Etching solution for multilayer thin film having copper layer and molybdenum layer contained therein

a multi-layer thin film and etching solution technology, which is applied in the direction of surface treatment compositions, semiconductor/solid-state device details, chemistry apparatus and processes, etc., can solve the problems of copper diffusion into the silicon semiconductor underlayer, the adhesiveness between the substrate such as glass or the like and copper is not sufficient, and the difficulty of uniform panel display, etc., to achieve good etching effect and low etching residue and unevenness, the effect of long bath li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0041]Next, the present invention is described in more detail by reference to the following Examples, but it should be construed that the present invention is not limited by these Examples at all.

(Observation of Cross Section of Multilayer Thin Film Having Copper Layer and Molybdenum Layer Contained Therein after Etching)

[0042]A sample of the etched multilayer thin film containing a copper layer and a molybdenum layer, as obtained in Examples and Comparative Examples, was cut and observed with a 30000 magnification through scanning electronic microscope (“S5000H

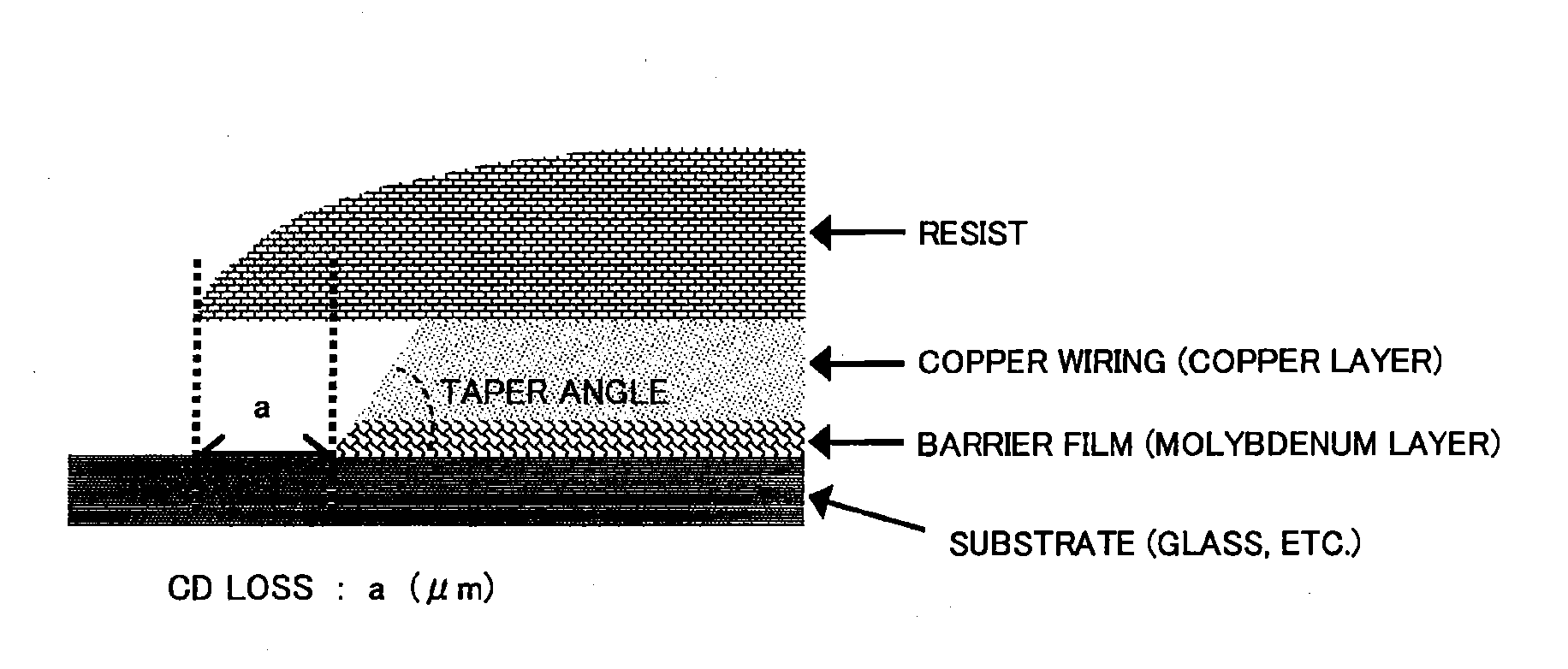

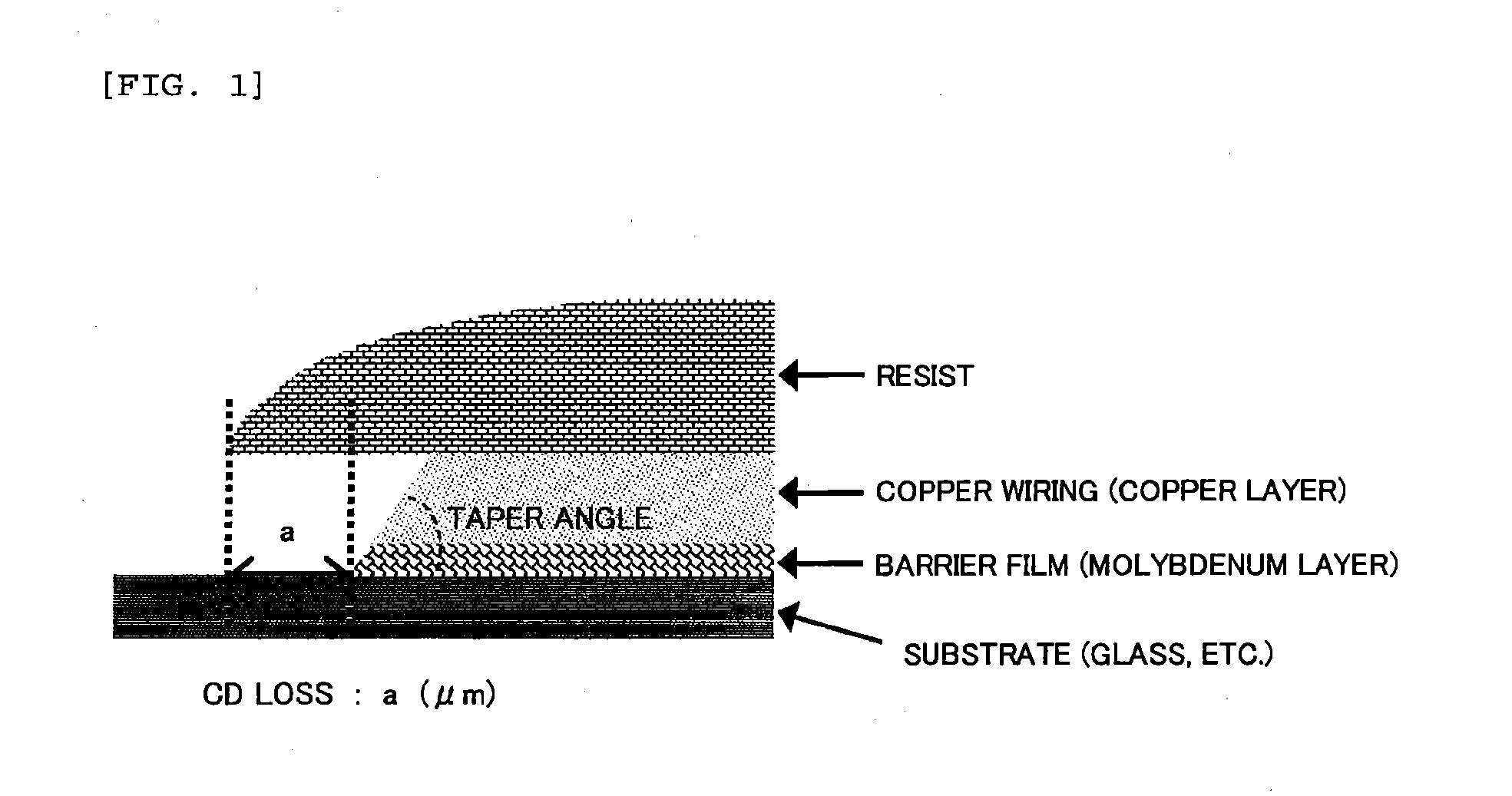

[0043]Type (Model Number)”, by Hitachi) (acceleration voltage 2 kV, acceleration current 10 μA). On the thus-taken SEM image, the taper angle and the CD loss (μm) as shown in FIG. 1 were determined.

[0044]When the taper angle and the CD loss (μm) fell within the standard ranges shown in Table 1, the sample was considered to be acceptable for the etching performance.

(Evaluation of Etching Residue)

[0045]A surface of a multilayer...

examples 1 to 5

[0050]The multilayer thin film having a copper layer and a molybdenum layer as obtained in the Fabrication Example was repeatedly subjected to an operation of etching with an etching solution shown in Table 2 at 35° C. by means of shower spraying; and with respect to the obtained multilayer thin film having a copper layer and a molybdenum layer after etching, a taper angle and a CD loss (μm) were obtained in a low-concentration region of a copper ion concentration in the etching solution (also expressed as “Cu concentration”) (from 200 to 1,000 ppm; also expressed as “low Cu concentration region”) and a high-concentration region of a copper ion concentration in the etching solution (from 3,000 to 4,000 ppm; also expressed as “high Cu concentration region”) by means of SEM observation.

[0051]Also, a time at which an etching subject of an area where the resist had not been patterned was determined to be etched by means of visual inspection was set up as a just etching time; and a time ...

examples 6 and 7

[0052]As Examples 6 and 7, etching was performed in the same manner as that in Example 4, except that in Example 4, a copper powder was previously added in a copper ion concentration of 200 ppm and 6,000 ppm, respectively to the Etching Solution 4 to be used. A taper angle, a CD loss (μm), and evaluation of residue of the multilayer thin film having a copper layer and a molybdenum layer contained therein, as obtained in the first etching are shown in Table 3. Also, a taper angle, a CD loss (μm), and evaluation of residue of the multilayer thin film having a copper layer and a molybdenum layer of Example 4 as obtained in the first etching are shown in Table 3.

TABLE 3Example4 (Firstetching)67Copper ion concentrationppm02006000Cu film thickness / Moangstrom / 5000 / 2005000 / 2005000 / 200film thicknessangstromJust etching timesec8080101Etching timesec120120120Taper angledegree354030CD lossμm1.01.00.65Overall evaluation of wiring cross-AAAsectional shapeEvaluation of residueBAAEvaluation of crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| taper angle | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com