Polishing device for optical elements and method thereof

a technology of optical elements and polishing discs, which is applied in the direction of optical surface grinding machines, manufacturing tools, prostheses, etc., can solve the problems of increasing processing costs, difficult to provide certain parameter processing, inaccurate control of contact pressure between polishing discs and workpieces, etc., to achieve the effect of reducing manufacturing costs and increasing processing accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

Preferred Embodiment 1

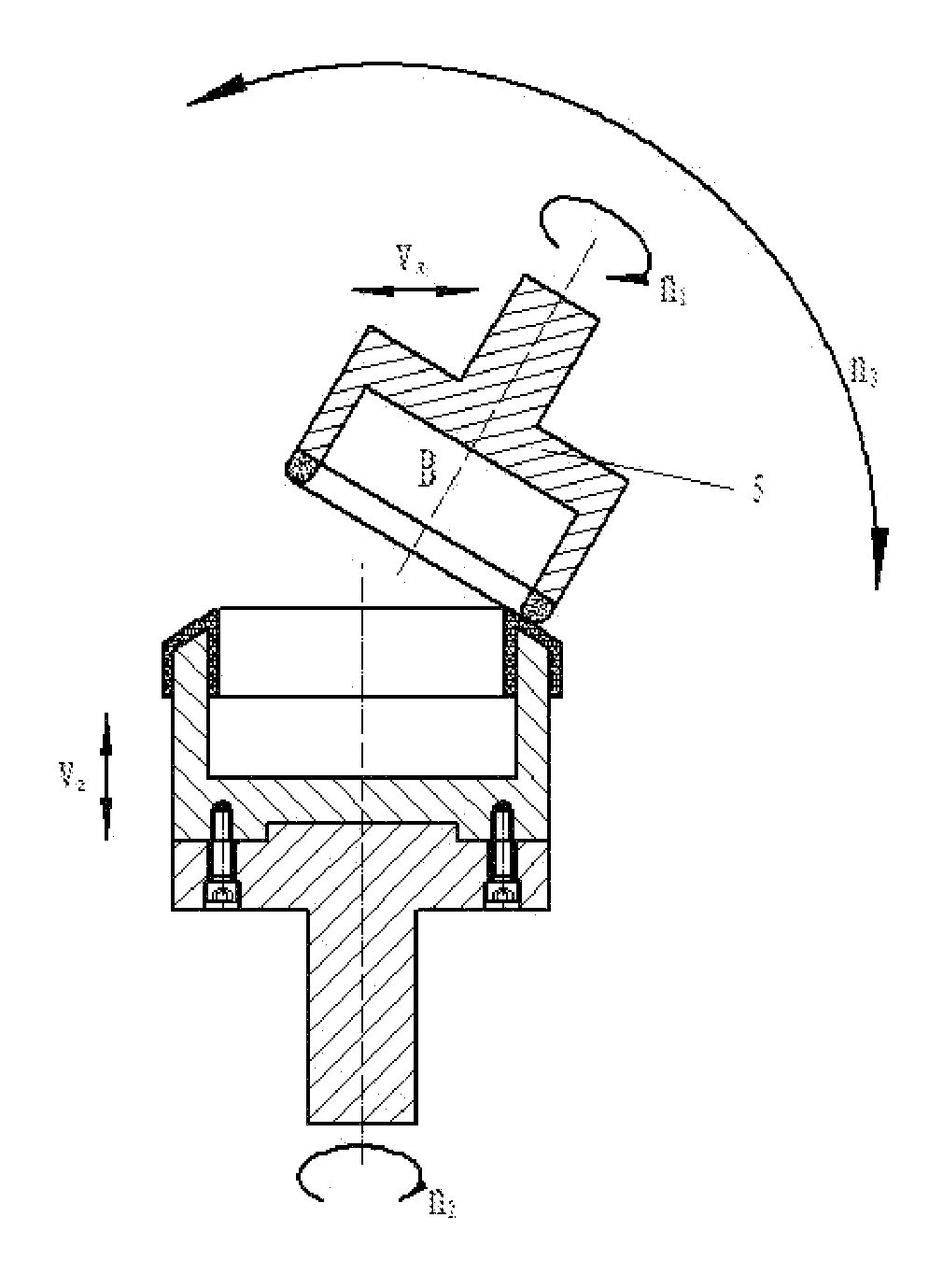

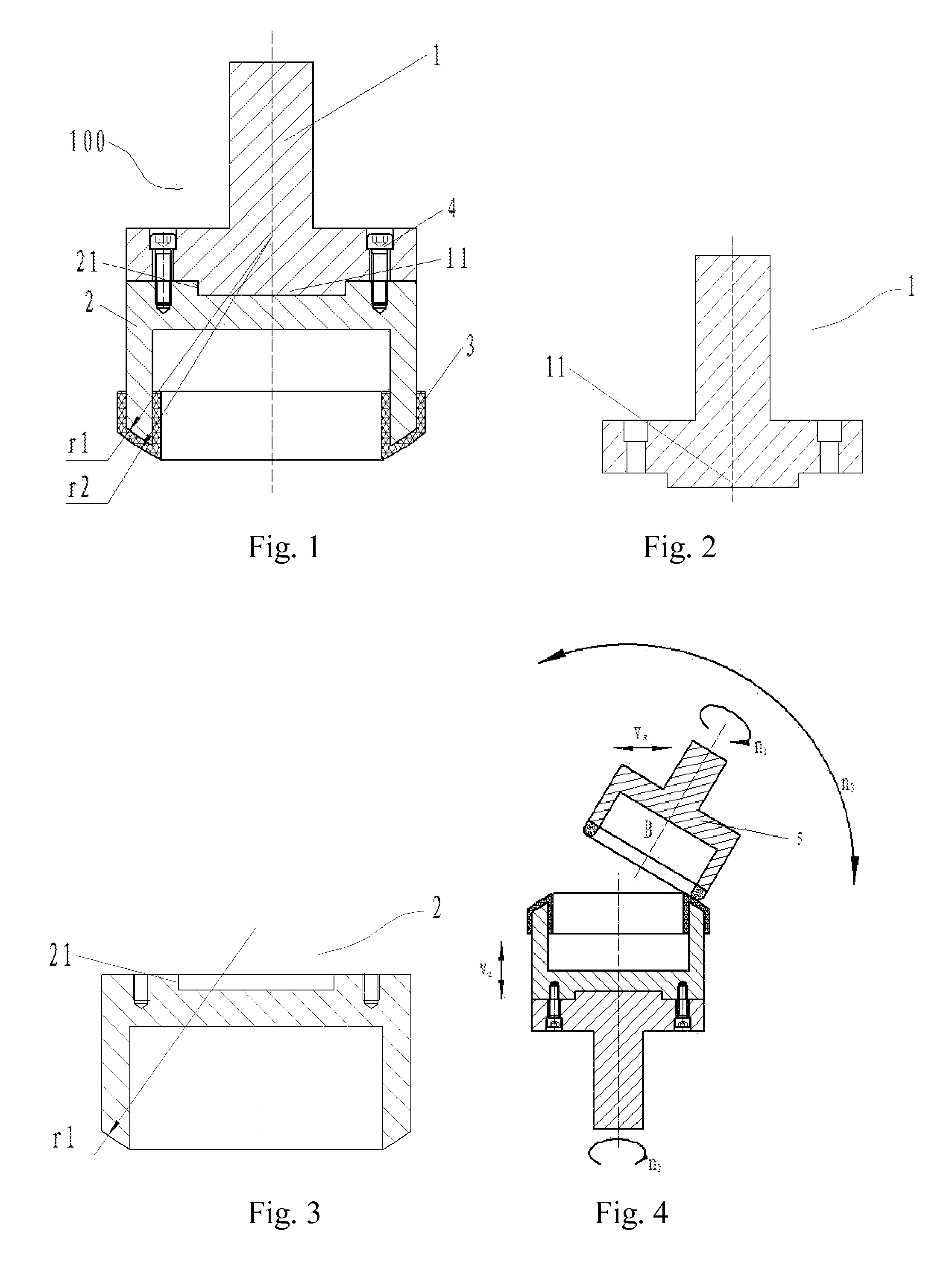

[0098]Referring to FIGS. 1-5, a polishing disc connecting rod 11 is at a bottom of a tool shank 1, which is able to be pressed into a polishing disc fixing port 21 at a top of a cylinder polishing disc base 2. During installing, the polishing disc connecting rod 11 is pressed into the polishing disc fixing port 21, and is fixed with the cylinder polishing disc base 2, in such a manner that there is no interval between the polishing disc connecting rod 11 and the polishing disc fixing port 21; wherein the tool shank 1 is fixed on the cylinder polishing disc base 2 by any spanner type, such as inner triangle, inner rectangle, inner hexagon, and double hole, which not only ensures connecting reliability therebetween, but also is convenient to install and maintain.

[0099]A polishing film 3 is stuck on an arc portion at a bottom of the cylinder polishing disc base 2. The polishing film 3 is selected according to a material of the unprocessed work piece 6. There is no...

embodiment 2

Preferred Embodiment 2

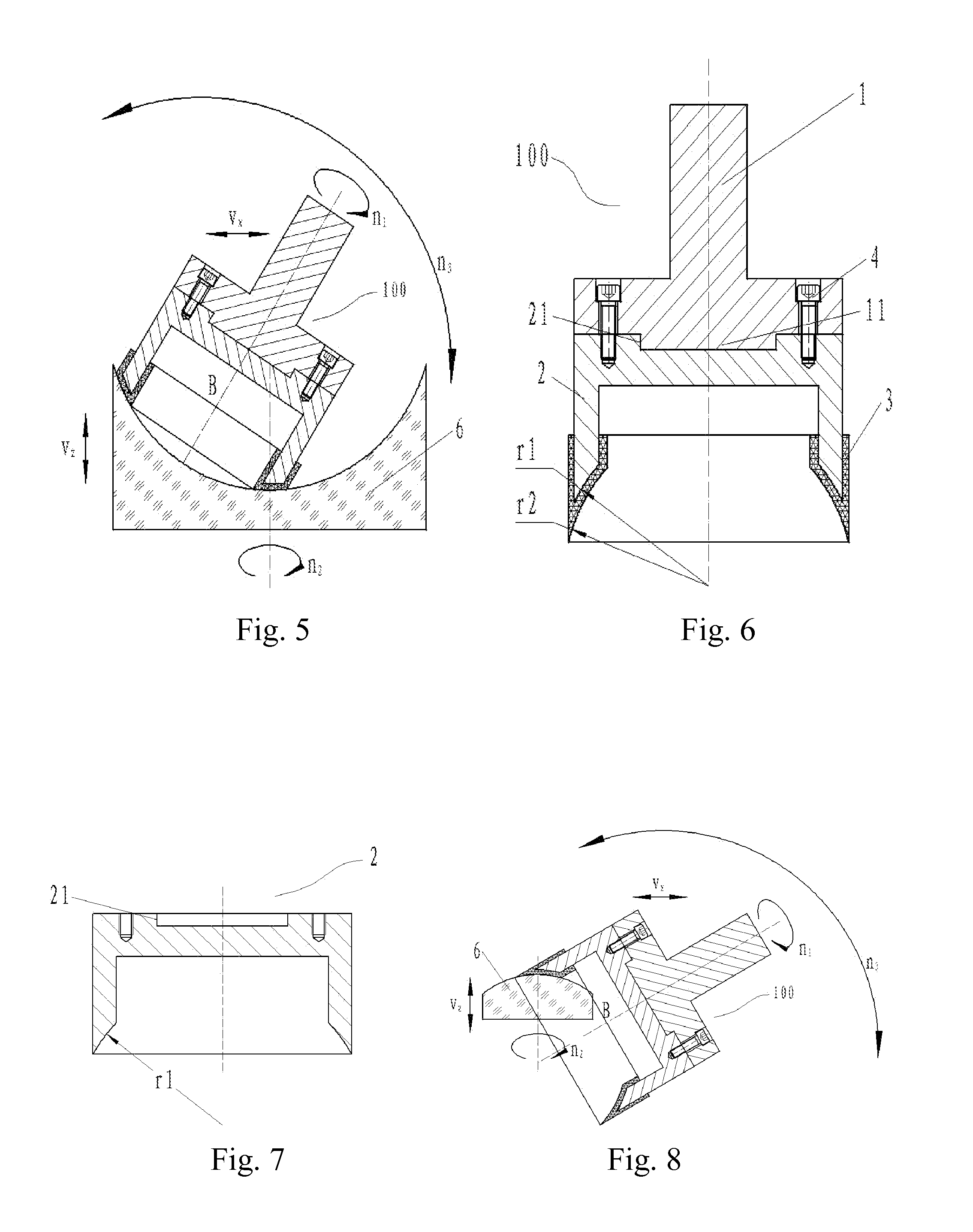

[0103]FIG. 6 is a sketch view of a polishing device 100 according to the preferred embodiment 2, wherein a tool shank 1 and a cylinder polishing disc base 2 are respectively illustrated in FIGS. 2 and 7. Accordingly, the polishing device 100 comprises: a tool shank 1 for installing a cylinder polishing disc; a cylinder polishing disc base 2 for sticking a polishing film 3; and the polishing film 3 for contacting with an unprocessed work piece 6 (not shown) for polishing. The preferred embodiment 2 is suitable for polishing convex elements, and installation and trimming of the polishing film 3 are the same with the preferred embodiment 1 and will not be described again.

[0104]FIG. 8 illustrates polishing the convex element according to the preferred embodiment 2, and a utilization method thereof is the same as the one of the preferred embodiment 1 and will not be described again.

embodiment 3

Preferred Embodiment 3

[0105]FIG. 9 is a sketch view of a polishing device 100 according to the preferred embodiment 3, wherein a tool shank 1 and a cylinder polishing disc base 2 are respectively illustrated in FIGS. 2 and 10. Accordingly, the polishing device 100 comprises: a tool shank 1 for installing a cylinder polishing disc; a cylinder polishing disc base 2 for sticking a polishing film 3; and the polishing film 3 for contacting with an unprocessed work piece 6 (not shown) for polishing. The preferred embodiment 2 is suitable for polishing planar elements, and installation and trimming of the polishing film 3 are the same with the preferred embodiment 1 and will not be described again. The preferred embodiment 3 is a specific type of the preferred embodiment 1 and 2, which is a special case when curvature radius of the arc portion of the polishing disc base in the preferred embodiment 1 or 2 tends to be infinity.

[0106]FIG. 11 illustrates polishing the convex element according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com