Cross-Sensor Standardization

a technology of cross-sensors and sensors, applied in the direction of instruments, optical radiation measurement, borehole/well accessories, etc., can solve the problems of affecting the way instrument standardization is performed, and the cost associated with fluid prediction model development and managemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example one

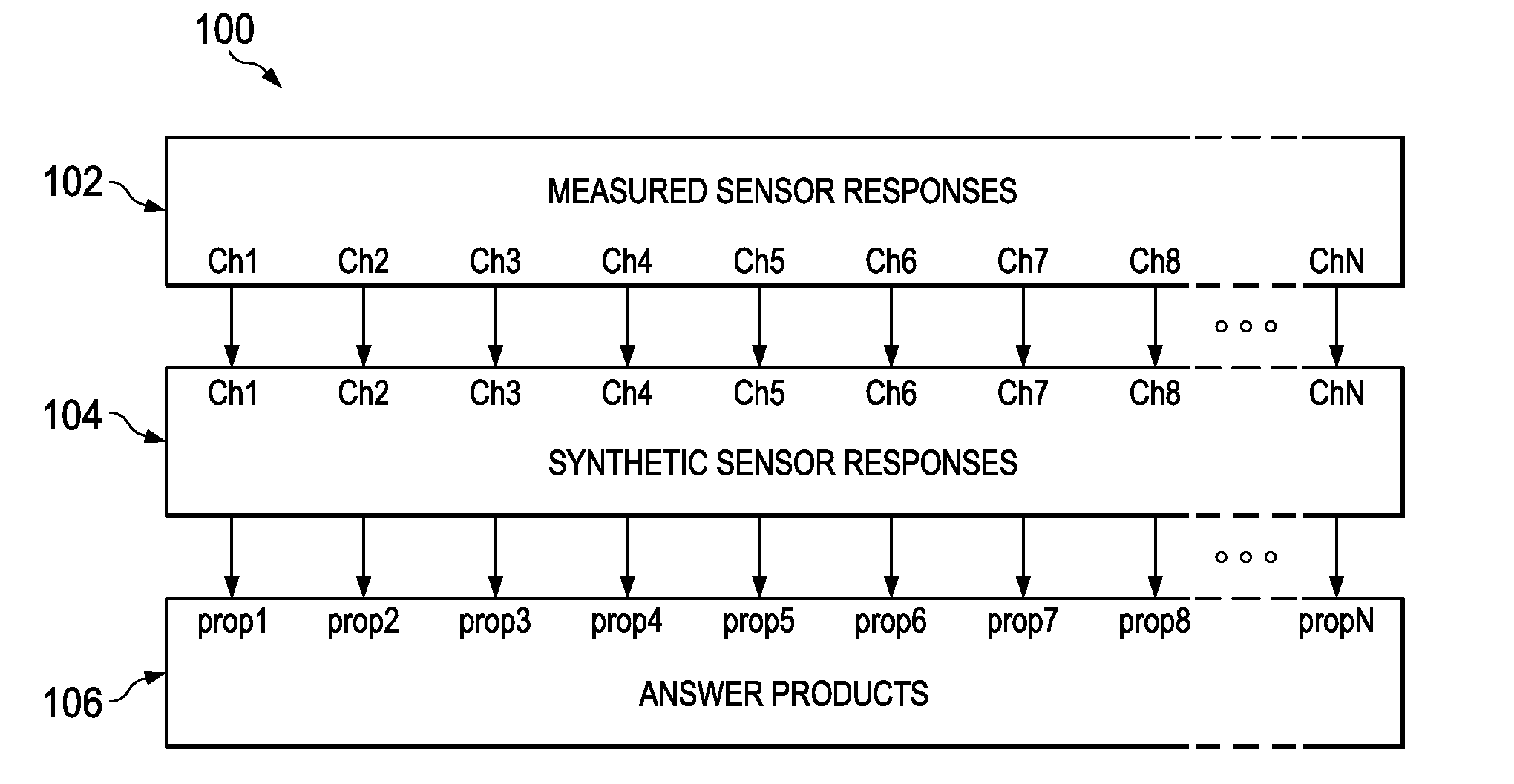

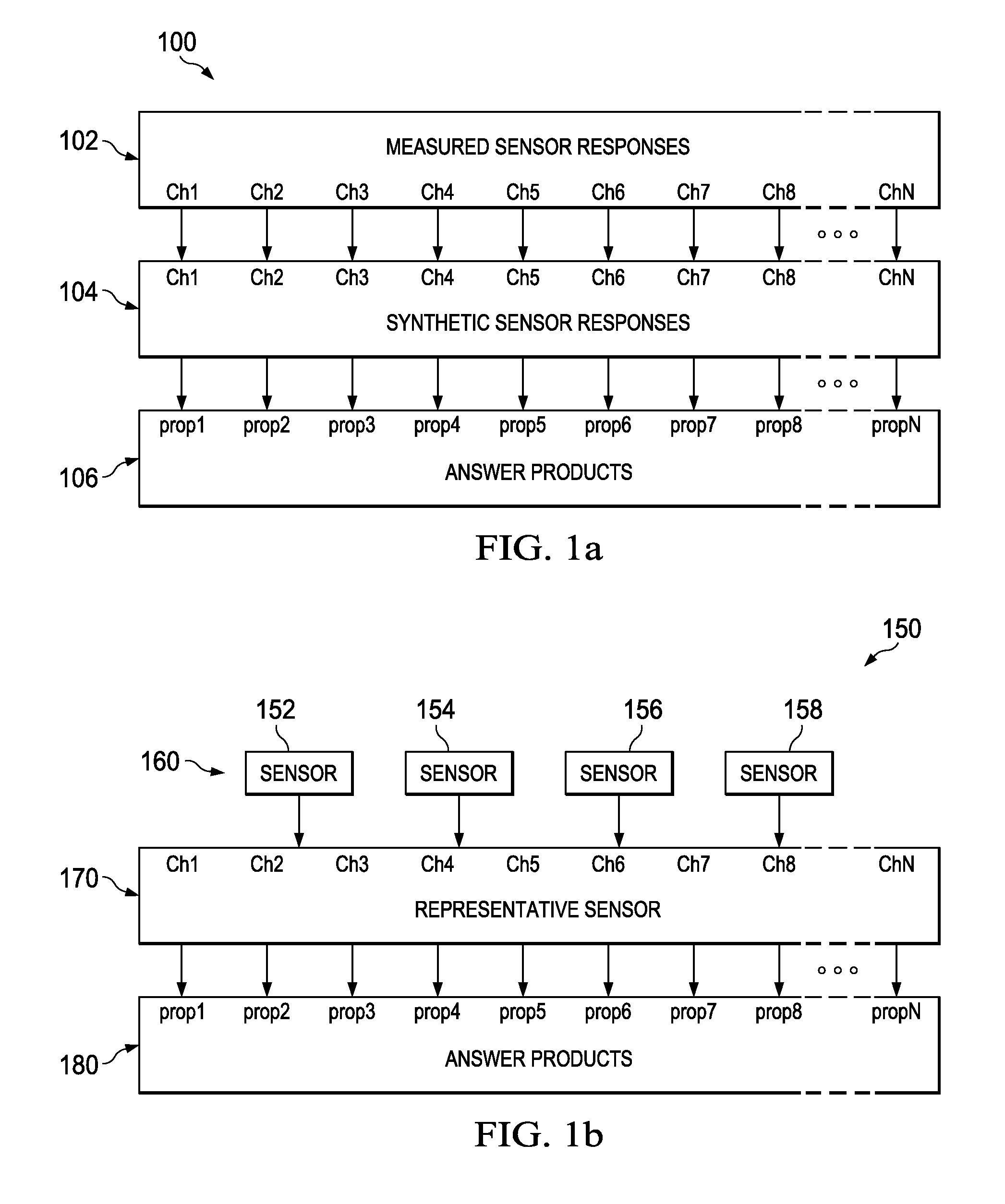

[0046]A computer-implemented method for generating a cross-sensor standardization model, the method comprising selecting a representative sensor from a group of sensors comprising at least one of same primary optical elements and similar synthetic optical responses; and calibrating the cross-sensor standardization model based on a matched data pair for each sensor in the group of sensors and for the representative sensor.

example two

[0047]A computer-implemented method for generating a cross-sensor standardization model, the method comprising selecting a representative sensor from a group of sensors comprising at least one of same primary optical elements and similar synthetic optical responses; calibrating the cross-sensor standardization model based on a matched data pair for each sensor in the group of sensors and for the representative sensor; and generating the matched data pair, wherein the matched data pair comprises calibration input data and calibration output data.

example three

[0048]A computer-implemented method for generating a cross-sensor standardization model, the method comprising selecting a representative sensor from a group of sensors comprising at least one of same primary optical elements and similar synthetic optical responses; calibrating the cross-sensor standardization model based on a matched data pair for each sensor in the group of sensors and for the representative sensor; and identifying each sensor to form the group of sensors, wherein each sensor comprises at least one of the same primary optical elements and the similar synthetic optical responses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com