Compressed Hollow Coreless Re-Formable Roll Products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

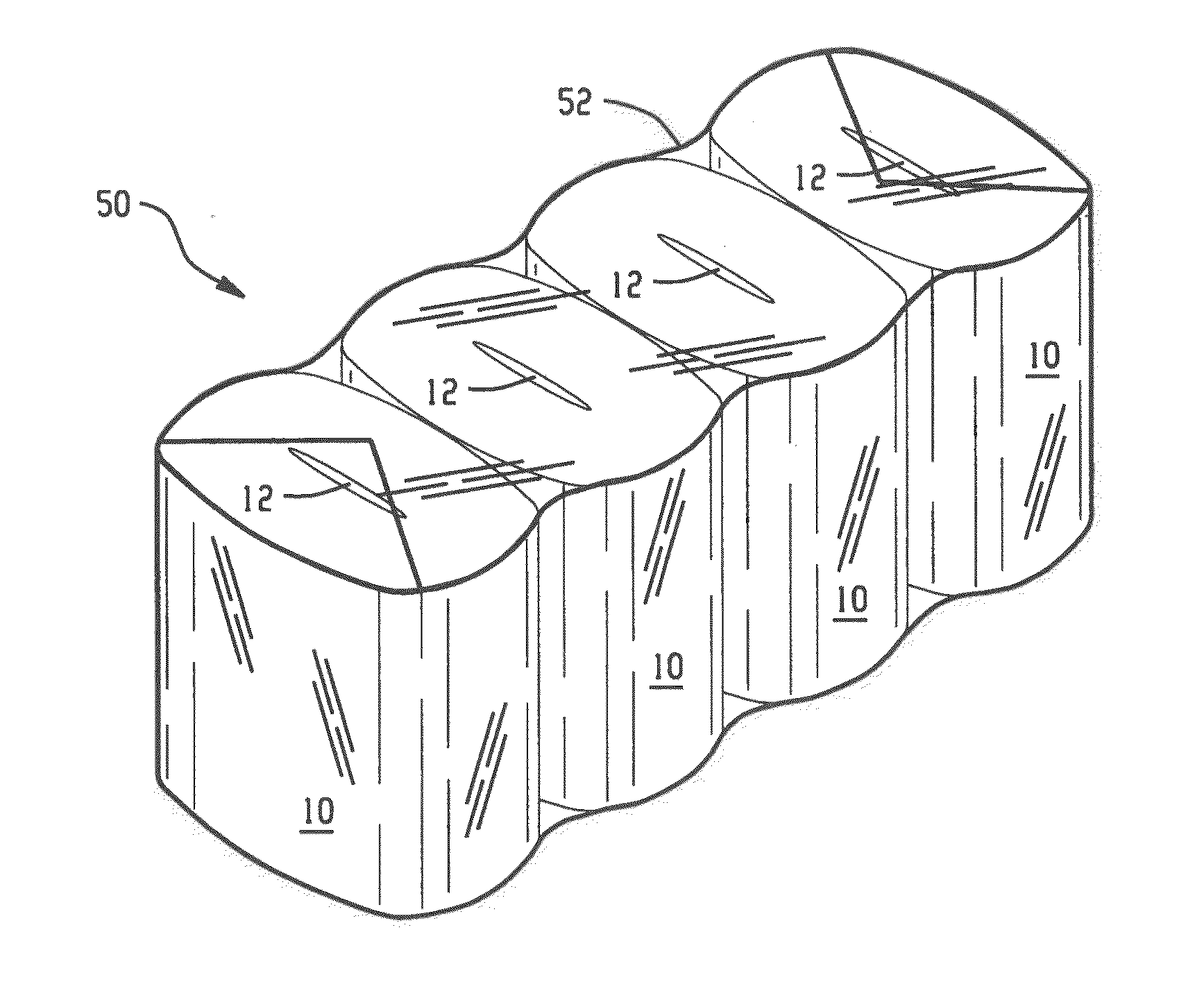

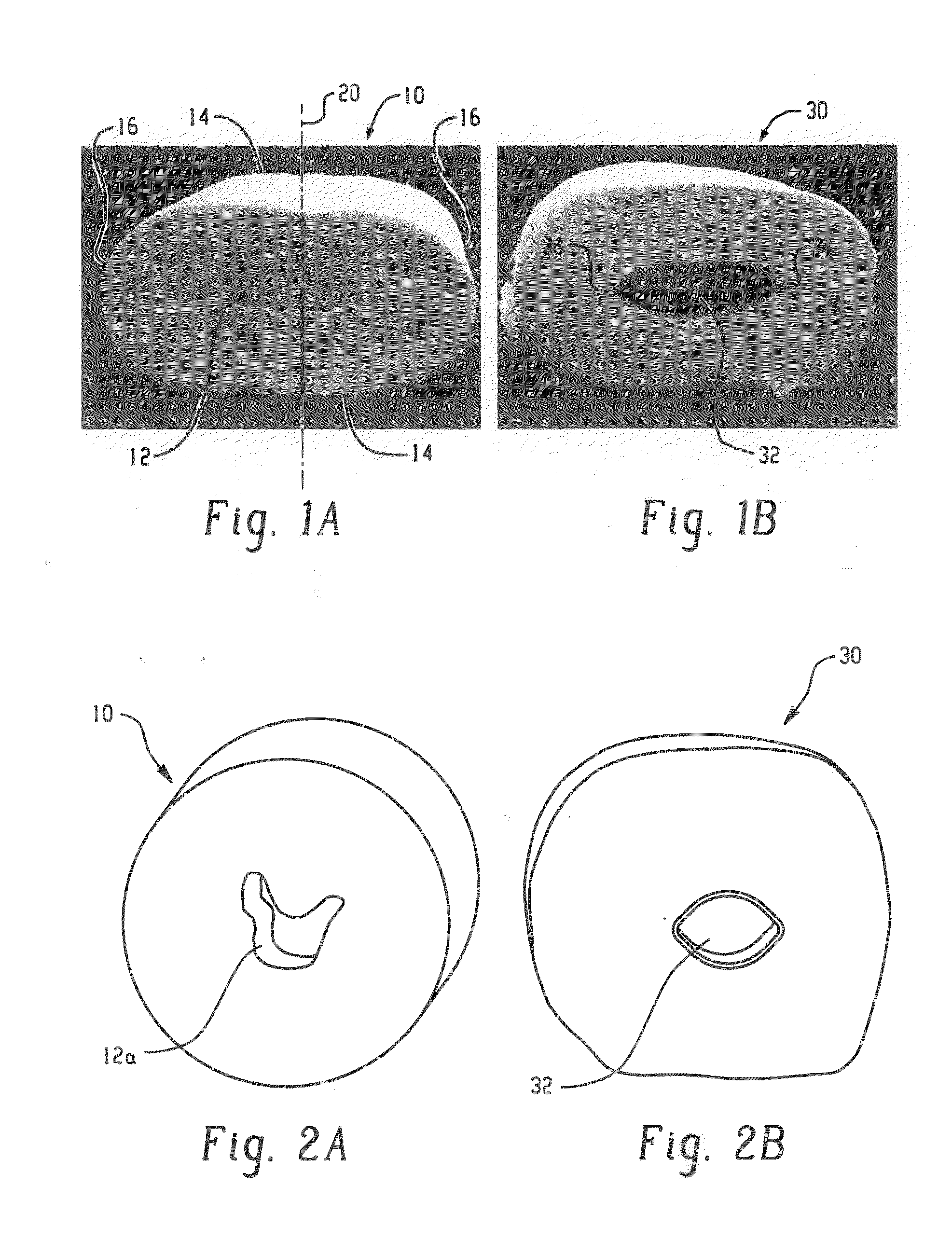

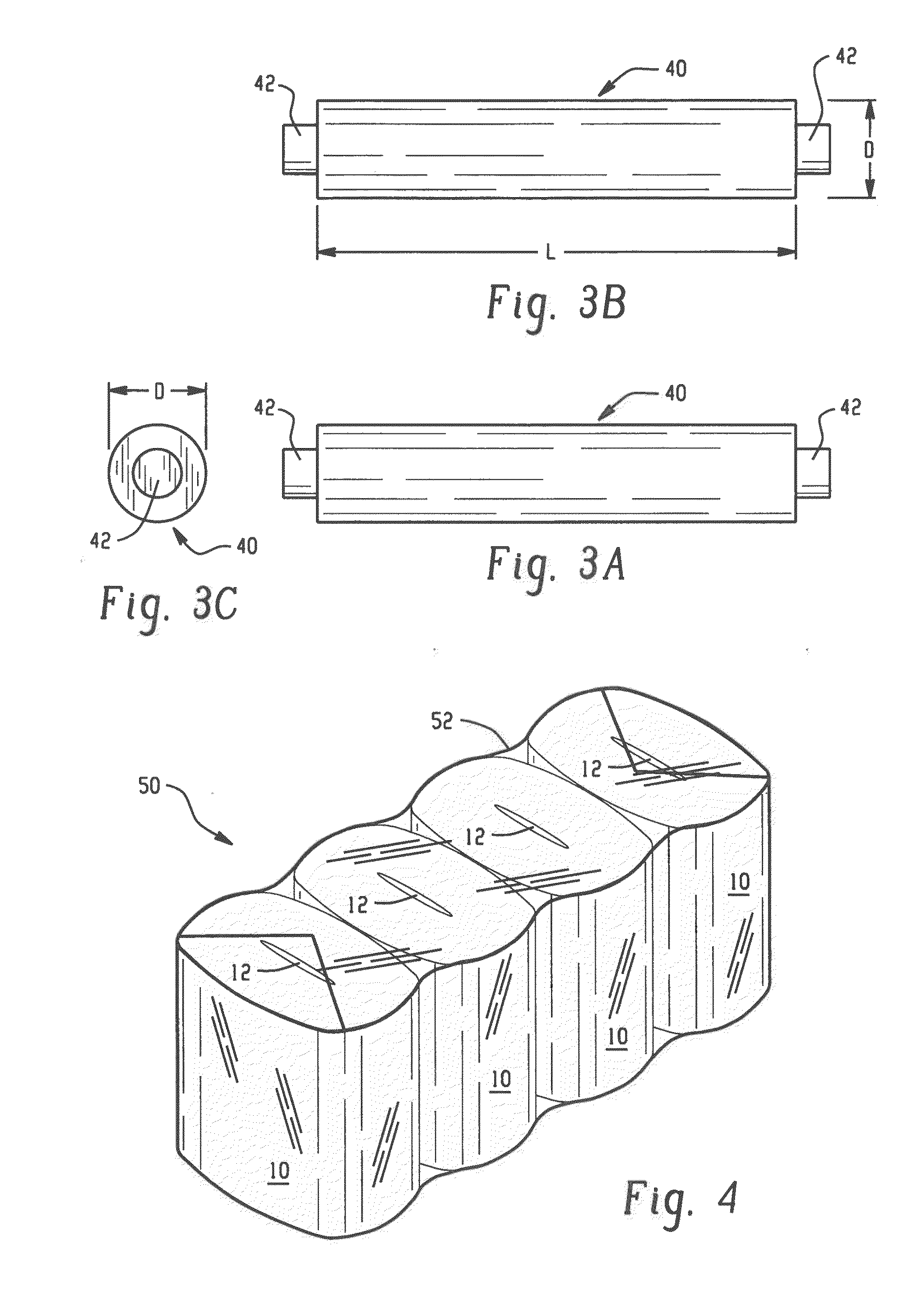

[0049]The invention is described in detail below in connection with the various Figures for purposes of illustration, only. The invention is defined in the appended claims. Terminology used throughout the specification and claims herein are given their ordinary meanings as supplemented immediately below.

[0050]When we refer to the axial cavity of the product as “substantially collapsed”, the reference is to a flattened form as shown in FIG. 1A. Preferably, the gap between opposing sides of the cavity in the substantially collapsed configuration is less than 25 mm, preferably less than 10 mm, more preferably less than 5 mm and still more preferably less than 2 mm on average. In a preferred embodiment, opposing sides of the collapsed cavity are in contact over a major portion of their area, preferably over at least about 60%, more preferably over at least about 70%, even more preferably over at least about 80%, and most preferably at least about 90%, when rolls are in the compressed st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com