Downhole Apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF DRAWINGS

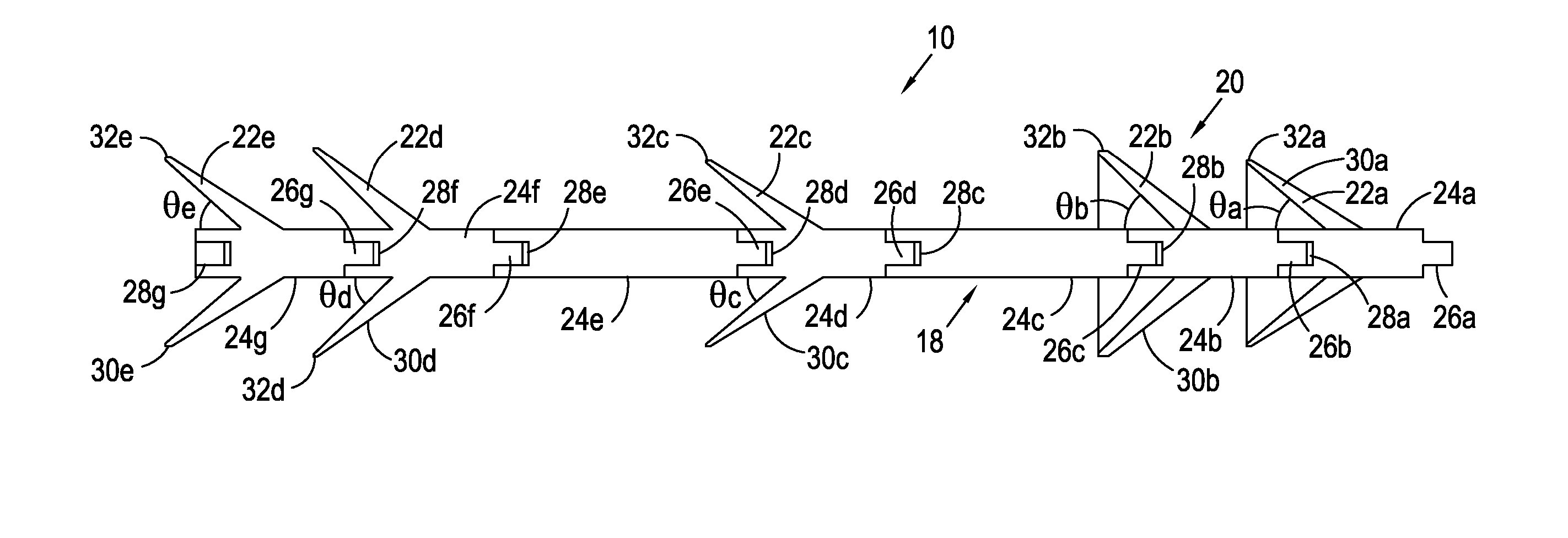

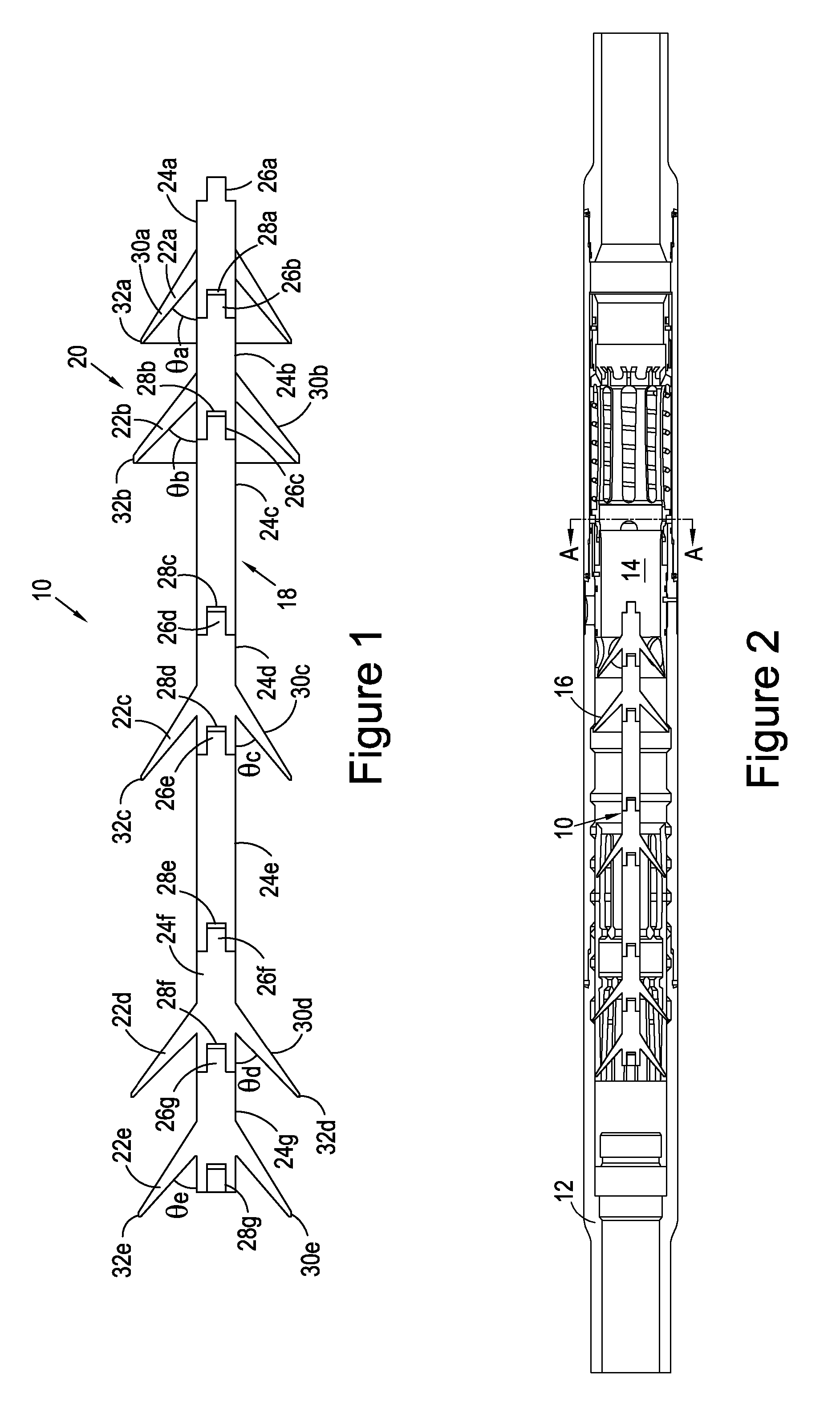

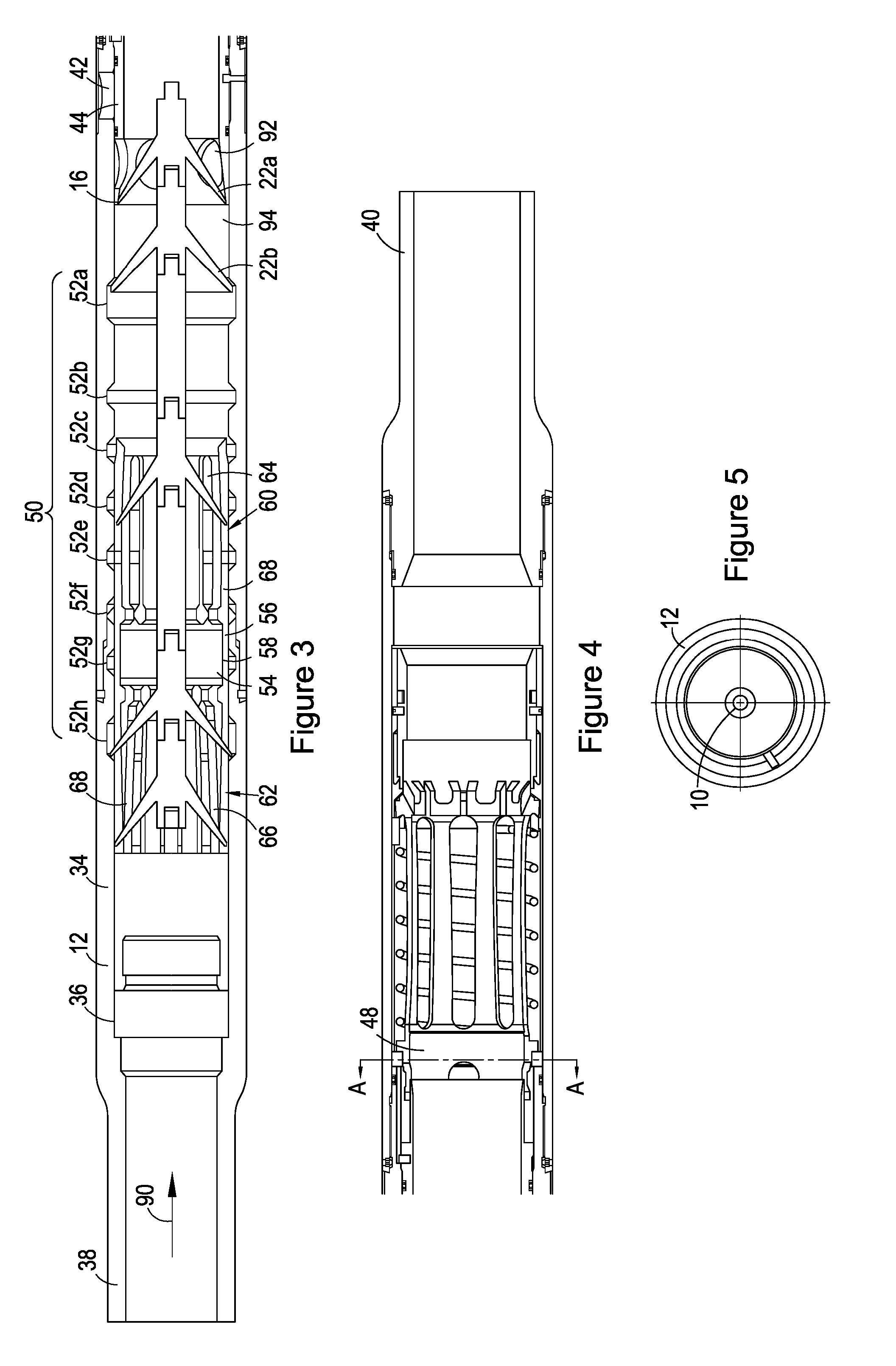

[0111]Referring first to FIGS. 1 and 2, there is shown a downhole cementing apparatus, in the form of a cement dart 10, according to an embodiment of the present invention. In use, the dart 10 may be employed during a downhole cementing operation, the dart 10 being deployable through a downhole tool 12 (FIG. 2) with a volume of cement 14 and configured to provide a varying point of sealing contact 16 between the dart 10 and the downhole tool 12 which permits the cement 14 to be driven through the downhole tool 12.

[0112]As shown in FIG. 1, the dart 10 comprises a body in the form of a mandrel 18 and a sealing arrangement 20 for providing the sealing contact 16. In the illustrated embodiment, the sealing arrangement 20 comprises a plurality of axially spaced seal members 22a, 22b, 22c, 22d, 22e and, in use, the dart 10 is configured so that as the dart 10 is deployed though the downhole tool 12 the point of sealing contact 16 between the dart 10 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com