 inches.

[0052]Other materials, such as polybutadiene, urethanes, and various resins may be used as layers, provided the constraint is met that no two adjacent layers have no more than two orders of magnitude difference in their respective elastic modulus.

example 2

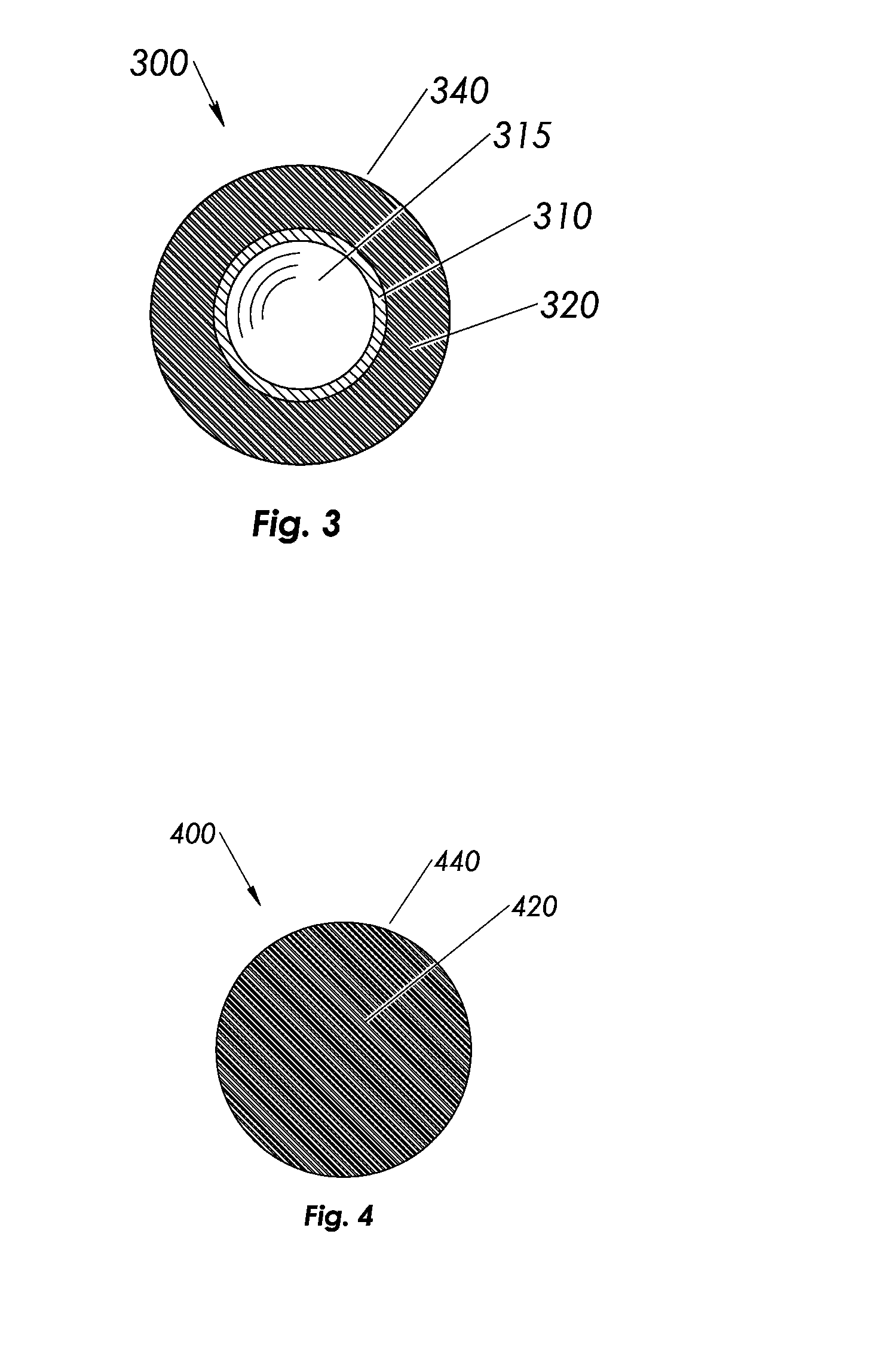

[0053]Three piece ball: hollow metal core, second polymer layer comprising a DuPont HPF 1000 or HPF 2000 resin blended with 0.25-1.0 mm particulate polybutadiene and a Surlyn cover. The hollow sphere comprising a 301 stainless steel core with an inside diameter of 21.21 mm (0.835 inches) and an outside diameter of 22.86 mm (0.9 inches), the specific gravity of the stainless steel of 7.8 and a core mass of 10.125 grams. HPF resin (base resin specific gravity=0.96) with a layer thickness of 8.32 mm (0.3275) inches blended with 25% polybutadiene in particulate form with a size of 0.25-1.0 mm, and 1% by weight of nanoclay material in a polypropylene carrier (such as PolyOne® Nanoblend™ Concentrate 1001—specific gravity of about 1.1) with a total layer mass of 27.4 grams. Further comprising a SURLYN (specific gravity of about 0.95) cover of thickness 1.59 mm (0.0625 inches), and a mass of 7.95 grams. The pressure of the residual gas or air in the hollow metal sphere is less than about 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com