Installation of Multi-Component Floor Mat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

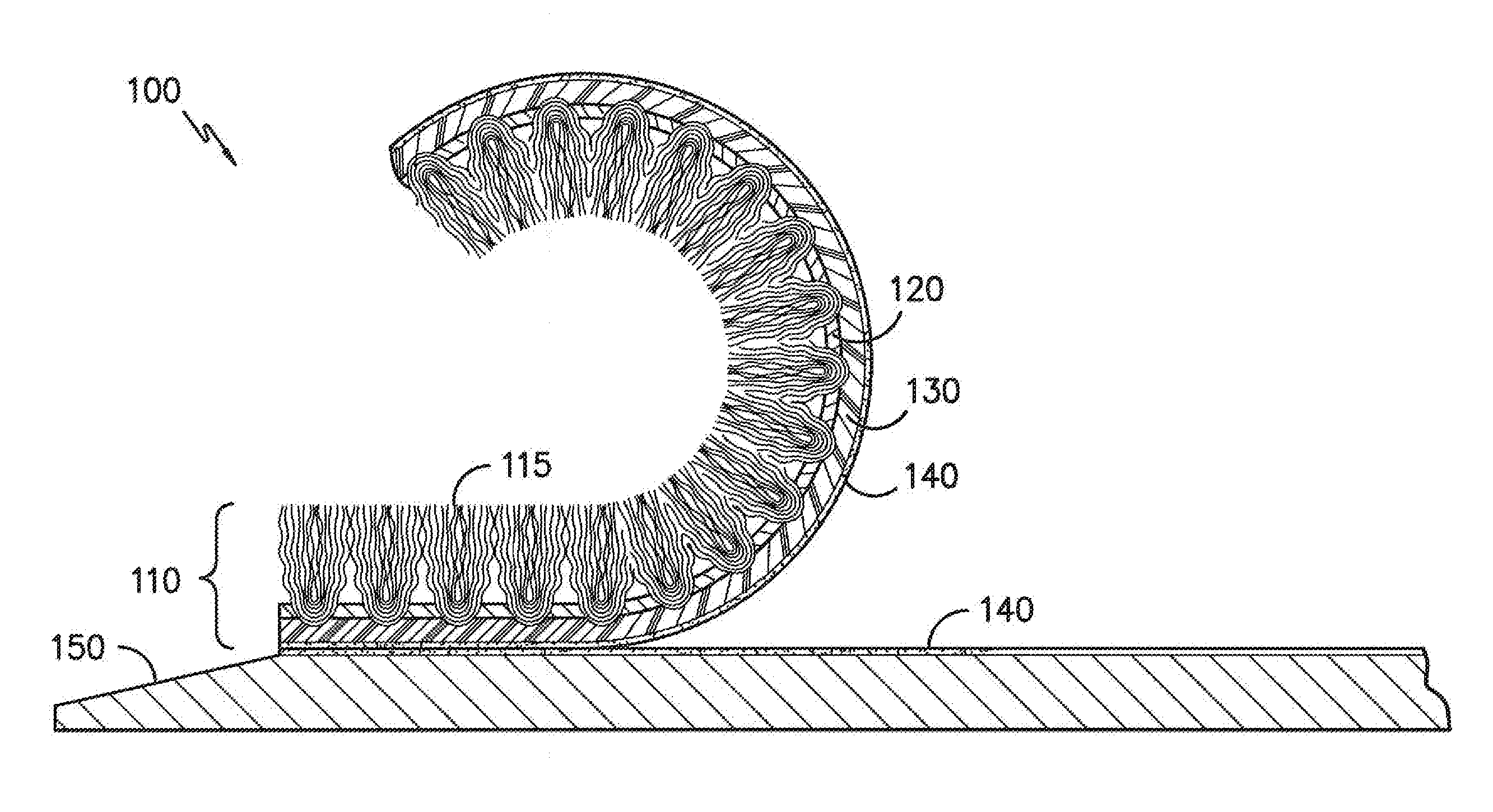

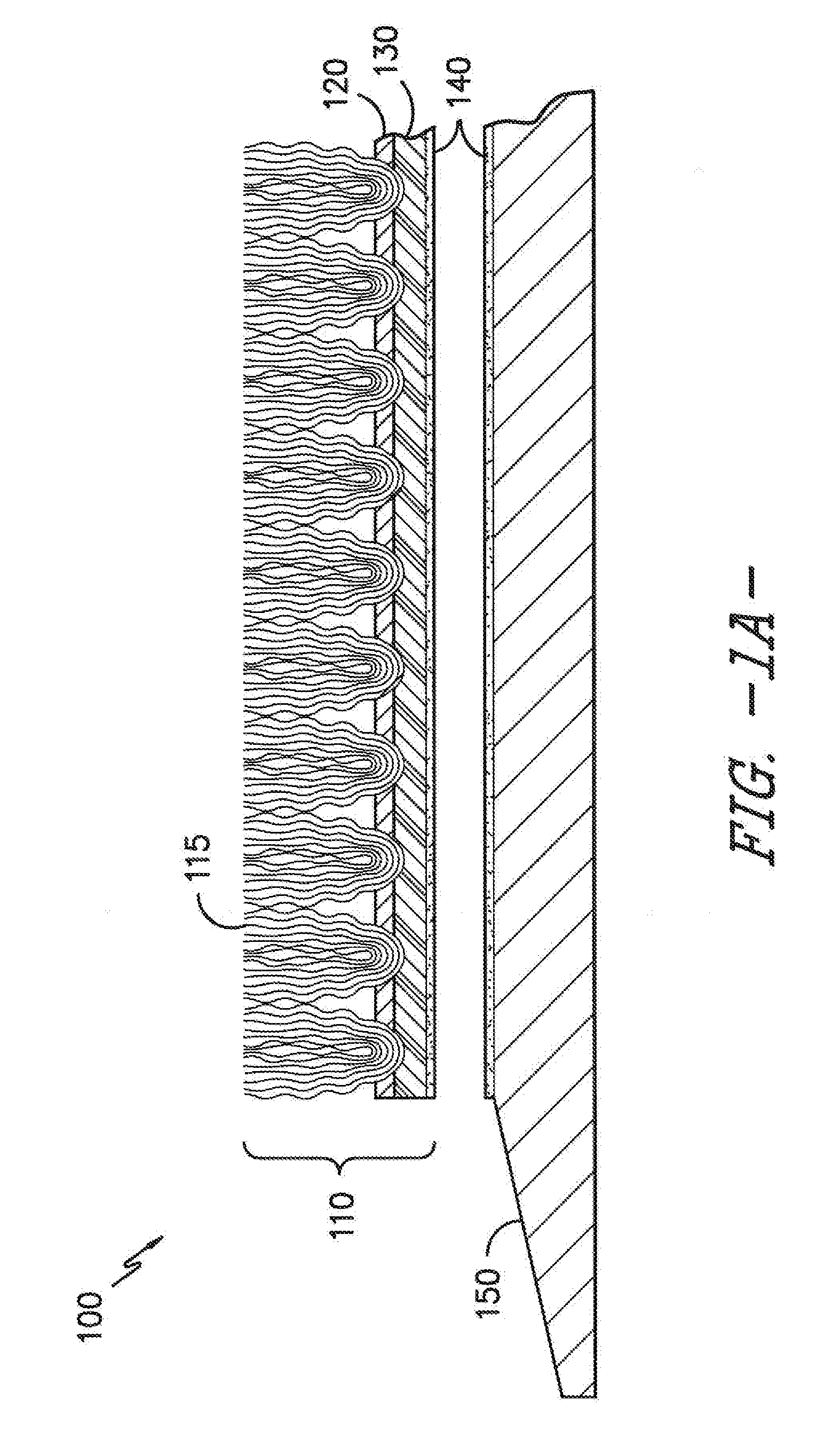

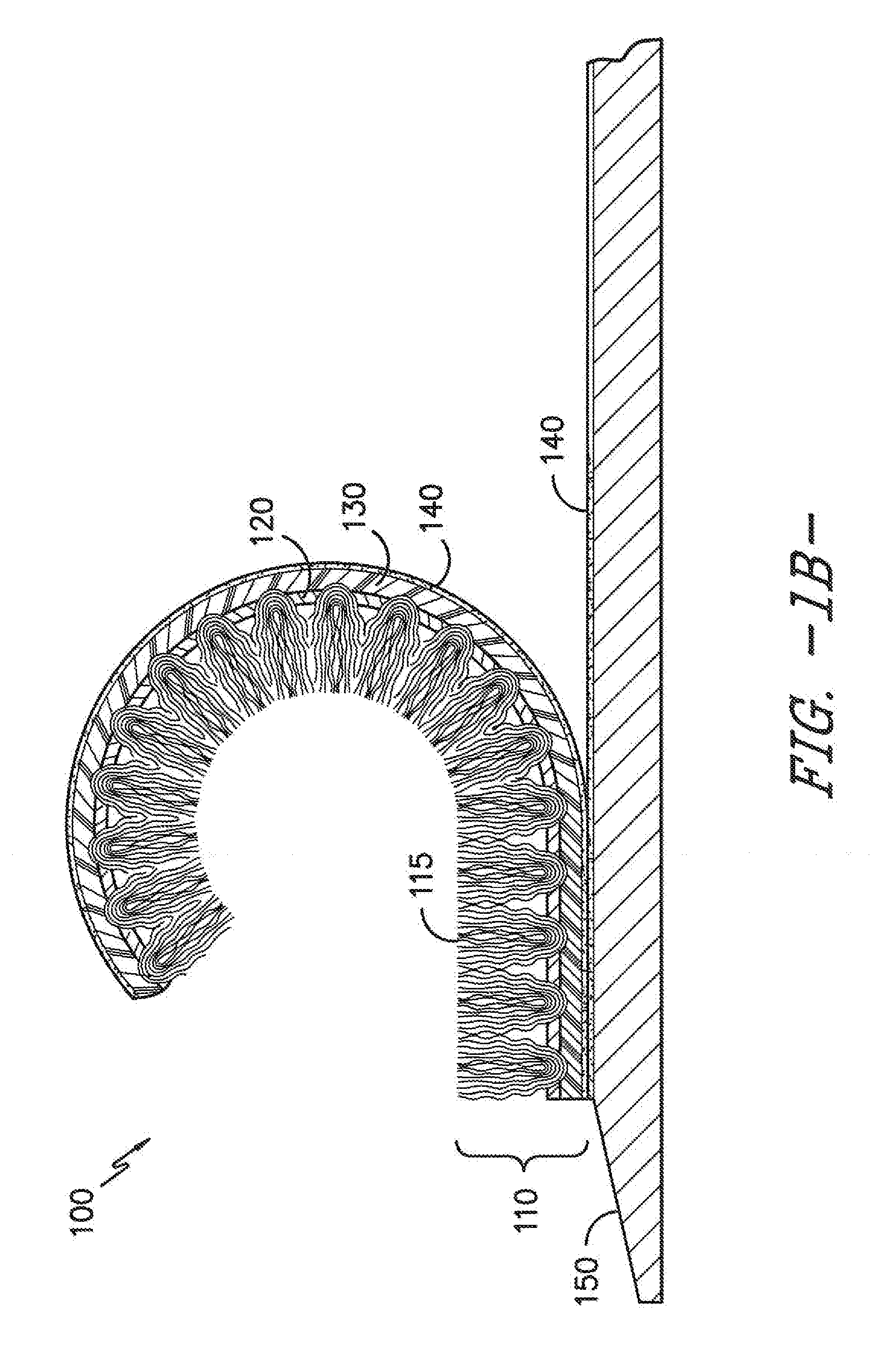

[0041]The present invention described herein is a method for installing multi-component floor mats. The method utilizes a variety of alignment and deployment mechanisms for properly and efficiently positioning the floor mats. The floor mats are comprised of a textile component and a base component.

[0042]The textile component and the base component are releasably attachable to one another via variety of attachment mechanisms. These include magnetic attraction (such as magnetic coatings, magnetic particles dispersed within a rubber or binder material, spot magnets, and the like), mechanical fasteners (such as Velcro® fastening systems, mushroom-shaped protrusions, grommets, and the like), adhesive attraction (such as cohesive materials, silicone materials, and the like), and combinations thereof. Each of these attachment mechanisms will be described in greater detail below.

[0043]Referring now to the Figures, FIG. 1A illustrates a floor mat 100 comprised of a textile component 110 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com