Automated guided cart system control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

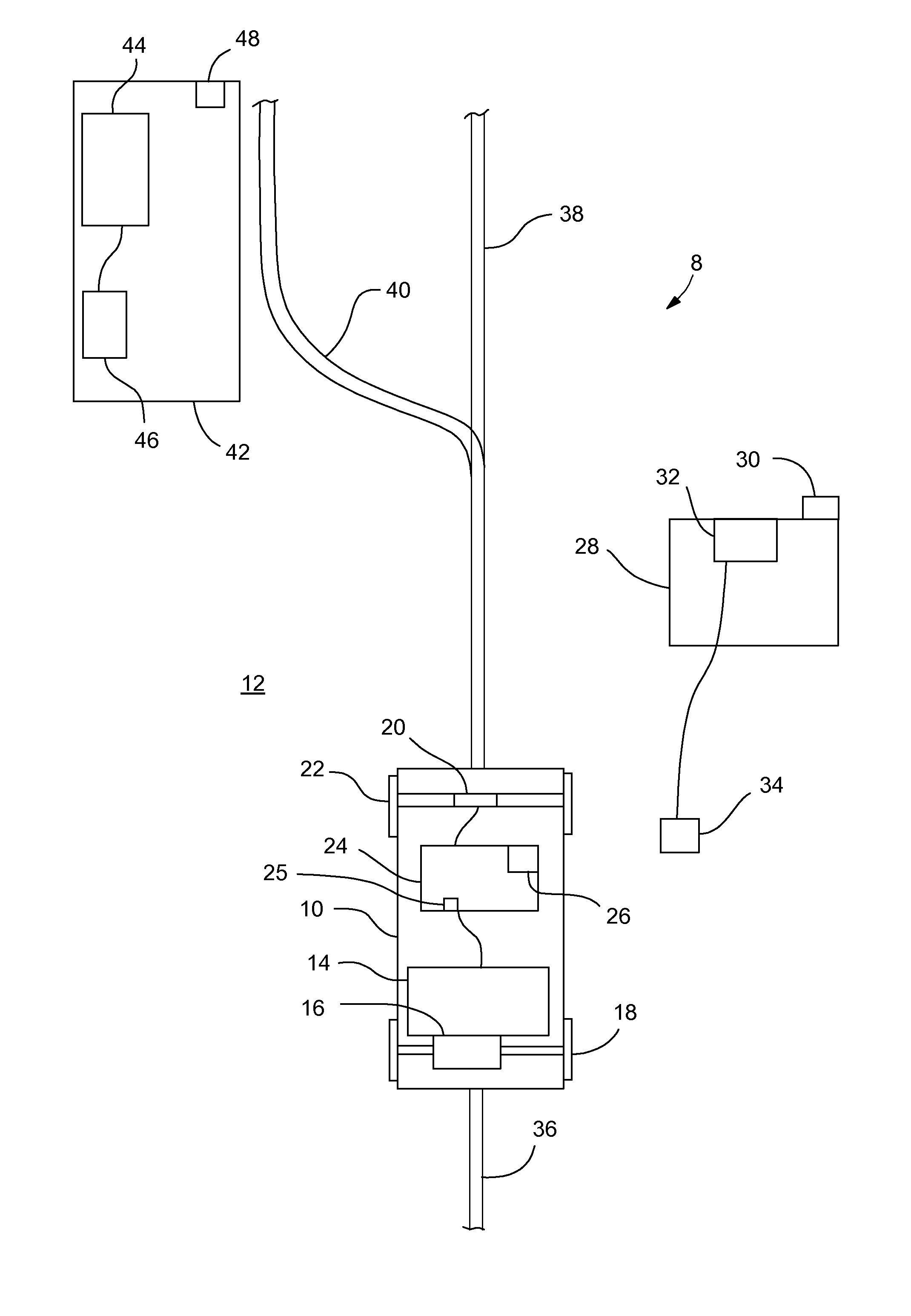

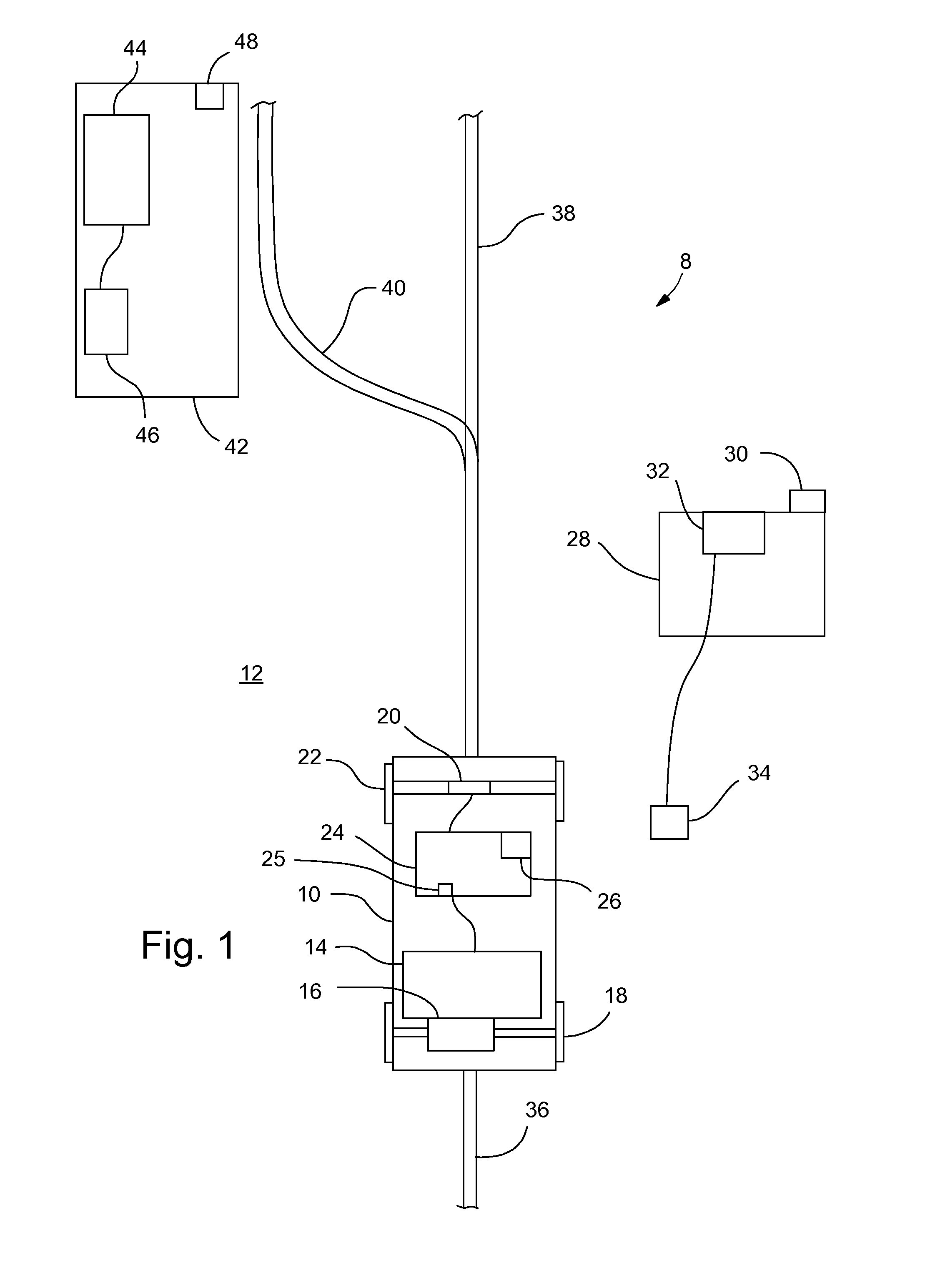

[0008]Referring to FIG. 1, an automated guide cart system 8 includes an automated guided cart 10 that is shown on a factory floor 12. The cart 10 may include a battery pack 14 that powers an electric motor 16, which drives wheels 18, and an automated steering assembly 20 that steers another set of wheels 22. The cart 10 may also include a controller 24 that is in communication with the steering assembly 20, battery pack 14 and motor 16. The controller 24 may be in communication with a battery charge detector 25, which can detect the state-of-charge of the battery pack 14. The detector 25 may any one of a number of devices that can detect the state-of-charge of a battery, as are known to those skilled in the art. The cart 10 may also include an on-board transceiver26 for communication between the controller 24 and a remote station 28 mounted at a location on the floor 12.

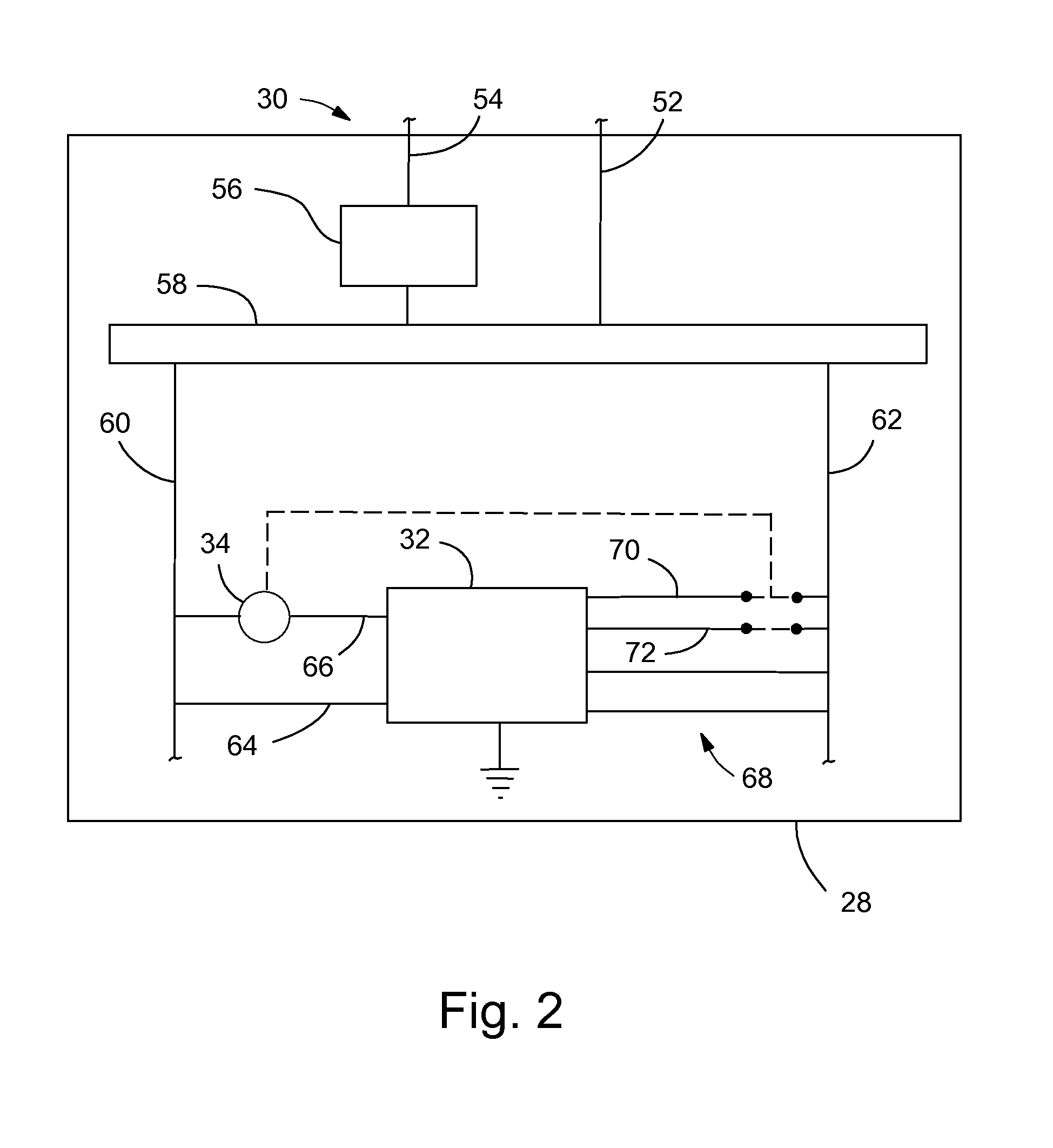

[0009]The remote station 28 may include a power supply 30, which may be the electrical power supply in the factory...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com